Low-temperature industrial preparation method of monodisperse superparamagnetic gamma-Fe2O3 nanoparticles

A nanoparticle and superparamagnetic technology, which is applied in the field of nanomaterial preparation and technical application, can solve the problems of toxicity, high temperature energy consumption, complex process, etc., and achieve the effect of simple process, less environmental pollution and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

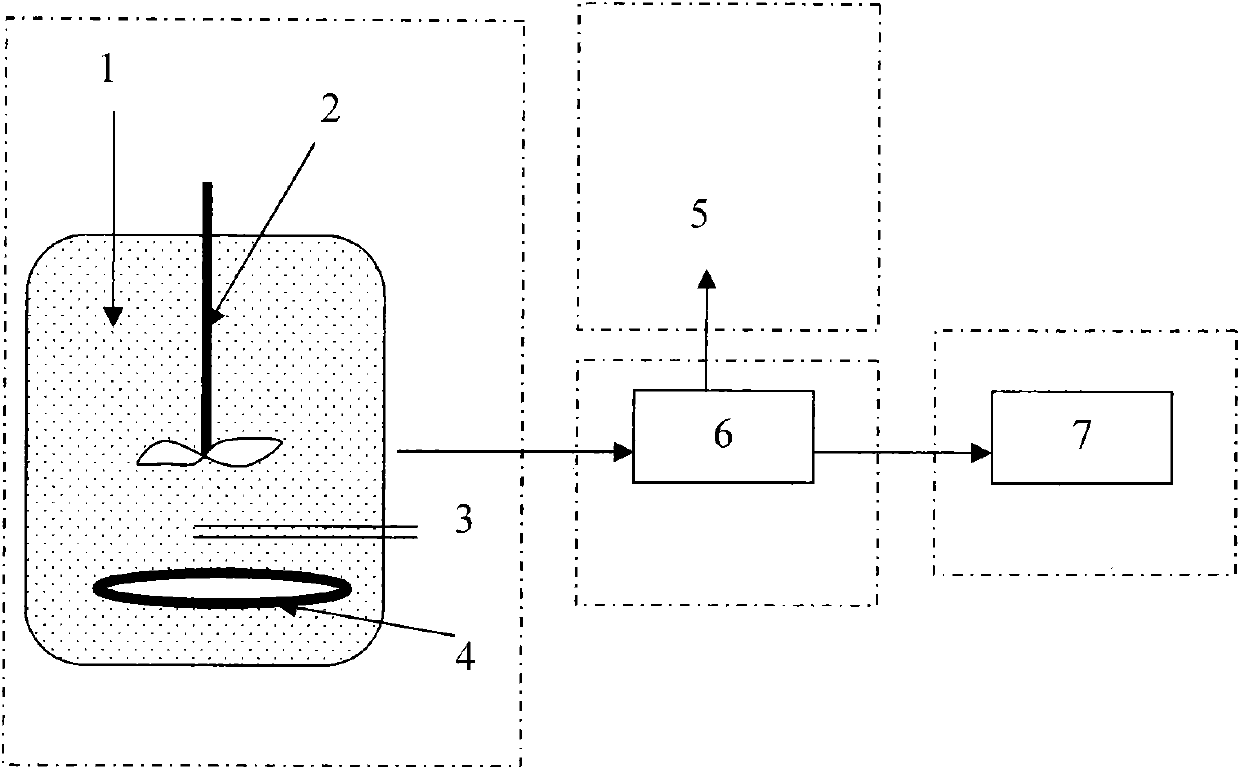

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Monodisperse superparamagnetic γ-Fe 2 o 3 Low-temperature (sol-gel) industrial preparation of nanoparticles: the raw material is ferrous chloride, and methanol is used as a solvent to prepare a transparent salt solution with a concentration of 0.2M, and then add an organic gelling agent with a molar ratio of 5 to ferrous ions Dichloromethane, after mixing evenly, place the solution in a 60°C water bath and stir for 2 hours, then dry the obtained sol at 100°C until a xerogel is obtained, and gently grind to obtain a loose monodisperse superparamagnetic γ-Fe 2 o 3 Nanoparticles.

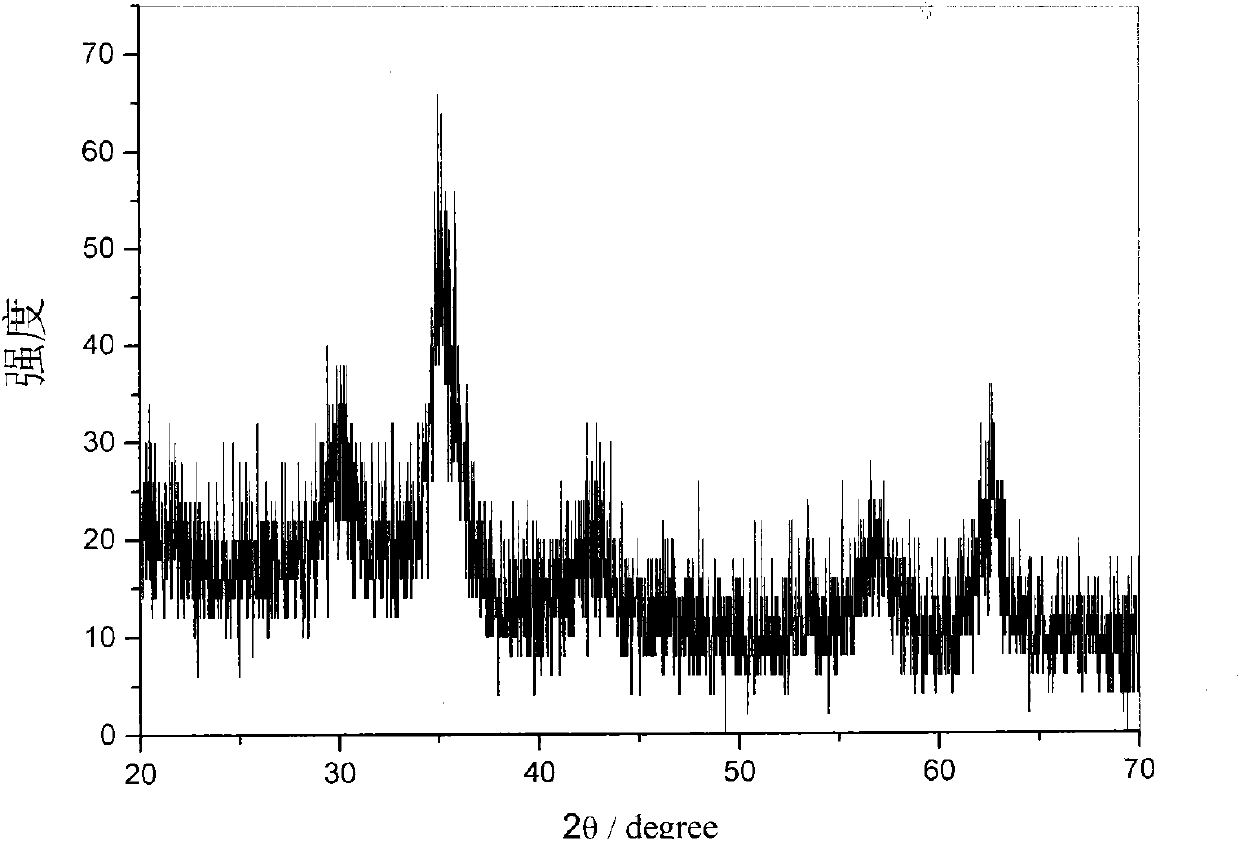

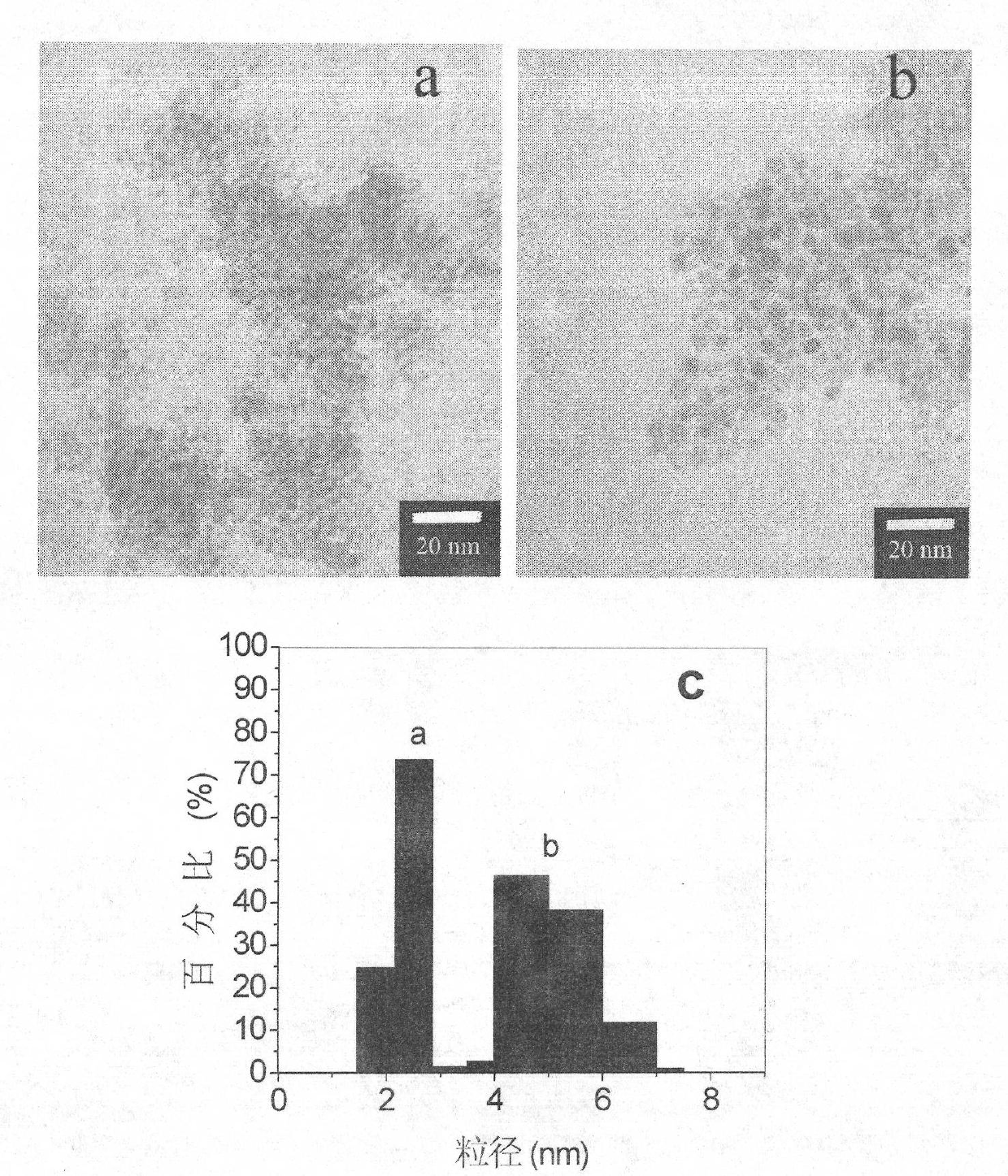

[0036] figure 2 The resulting monodisperse superparamagnetic γ-Fe 2 o 3 The X-ray diffraction pattern of nanoparticles, it can be judged that the diffraction peak in the figure is γ-Fe 2 o 3 The characteristic diffraction peak, and from its broadened peak, it can be judged that its particle size is in the nanometer range. image 3 For the monodisperse superparamagnetic γ-Fe...

Embodiment 2

[0037] Embodiment 2 Monodisperse superparamagnetic γ-Fe 2 o 3 Low-temperature industrial preparation of nanoparticles: ethanol is used as the solvent, and the others are the same as in Example 1.

Embodiment 3

[0038] Example 3 Monodisperse Superparamagnetic γ-Fe 2 o 3 Low-temperature industrial preparation of nanoparticles: the raw material is ferrous chloride, and methanol is used as a solvent to prepare a transparent salt solution with a concentration of 0.8M, and then add organic gelling agent ethylene oxide with a molar ratio of 5 to ferrous ions and Propylene oxide, after mixing evenly, place the solution in a 40°C water bath and stir for 0.5 hours, then pass air into the sol to oxidize for 2 hours to obtain dry gel, and obtain loose γ-Fe after light grinding 2 o 3 Nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com