Patents

Literature

34results about How to "Easy to control shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

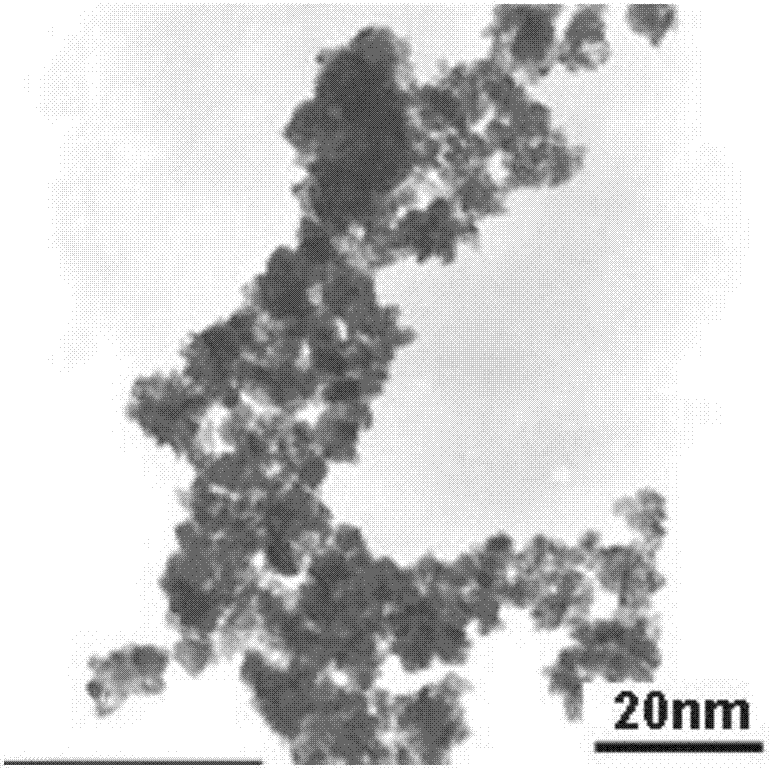

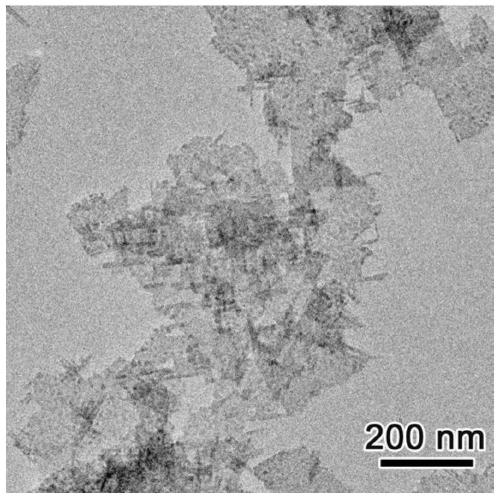

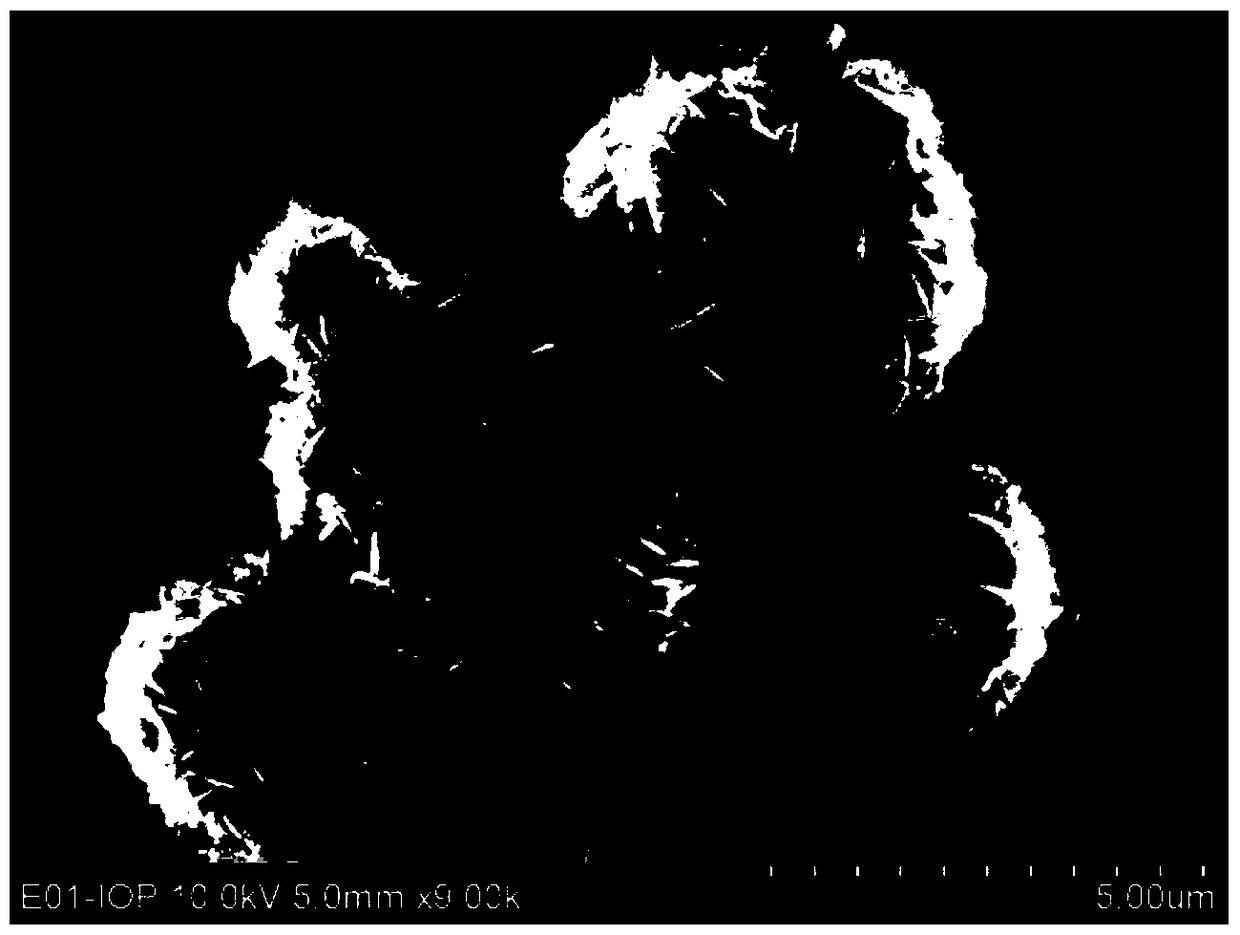

Foam metal-carbon nanotube composite material, and preparation method and application thereof

ActiveCN104868134AEasy to control shapeCatalyst composition free regulationMaterial nanotechnologyCell electrodesDispersityChemical plating

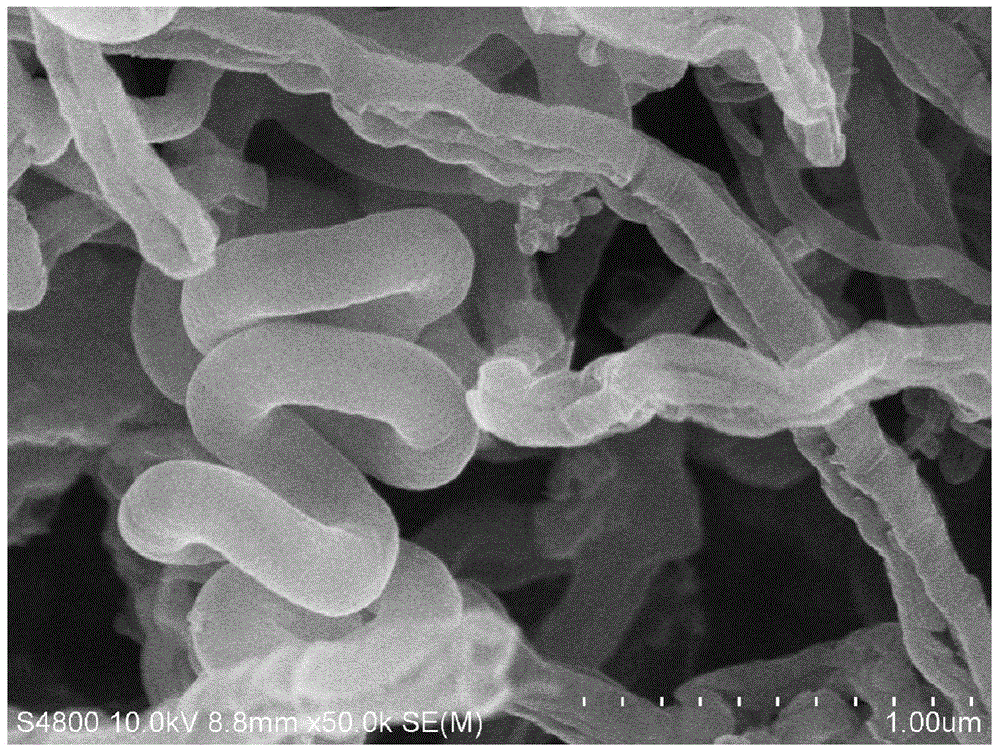

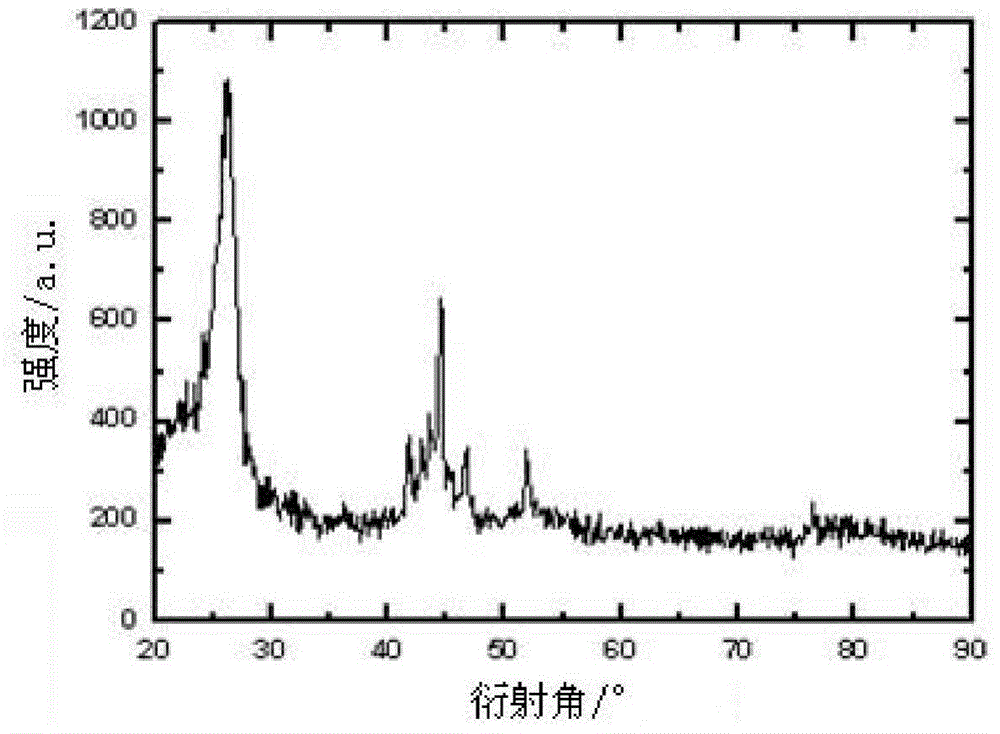

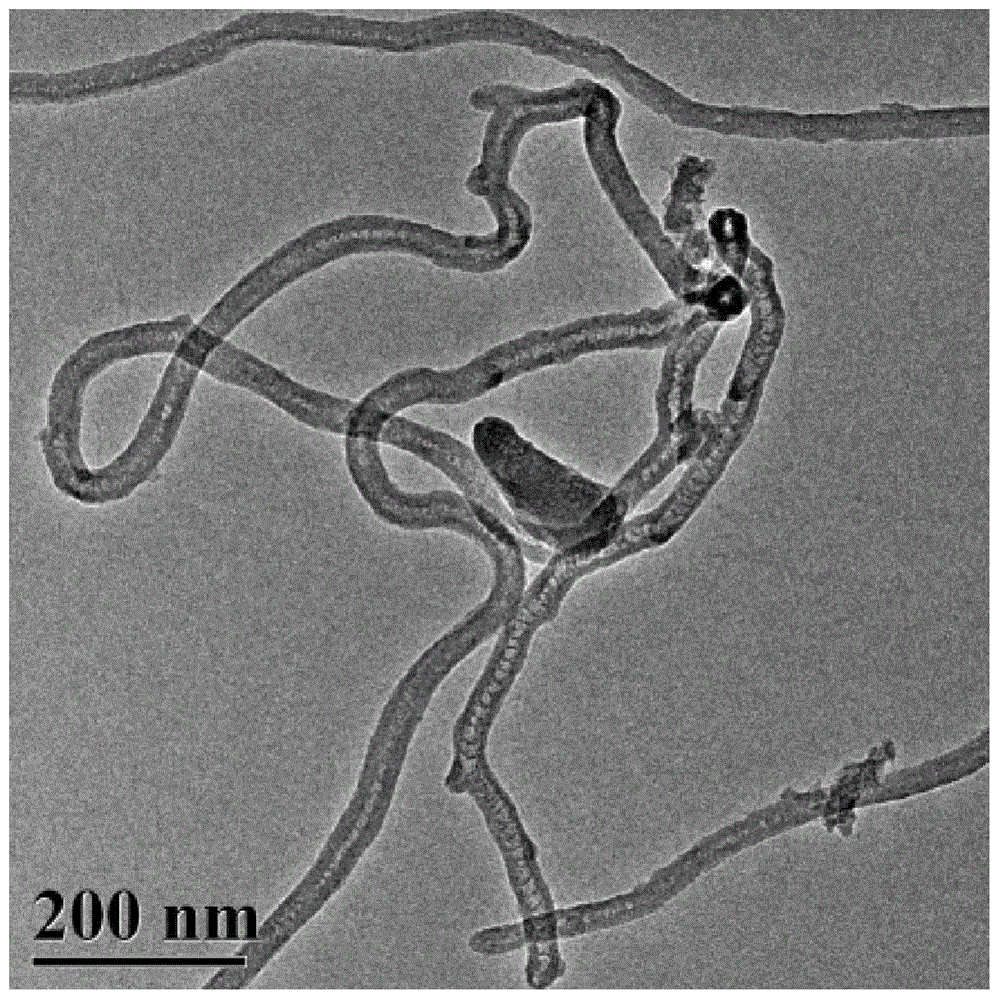

The invention belongs to the technical field of nano materials, and discloses a foam metal-carbon nanotube composite material, and a preparation method and application thereof. The preparation method comprises the steps of pretreating a polyurethane sponge substrate, then putting the pretreated polyurethane sponge substrate in a chemical plating solution containing metallic elements to perform a chemical plating reaction, and drying the obtained product to obtain a foam metal catalyst with the polyurethane sponge substrate; then putting the foam metal catalyst in a tube furnace, heating the furnace to 500-550 DEG C, and feeding hydrogen for 0.5-2 hours; heating the furnace up to 600-800 DEG C, feeding an acetylene mixed gas to be used as a carbon source, and growing carbon nano material on the surface of the foam metal catalyst through chemical vapor deposition so as to obtain the foam metal-carbon nanotube composite material. According to the preparation method provided by the invention, carbon nanofibers or carbon nanotubes grow in-situ on the surface of a transition metal catalyst, so that the combination at the metal / carbon interface is tight, the carbon nanofibers or carbon nanotubes have good dispersity, and the tube diameters are controllable and uniform.

Owner:SOUTH CHINA UNIV OF TECH

Medical porous polyether-ether-ketone with drug loading function and preparing method and application thereof

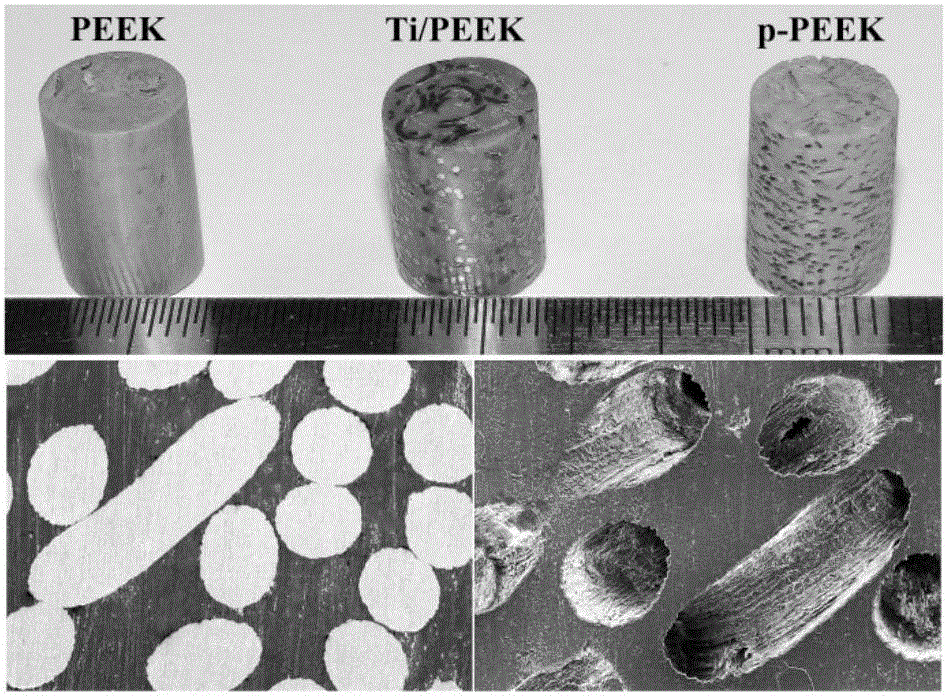

ActiveCN106178104AGood mechanical propertiesExcellent bone transportTissue regenerationProsthesisPorosityPressure casting

The invention relates to medical porous polyether-ether-ketone with a drug loading function and a preparing method and application thereof. The medical porous polyether-ether-ketone has a uniform porous structure or gradient change type porous structure, pore size is 0.05-2 mm, and porosity is 10-90%. During preparation, molten polyether-ether-ketone is extruded into preform pores through pressure casting, and then preform is etched off with the chemical method to form the porous polyether-ether-ketone. The material has excellent mechanical property, and pore size and porosity are controllable. The porous structure of the material can be loaded with drugs to prevent infection and promote bone growth and healing. Compared with the prior art, the medical porous polyether-ether-ketone with the drug loading function and the preparing method and application thereof have the advantages that operation is easy, structure is controllable, drug loading is convenient, drug binding is firm, and cost is low.

Owner:SHANGHAI JIAO TONG UNIV

Application of porous magnesium alloy as carrier in medicine

InactiveCN106267332AGood mechanical propertiesExcellent bone transportSurgeryProsthesisAdsorption equilibriumPlasma electrolytic oxidation

The invention relates to application of a porous magnesium alloy as a carrier in medicine. Drugs can be carried onto the porous magnesium alloy to be used as a blood vessel stent, bone repair or bone propping material. The porous magnesium alloy is prepared by direct foaming, corrosion pore forming, laser drilling, powder metallurgy, quick forming, co-permeation vibration, 3D printing and the like. Laser cladding, microarc oxidation, anode oxidation, osmosis, embedding, solvent evaporation drying, melting, adsorption equilibrium and the like are performed to carry drugs into the porous magnesium alloy surface or the inside of the porous structure, thereby performing the functions of increasing the surface activity, promoting the bone cell growth and differentiation, preventing infection, implementing specific drug delivery and partial drug delivery and the like. The preparation method is simple to operate and easy to implement, and has the advantages of controllable structure, convenient drug carrying, firm drug combination, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

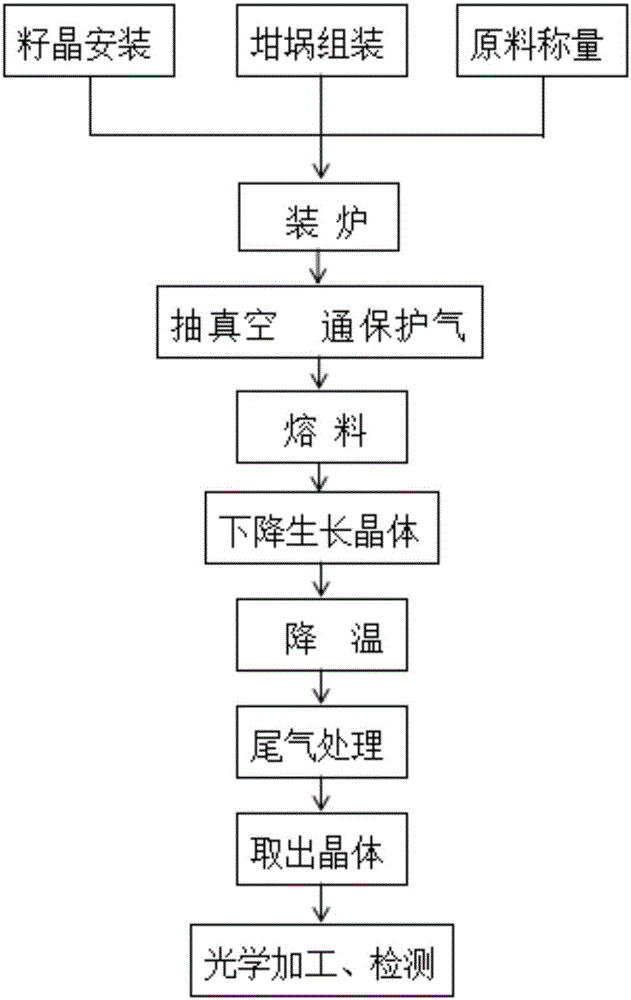

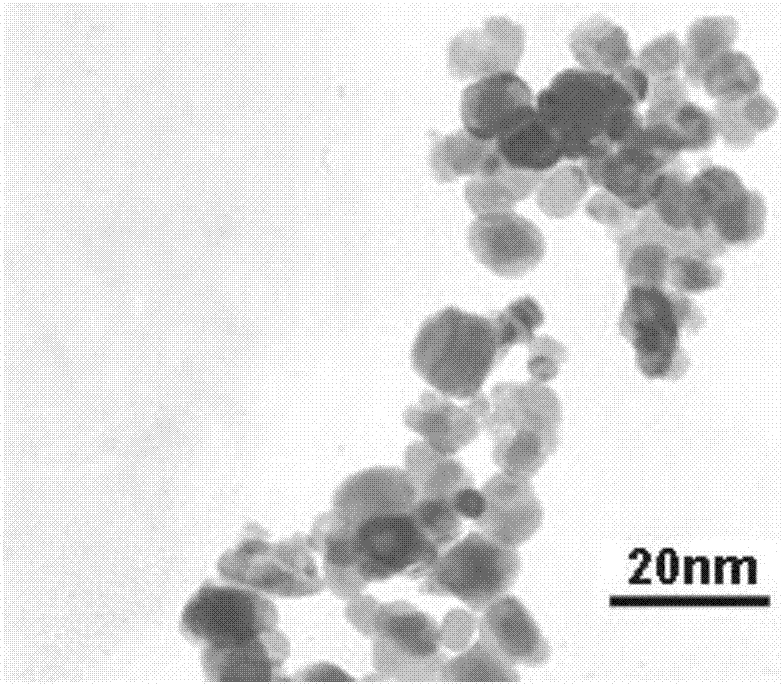

Magnetic nano particle compound for nucleic acid separation and its preparation method and uses

InactiveCN1995052ANo agglomerationEasy to control shapeSugar derivativesSugar derivatives preparationSuperparamagnetismInner nuclear layer

The invention discloses a magnetic nanometer particle compound and making method and application to separate nucleic acid especially mRNA, which comprises the following three layers: (1) inner nuclear layer with magnetic nanometer particle with superparamagnetism, (2) biological inert outer layer to clad inner nuclear layer, (3) decorating layer with affinity or antibiotin on the surface of outer layer.

Owner:上海柏汇申生物科技有限公司

Application of porous titanium alloy in medical science as carrier

InactiveCN106390207AEasy to control shapeThe size is easy to controlTissue regenerationProsthesisSpinal columnMicro arc oxidation

The invention relates to an application of porous titanium alloy in medical science as a carrier. The application comprises the following steps: 1, winding and braiding medical titanium alloy wires to prepare porous titanium alloy; and 2, loading a drug to the surface or the porous structure of the porous titanium alloy through laser cladding, micro-arc oxidation, anodization, osmosis, an entrapping method, a solvent volatilization, a melting method or an adsorption balancing method. The porous titanium alloy can be used as an artificial joint, spinal column fusion, bone filling, bone restoration or bone transplantation material in order to realize surface activity increase, osteocyte growth and differentiation promotion, infection prevention, targeted administration and local administration effects. Compared with carriers in the prior art, the porous titanium alloy used as the carrier has the advantages of simplicity and easiness in operation, controllable structure, convenience in drug load, firm drug combination and low cost.

Owner:SHANGHAI JIAO TONG UNIV

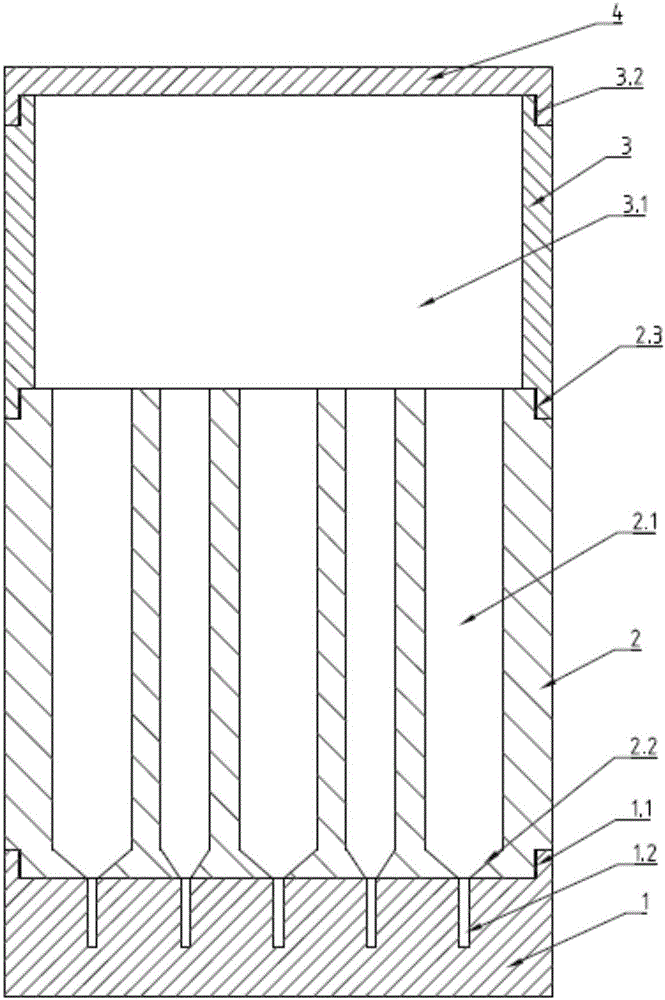

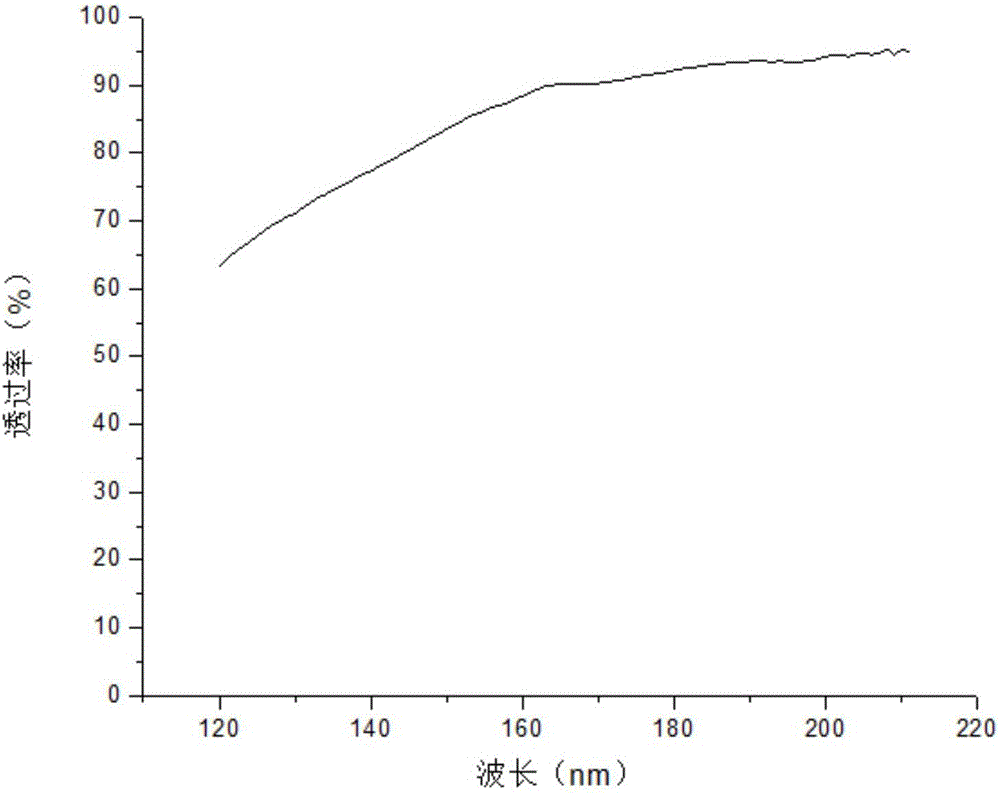

Growth equipment for preparation of magnesium fluoride crystals with multi-crucible descending method and growth method of magnesium fluoride crystals

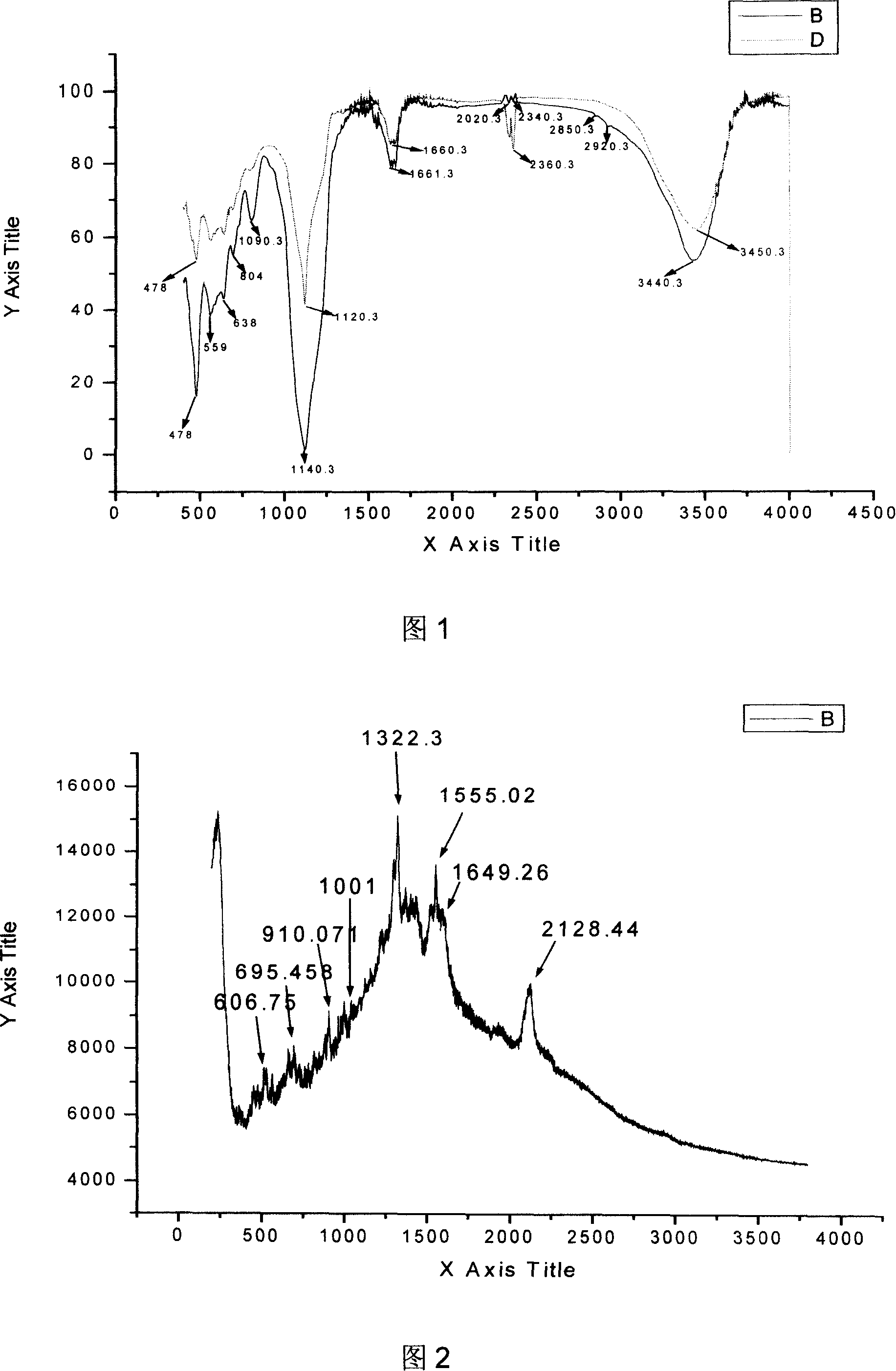

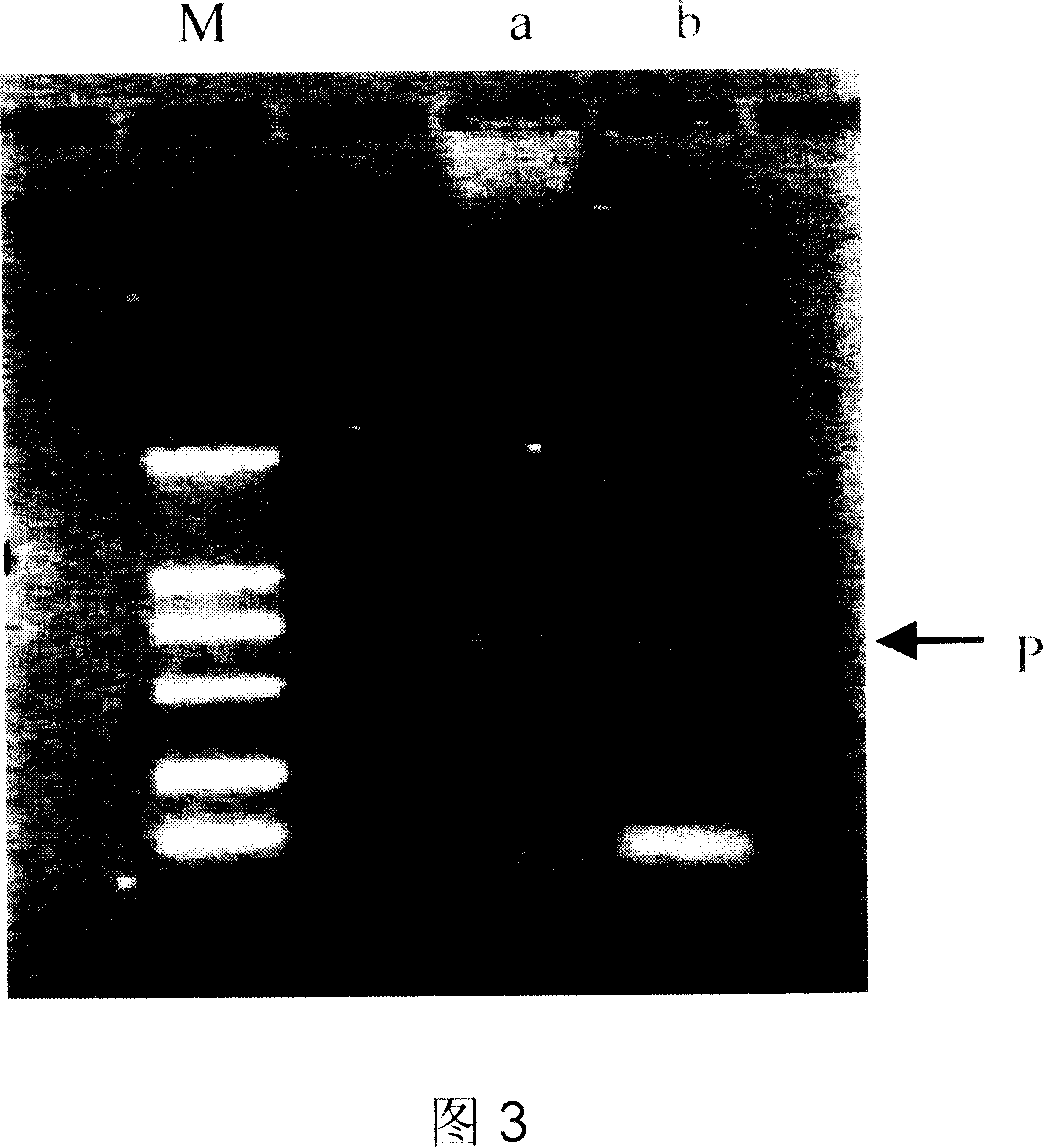

InactiveCN106435730AEasy to control shapeGood size controlPolycrystalline material growthFrom frozen solutionsShielding gasSeed crystal

The invention discloses growth equipment for preparation of magnesium fluoride crystals with a multi-crucible descending method and a growth method. A porous graphite crucible comprises four parts including a seed crystal zone, a crystal growth zone, a bin zone and a crucible lid; the growth equipment further comprises a furnace hearth, a descending device and a copper induction heating coil, ventilating holes are formed in the upper side and the lower side of the furnace hearth, the inner wall of the furnace hearth, and the copper induction coil and a descending rod surface are plated with a nickel layer or a high-temperature-resistant organic resin layer which can resist corrosion of gases such as hydrogen fluoride and the like. The preparation method comprises steps as follows: parameter setting, furnace charging, vacuum pumping, introduction of protecting gases, waiting for complete melting of raw materials and forming of melts, starting of descending after seed crystals are melted to be thin and preparation of the magnesium fluoride crystals. The prepared magnesium fluoride crystals have excellent optical quality, and the transmittance of 190 nm wavelength can reach 93.5%; the appearance and the size of the magnesium fluoride crystals are easy to control; the magnesium fluoride crystals grow simultaneously in multiple crucibles, the growth efficiency is high, and industrial production is facilitated.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

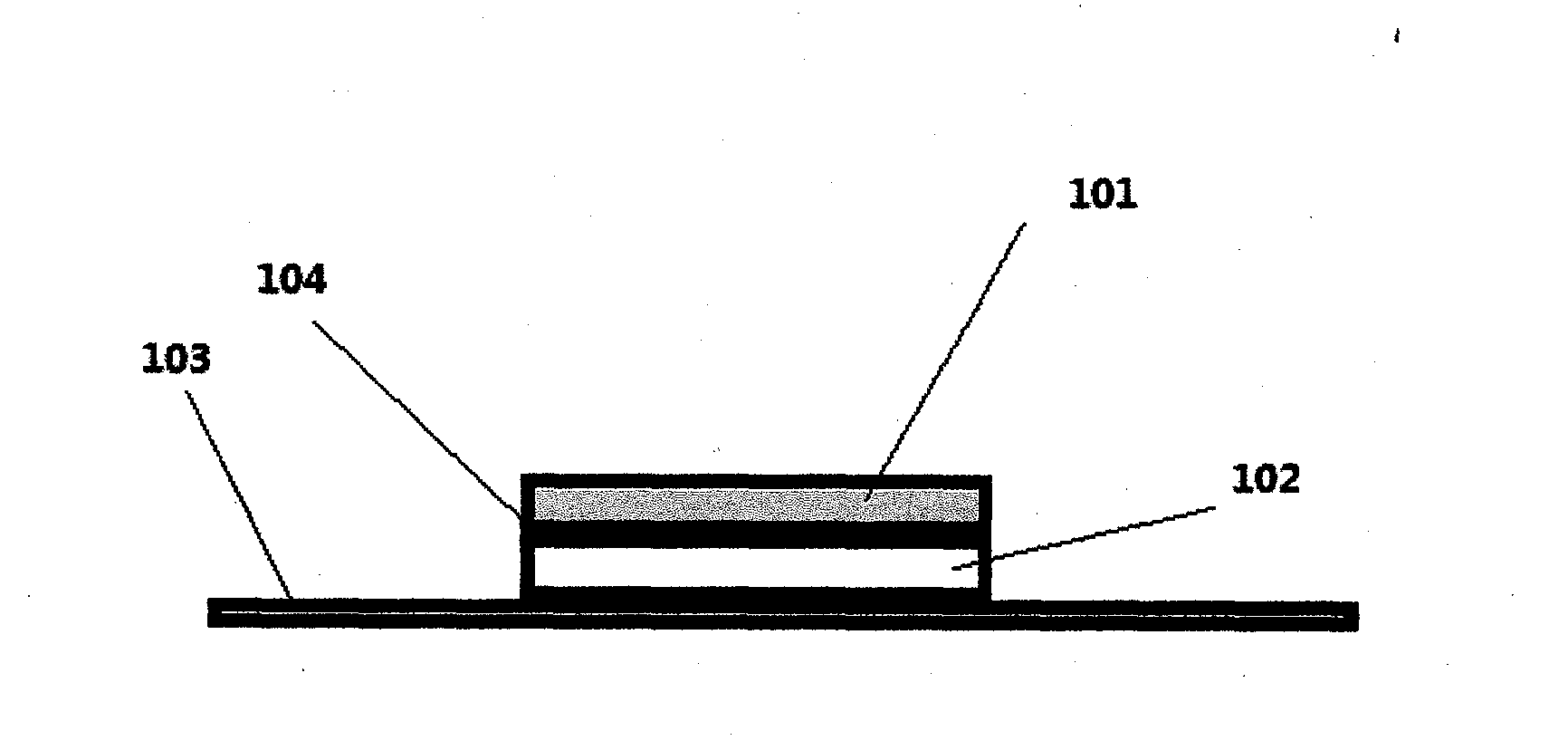

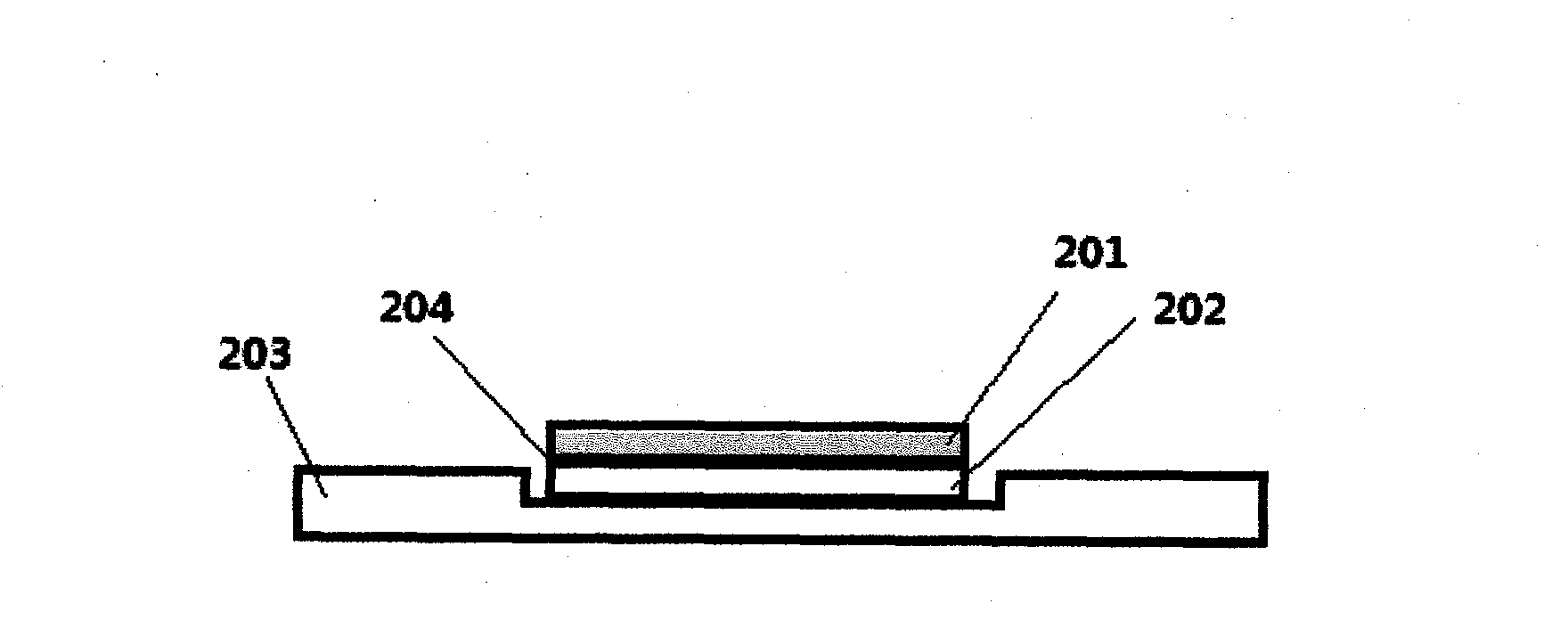

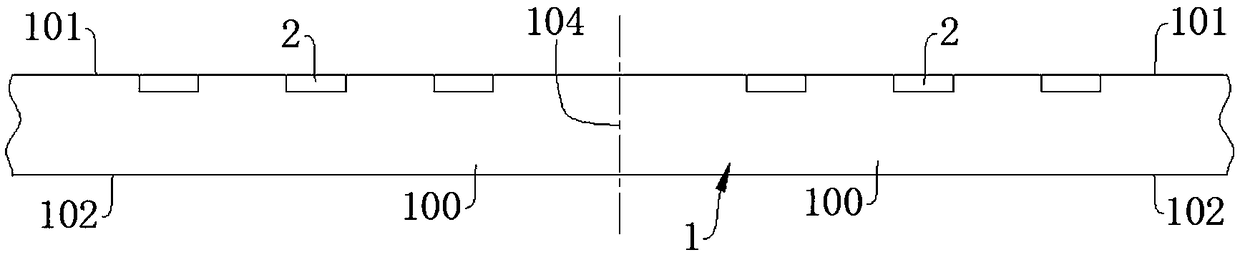

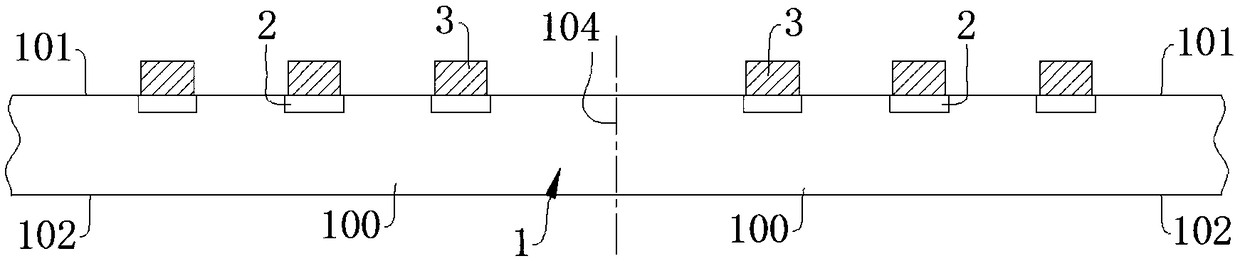

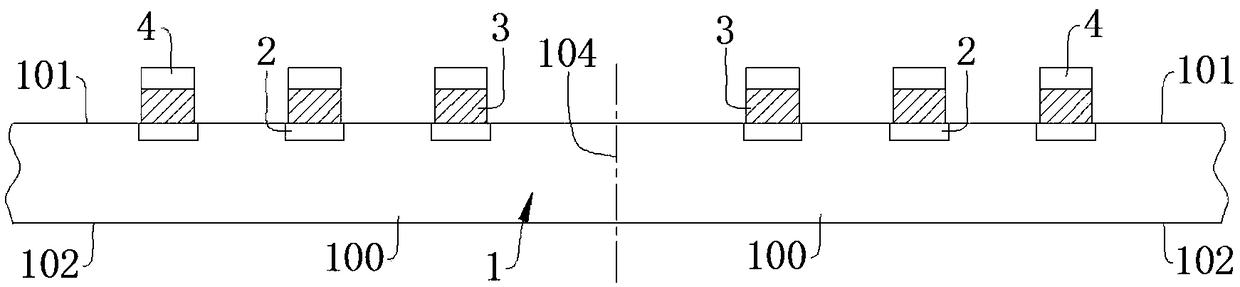

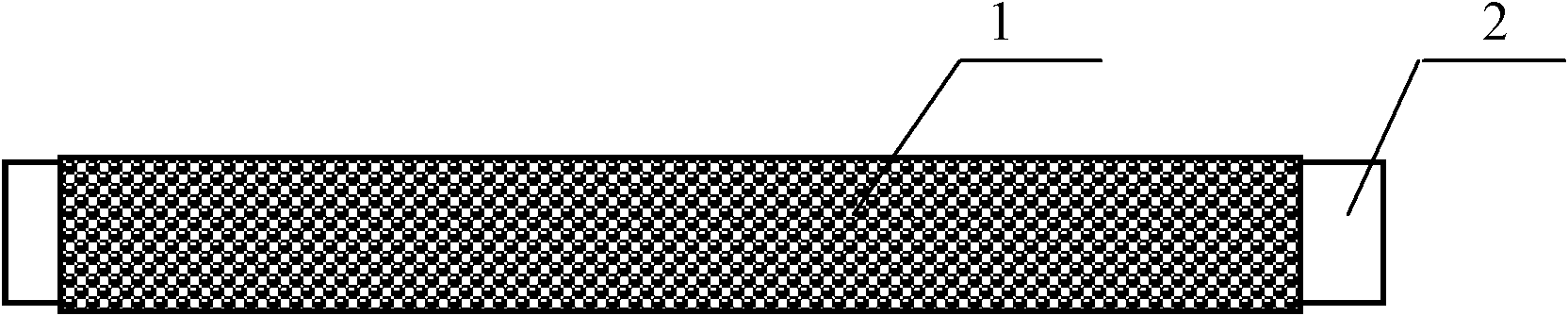

Preparation method of white chip for LED (Light Emitting Diode)

InactiveCN103050609ASolve the spot problemSolve problems with yellow circles aroundSemiconductor devicesLight-emitting diodeWhite light

The invention relates to a preparation technology of a white chip for an LED (Light Emitting Diode). The white chip comprises fluorescent powder prefabricated thin films (101, 201) for the white LED, bonders (104, 204) and LED chips (102, 202). The preparation method comprises the steps of: placing the LED chip (202) on a metal plate (203) with a groove; bonding the fluorescent powder prefabricated thin film (201) for the white LED on the LED chip (202) through the bonder (204); and solidifying the bonder at 80-200 DEG C for 1-6 hours to obtain the white chip for the LED; or adhering the LED chip (102) on a blue film (103); adhering the fluorescent powder prefabricated thin film (101) for white LED on the LED chip (102) through the naturally solidified bonder (104); standing for 1-10 hours and curing the bonder naturally to obtain the white chip for the LED.

Owner:XIANGLING LED

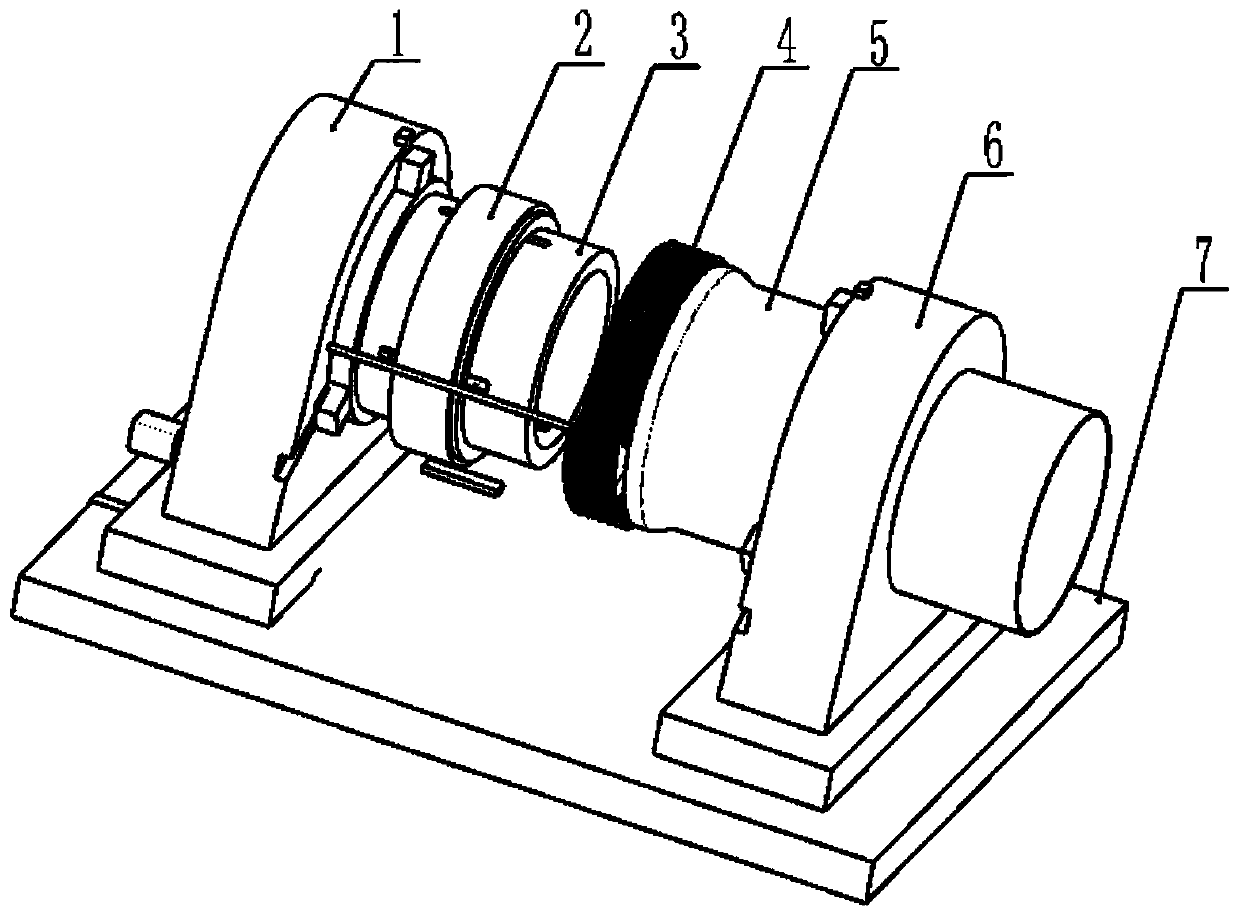

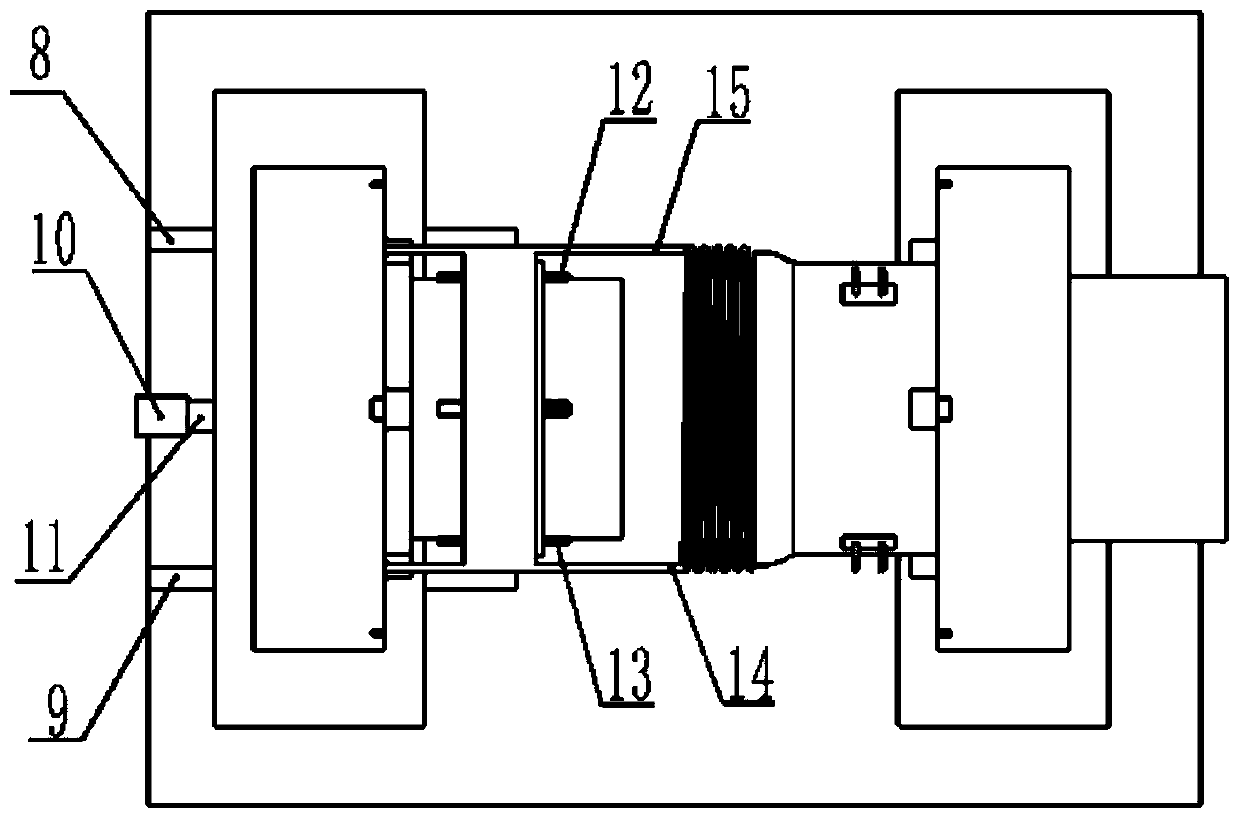

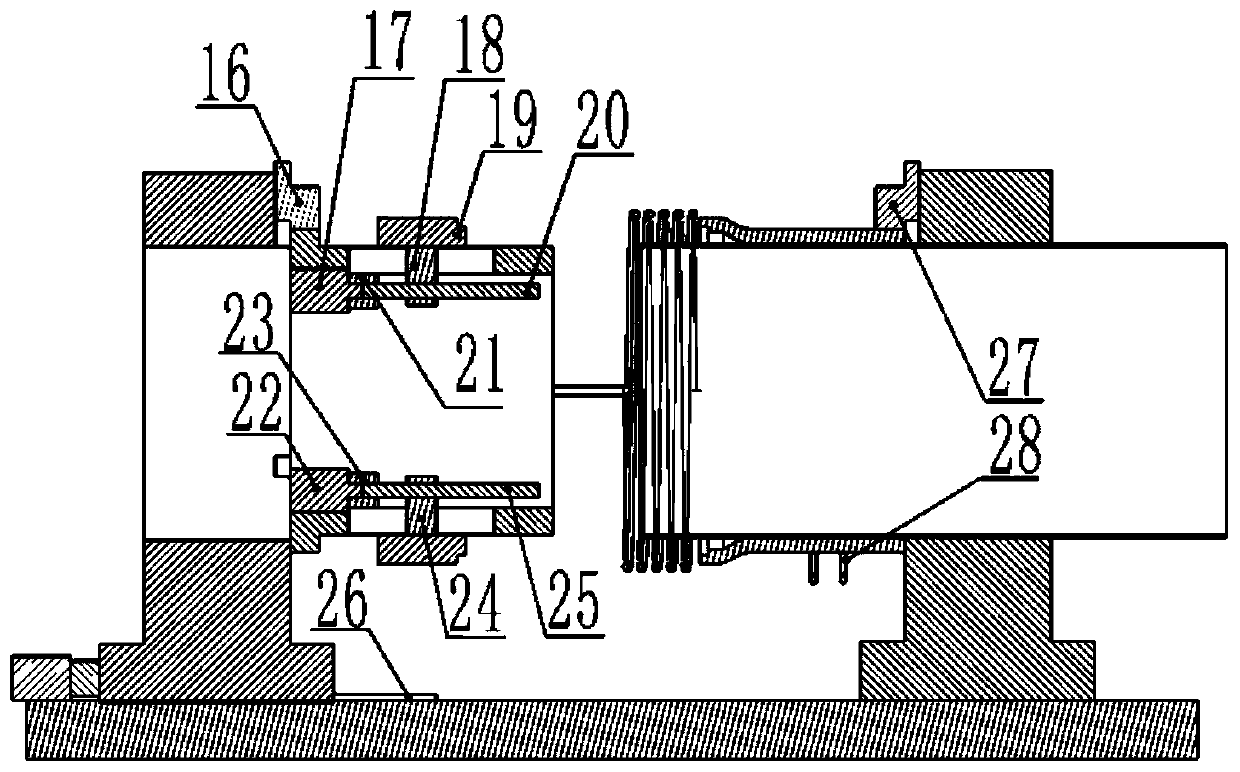

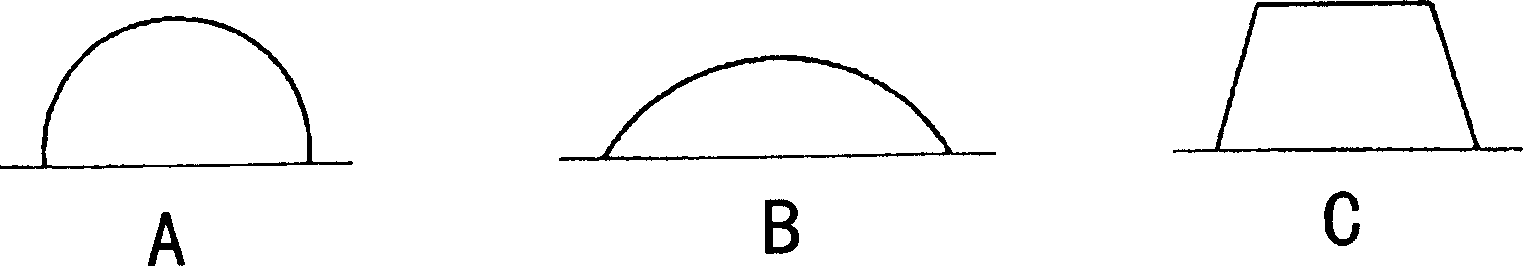

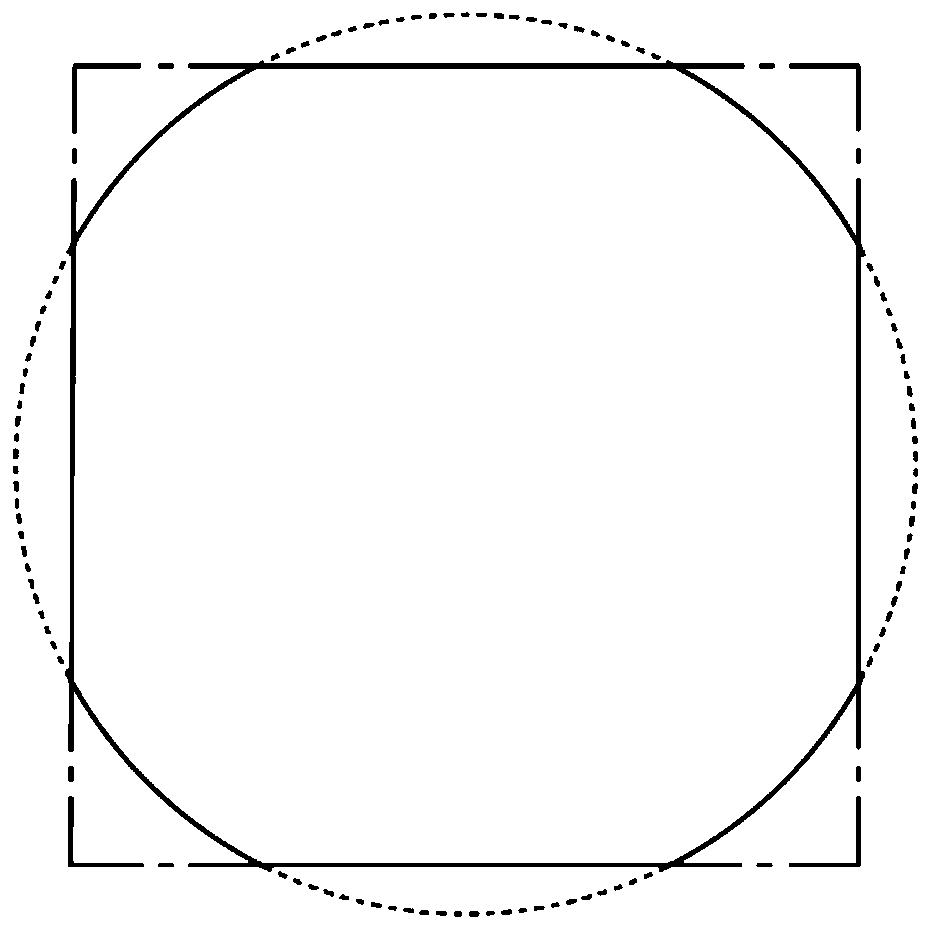

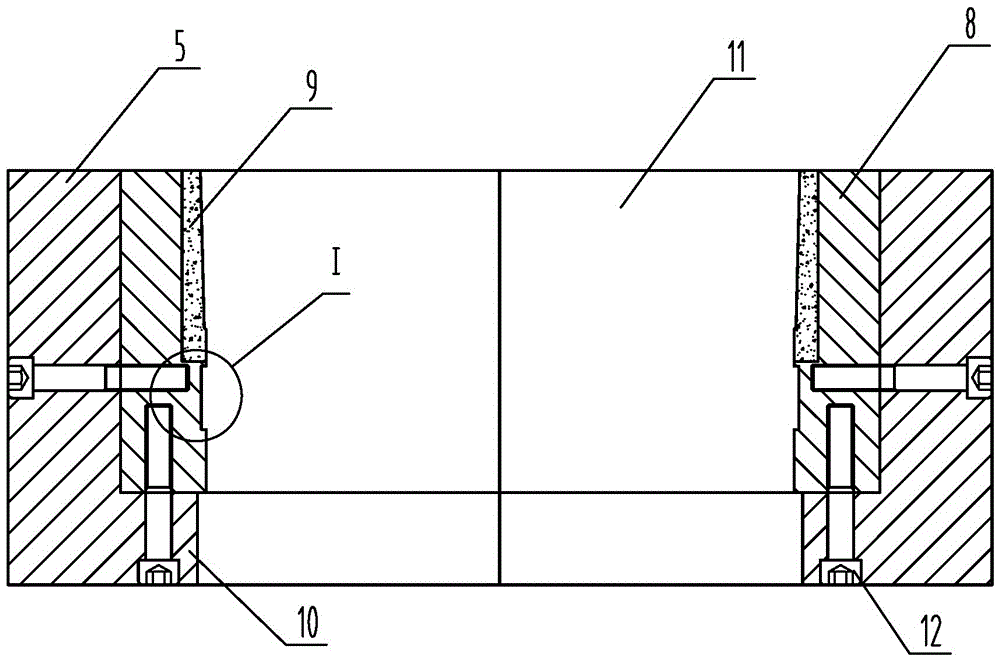

Induction heating upsetting device for aluminum alloy cylinder

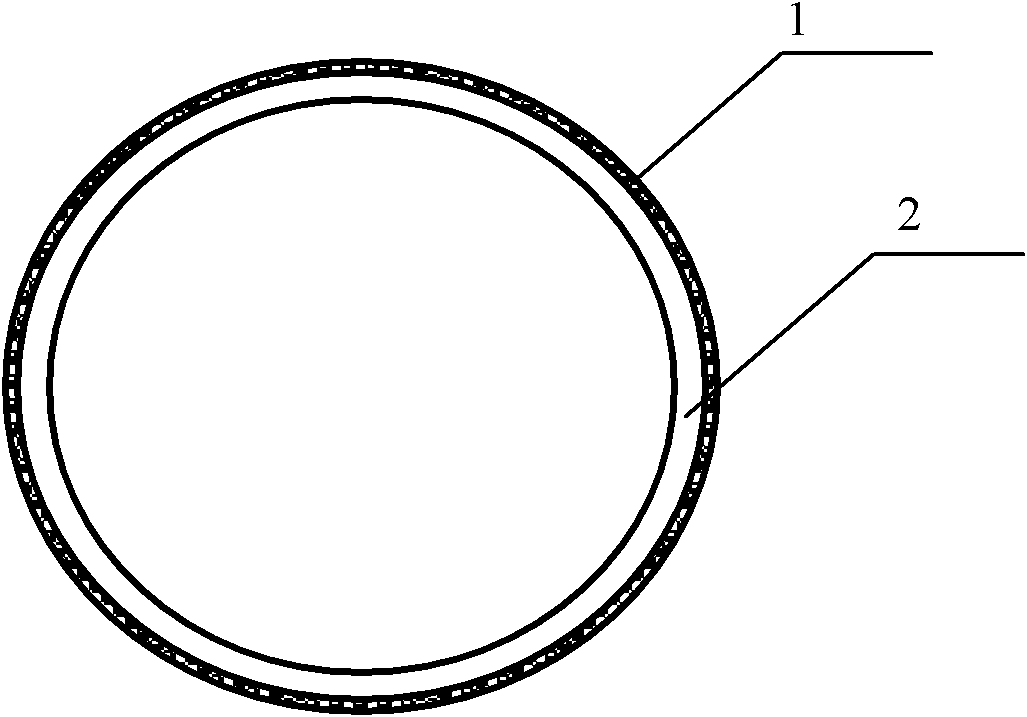

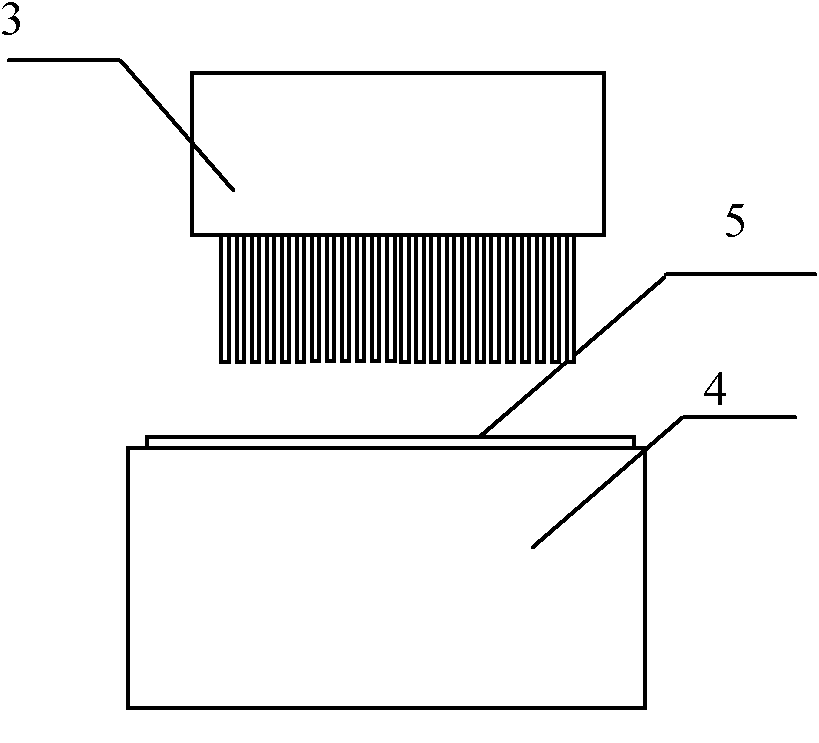

PendingCN111531103ASatisfy pier thick demandImprove automationUpsetting pressesSwagging pressesEngineeringTailstock

The invention provides an induction heating upsetting device for an aluminum alloy cylinder. The induction heating upsetting device comprises a headstock, an upsetting mechanism, an upsetting supportring, an induction coil, a forming die and a tailstock; the front end of the upsetting support ring is arranged on the headstock, the upsetting mechanism is arranged on the upsetting support ring in asleeving mode, the induction coil is arranged at the rear end of the upsetting support ring and is fixed at the front end of the forming die, and the rear end of the forming die is fixed on the tailstock; the central axes of the upsetting support ring, the induction coil and the forming die are positioned on the same straight line; the upsetting support ring can move relative to the induction coil along the axial direction; and the shapes of the upsetting support ring, the induction coil and the forming die are matched with each other. The induction heating upsetting device for the aluminum alloy cylinder in the invention greatly facilitates automation, the operation is simple, the size and the shape of a finished upsetting product are easy to control, the upsetting requirements of all aluminum alloy cylinders can be basically met, and great application prospect and market value are achieved.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

X-ray sensitive resin composition, protruded body and barrier body formed thereby, forming method thereof, and liquid crystal display element

InactiveCN1841195AExcellent voltage retentionIncrease production capacityPhotomechanical apparatusCoatingsCationic polymerizationVertical alignment

The object of this invention is to provide a radiation-sensitive resin composition which is suitably used for simultaneously forming protrusions and spacers of a vertical alignment liquid crystal display element. The radiation-sensitive resin composition for simultaneously forming the protrusions and the spacers for the vertical alignment liquid crystal display element contains: a copolymer [A] of an unsaturated carboxylic acid and / or an unsaturated carboxylic acid anhydride (a1), an unsaturated compound having an epoxy group or an oxetanyl group (a2) and an olefinically unsaturated compound other than (a1) and (a2) (a3); and a photo-cationic polymerization initiator [B].

Owner:JSR CORPORATIOON

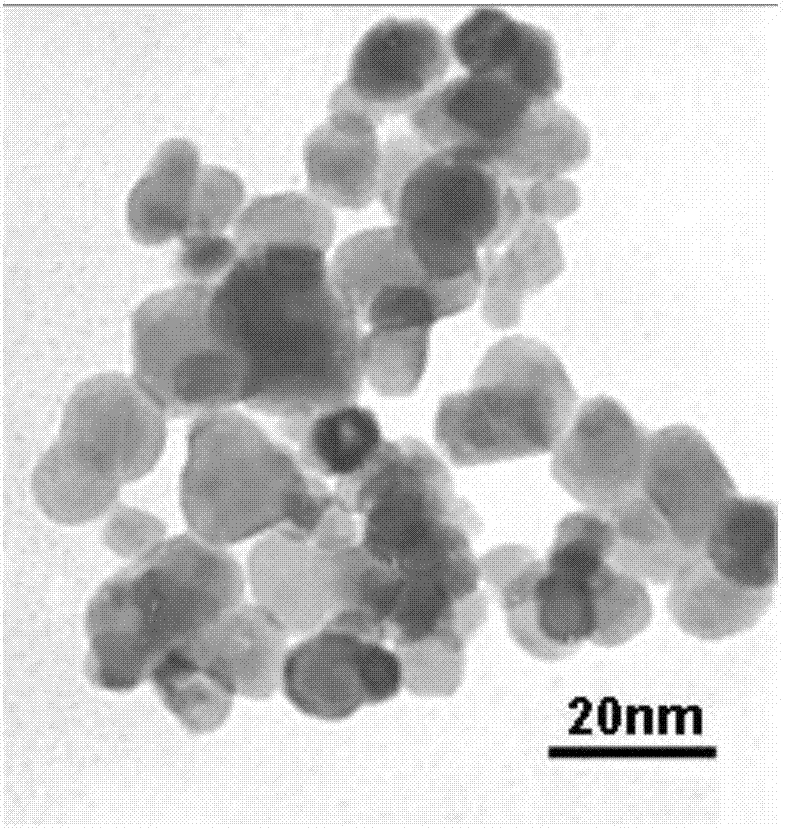

Preparation method for samarium-doped cerium oxide solid electrolyte powder

InactiveCN106953111AReduce concentrationGranularity controllableRare earth metal oxides/hydroxidesFinal product manufactureDispersityCerium nitrate

The invention provides a preparation method for samarium-doped cerium oxide solid electrolyte powder, and belongs to the field of a fuel cell. The preparation method is characterized by comprising the steps of preparing cerium nitrate, samarium nitrate and ammonium carbonate into solutions A and B, adding a BYK series dispersing agent into an ammonium carbonate solution, and preparing citric acid, oxalic acid and ammonium chloride into a solution C; mixing the solution A and the solution C in deposition, and dropwise adding into the solution B, and stirring and reacting to generate precipitates; and performing separating, cleaning, drying, calcining and smashing on the precipitates to obtain nanoscale SDC powder. By virtue of the preparation method, the nanoscale, spherical and high-dispersity SDC powder can be obtained easily; the overall technological process of the method can be controlled easily, and the process is convenient and rapid; meanwhile, the stability of the production process is improved, and the uniformity and consistency of the product are enhanced; and the powder state is quite beneficial to the subsequent preparation of a solid electrolyte thin film.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing graphene-base superconductive capacitor electrode

InactiveCN106847555AHigh specific surface areaIncrease load capacityHybrid/EDL manufactureLiquid mediumFoaming agent

The invention discloses a method for preparing a graphene-base superconductive capacitor electrode. The method comprises steps of: (a) dispersing graphene in a liquid medium to prepare graphene dispersions containing a foaming agent; (b) depositing the dispersions on a base material to form a liquid film; (c) removing the liquid medium to form a dry graphene material layer; (d) thermally treating the dry layer at a temperature of 85 to 2500 degrees centigrade so that non-carbon volatile gas molecules volatilizes and the foaming agent foams to generate a grapheme foam layer; and (e) impregnating the graphene foam layer with an electrolyte to form a pre-impregnated graphene foam layer and then compressing the pre-impregnated graphene foam layer to form the grapheme-base superconductive capacitor electrode. The method subjects the graphene to foaming treatment to improve specific surface area and load capacity and to achieve good electrical conductivity and large capacity, and then performs pressing to achieve high tap density, large energy density, high active load, a long cycle life, and easy shape control.

Owner:ANHUI SUNROAD ENVIRONMENT PROTECTIVE NEW MATERIALS

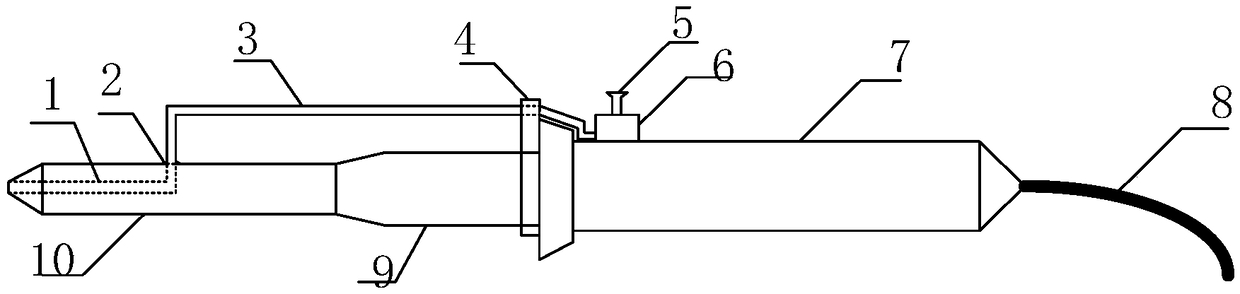

Pushing and injecting type electric soldering iron

InactiveCN108788364AEasy to control shapeEasy to control the degree of cleanlinessSoldering ironSolder feeding devicesGuide tubeMetal

The invention relates to a pushing and injecting type electric soldering iron. Compared with a traditional electric soldering iron, the pushing and injecting type electric soldering iron has the characteristics that parts such as an improved soldering iron head, a metal conduit, a pushing and injecting machine and the like are added. A cavity is formed in the improved soldering iron head to storea certain amount of melted solder. One end of the cavity is connected with a small hole at the point end of the soldering iron head, and the other end of the cavity is connected with a metal conduit opening. An obstruction screen is arranged at the connecting position of the metal conduit and the cavity. The metal conduit is fixed by a supporting bracket at a soldering iron handle. One end of themetal conduit is connected with the pushing and injecting machine and the other end of the metal conduit is connected with the cavity of the soldering iron head. When a pushing rod of the pushing andinjecting machine is pressed downwards, the melted solder in the cavity is discharged through the small hole formed in the point end of the soldering iron head. When the pushing rod is loosened, the pushing rod rebounds back and sucks the melted solder back. The pushing and injecting type electric soldering iron overcomes the defects that, according to a traditional electric soldering iron, the melted solder can not attach to the working surface caused by abrasion and oxidation of a soldering iron head,

Owner:ANHUI UNIV OF SCI & TECH

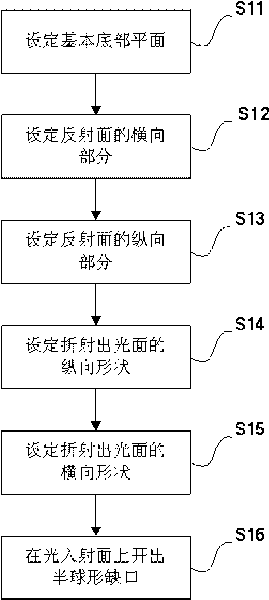

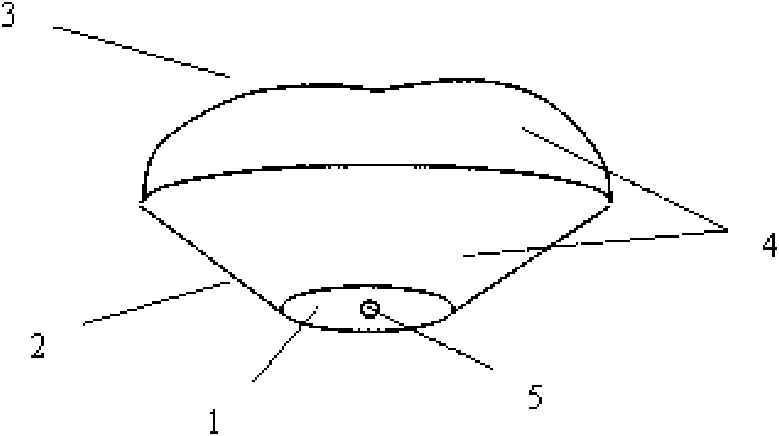

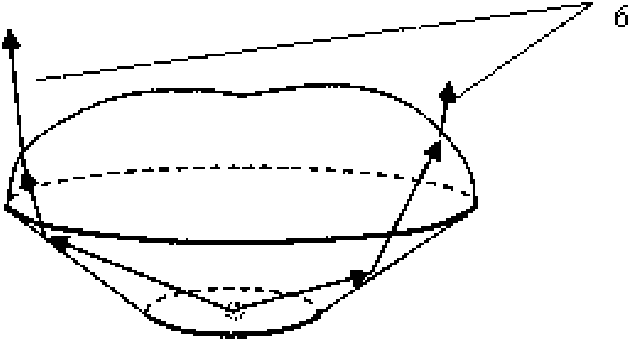

Method for manufacturing LED streetlight lens and lens thereof

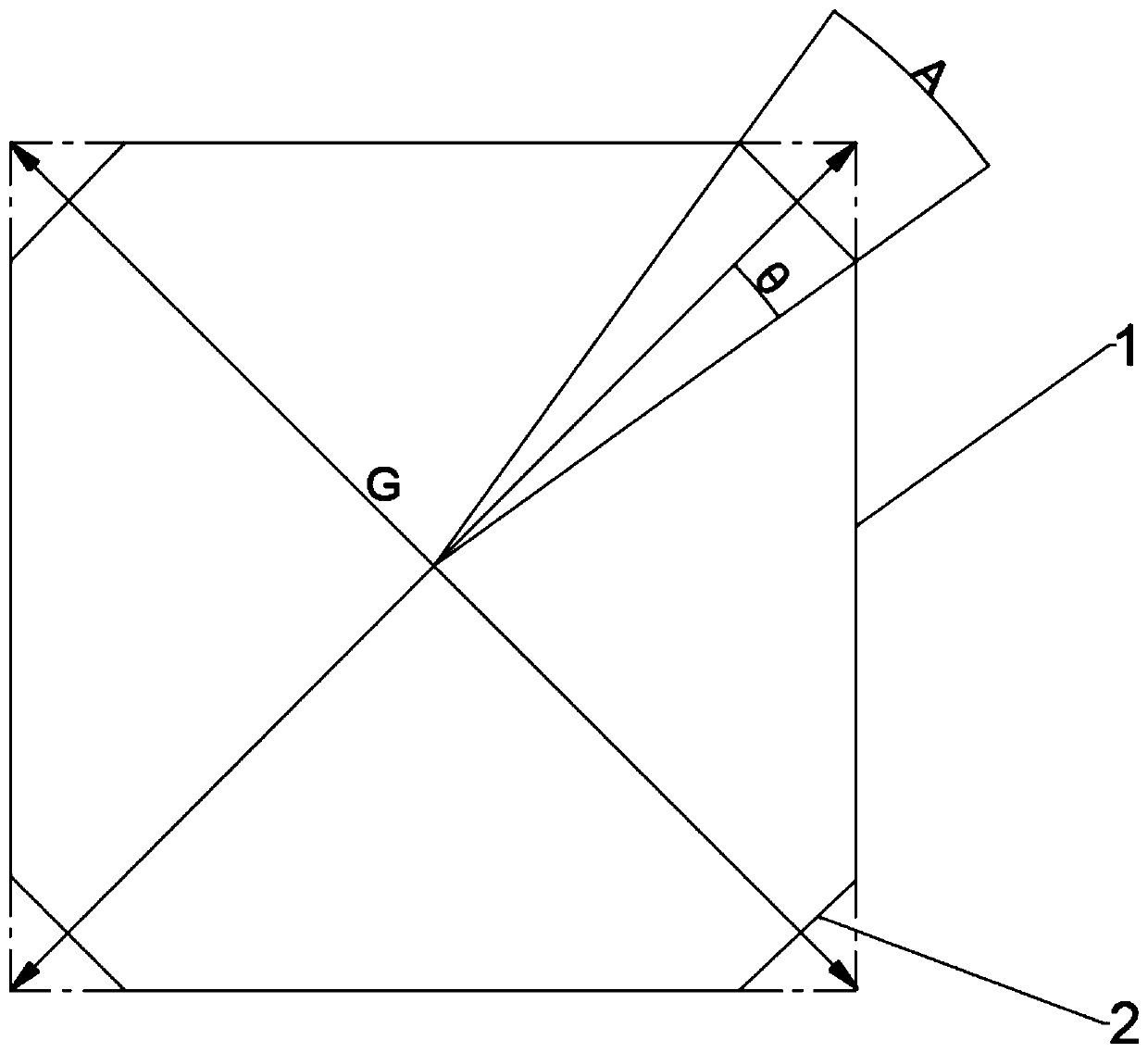

InactiveCN101699149AImprove lighting effectsEasy to control the illuminated areaMechanical apparatusPoint-like light sourceEffect lightEngineering

The invention relates to a method for manufacturing an LED streetlight lens, comprising the following steps: setting a basic bottom part plane of a lens; setting the reflecting part of the lens; and setting the refraction bright dipping part of the lens. The invention also discloses an LED streetlight lens. The beneficial effect is as follows by implementing the manufacturing method of the LED streetlight lens and the lens thereof: due to independent designing or selecting each component of the reflecting surface and the refraction bright dipping part of the lens, the lens has good bright dipping effect, and the lighting area and shape thereof are easy to control.

Owner:深圳市百信百投资有限公司 +1

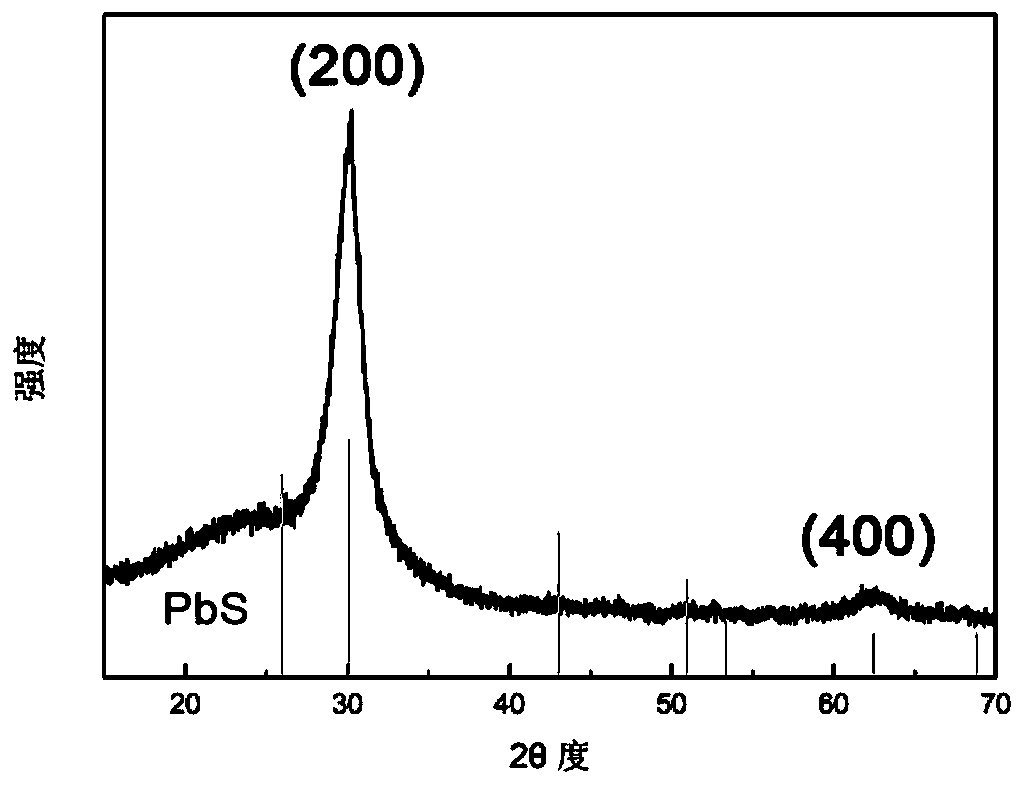

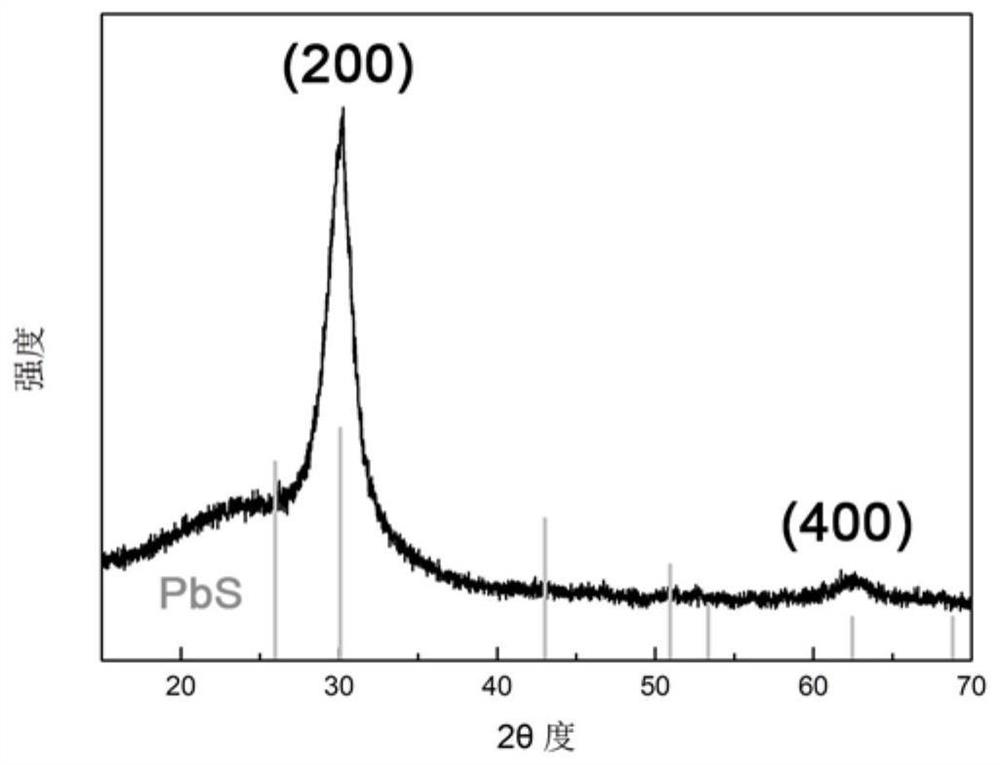

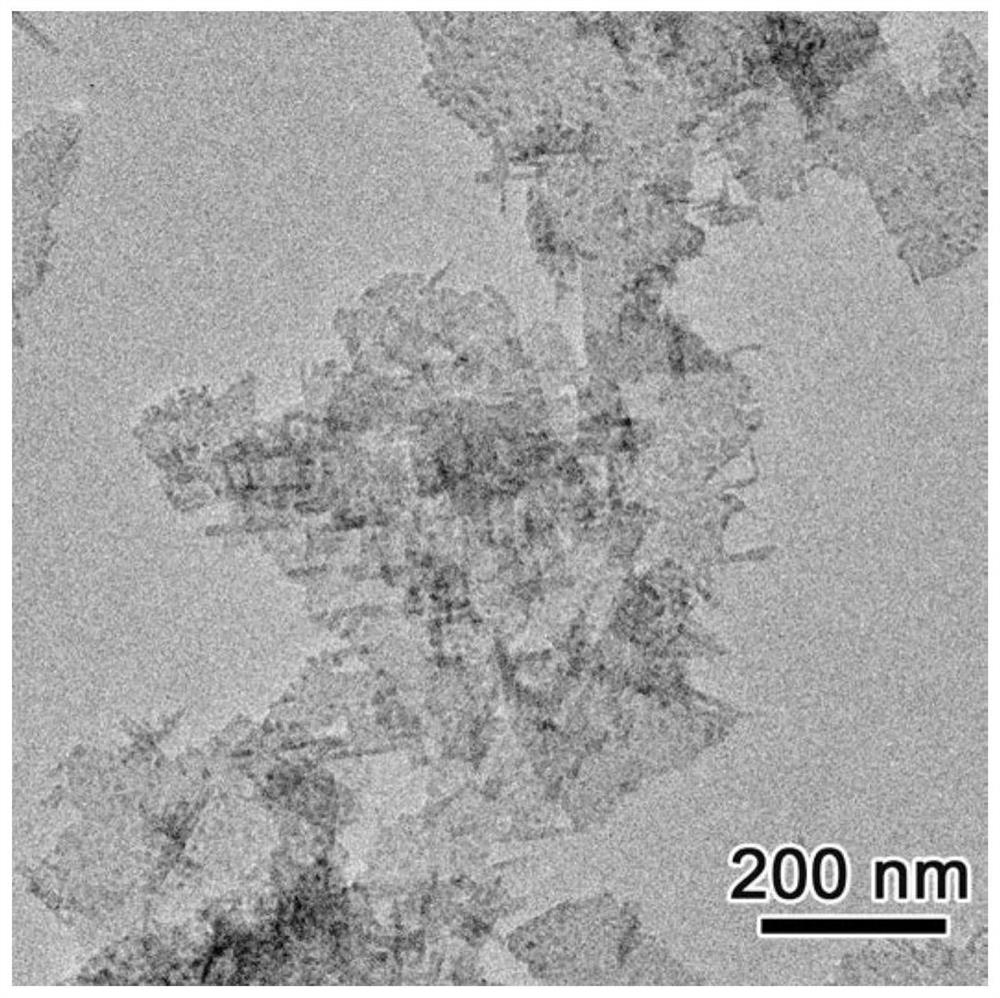

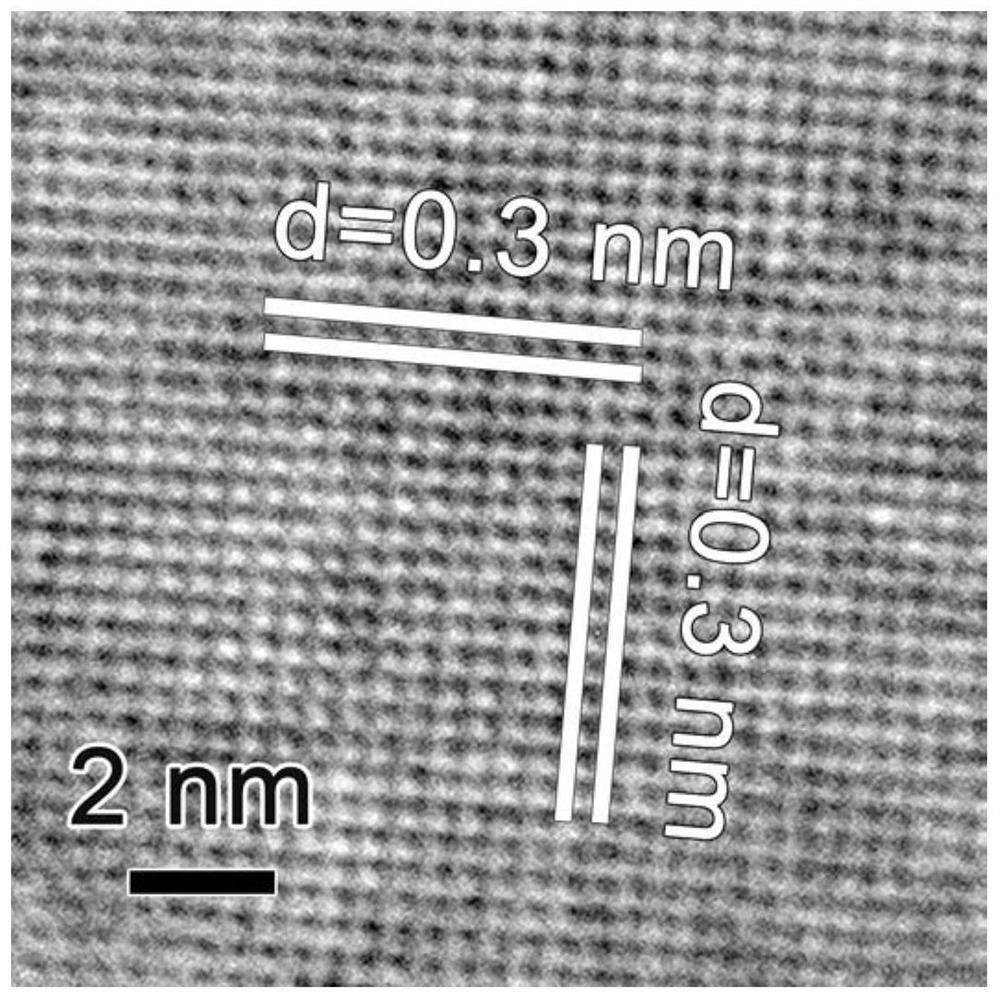

Unstratified metal sulfide nanosheet and preparation method thereof

ActiveCN109928369ASimple ingredientsSimple processTin compoundsCadmium sulfidesOrganic solventRoom temperature

The invention discloses a preparation method of a unstratified metal sulfide nanosheet. The preparation method of the unstratified metal sulfide nanosheet comprises the following steps: dissolving metal salt and a sulfur source in an organic solvent, and uniformly mixing for reacting to obtain a first muddy solution; heating till the first muddy solution is clear and transparent, introducing inertia gas, performing an illumination reaction, and then cooling to room temperature to obtain a second muddy solution; washing, centrifugally separating and drying to obtain the unstratified metal sulfide nanosheet. The preparation method provided by the invention has the advantages of few raw material kinds, simple process, mild conditions, universality and controllable nanosheet appearance. Moreover, the unstratified metal sulfide nanosheet prepared by the method is small in thickness, being 1.2 to 9 nm, and has high anisotropy and crystallinity, and good application prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

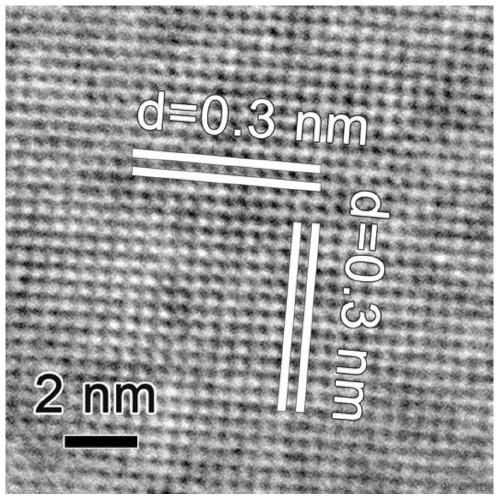

Monocrystalline silicon wafer, monocrystalline silicon rod, preparation method of monocrystalline silicon rod, solar cell and assembly

PendingCN111477540AGood consistency of grinding arcThe consistency of the grinding arc is controllableEdge grinding machinesFinal product manufactureSilicon chipSingle crystal silicon wafer

The invention provides a monocrystalline silicon wafer. The monocrystalline silicon wafer comprises a silicon wafer body, the silicon wafer body comprises a plurality of straight wall parts and a plurality of chamfer parts, the straight wall parts and the chamfering parts are sequentially and alternately connected end to end, the chamfering parts are linear, and the included angle between a straight line formed by connecting the end point of any end of each chamfering part and the center point of the silicon wafer body and the crystal direction of the silicon wafer body (110) is not smaller than 0.35 degree and not larger than 3.2 degrees. The monocrystalline silicon wafer has the beneficial effects that the monocrystalline silicon wafers are provided with the chamfering parts, and the chamfering parts are linear, so that the poor positioning effect of the monocrystalline silicon wafers during downstream battery electrode printing and battery assembly assembling is avoided, and the dislocation phenomenon occurring during monocrystalline silicon wafer splicing is avoided; and meanwhile, in the preparation process of the monocrystalline silicon rod, the polishing mode that the monocrystalline silicon rod does not rotate and the polishing grinding wheel rotates is adopted, so that the consistency of the corner angle polishing radian of the monocrystalline silicon rod is good.

Owner:天津市环智新能源技术有限公司

Organic and inorganic composite nanofiber, organic and inorganic composite structure and methods for producing the same

ActiveCN1922275AIncrease surface areaExcellent molecular selectivityMaterial nanotechnologyFiberComposite nanofibers

Disclosed is an organic-inorganic composite nanofiber composed of a crystalline polymer filament made of a polymer having a linear polyethyleneimine skeleton and a silica covering the crystalline polymer filament. Also disclosed are a structure composed of such an organic-inorganic composite nanofiber, and a method for producing the same.

Owner:KAWAMURA INST OF CHEM RES +1

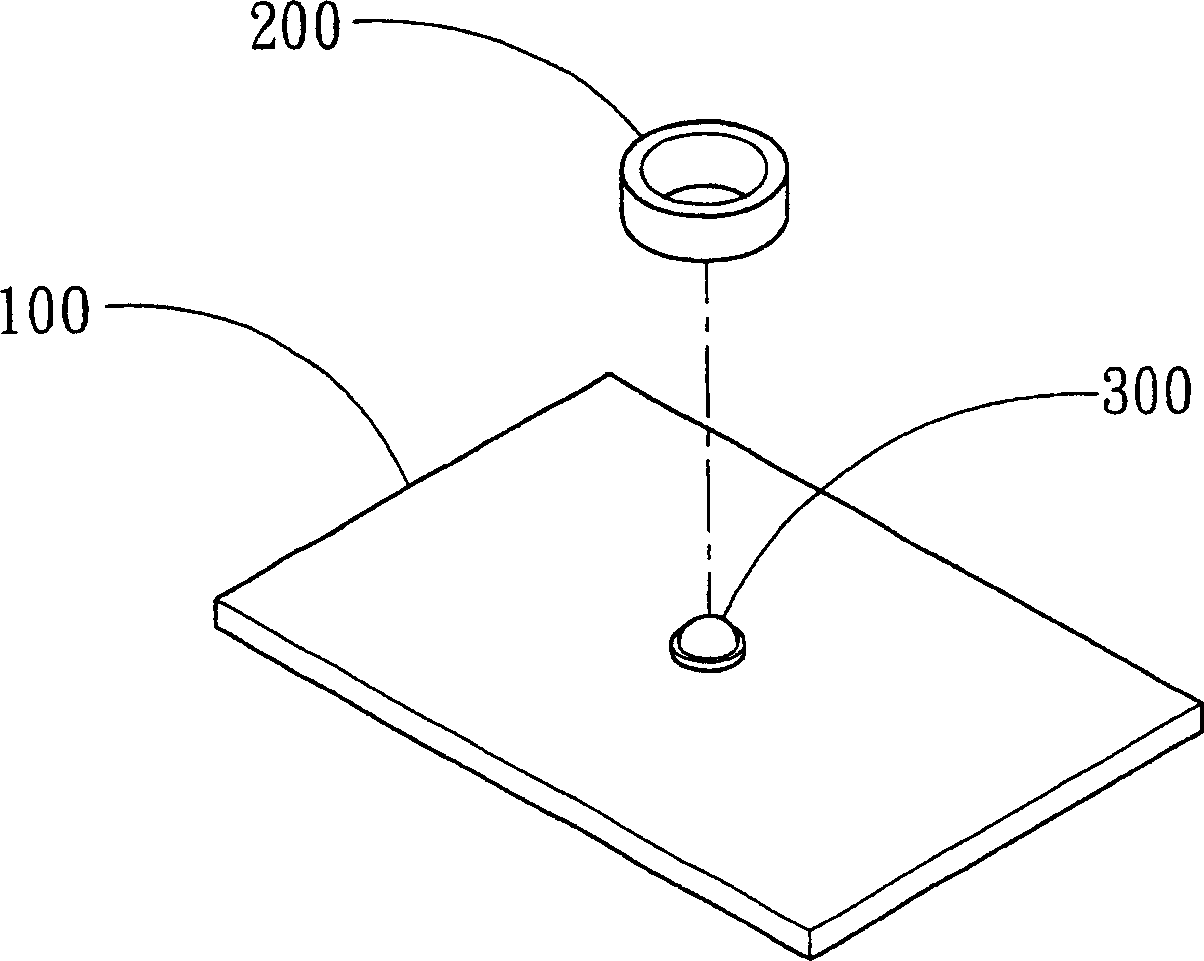

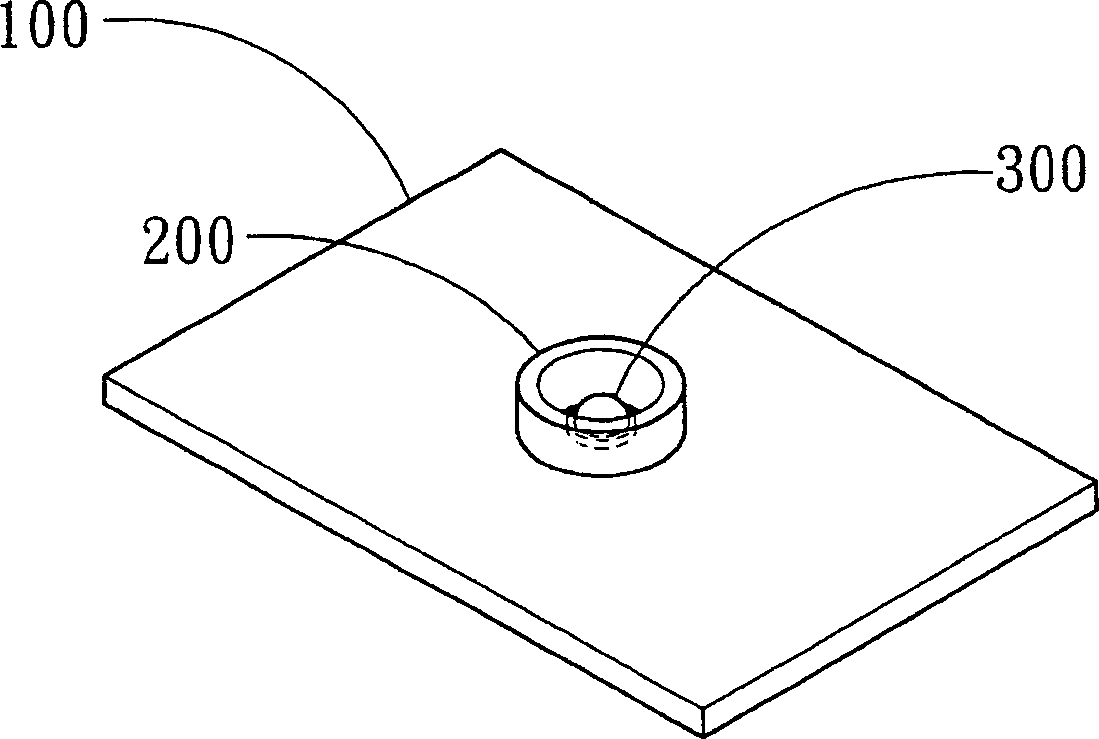

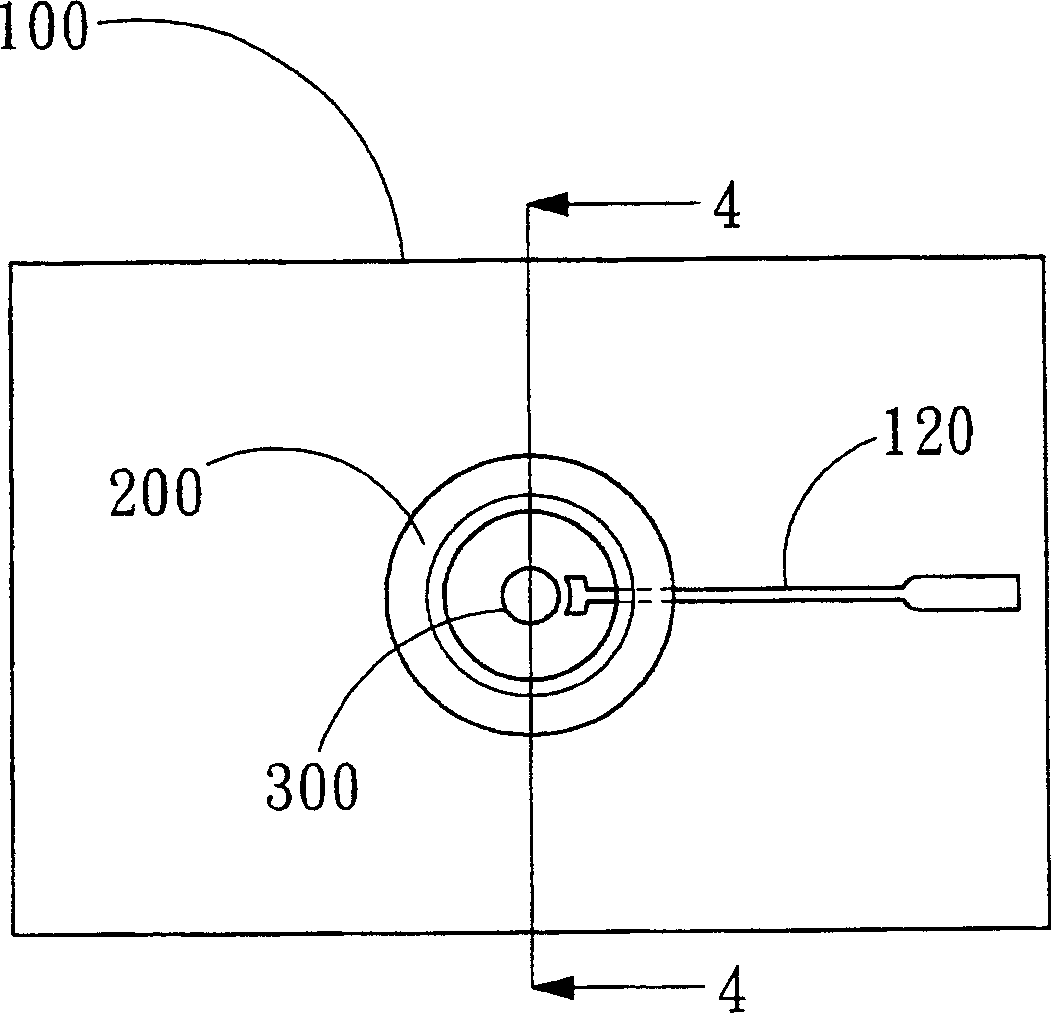

Base with ring-body and producing method

InactiveCN1893126APrevent outflowAvoid out-of-shapeSemiconductor/solid-state device detailsSolid-state devicesColloidEngineering

The base seat with ring body is composed of following arts: a base plate possesses at least an insulating layer and a circuit layer; a ring body setup on surface of the base plate; being setup on surface of the base plate circled by the ring body, a chip of light emitting diode (LED) is connected to the circuit layer on the base plate electrically, height of the ring body on the base plate is larger than height of the LED on the base plate; being prepared from euphotic material, an euphotic colloid layer is in use for covering the chip of LED so as to prevent the chip of LED from contacting outside directly.

Owner:周志邦

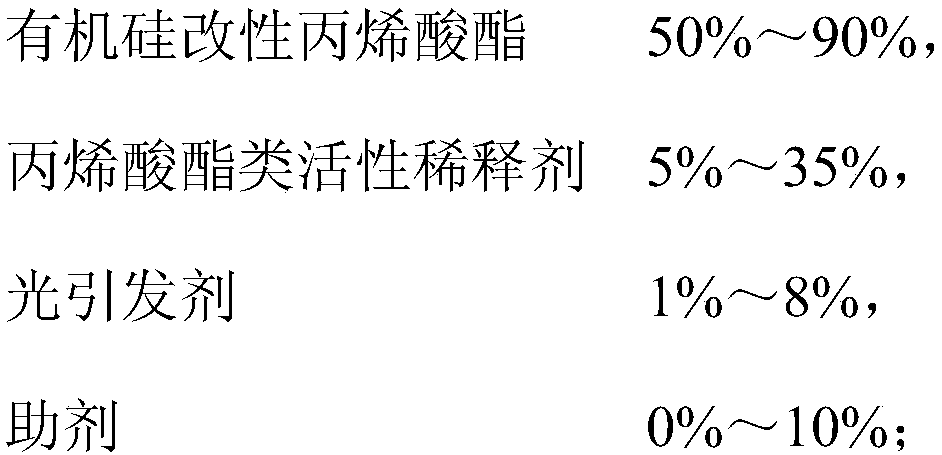

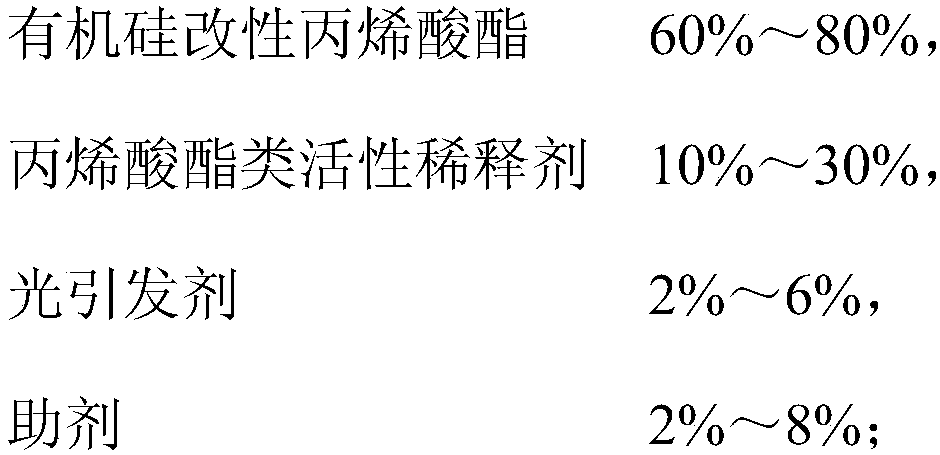

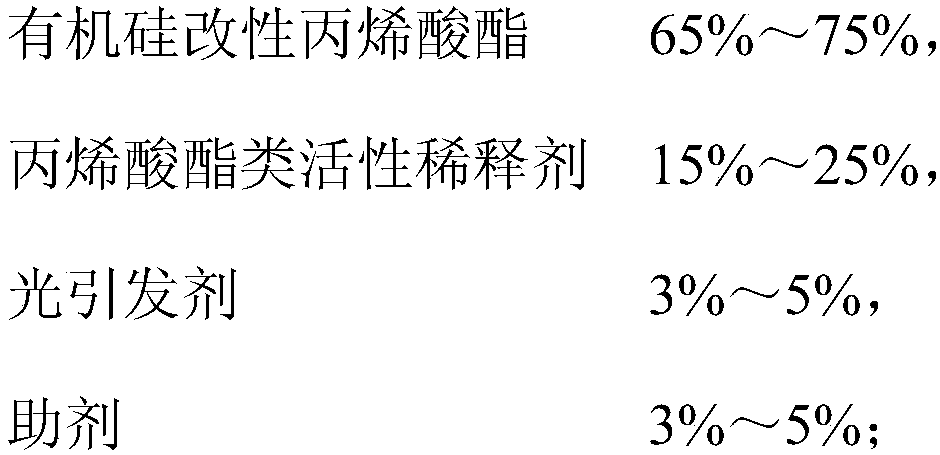

Ultraviolet curing adhesive for insulation protection, preparation method and application thereof

InactiveCN109251718AEasy to control shapeThickness is easy to controlNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveUltraviolet

The invention discloses an ultraviolet curing adhesive for insulation protection, a preparation method and an application thereof. The ultraviolet curing adhesive is composed of the following components by weight percentage: 50% to 90% of organosilicon modified acrylate, 5% to 35% of an acrylate reactive diluent, 1% to 8% of a photoinitiator, and 0% to 10 % of an auxiliary agent; the organosiliconmodified acrylate is synthesized from hydroxyl terminated polydimethylsiloxane, methylene dicyclohexyl diisocyanate, hydroxy acrylate and a polymerization inhibitor. In addition, the invention also discloses a preparation method of the ultraviolet curing adhesive and an application thereof. The viscosity of the ultraviolet curing adhesive reaches 10000 mPa or more, the ultraviolet curing adhesiveis not easy to sag, and the UV-curable double bonds are introduced into the organosilicon molecular chain, the high-flexibility ultraviolet curing adhesive is prepared, the insulating electrical strength of the ultraviolet curing adhesive after UV curing reaches 20KV / mm or more, and the ultraviolet curing adhesive can be applied to the insulation protection of bare electrical core aluminium edgeof a soft-packed secondary lithium battery.

Owner:广东阿普邦新材料科技股份有限公司

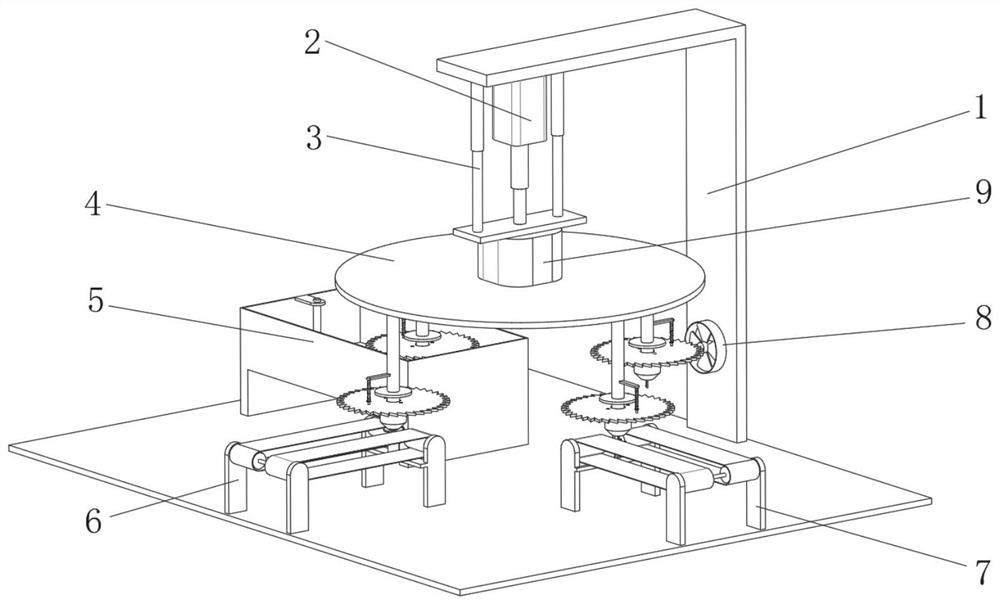

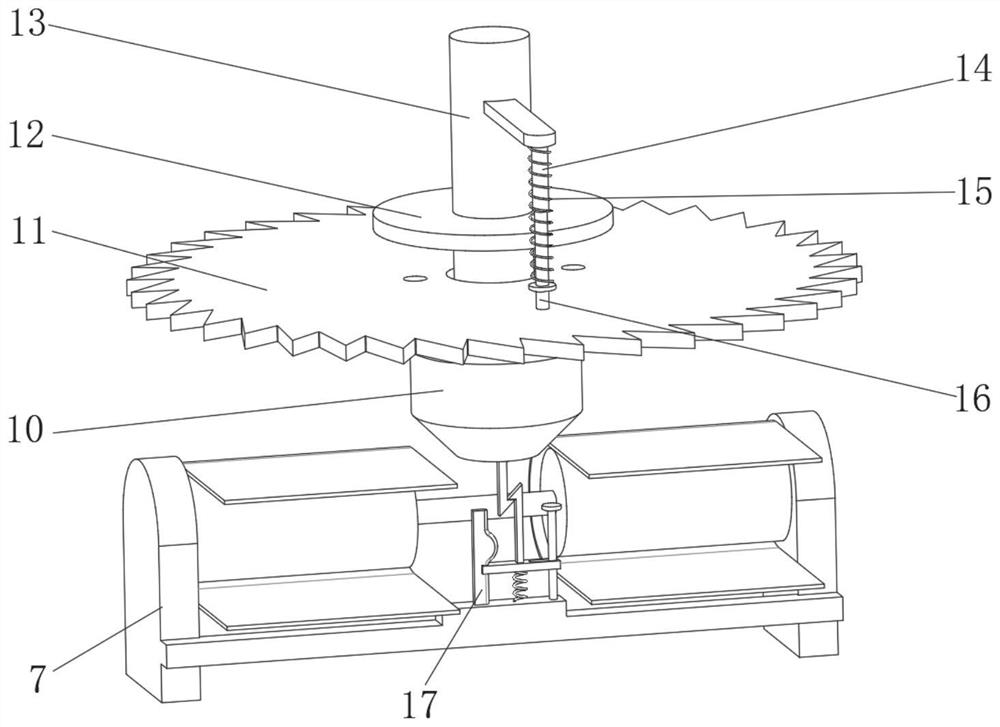

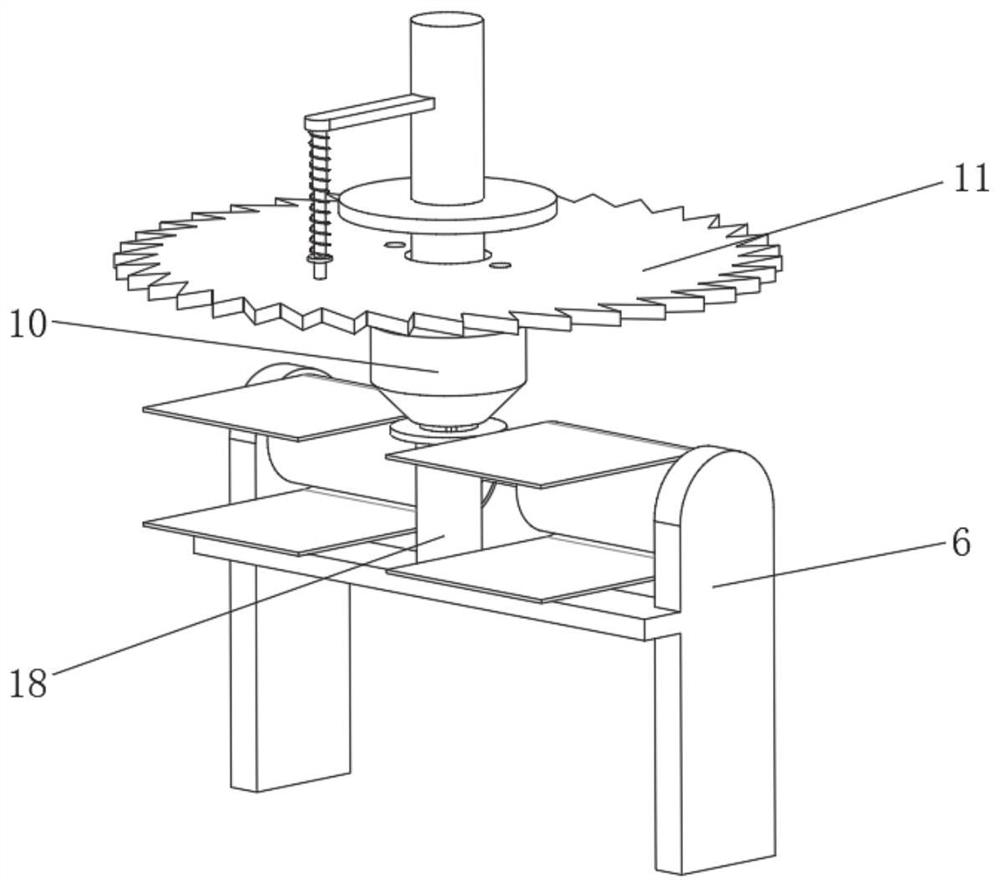

Saw blade grasping assembly, transmission device, electroplating device and electroplating method

The invention relates to a saw blade grasping assembly, a transmission device, an electroplating device and an electroplating method, and belongs to the technical field of circular saw blade electroplating. The assembly comprises a capsule-shaped shell that can shrink and expand when a force is applied in the length direction, wherein one end of the capsule-shaped shell is provided with a first coupling member; the assembly also comprises a second coupling member that is snap-connected to the first coupling member; and the second coupling member can be deflected and separated from the first coupling member when a force is applied. Through the capsule-shaped shell running through the central hole of the saw blade, the saw blade can be grasped through shrinkage and expansion. At the same time, the electroplating device containing the grabbing assembly can realize the simultaneous operation of different stations by cooperating with a feeding conveying component, a electroplating tank anda discharging conveying assembly, so that the loading, unloading, electroplating and drying work can be performed simultaneously, with no need for manual participation, which saves manpower and improves production efficiency.

Owner:RIZHAO HEIN SAW

Method for synthetizing nano Ag-Ni alloy

The process of composing nanometer Ag-Ni alloy includes the following steps: adding ammonia water to the mixed solution of NiSO4 in 0.70-1.80 mol / L and AgNO3 in 1.00-2.50 mol / L to regulating pH value to 7.5-8.5, adding certain amount of polyvinyl pyrrolidone, heating to 60-80 deg.c, adding reductant N2H4.H2O in 1.50-3.00 mol / L to produce reaction reaction; filtering, washing the obtained powder with alcohol and acetone, drying at normal temperature to obtain nanometer level Ag-Ni alloy powder; sintering at 600-650 deg.c and 15-25 MPa for 10-15min to obtain high density crystallized Ag-Ni alloy. The process features the convenient operation, molecule level mixing of the reactant components and homogeneous micro alloy structure.

Owner:SHENYANG NORMAL UNIV

Method for preparing graphene membrane from graphite liquid CO2 suspension

The invention discloses a method for preparing a graphene membrane from a graphite liquid CO2 suspension. The device comprises an insulation barrel, a stirrer and a volatilization disc; the method ischaracterized by comprising the following steps: adding the liquid CO2 with ultralow viscosity, ultra-strong flowability, ultra-strong permeability and super-strong adsorbability and high-mesh graphite powder into the sealed insulation barrel and stirring same; further breaking the graphite particles into suspension liquid with uniformly mixed free carbon atoms; pouring the suspension liquid intoa volatilization disc, allowing carbon atoms to settle due to the difference of specific gravity, wherein under condition of no interference of upper and lower atom motion power, carbon atoms firstlyreaching plane of volatilization disc are mutually combined to form two-dimensional crystallized graphene membrane.; compared with the prior art, the preparation method disclosed by the invention hasthe characteristics of simple use facilities, rich raw material sources, mature application technology and the like, and also has the advantages of high graphene preparation efficiency, easy control of size and shape, random composite layer thickness and the like, so that the preparation method has very good popularization and application values.

Owner:董恬纲

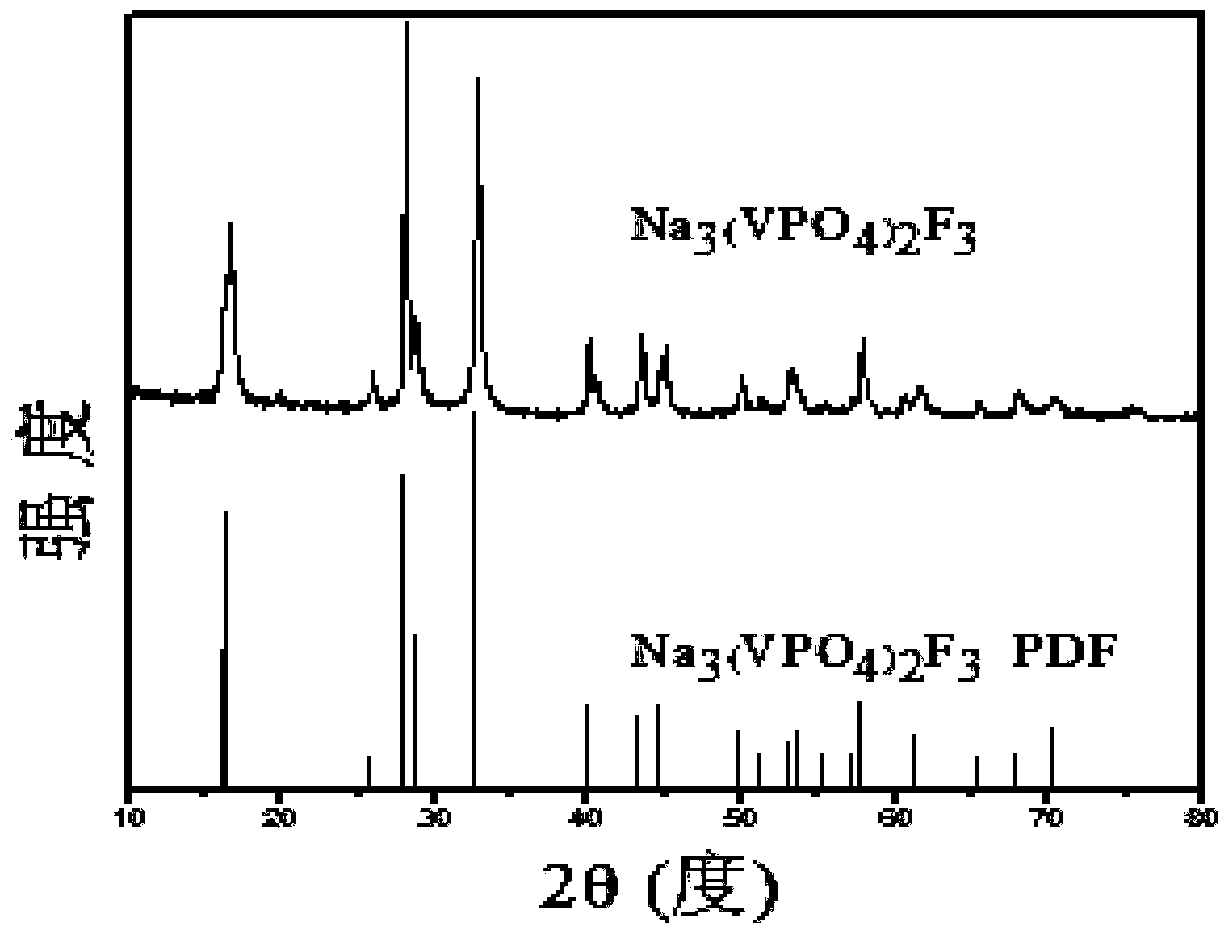

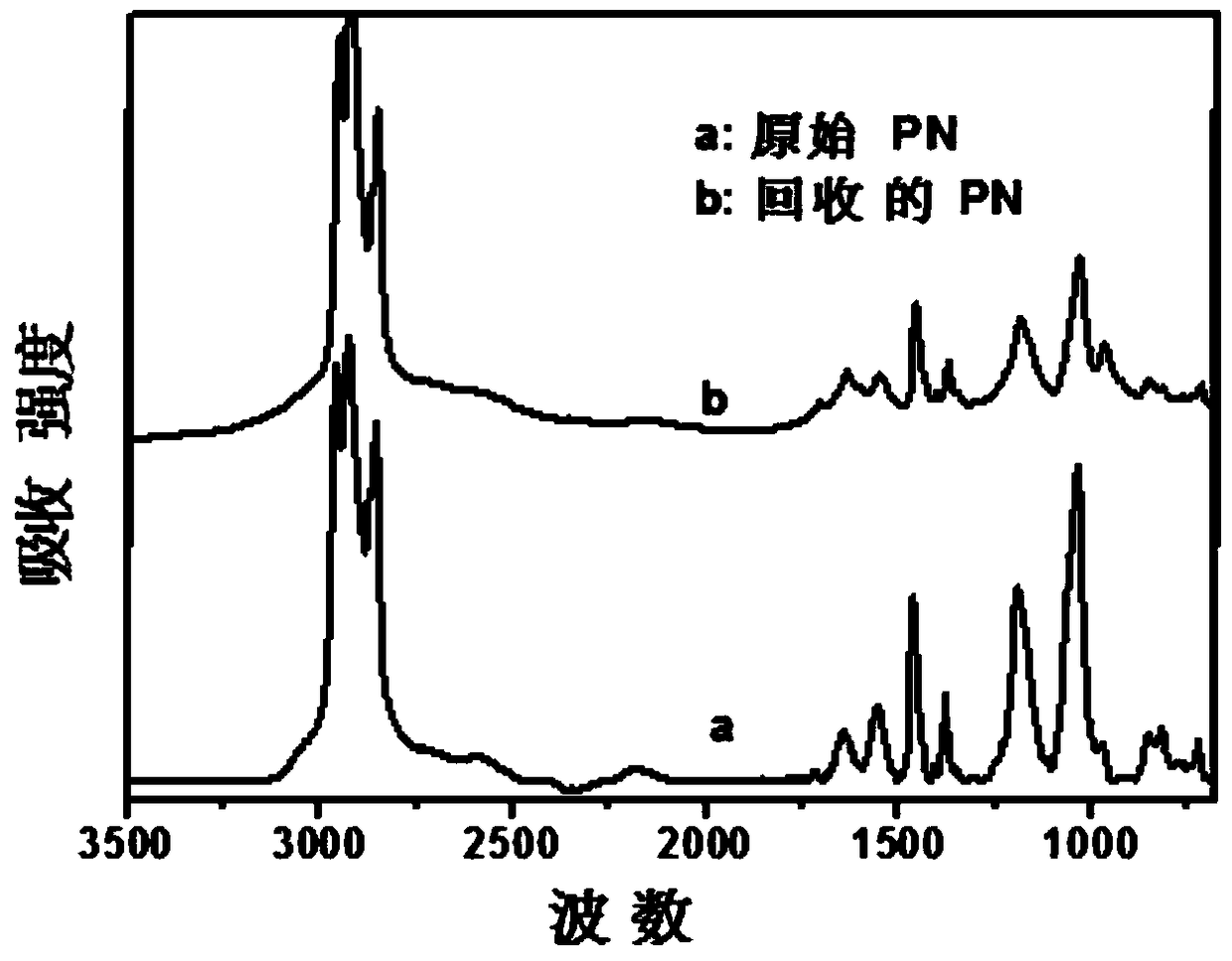

A kind of sodium vanadium fluorophosphate and its preparation method and application

ActiveCN105762355BHigh discharge specific capacityEasy to control shapeCell electrodesOrganic solventCentrifugation

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

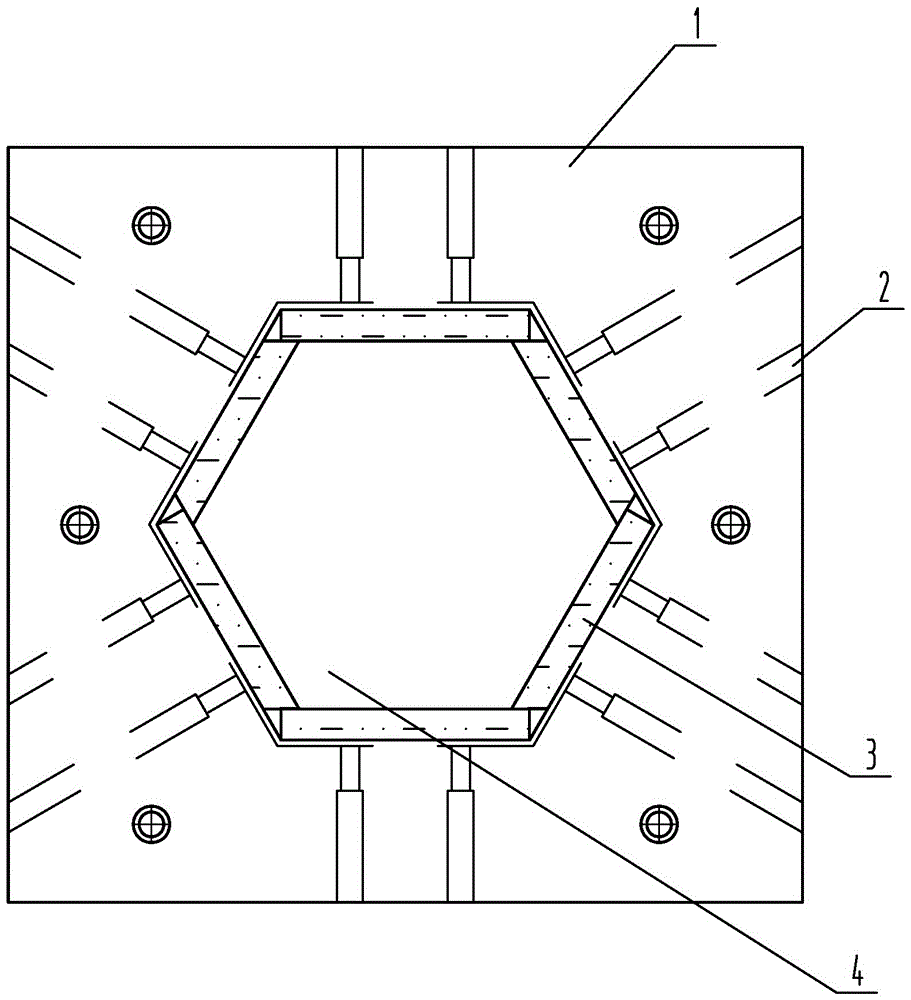

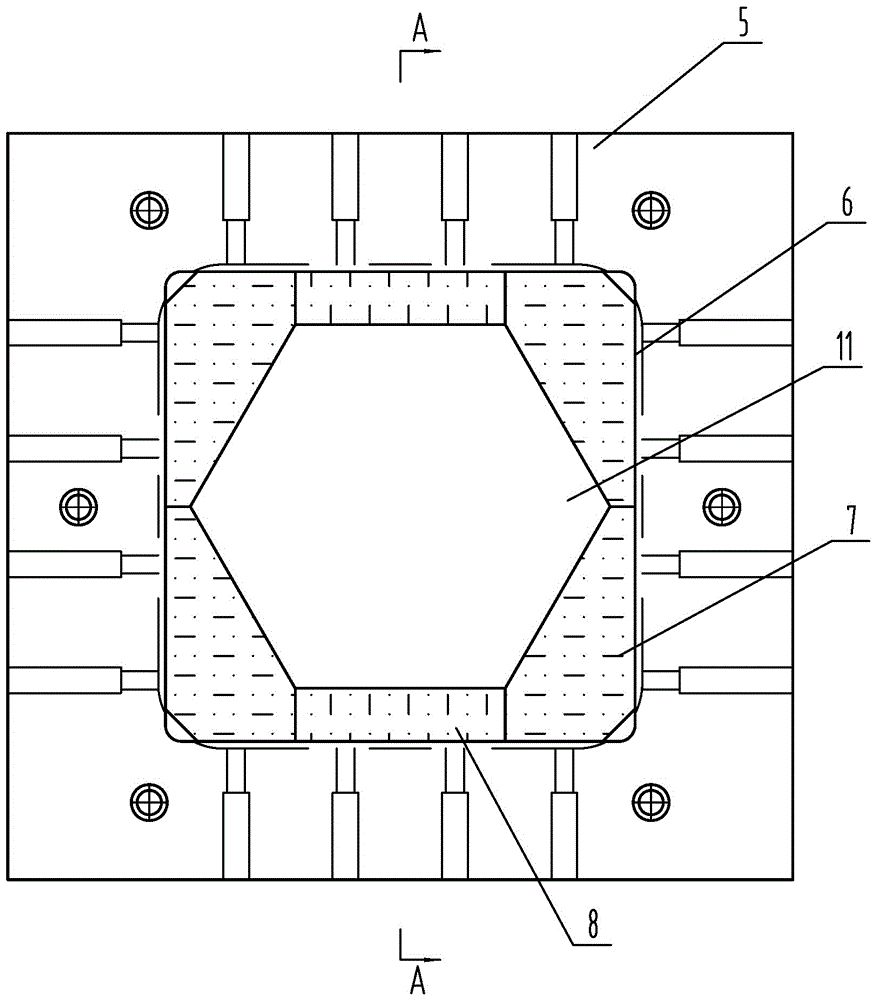

A special-shaped ceramic brick forming mold and its preparation method

ActiveCN104723443BEasy to control shapeReduce difficultyMouldsMould auxillary partsBrickMature technology

Owner:淄博沃德机械科技有限公司 +2

A kind of non-layered metal sulfide nanosheet and preparation method thereof

ActiveCN109928369BSimple ingredientsSimple processTin compoundsCadmium sulfidesOrganic solventPhysical chemistry

The invention discloses a preparation method of a unstratified metal sulfide nanosheet. The preparation method of the unstratified metal sulfide nanosheet comprises the following steps: dissolving metal salt and a sulfur source in an organic solvent, and uniformly mixing for reacting to obtain a first muddy solution; heating till the first muddy solution is clear and transparent, introducing inertia gas, performing an illumination reaction, and then cooling to room temperature to obtain a second muddy solution; washing, centrifugally separating and drying to obtain the unstratified metal sulfide nanosheet. The preparation method provided by the invention has the advantages of few raw material kinds, simple process, mild conditions, universality and controllable nanosheet appearance. Moreover, the unstratified metal sulfide nanosheet prepared by the method is small in thickness, being 1.2 to 9 nm, and has high anisotropy and crystallinity, and good application prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Combined type heat-insulating baffle for increasing monocrystal solidification temperature gradient

ActiveCN102400206BLow thermal conductivityStrong coefficient of thermal expansionFrom frozen solutionsGraphiteHeight difference

The invention relates to a combined type heat-insulating baffle which is applied to directional solidification equipment and is used for increasing monocrystal solidification temperature gradient. The combined type heat-insulating baffle comprises graphite rings and a flexible graphite felt, wherein the graphite rings and the flexible graphite felt are combined into an annular body, the inner diameter of which is more than the outer diameter of a shell mould to be cast; and the graphite rings are divided into two layers, the upper-layer graphite ring is directly placed on a water cooling sleeve in a directional solidification furnace, the flexible graphite felt is filled between the two layers of graphite ring, a height difference exists between the height of the inner diameter of the upper-layer graphite ring and the height of the outer diameter of the upper-layer graphite ring, and the height from the inner diameter to the outer diameter is increased in a smooth transition manner. The combined type graphite high-temperature heat-insulating baffle disclosed by the invention is convenient to manufacture by just clipping the flexible graphite felt according to dimensions and placing the clipped flexible graphite felt on the graphite rings on the water cooling sleeve as well as directly placing the second-layer graphite ring on the graphite felt, no bolts and nuts are needed for fixation, the placement is convenient and the price cost is low. Compared with the prior art in which a hard graphite felt is used as the heat-insulating baffle, the combined type heat-insulating baffle has the advantage that the temperature gradient is increased by almost 50%.

Owner:GUIYANG AVIC POWER PRECISION CASTING

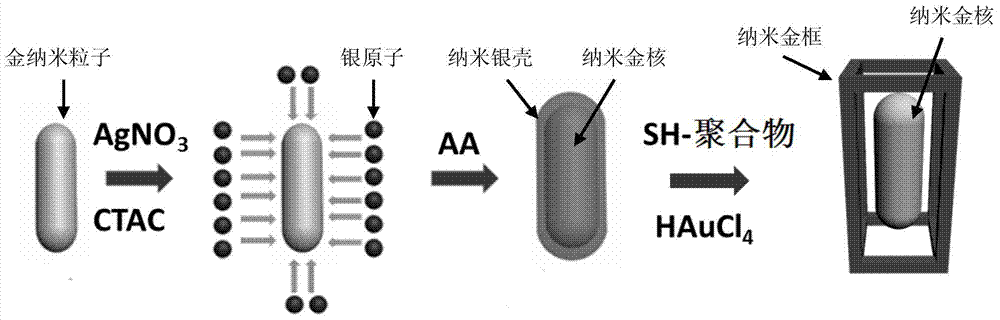

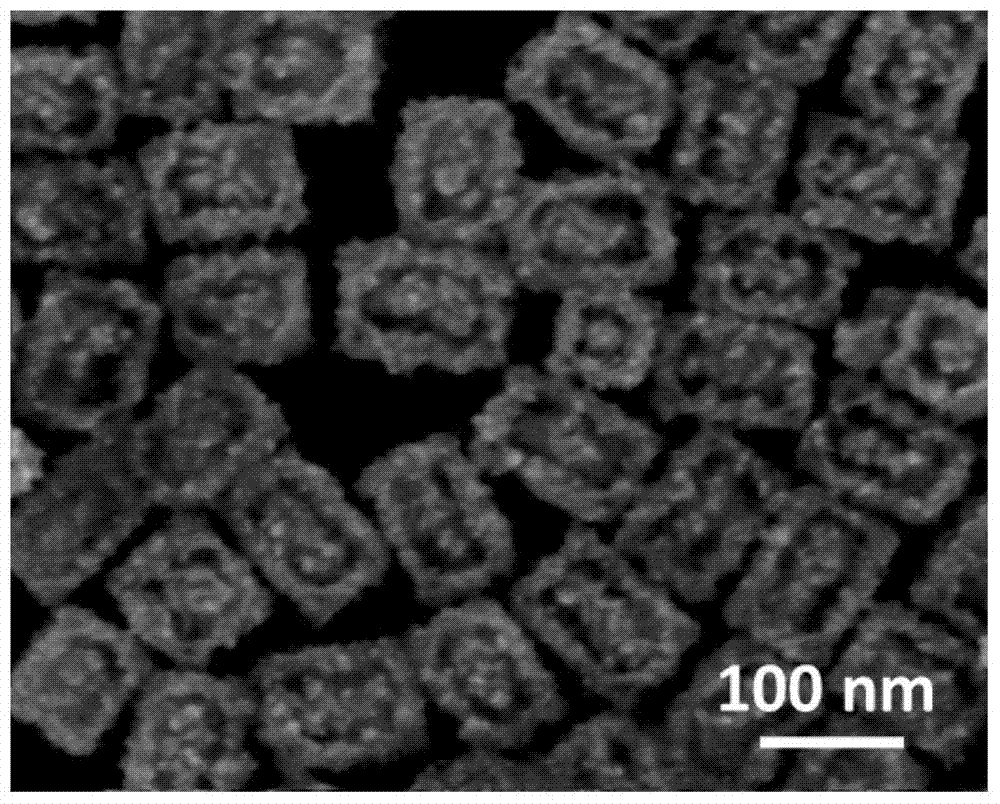

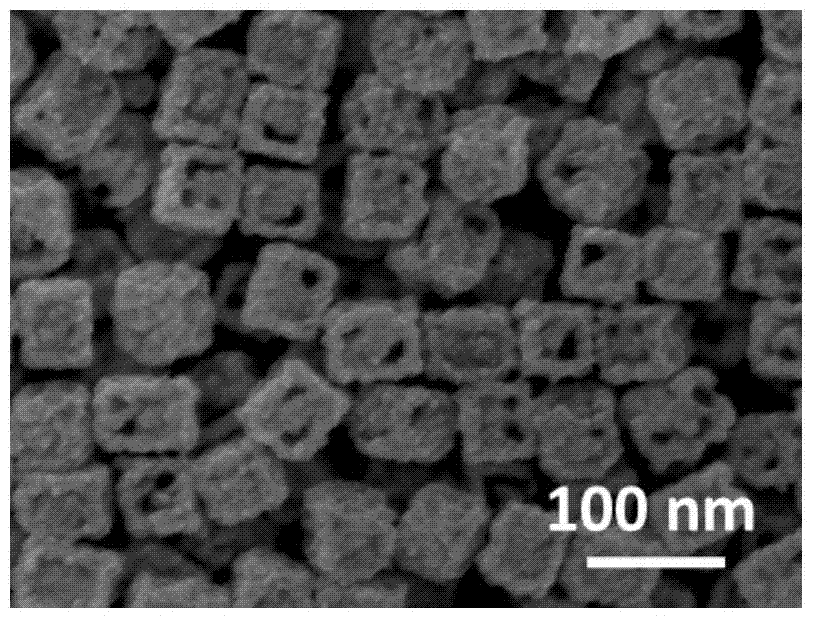

Three-dimensional "photo frame and photo" structure nano gold material, its synthesis method and application

ActiveCN106141172BEfficient synthesisEasy to control componentsMaterial nanotechnologyNano structuringGold particles

The invention discloses a three-dimensional "photo frame and photo" structure nano-gold material, which includes gold nanoparticles and a discontinuous gold shell layer in a three-dimensional frame structure covering the gold nanoparticles; its synthesis method includes: providing a core Gold and silver nanoparticles with shell structure, including gold nanoparticle crystal core and silver-coated nanoshell layer; after the selected molecules are modified on the surface of gold and silver nanoparticles, they are placed in a selective solvent to make the selected molecules collapse or stretch , thereby forming discontinuous nano-regions on the surface of the gold-silver nanoparticles, and the silver nano-shells in the nano-regions are exposed; the gold-silver nanoparticles are at least reacted with chloroauric acid to form the target product. The invention provides a new type of discontinuous growth mode, which is simple in process and easy to control, and can effectively synthesize three-dimensional "photo frame and photo" structure nanomaterials. This nanomaterial has unique optical properties and is useful in catalysis, sensing and detection, etc. It will have a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

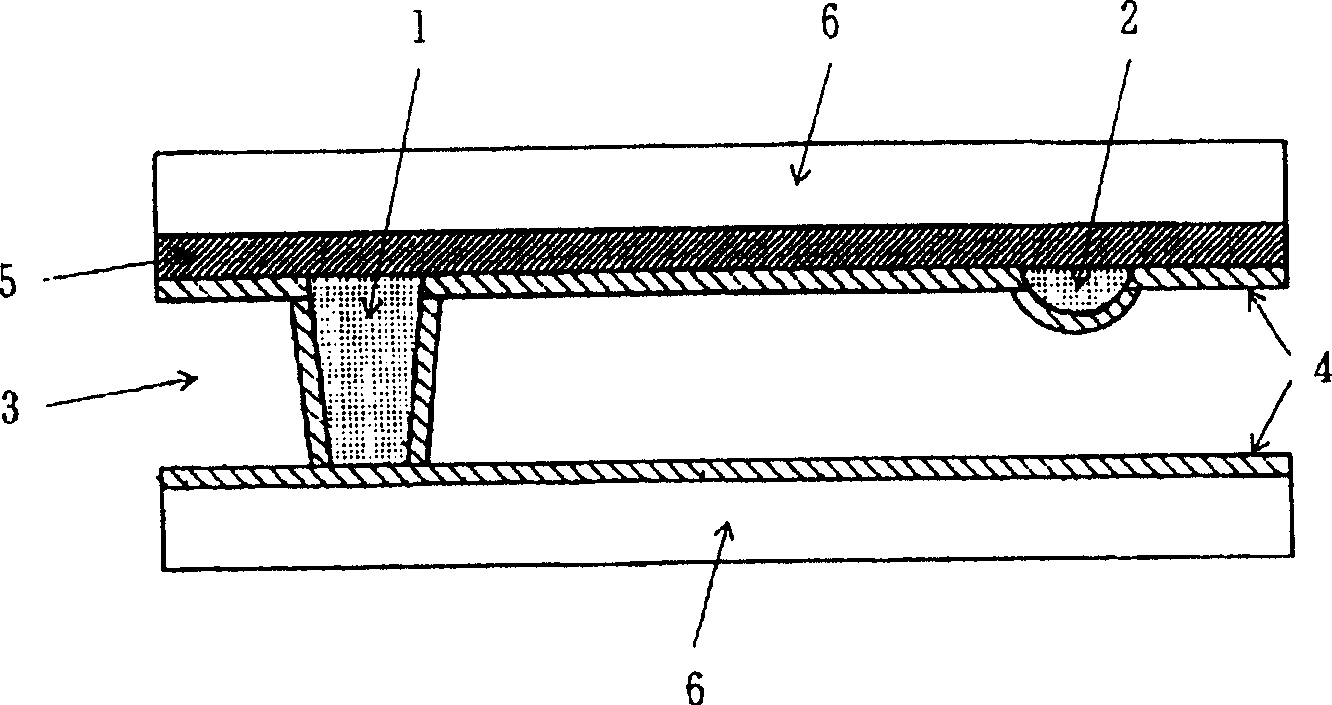

Packaging method of wafer chip and structure of wafer chip

ActiveCN109119346AEasy to control shapeEasy to control cross-sectional areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The present invention provides a packaging method of a wafer chip and a structure of a wafer chip. The method comprises the steps of: forming a conductive convex column on a welding pad at the front surface of a wafer; forming a welding column on the conductive convex column, wherein the section area of the welding column is not changed in the thickness direction; forming a first plastic layer atthe front surface of the wafer, the conductive convex column and the periphery of the welding column; and executing a thinning program for the first plastic layer to allow the welding column to be exposed. The packaging method of the wafer chip and the structure of the wafer chip are good in weldability, simple in preparation process, low in cost, high in yield, smaller in the packaging product size and thinner in thickness.

Owner:嘉盛半导体(苏州)有限公司

Method for machining porous-surface heat-exchange pipe for boiling heat-transfer equipment

The invention discloses a method for machining a porous-surface heat-exchange pipe for boiling heat-transfer equipment, aiming at providing a heat-exchange pipe and a machining method with the advantages of simple process, convenience for machining, no falling of a machined porous surface and capability of machining various complex structural forms. The method comprises the steps of: cutting an aluminum alloy sheet according to developed dimensions of a base pipe and a porous layer of a heat-exchange pipe respectively to obtain aluminum alloy sheets which are respectively used for machining the base pipe and the porous layer and have the same dimensions as the developed dimensions of the base pipe and the porous layer of the heat-exchange pipe; respectively evening out; placing the evened-out aluminum alloy sheet for machining the porous layer in the middle of a terrace die and a hollowing die, and punching the aluminum alloy sheet for machining the porous layer by using the terrace die and the hollowing die; superposing and thermally pressing a porous layer substrate and the evened-out aluminum alloy sheet for machining the base pipe so that the porous layer substrate and the evened-out aluminum alloy sheet for machining the base pipe are integrated; and then, machining the evened-out aluminum alloy sheet for machining the base pipe into a pipe shape, and welding both the machined aluminum alloy sheets to obtain the aluminum alloy heat-exchange pipe with the porous surface.

Owner:TIANJIN UNIV OF COMMERCE

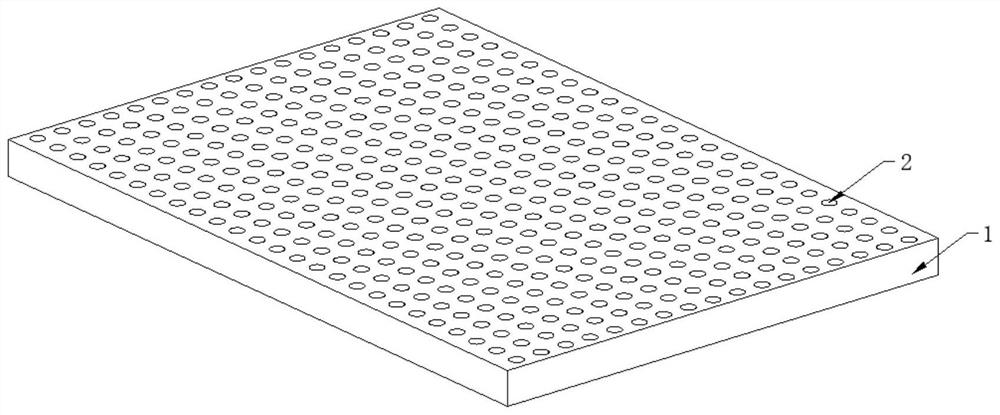

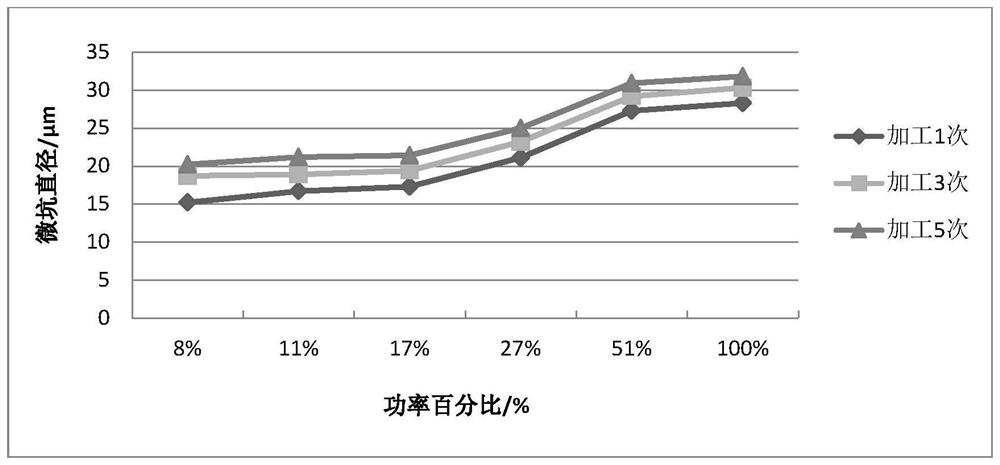

Base material with high surface binding force and preparation method thereof

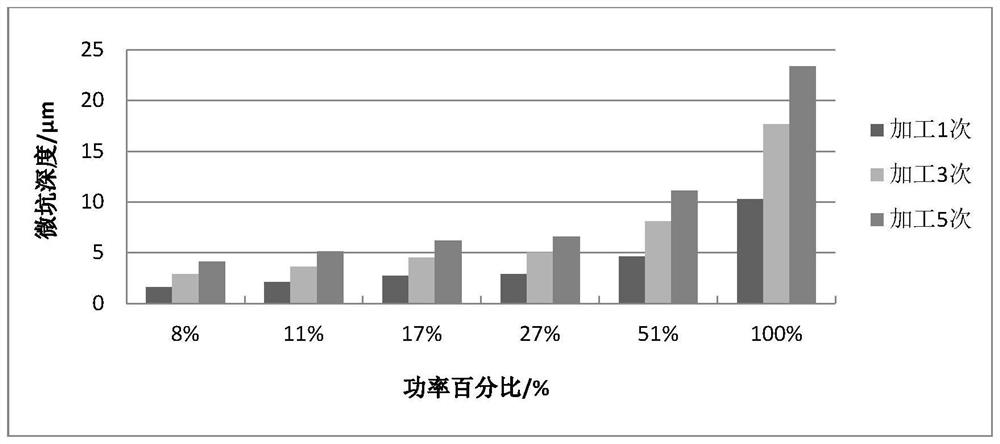

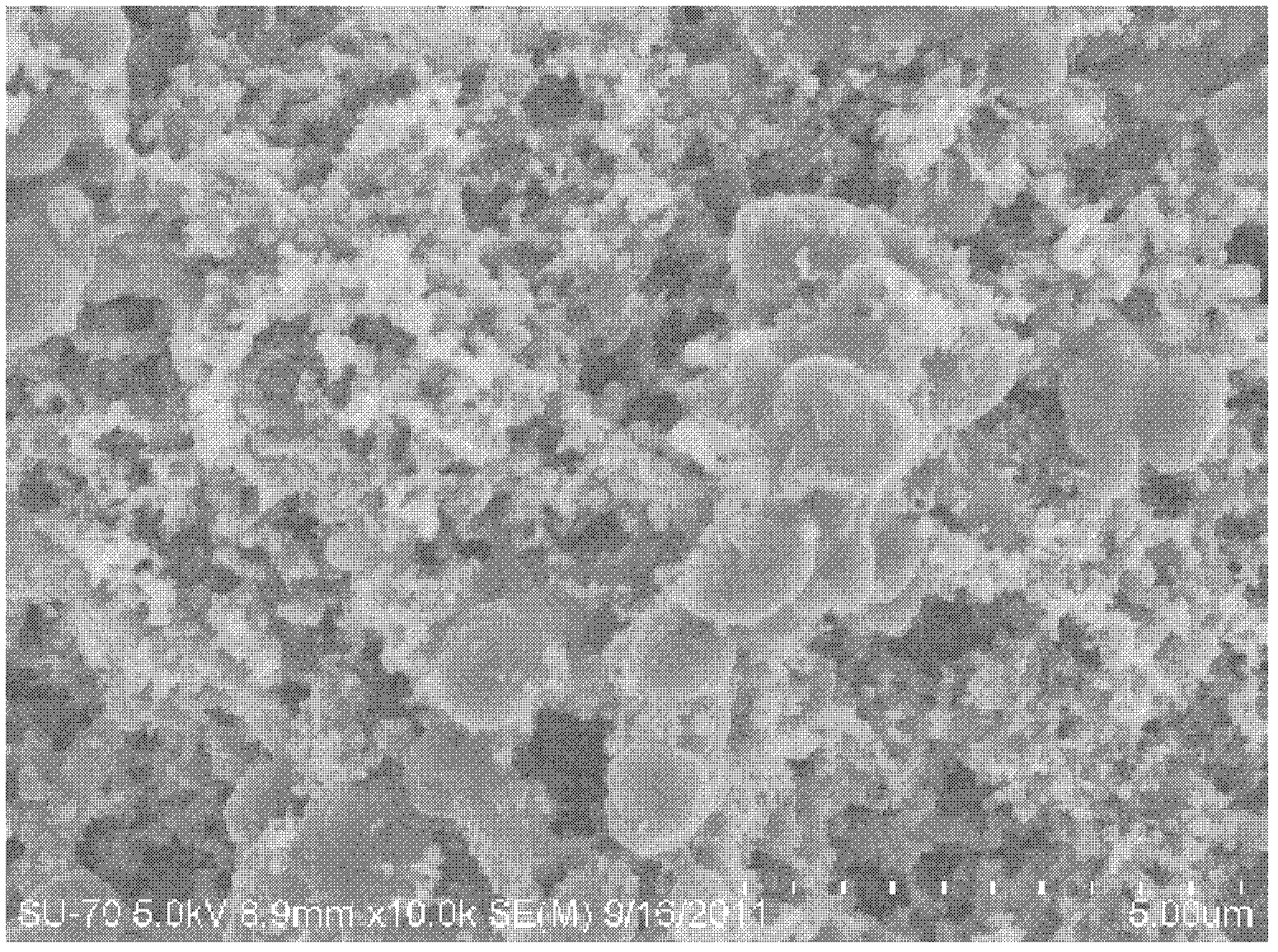

PendingCN113441836AEasy to control shapeThe size is easy to controlLaser beam welding apparatusLaser processingPulse energy

The invention provides a base material with high surface binding force and a preparation method thereof. The preparation method comprises the following steps of testing the diameter and depth of a micro-pit on the base material after a single pulse reacts with a material by using pulse laser. By changing the power or the number of machining times, a relation curve between the single-pulse energy and the number of machining times and the size and depth of the micro-pit can be obtained, and in practical application, a certain machining path and a certain scanning speed can be rapidly set for machining according to the relation curve and the size of the needed micro-pit, and thus, a high-binding-force base material with micro-pits regularly arranged and non-overlapped on the surface of the base material. According to the method, the roughness, the binding force and the variable surface tension (hydrophilic-hydrophobic property) of the surface of the base material can be remarkably improved. The preparation method is particularly suitable for a hydrophobic substrate, and the hydrophilicity of the hydrophobic substrate is remarkably improved after laser processing, so that the deposition speed of the hydrophobic substrate in an aqueous solution can be increased, the wettability can be improved, and the deposition speed of the material can be increased.

Owner:德中(天津)技术发展股份有限公司

Carbon black polymer combined counter electrode of dye-sensitized nano crystal solar battery and preparation method thereof

InactiveCN102543474BReduce manufacturing costHigh catalytic activityLight-sensitive devicesSolid-state devicesHexafluoropropyleneSolar battery

The invention provides a carbon black polymer combined counter electrode of a dye-sensitized nano crystal solar battery. The carbon black polymer combined counter electrode of dye-sensitized nano crystal solar battery comprises a base material and a composite material which is covered on the base material, wherein the composite material comprises a mixture A, polyoxyethylene, polyfluortetraethylene-P-hexafluoropropylene, carbon black and a silane coupling agent, wherein the mixture A is prepared by mixing propylene carbonate and ethylene glycol dimethyl ether. The invention further discloses a preparation method of the counter electrode. Compared with prior art, the invention has the advantages that carbon materials with high catalytic activity and low price are used for replacing platinum, so that production cost of a battery is lowered, and photoelectric conversion efficiency equivalent to that of a platinum counter electrode can be obtained.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com