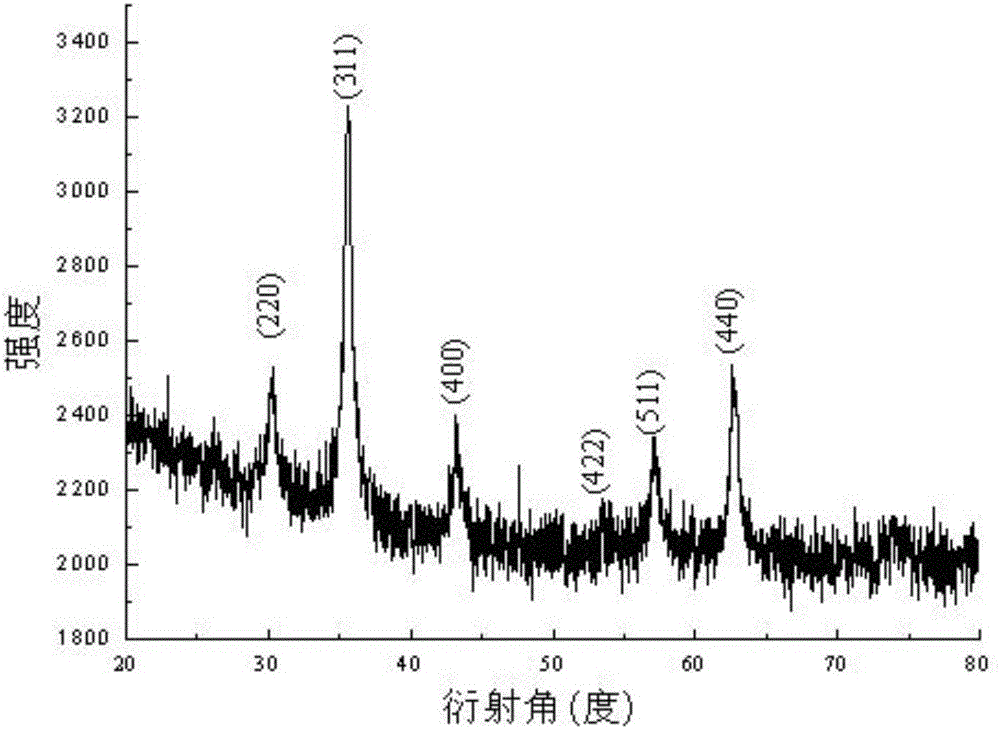

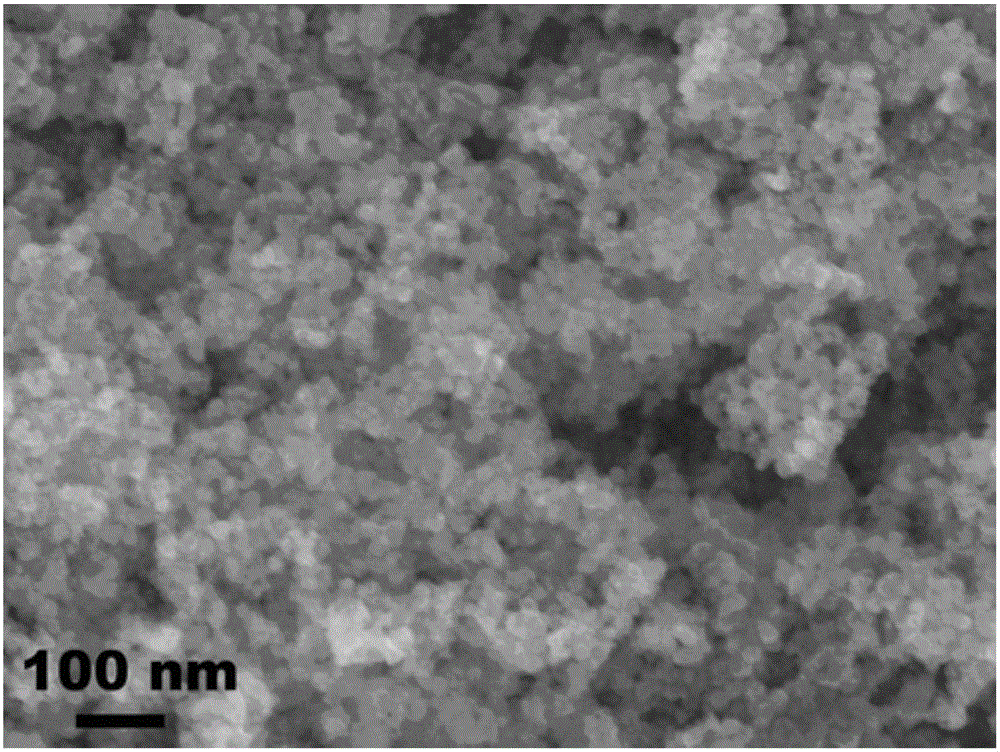

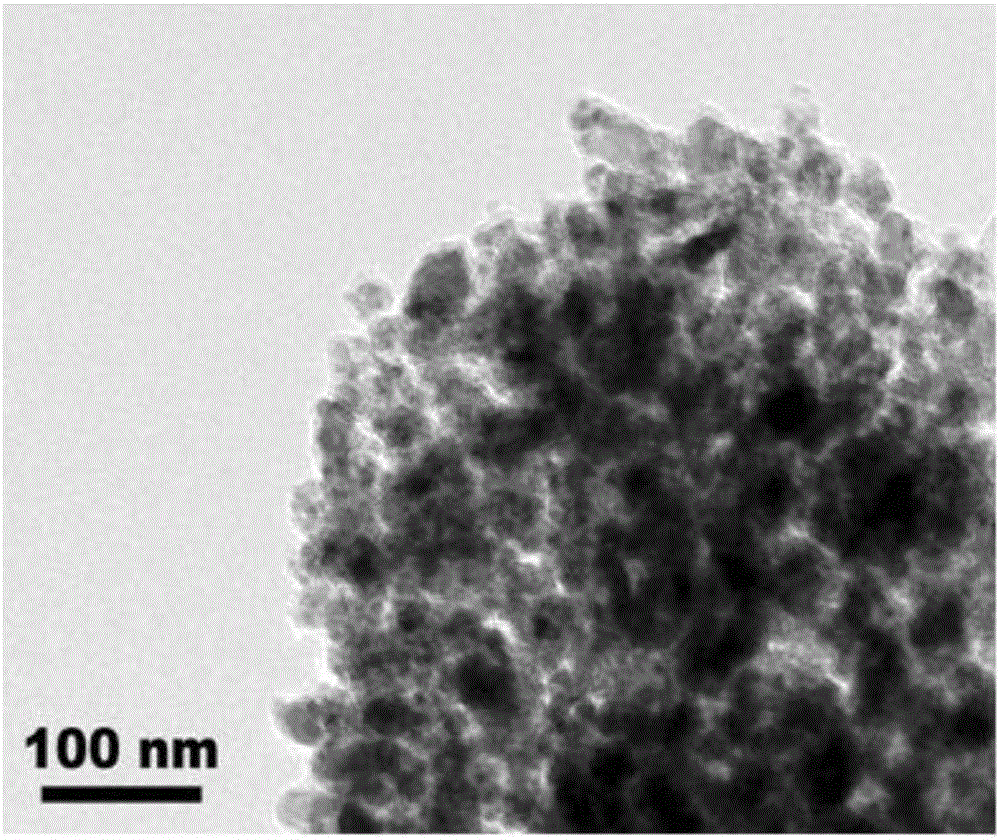

Preparation method and application of carbon-coated Fe3O4 nanoparticle lithium ion battery negative electrode material

A lithium-ion battery and nanoparticle technology, applied in battery electrodes, nanotechnology, secondary batteries, etc., can solve the problems of difficult control of microscopic morphology and structure, high production cost, large particle size, etc., and achieve good conductivity And the effect of stabilizing electrochemical performance, improving stability, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The first step, precursor carbon coated Fe 2 o 3 Preparation of nanoparticles:

[0032] Weigh the required amount of ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and citric acid (C 6 h 8 o 7 ) and dissolved in deionized water to prepare a mixed solution of ferric chloride and citric acid, so that ferric chloride (FeCl 3) concentration is controlled at 0.005mol / L, the molar percentage of carbon atoms in citric acid and iron atoms in ferric chloride is 1:1, use a magnetic stirrer to stir the mixed solution at a speed of 100r / min for 15min, and then ultrasonically disperse the mixed solution for 15min , to obtain a clear mixed solution mixed uniformly between the two, transfer the clear mixed solution to a reaction kettle with polytetrafluoroethylene as the substrate, place the reaction kettle in an oven, keep it warm at 150°C for 1h, and then react the The kettle was naturally cooled to room temperature with the oven, and the mixed solution after the reaction was t...

Embodiment 2

[0045] The first step, precursor carbon coated Fe 2 o 3 Preparation of nanoparticles:

[0046] Weigh the required amount of ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and citric acid (C 6 h 8 o 7 ) and dissolved in deionized water to prepare a mixed solution of ferric chloride and citric acid, so that ferric chloride (FeCl 3 ) concentration is controlled at 2.5mol / L, the molar percentage of carbon atoms in citric acid and iron atoms in ferric chloride is 20:1, use a magnetic stirrer to stir the mixed solution for 35min at a speed of 250r / min, and then ultrasonically disperse the mixed solution for 35min , to obtain a clear mixed solution mixed uniformly between the two, transfer the clear mixed solution to a reaction kettle with polytetrafluoroethylene as the substrate, place the reaction kettle in an oven, keep it warm at 200 ° C for 8 hours, and then react the The kettle was naturally cooled to room temperature with the oven, and the mixed solution after the reactio...

Embodiment 3

[0053] The first step, precursor carbon coated Fe 2 o 3 Preparation of nanoparticles:

[0054] Weigh the required amount of ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and citric acid (C 6 h 8 o 7 ) and dissolved in deionized water to prepare a mixed solution of ferric chloride and citric acid, so that ferric chloride (FeCl 3 ) concentration is controlled at 5mol / L, the molar percentage of carbon atoms in citric acid and iron atoms in ferric chloride is 40:1, using a magnetic stirrer to stir the mixed solution for 60min at a speed of 400r / min, and then ultrasonically disperse the mixed solution for 60min, Obtain a clear mixed solution that is uniformly mixed with the two, transfer the clear mixed solution to a reaction kettle with polytetrafluoroethylene as the substrate, place the reaction kettle in an oven, and keep it warm at 250°C for 15h, and then the reaction kettle Naturally cool to room temperature with the oven, take out the mixed solution after reaction, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com