Monocrystalline silicon wafer, monocrystalline silicon rod, preparation method of monocrystalline silicon rod, solar cell and assembly

A technology for solar cells and monocrystalline silicon wafers, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as inconsistent angles, asymmetric arc angles, and easy misalignment, and achieve consistent and controllable grinding arcs. The effect of good consistency and avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A method for preparing a single crystal silicon rod, for preparing the above-mentioned single crystal silicon rod, such as Figure 4 shown, including the following steps,

[0056] Square the single wafer rod to form a plurality of first straight wall parts and multiple edge parts: use a diamond wire to cut the single wafer rod formed by Czochralski single crystal, remove the edge skin of the single wafer rod, and form The polygonal cylinder has a plurality of first straight wall parts and edge parts, and the number of the first straight wall parts is selected according to actual needs, and no specific requirements are set here. When the number of the first straight wall parts is four, the single wafer bar is cut to form a square bar with a cuboid structure.

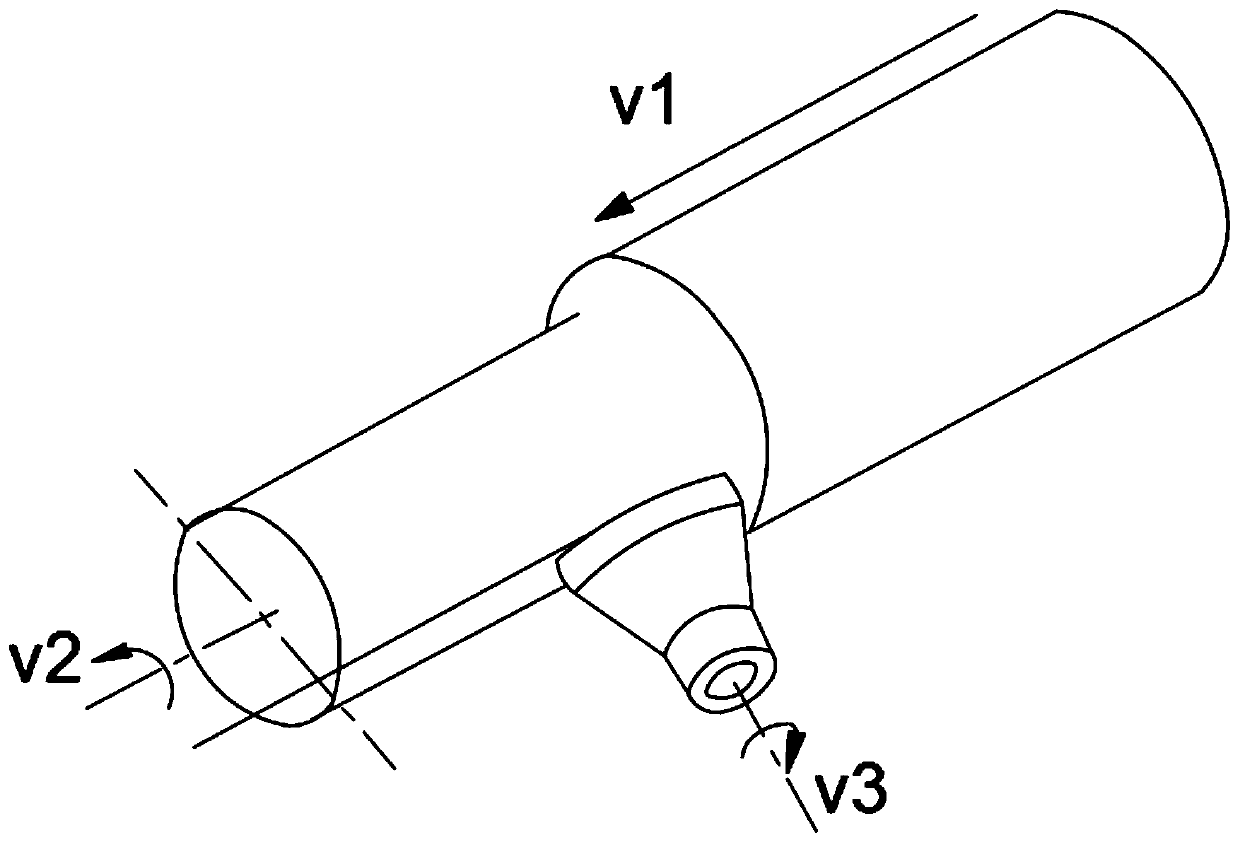

[0057] Chamfer the edges of the squared single-wafer rod. When chamfering the edges, use a grinding wheel to grind the edges, such as Figure 4 As shown in the figure, v1 is the feeding direction of the silicon r...

Embodiment 1

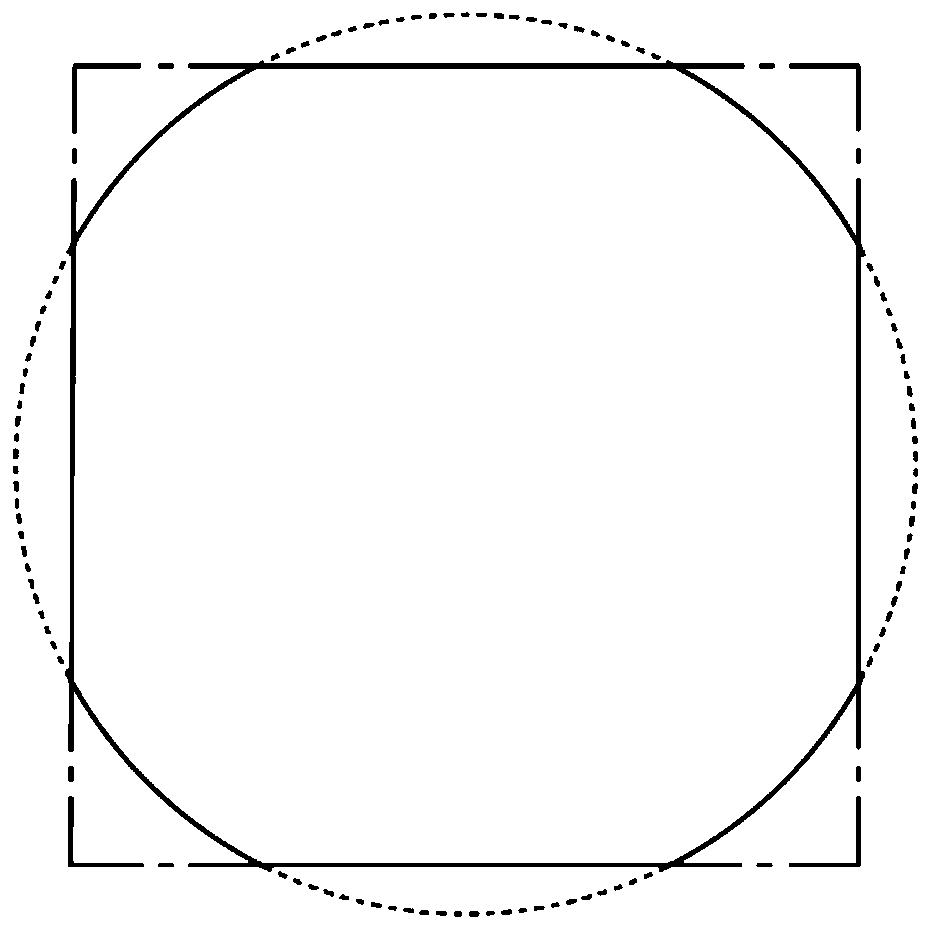

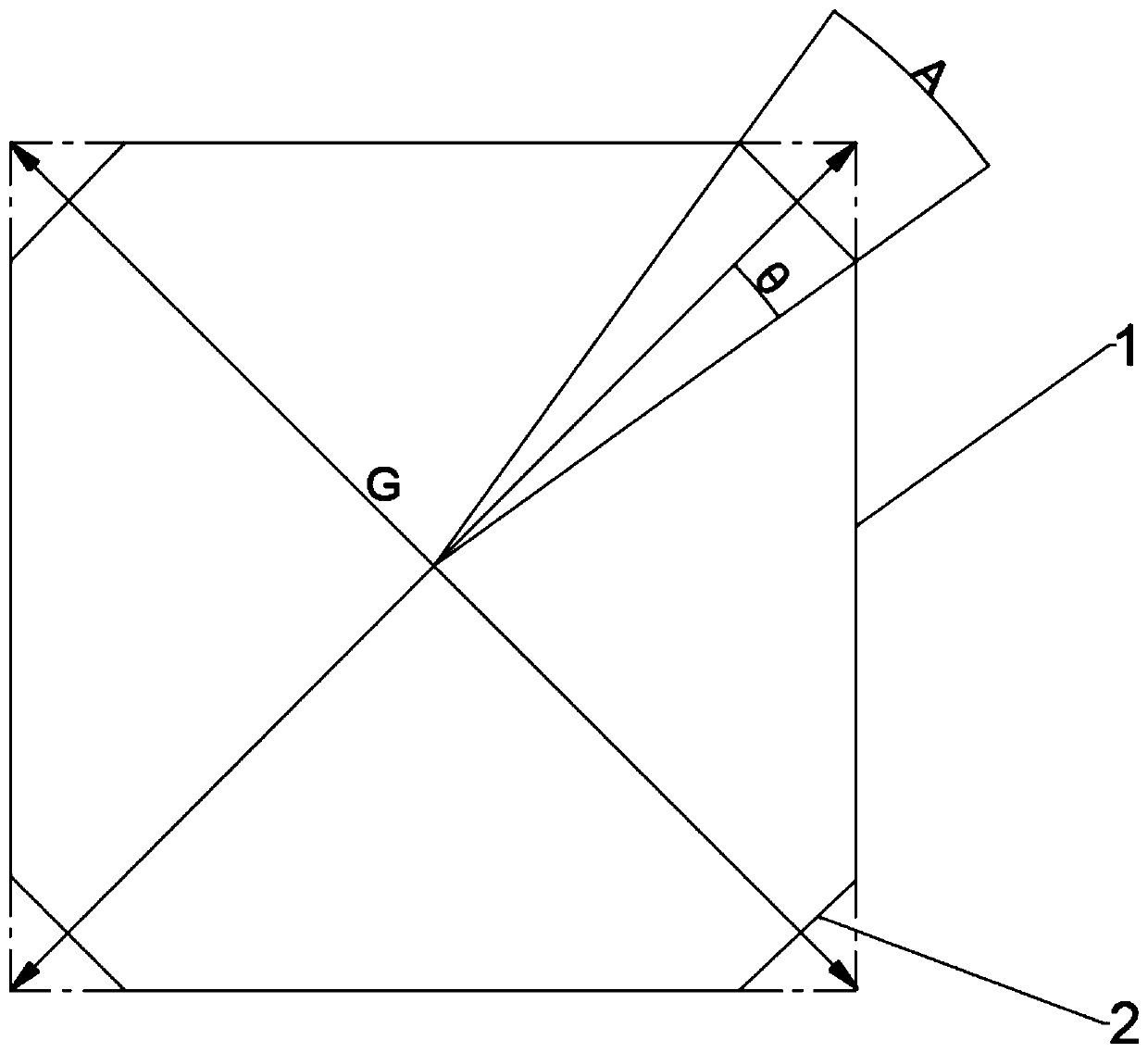

[0064] A single crystal silicon wafer, comprising a silicon wafer body, the silicon wafer body includes a plurality of straight wall parts 1 and a plurality of chamfered parts 2, the straight wall parts 1 and the chamfered parts 2 are connected end to end alternately in sequence, and the chamfered parts 2 are straight lines type, the length of the chamfered part 2 is 1.53mm, the end point of either end of the chamfered part 2 of the silicon wafer body and the center point of the silicon wafer body are connected to the line formed by the crystal direction of the silicon wafer body The angle of the included angle is 0.33 °, the angle of the central angle A corresponding to the center of the chamfering portion 2 and the silicon wafer body is 0.65 °, and the center line of the central angle A coincides with the diagonal line G of the silicon wafer body, then it is assumed that the Half of the central angle A is θ, and the crystal orientation in the thickness direction of the silic...

Embodiment 2

[0071] A single crystal silicon wafer, comprising a silicon wafer body, the silicon wafer body includes a plurality of straight wall parts 1 and a plurality of chamfered parts 2, the straight wall parts 1 and the chamfered parts 2 are connected end to end alternately in sequence, and the chamfered parts 2 are straight lines type, the length of the chamfered part 2 is 10mm, the end point of either end of the chamfered part 2 of the silicon wafer body is connected with the center point of the silicon wafer body, and the line formed by the connection between the crystal direction of the silicon wafer body The angle of the corner is 3.2 °, the angle of the central angle A corresponding to the center of the chamfering part 2 and the center of the silicon wafer body is 6.4 °, and the center line of the central angle A coincides with the diagonal line G of the silicon wafer body, then the center Half of the angle A is θ, and the crystal orientation in the thickness direction of the sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com