Method for preparing composite micro-spheres with Fe3O4@C core-shell structures and application of composite micro-spheres

A technology of composite microspheres and core-shell structures, applied in the field of biomedical materials, can solve the problems of unfavorable magnetic particle distribution, changing particle surface properties, reducing biocompatibility, etc., and achieving the effect of good drug sustained release performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

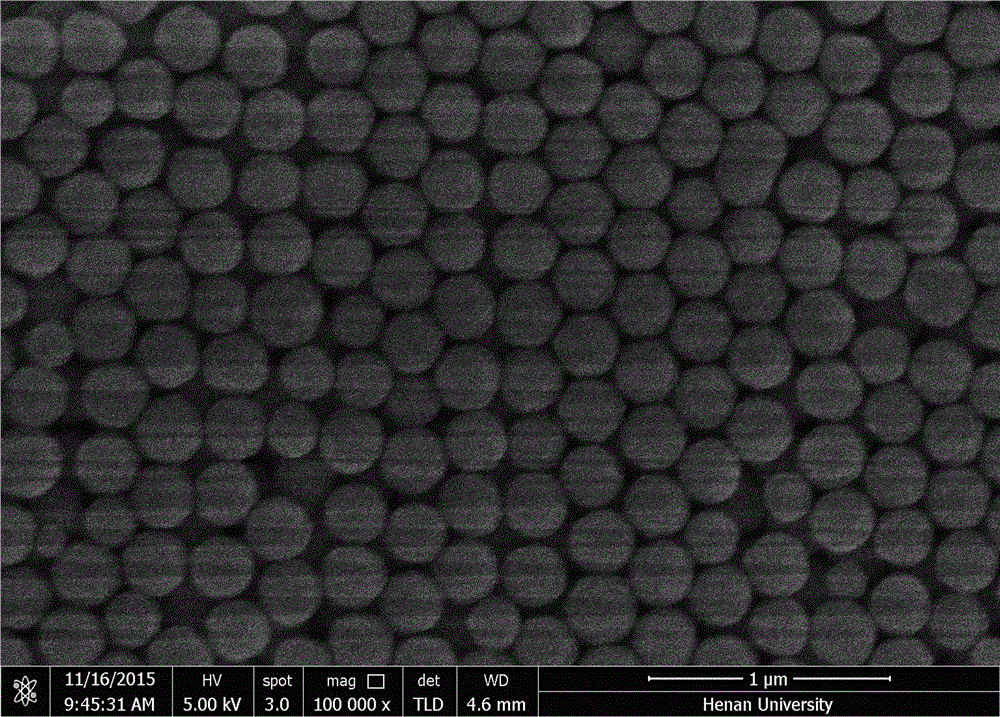

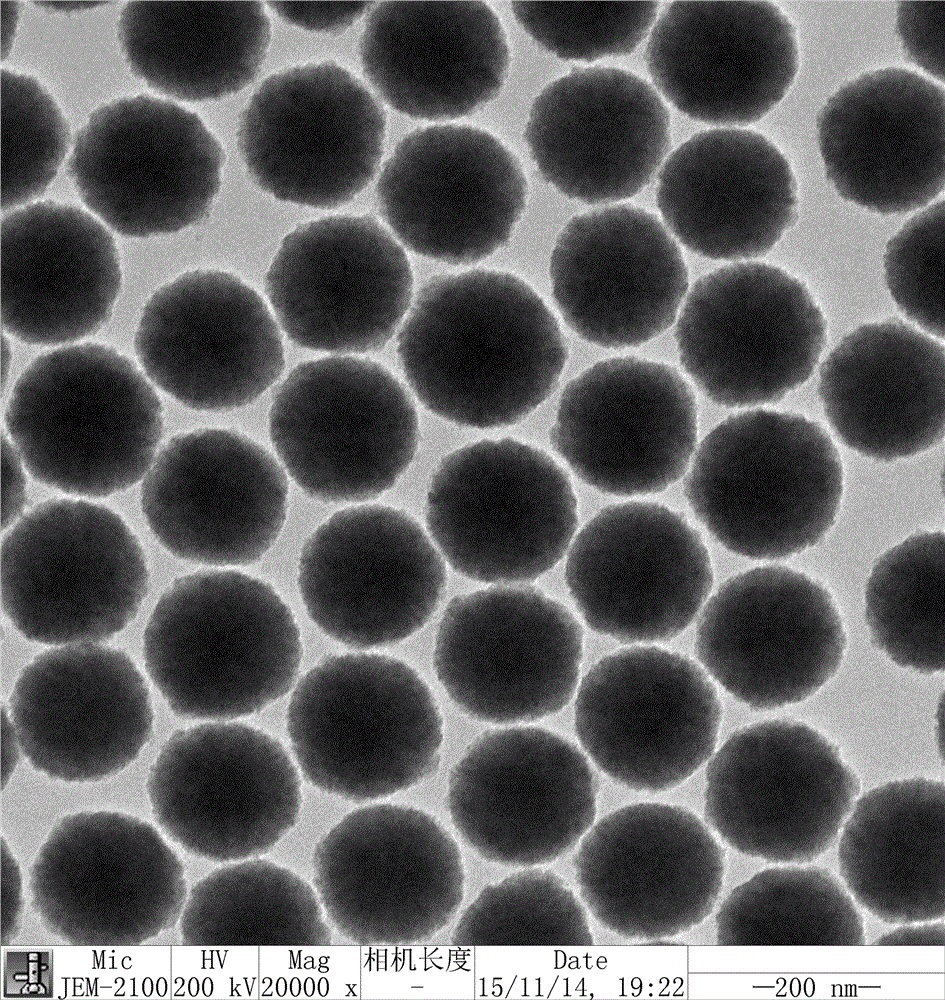

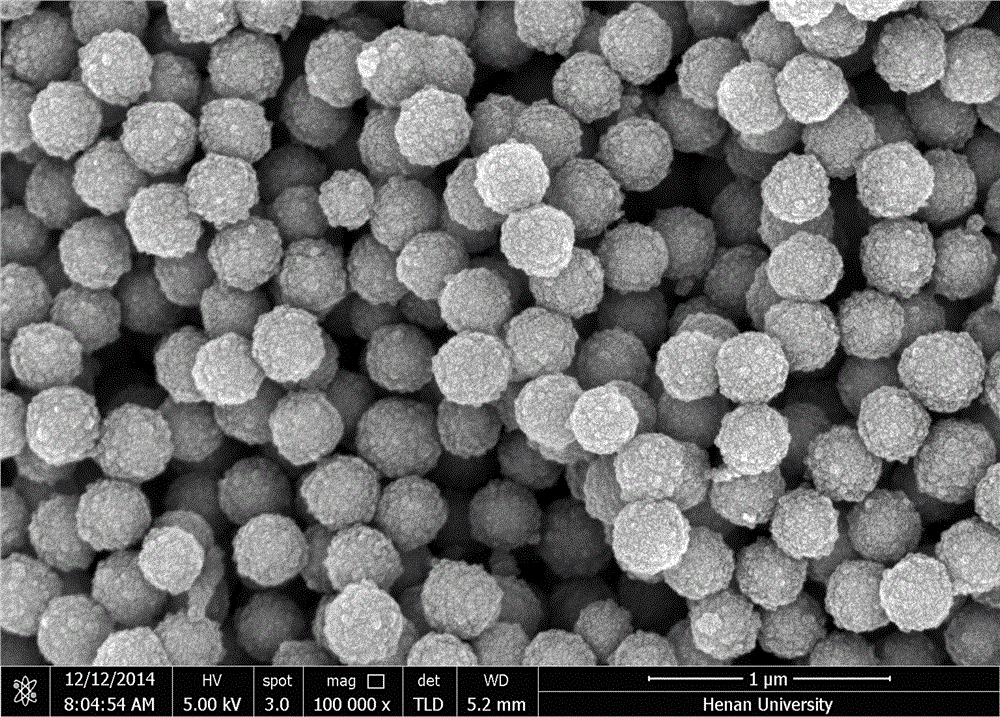

[0026] a kind of Fe 3 o 4 The preparation method of C core-shell structure composite microsphere comprises the following steps: 1. FeCl 3 ·6H 2 O, urea, and trisodium citrate were added to water and stirred to dissolve, then sodium polyacrylate was added, stirred evenly, transferred to a reaction kettle, hydrothermally reacted at 200°C for 4 hours, cooled to room temperature, and the obtained orange-yellow solid was washed with ethanol , then washed with water, and then dried at 60°C to obtain Fe 2 o 3 Nanospheres (Fe 2 o 3 Scanning electron microscope and transmission electron microscope photos of the nanospheres are as follows: figure 1 -2, the microspheres are regularly arranged, the size is about 200nm, and has good monodispersity); ②The Fe prepared in step ① 2 o3 Disperse the nanospheres in 65vol% ethanol according to the solid-to-liquid ratio of 1g:450ml, ultrasonically treat for 30min at 25°C, then add the ethanol solution of pyrrole, add hydrochloric acid under ...

Embodiment 2

[0042] a kind of Fe 3 o 4 The preparation method of C core-shell structure composite microsphere comprises the following steps: 1. FeCl 3 ·6H 2 O, urea, and trisodium citrate were added to water and stirred to dissolve, then sodium polyacrylate was added, stirred evenly, transferred to a reaction kettle, hydrothermally reacted at 180°C for 8 hours, cooled to room temperature, and the obtained orange-yellow solid was washed with ethanol , then washed with water, and then dried at 55°C to obtain Fe 2 o 3 Nano microspheres; ② the Fe prepared by step ① 2 o 3 Disperse the nanospheres in 10vol% ethanol according to the solid-to-liquid ratio of 1g:300ml, ultrasonically treat for 60min at 20°C, then add the ethanol solution of pyrrole, add hydrochloric acid under stirring conditions, react at room temperature for 50min, and use the solid obtained after the reaction with Washed with ethanol, washed with water, and dried at 60°C to obtain Fe 2 o 3 ppy composite microspheres; ③ t...

Embodiment 3

[0046] a kind of Fe 3 o 4 The preparation method of C core-shell structure composite microsphere comprises the following steps: 1. FeCl 3 ·6H 2 O, urea, and trisodium citrate were added to water and stirred to dissolve, then sodium polyacrylate was added, stirred evenly, transferred to a reaction kettle, hydrothermally reacted at 220°C for 6 hours, cooled to room temperature, and the obtained orange-yellow solid was washed with ethanol , then washed with water, and then dried at 65°C to obtain Fe 2 o 3 Nano microspheres; ② the Fe prepared by step ① 2 o 3 Disperse the nanospheres in 35vol% ethanol according to the solid-to-liquid ratio of 1g:500ml, ultrasonically treat for 40min at 30°C, then add the ethanol solution of pyrrole, add hydrochloric acid under stirring conditions, and react for 150min at room temperature. Washed with ethanol, washed with water, and dried at 60°C to obtain Fe 2 o 3 ppy composite microspheres; ③ the Fe obtained in step ② 2 o 3 The ppy compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com