Water-retaining and slowly-release compound fertilizer and preparation method thereof

A compound fertilizer and fertilizer technology, applied in the fields of compound fertilizer and its preparation, water-retaining slow-release compound fertilizer and its preparation, can solve problems such as uneven distribution of rainfall, lack of water, easy leaching of nutrients, etc., and achieve enhanced Water retention ability, nutrient slow release effect is obvious, and the effect of improving water resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

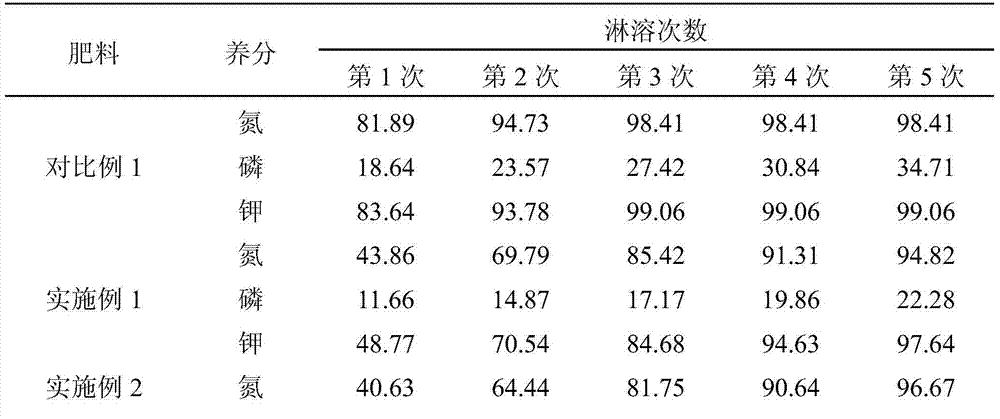

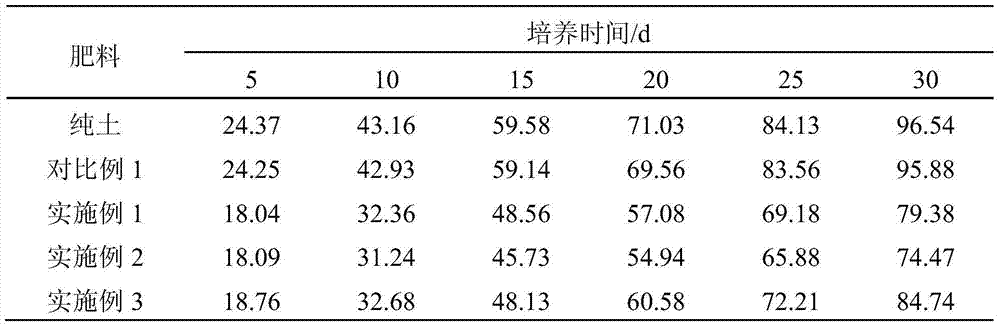

[0036] Embodiment 1, the preparation of water-retaining slow-release compound fertilizer

[0037] Take by weighing the chemical fertilizer of following composition: 334g potassium chloride (potassium source fertilizer), 274g monoammonium phosphate (phosphorus source fertilizer), 315g diammonium phosphate (phosphorus source fertilizer) and 912g urea (nitrogen source fertilizer), crushed respectively 60 mesh sieve, and then mixed with 50g anionic polyacrylamide (water retaining agent, molecular weight 30 million, 120 mesh) and 315g bentonite (filler, 300 mesh). Put the mixed raw materials into the laboratory disc granulator, set the rotation speed to 45 rpm, and set the blast heating temperature to 65°C; use the air pressure spray gun to atomize water into the continuously rotating disc granulator In the process, when the material in the disc granulator forms small particles, stop spraying (the amount of spraying liquid is controlled between 5% and 12% of the total mass of raw m...

Embodiment 2

[0038] Embodiment 2, the preparation of water-retaining slow-release compound fertilizer

[0039] Take by weighing the chemical fertilizer of following composition: 334g potassium chloride, 274g monoammonium phosphate, 315g diammonium phosphate, 912g urea, break respectively and cross 60 mesh sieves, then mix with 50g sodium polyacrylate (water retaining agent, molecular weight is 30 million, 120 mesh) and 315g attapulgite (filler, 200 mesh) were mixed evenly. Put the mixed raw materials into the laboratory disc granulator, set the rotation speed to 45 rpm, and set the blast heating temperature to 65°C; use the air pressure spray gun to atomize water into the continuously rotating disc granulator In the process, when the raw materials in the disc granulator form small particles, stop spraying (the amount of spraying liquid is controlled between 5% and 12% of the total mass of raw materials), and slowly sprinkle 300g of bentonite with a fineness of 300 mesh for powdering, and t...

Embodiment 3

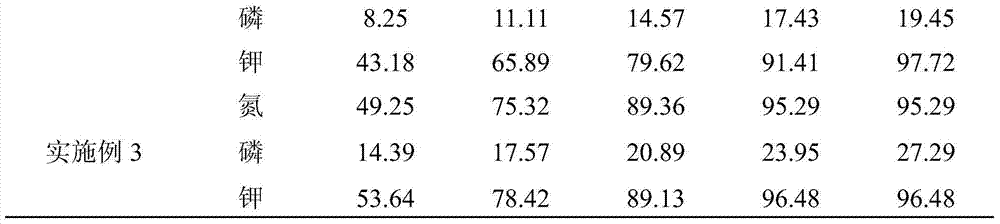

[0040] Embodiment 3, the preparation of water-retaining slow-release compound fertilizer

[0041] Take by weighing the chemical fertilizer of following composition: 334g potassium chloride, 274g monoammonium phosphate, 315g diammonium phosphate, 912g urea, break respectively and cross 60 mesh sieves, then mix with 50g sodium carboxymethylcellulose (water retaining agent, molecular weight is 17000 , 120 mesh), 315g kaolin (filler, 200 mesh) and mix well. Put the mixed raw materials into the laboratory disc granulator, set the rotation speed to 45 rpm, and set the blast heating temperature to 65°C; use the air pressure spray gun to atomize water into the continuously rotating disc granulator In the process, when the material in the disc granulator forms small particles, stop spraying (the amount of spraying liquid is controlled between 5% and 12% of the total mass of raw materials), and slowly sprinkle 300g of bentonite with a fineness of 300 mesh for powdering, and the powderin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com