Method for preparing nano-particles of magnetic ferric oxide

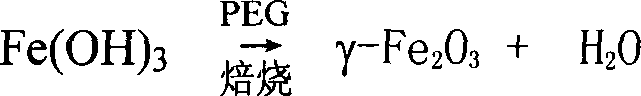

A nanoparticle and cubic technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of complicated preparation process of γ-FeOOH, and achieve the effect of easy control, simplified preparation process and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The polyethylene glycol is PEG-400. Prepared separately containing FeCl 3 .6H 2 O (C.R. grade) 5.4g and NaOH 2.8g (C.R. grade) solution 20ml, FeCl 3 .6H 2 The concentrations of the O solution and the NaOH solution are 1 mol / L and 3.5 mol / L respectively, and PEG-4004ml is added to the two solutions, and stirred evenly. While stirring, pour the NaOH solution into the FeCl 3 solution, NaOH and FeCl were stirred 3 A precipitation reaction occurs in the reaction solution for 20-40 minutes. The reaction solution was suction filtered, and the filter cake was dried at 50-70°C for 4-8 hours to obtain a crude product. Roast the crude product at 300-400°C for 1-2h, wash with water, filter, dry in vacuum at 60°C for 4-8h, and grind to obtain the product, rod-shaped γ-Fe 2 o 3 .

[0039] The aspect ratio of the product particles is about 6, the length of which is 200nm, and the diameter is about 30nm.

Embodiment 2

[0041] The polyethylene glycol is PEG-600. Prepared separately containing FeCl 3 .6H 2 O (C.R. grade) 7.56g and NaOH3.92g (C.R. grade) solution 20ml, FeCl 3 .6H 2The concentrations of the O solution and the NaOH solution were 1.4 mol / L and 4.9 mol / L respectively, and 5.6 ml of PEG-600 was added to the two solutions, and stirred evenly. While stirring, pour the NaOH solution into the FeCl 3 solution, NaOH and FeCl were stirred 3 A precipitation reaction occurs in the reaction solution for 20-40 minutes. The reaction solution was suction filtered, and the filter cake was dried at 50-70°C for 4-8 hours to obtain a crude product. The crude product is calcined at 300-400°C for 1-2h, washed with water, filtered, dried in vacuum at 60°C for 4-8h, and ground to obtain the product, rod-shaped γ-Fe 2 o 3 .

Embodiment 3

[0043] The polyethylene glycol is PEG-400. Prepared separately containing FeCl 3 .6H 2 O (C.R. grade) 5.4g and NaOH 2.8g (C.R. grade) solution 20ml, FeCl 3 .6H 2 The concentrations of the O solution and the NaOH solution are 1 mol / L and 3.5 mol / L respectively, and PEG-4004ml is added to the two solutions, and stirred evenly. While stirring, pour the NaOH solution into the FeCl 3 solution, NaOH and FeCl were stirred 3 A precipitation reaction occurs in the reaction solution for 20-40 minutes. The reaction solution was filtered with suction, the precipitate was washed with deionized water, filtered, the filter cake was stirred in the aqueous solution of PEG-400 for 30-60min, filtered with suction, the filter cake was dried at 50-70°C for 5-7h, and calcined at 300-400°C for 1 -2h, grind to get product, cubic γ-Fe 2 o 3 .

[0044] The particle size of the product is about 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com