Patents

Literature

67results about How to "Good positioning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

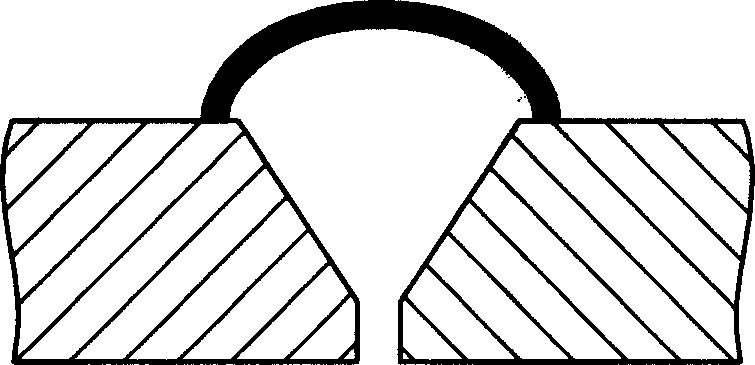

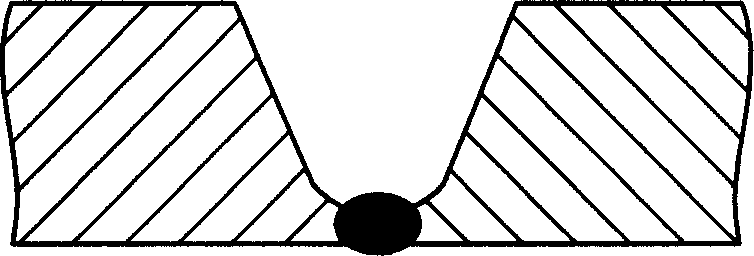

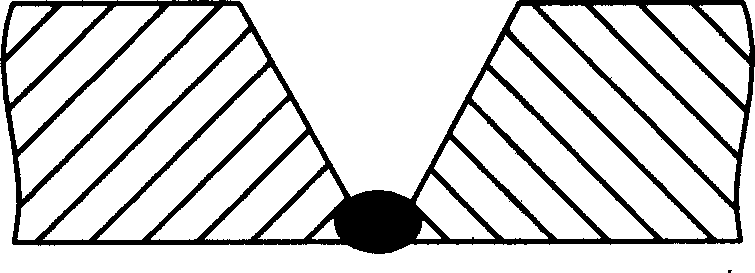

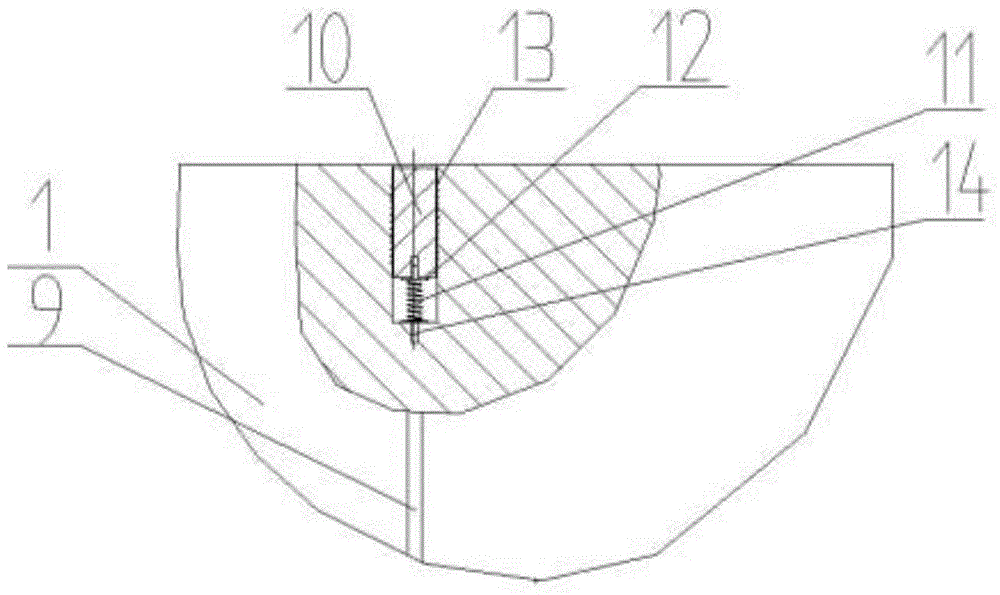

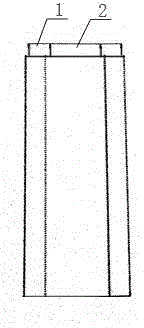

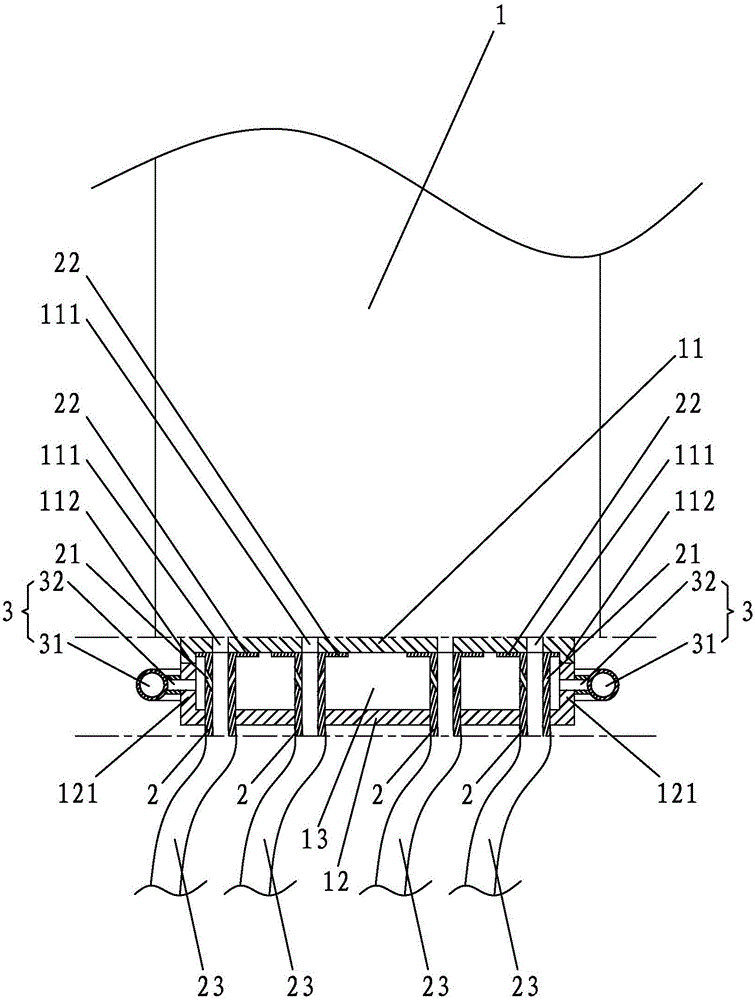

Assembly method of positioning chock for ensuring gap at root parts butt jointing tubes in use for welding

ActiveCN1695879AGood positioning effectEasy to fix and removeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringButt joint

Owner:渤海造船厂集团有限公司

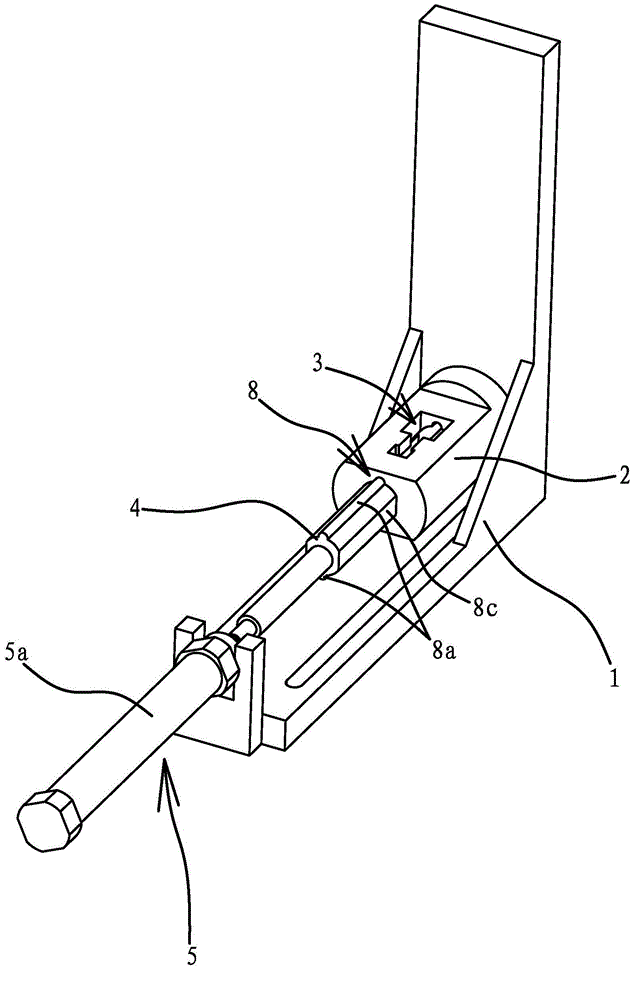

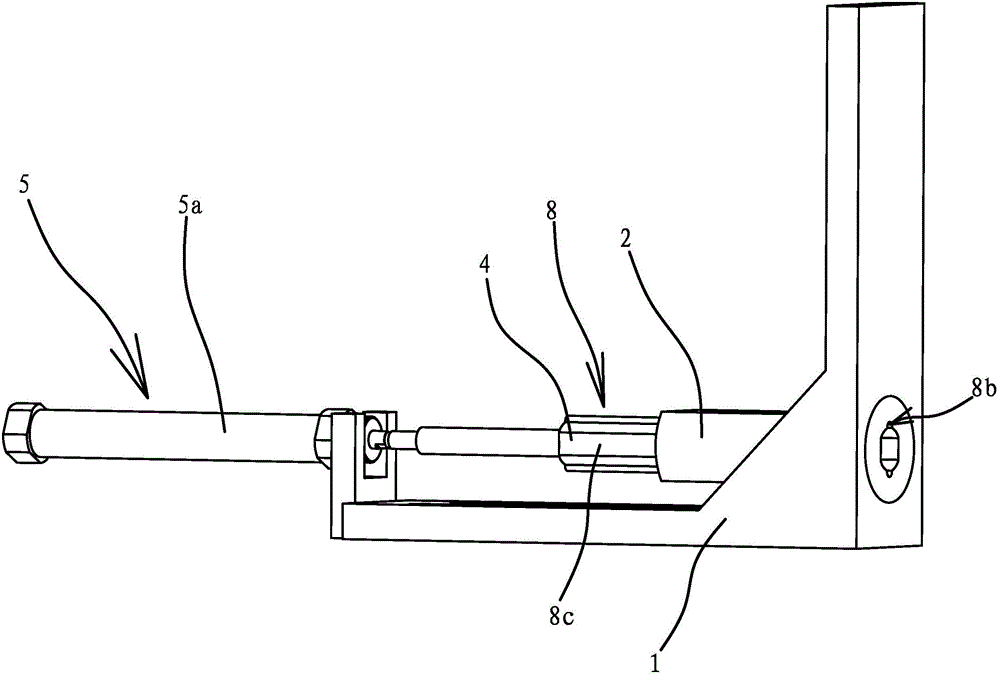

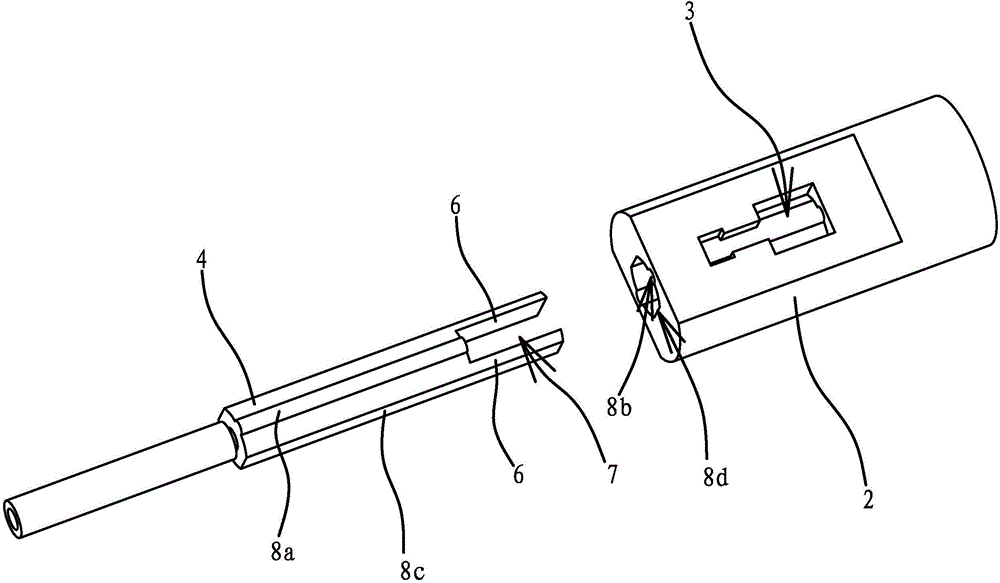

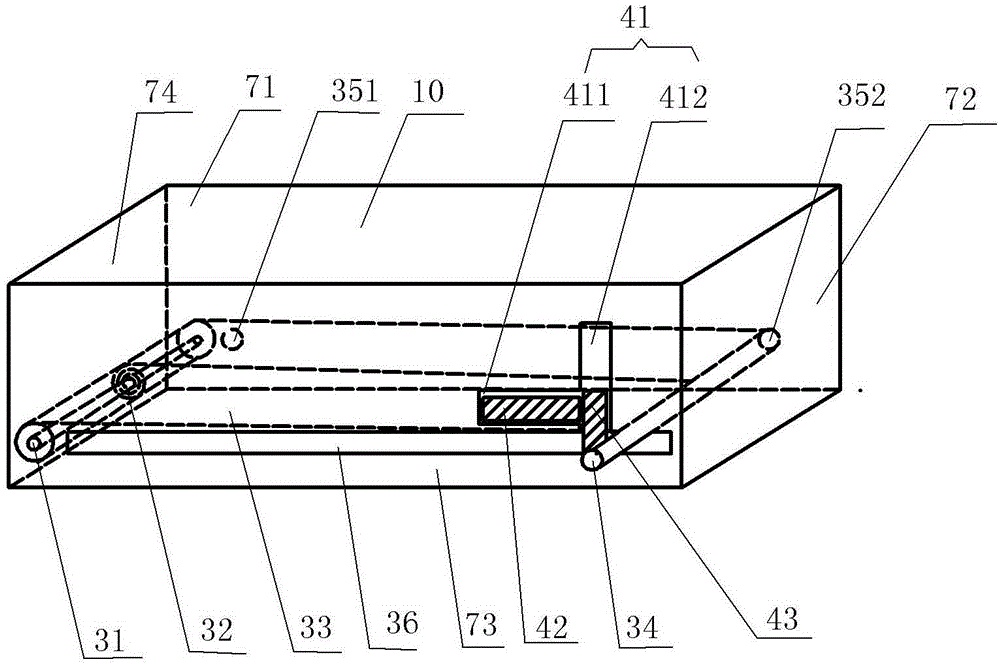

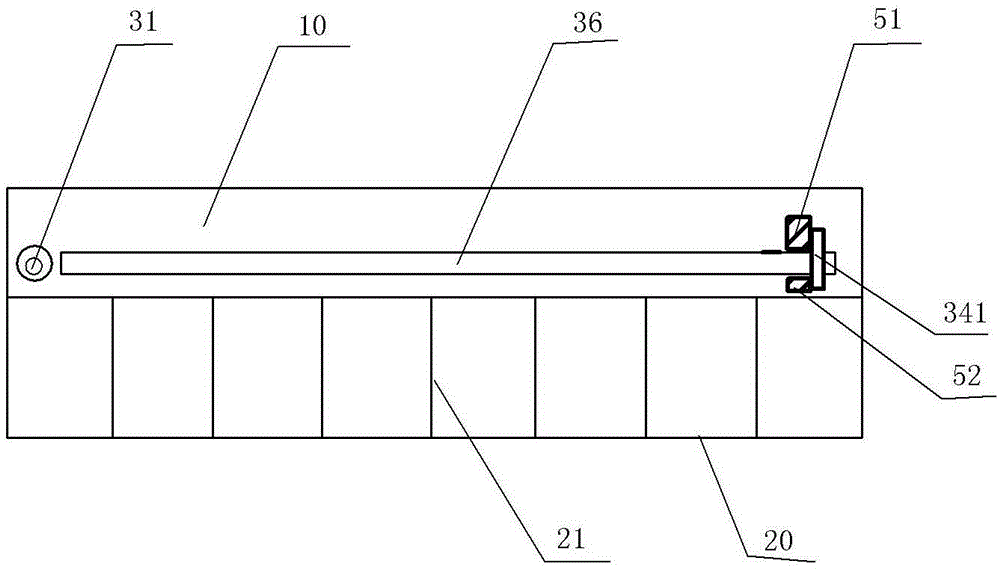

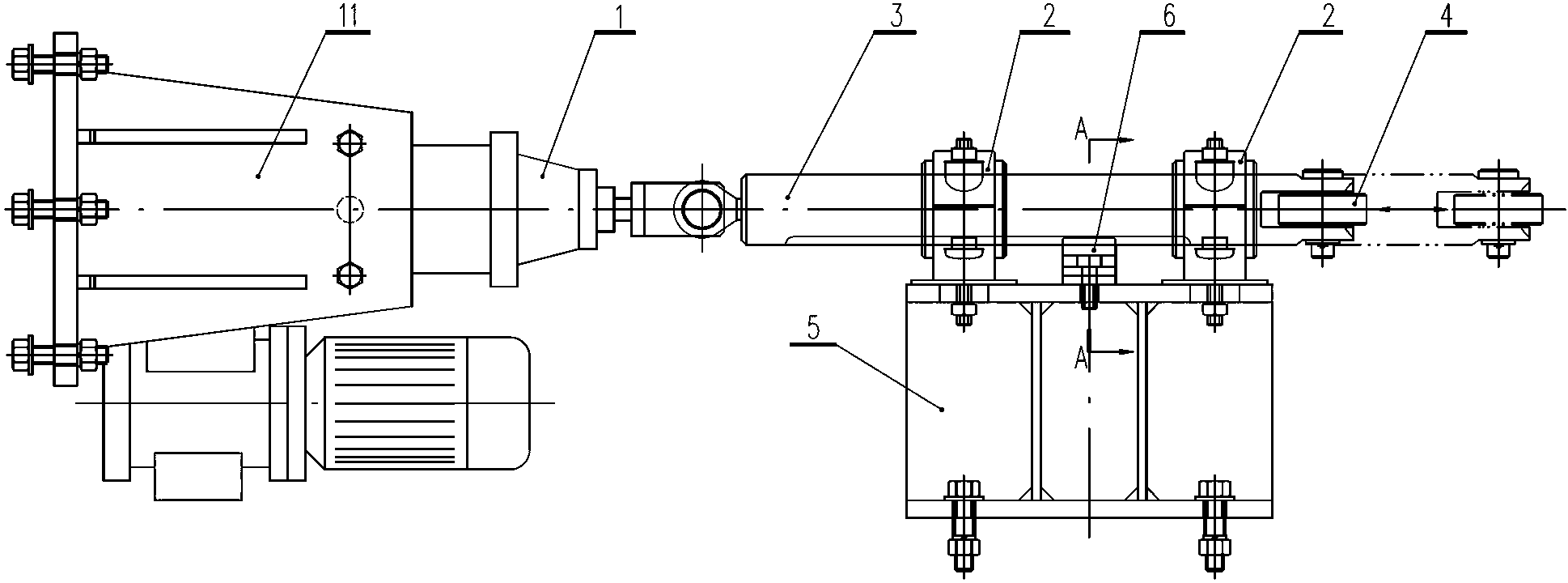

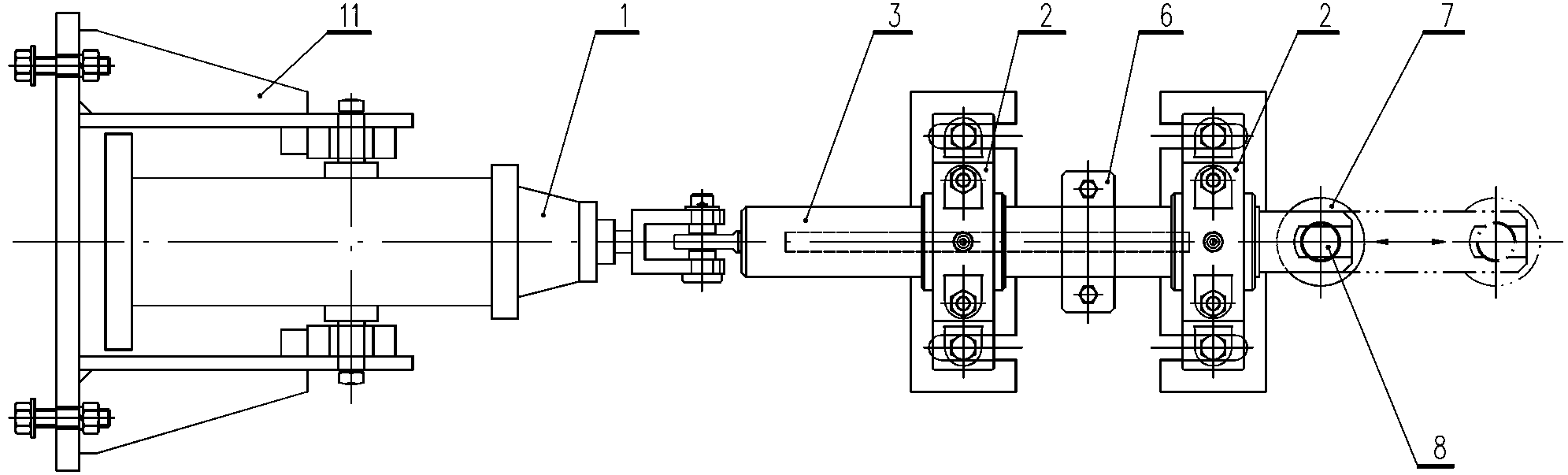

Pushing mechanism of feeding device

ActiveCN103978400AWork reliablyGood positioning effectMetal working apparatusGastric tube feedingFeeding tube

The invention provides a pushing mechanism of a feeding device, belongs to the technical field of machine components, and solves the problem of incapability of pushing smoothly of the existing feeding device. The pushing mechanism of the feeding device comprises a support and a feeding tube arranged on the support, wherein one side of the feeding tube is provided with a feed port I which is communicated with a cavity of the feeding tube; a pushing rod is arranged in the feeding tube; the support is further provided with a driving mechanism I capable of driving the pushing rod to do reciprocating movements; a pushing part which is protruded out of the end face of the pushing rod and is in a shape of a column is arranged on the inner end face of the pushing rod. The pushing mechanism of the feeding device has the advantages of reliable operation and smooth feeding of workpieces.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

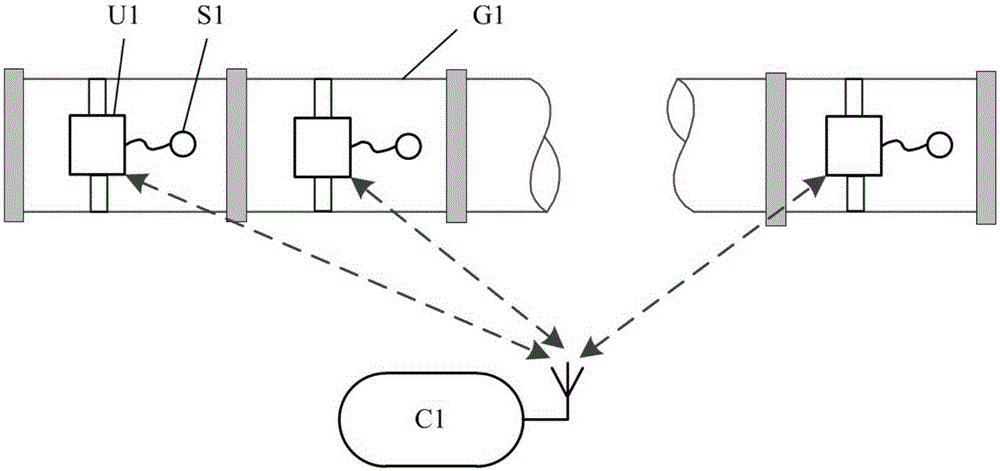

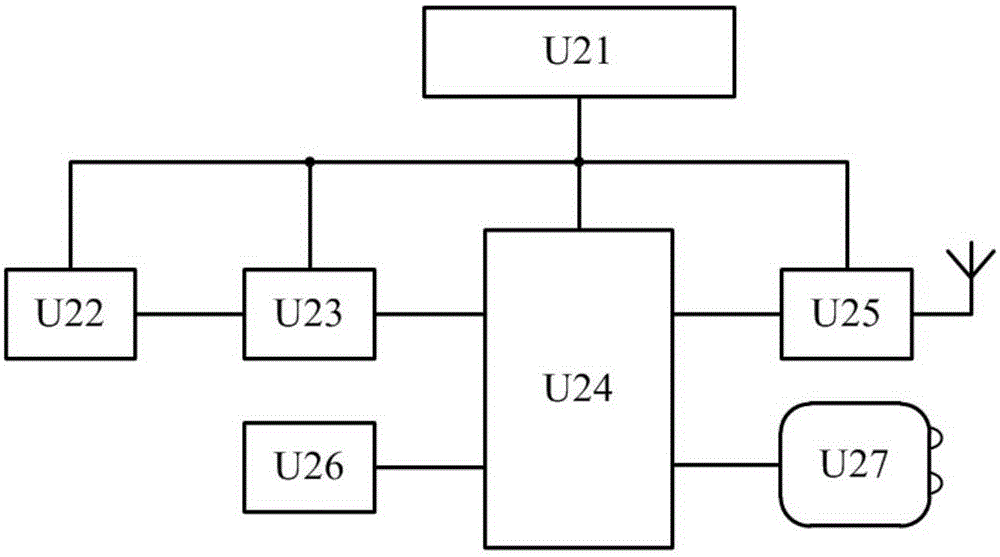

GIL/GIS discharge source detection and positioning apparatus and method

The invention discloses a GIL / GIS discharge source detection and positioning apparatus and a method. The apparatus and the method are used to detect and position a discharge fault of a GIL / GIS during a voltage withstanding test or operation. The apparatus comprises vibration sensors fixed to a GIL / GIS shell, detection terminals and an upper computer. The vibration sensors and the detection terminals are arranged in each air chamber of equipment to be detected. When the GIL / GIS generates discharge, each vibration sensor receives a discharge-excited vibration signal. Each detection terminal carries out amplification, filtering and acquisition processing on a discharge signal. The upper computer carries out synchronization on acquisition of each terminal through a wireless network and receives acquisition data so that accurate analysis and positioning to the discharge signal are realized.

Owner:CHINA XD ELECTRIC CO LTD

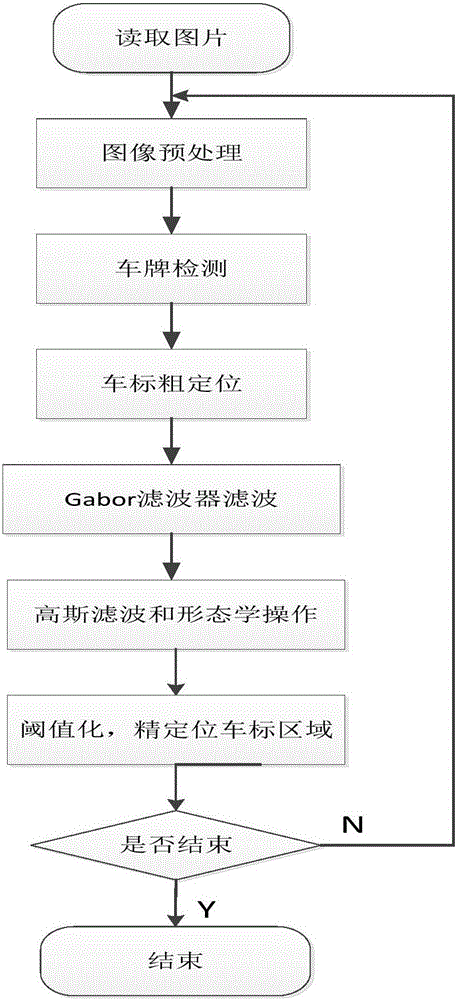

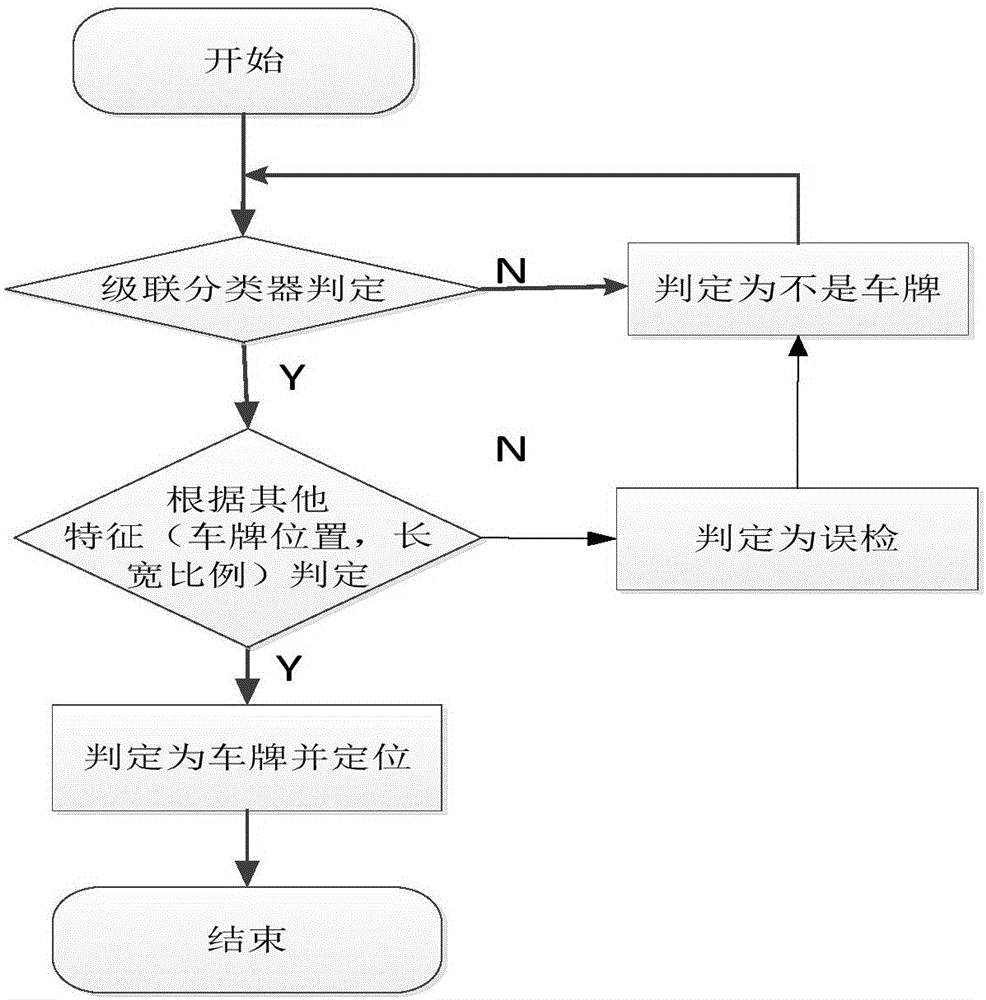

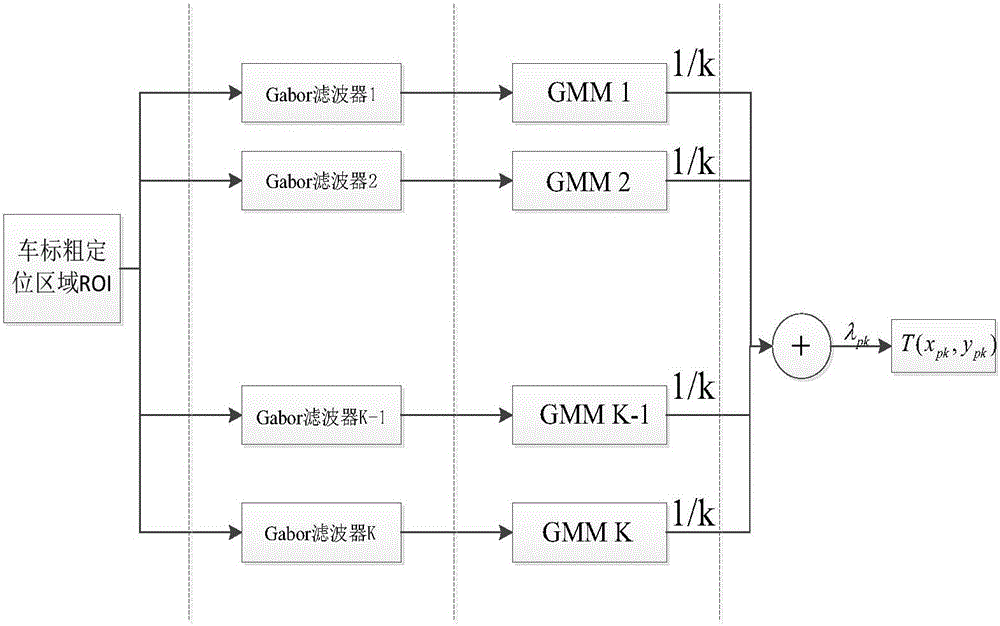

Gabor filter background texture inhibition-based car logo detection method

ActiveCN106778742AImprove detection accuracyGood positioning effectCharacter and pattern recognitionComputer visionOblique correction

The invention discloses a Gabor filter background texture inhibition-based car logo detection method. The method comprises the following steps of firstly, performing oblique correction preprocessing on an image; secondly, performing license plate detection in the preprocessed image to obtain a license plate region; thirdly, locating a license plate according to a position relationship between the license plate and a car logo based on priori knowledge, and obtaining a car logo rough locating region containing a car logo pattern; 4, performing Gabor filtering on the car logo rough locating region, inhibiting textures of a cooling net around the car logo, and highlighting a car logo region; 5, performing Gaussian filtering and mathematical morphological closing operation; and 6, selecting a threshold for thresholding a grayscale image, and framing and detecting a target region, thereby realizing car log fine locating. The car logo detection method is short in detection time and high in detection rate.

Owner:SOUTHEAST UNIV

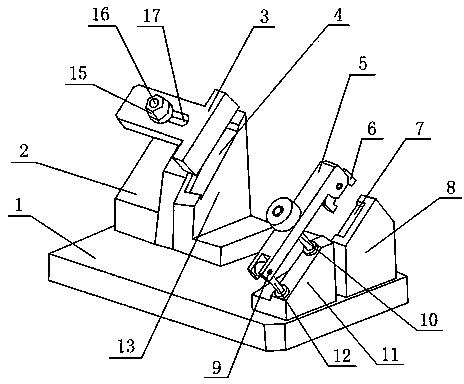

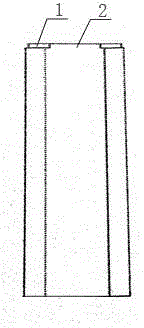

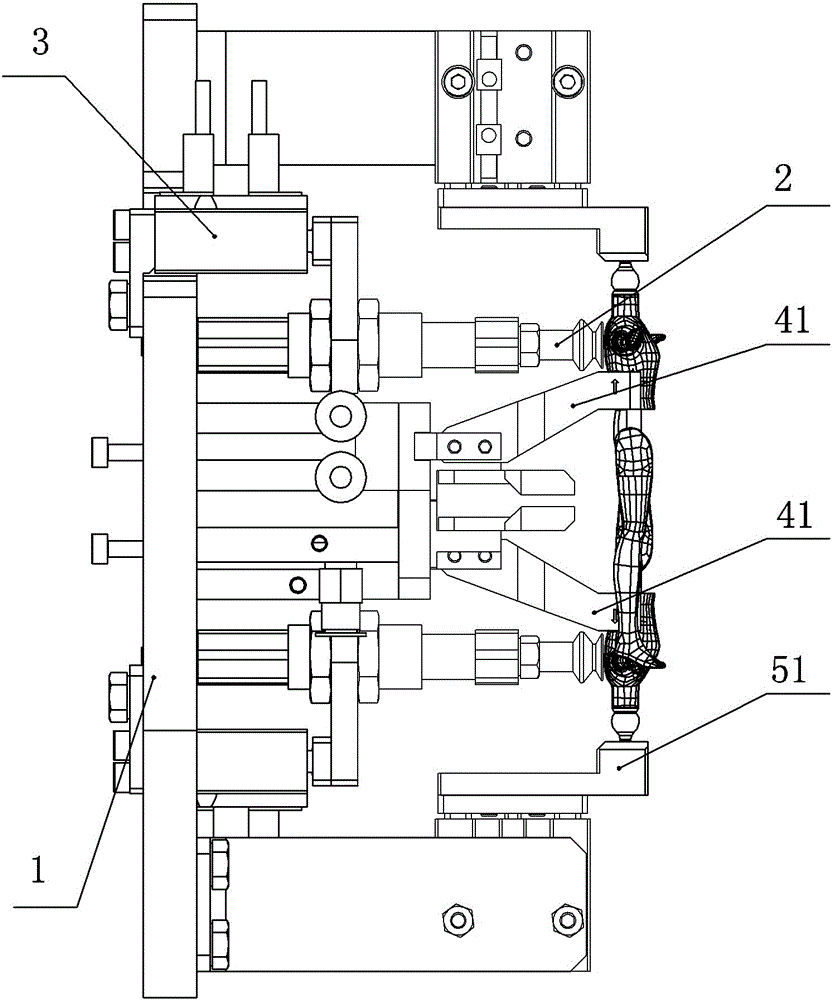

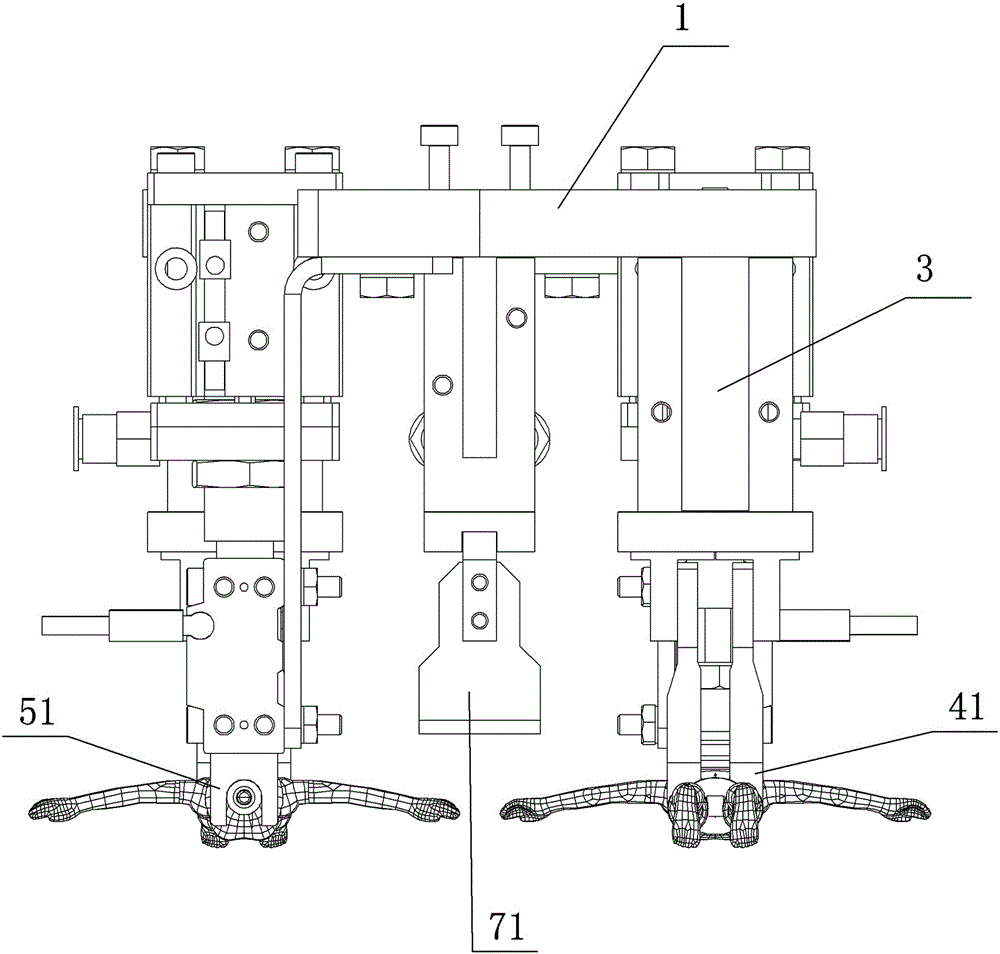

Device for positioning special-shaped components with specific structures

ActiveCN103659357AGood positioning effectPrecise positioningPositioning apparatusMetal-working holdersBiochemical engineering

Owner:SICHUAN SHENGONG TUNGSTEN STEEL CUTTING TOOLS

Inner bag and outer bag bonding mechanism of double-layer bag and bonding method thereof

ActiveCN110524957APrecise joint surfaceReduce pollutionBag making operationsPaper-makingEngineeringJoint surface

The invention discloses a double-layer bag inner bag and outer bag bonding mechanism and a bonding method thereof. The mechanism is provided with a base, the base is provided with a first sucker, a joint device, a second sucker and a positioning device with a third sucker, and the joint method is as follows: the inner bag is located in the outer bag and protrudes out of an opening of the outer bagto form a protruding part; the upper and lower suckers of the first sucker respectively suck the side surface of the outer bag and move in opposite directions, and the upper and lower suckers of thesecond sucker respectively suck the side surface of the protruding part and move in opposite directions; the third sucker enters the inner bag to suck the inner bag, the second sucker cancels adsorption, and the third sucker moves inwards until the opening of the inner bag is aligned with the opening of the outer bag; the outer bag and the inner bag are jointed with each other by the joint device;therefore, the inner bag and the outer bag can be automatically jointed, the joint surface is more accurate, and the situation of pollution caused by touch can be reduced.

Owner:陈坚承

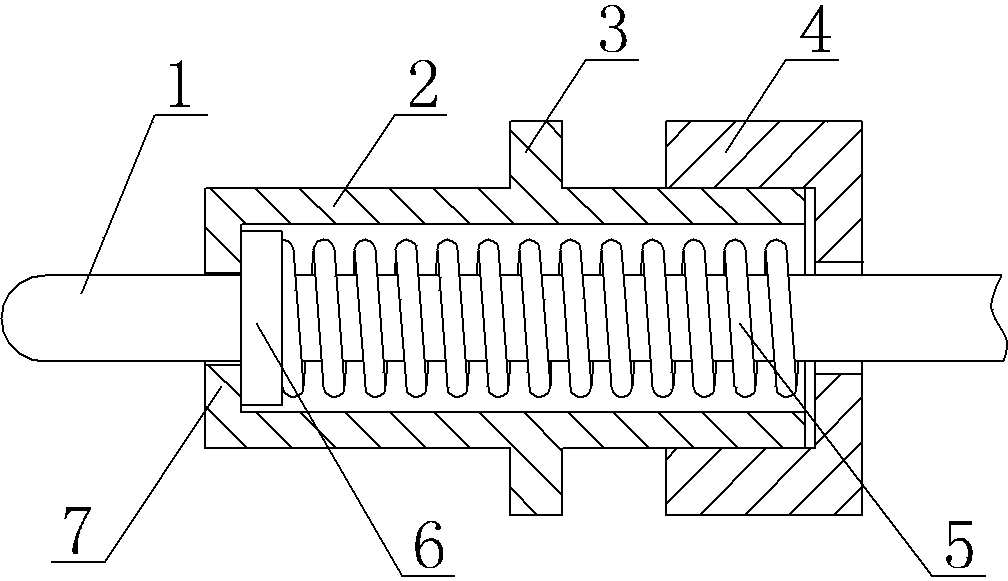

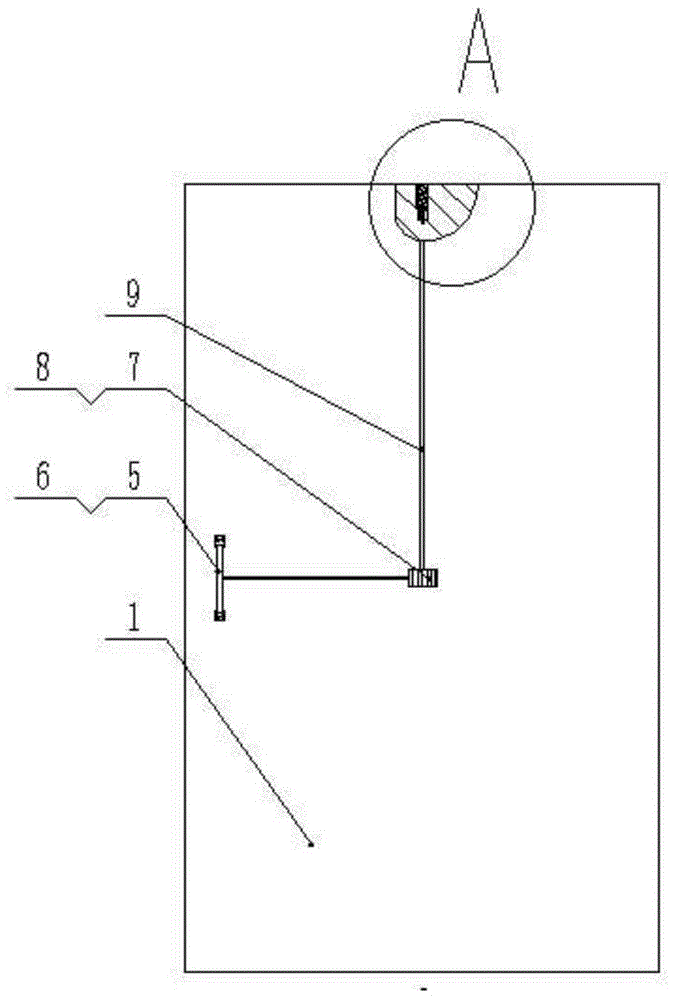

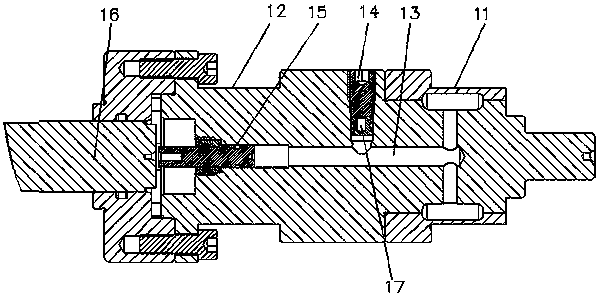

Elastic plug structure

The invention discloses an elastic plug structure. A flexible plug is inserted into a fixed sleeve body of the elastic plug structure; a blocking edge which is folded inwards is arranged on the inner end part of the fixed sleeve body; a shaft collar which is matched with the blocking edge in an ejecting pressing way is convexly arranged on the periphery of the flexible plug; a locknut is screwed on the rear end of the fixed sleeve body through threads; a flange which is matched with the rear end face of the fixed sleeve body in the ejecting pressing way is arranged on the rear end of the locknut; a reset spring is sleeved on the flexible plug; the front end of the reset spring is ejected and pressed on the shaft collar; and the rear end of the reset spring is ejected and pressed on the flange. The fixed sleeve body can be fixedly on one of two components which are in mutual slide match; a limit hole is formed in the other component; the flexible plug in the fixed sleeve can stretch into the limit hole so as to limit the two components; the flexible plug is longer and can stretch into the limit hole, so the positioning effect is good; the reset spring can provide force capable of keeping the flexible plug in a non-retractable state for the flexible plug; and the positioning of the elastic plug structure is reliable.

Owner:XJ SCHINDLER XUCHANG ELEVATOR

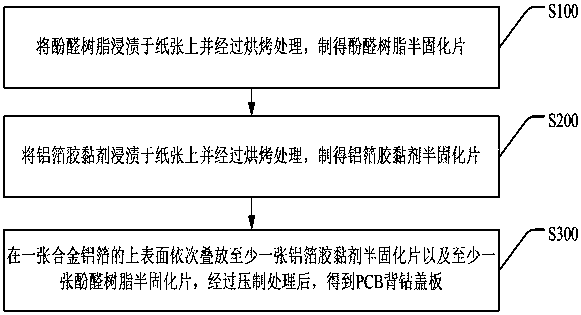

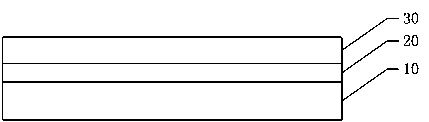

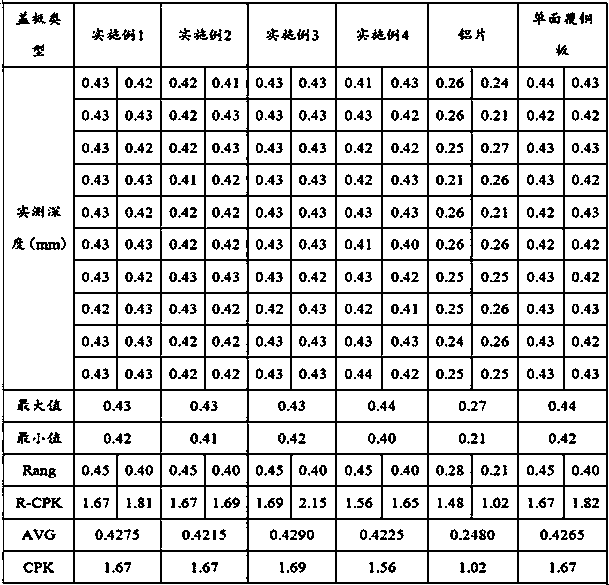

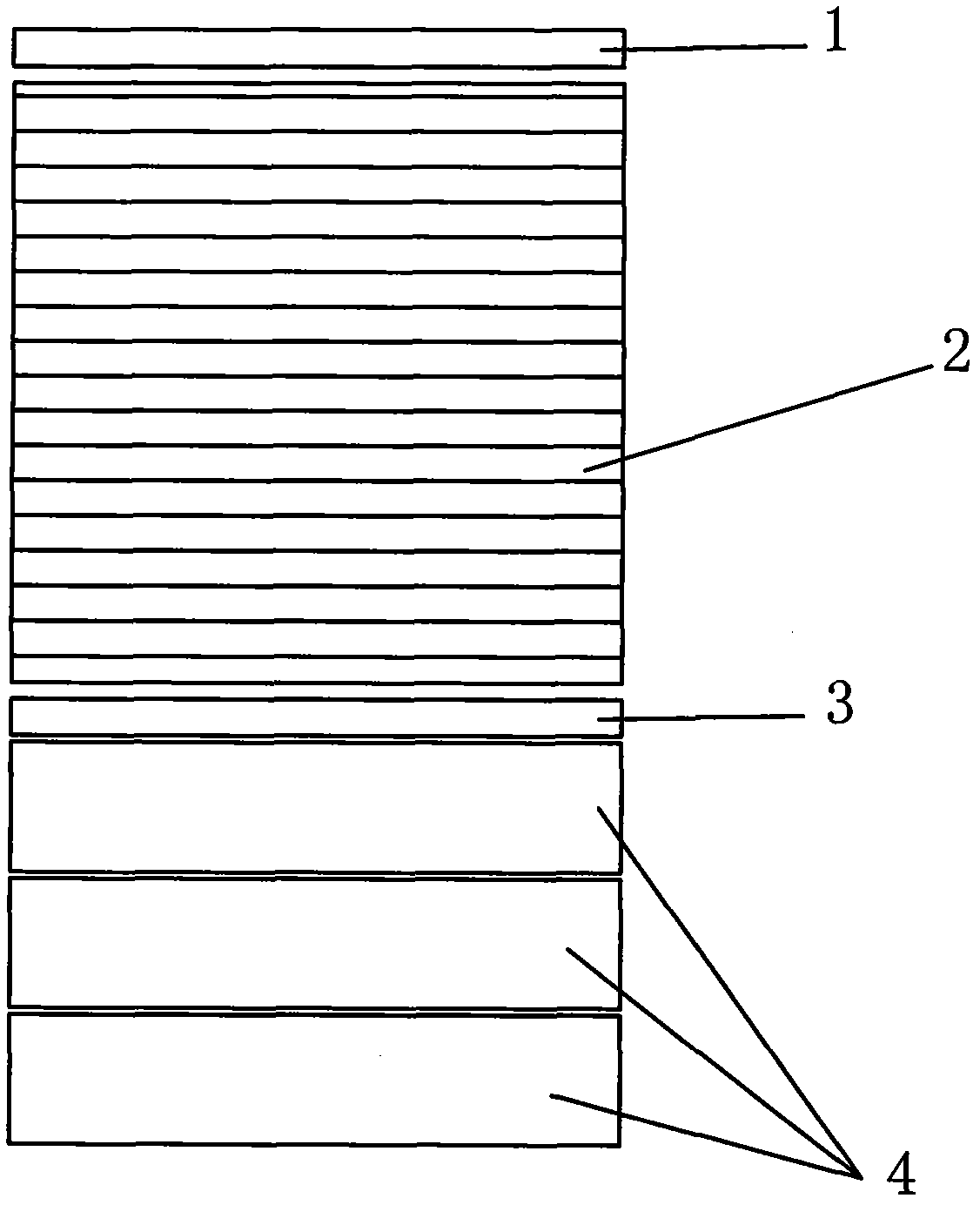

PCB back-drilling cover plate and preparation method thereof

ActiveCN107718840AEasy to drillGood positioning effectLayered product treatmentLaminationDrill holeAdhesive

The invention discloses a PCB back-drilling cover plate and a preparation method thereof. The cover plate is a single-sided aluminum-laminated foil phenolic aldehyde cover plate formed by compoundingphenolic resin, an aluminum foil adhesive, paper and alloy aluminum foil. An insulating medium layer formed by the phenolic resin, the aluminum foil adhesive and the paper is utilized for replacing ahigh-cost epoxy resin glass fiber composite insulating medium layer, and the prepared cover plate has the effects that the drilling is easy, the positioning effect is good, the abrasion of a drillingneedle is reduced; and the alloy aluminum foil is utilized for replacing a high-cost aluminum foil, so that the cost is substantially lowered, and the prepared cover plate has the characteristics thata metal conductive layer is thin, the thickness tolerance is small, the adhesion with a PCB is good, and the control depth precision of a drill hole is high. According to the PCB back-drilling coverplate, the problems of an aluminum piece that the positioning effect and the drilling precision are poor, adhesion with the PCB is poor and the control depth precision of a drill hole is poor are solved, and the problem that a single-sided copper-laminated plate is high in cost is solved, and the appearance problems of appearance corrugation and water stain in the production of single-sided aluminum-laminated foils similar to the single-sided aluminum-laminated foil phenolic aldehyde cover plate as well as and scratching in a baking process are solved.

Owner:烟台柳鑫新材料科技有限公司

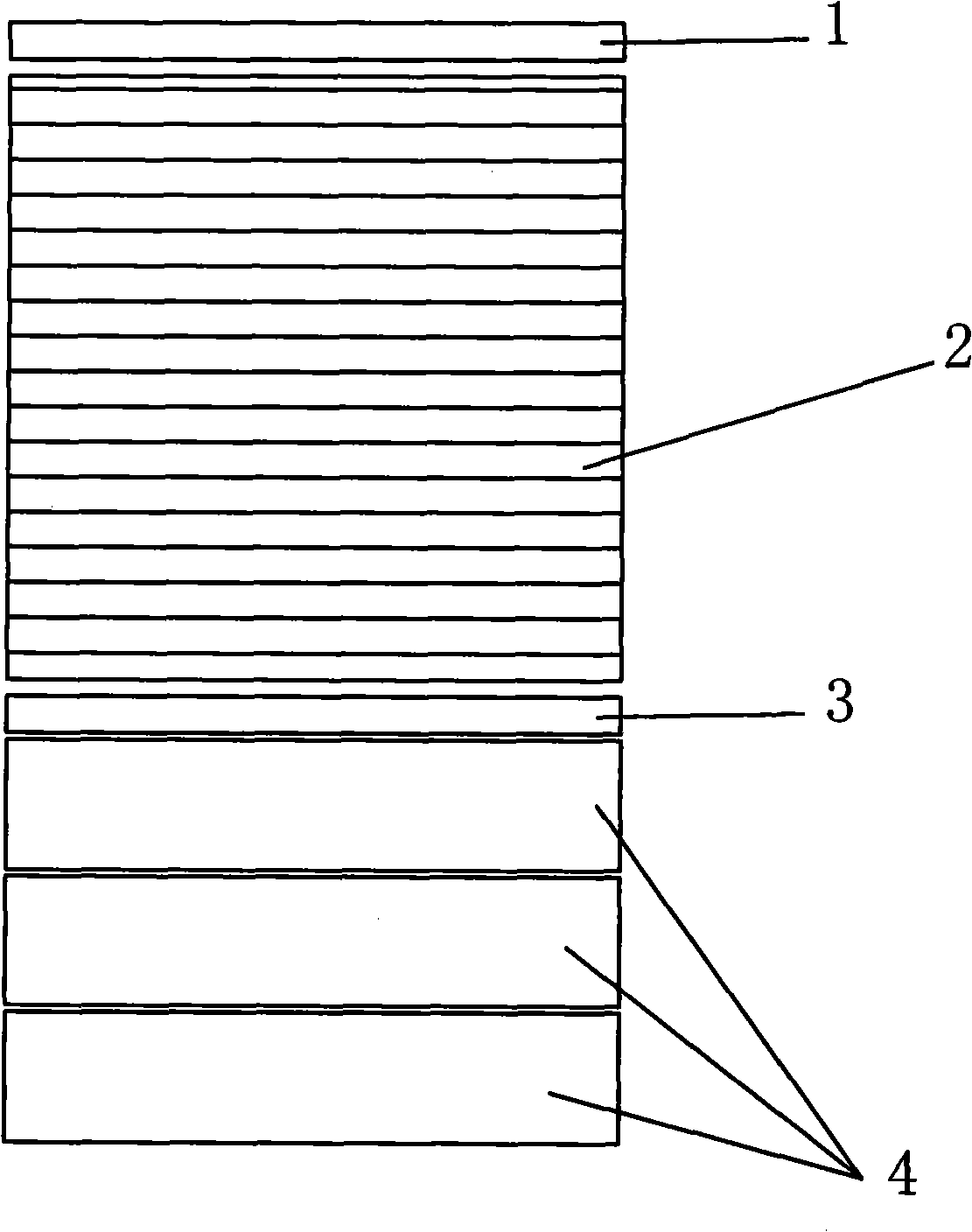

Production process method of infrared cut-off filters

InactiveCN101957468AGood positioning effectPrecise positioningOptical filtersGlass severing apparatusAdhesiveEngineering

The invention discloses a production process method of infrared cut-off filters, which is characterized by comprising the following steps of: (1) coating glass sheets; (2) drying the coated glass sheets; (3) sticking multiple layers of glass sheets together; (4) cutting the multiple layers of glass sheets stuck together; (5) rounding the multiple layers of glass sheets; (6) soaking the coated glass sheets in glue; (7) cleaning the coated glass sheets; and (8) packaging cut lenses on injection molding plate. In the production process method of the infrared cut-off filters, multiple layers of the coated glass sheets are stuck together by using yellow wax and other adhesives, so that lenses have good locating effect in the cutting process, multiple lenses can be cut at one time, and the automatic production of the lenses becomes possible.

Owner:苏州五方光电科技有限公司

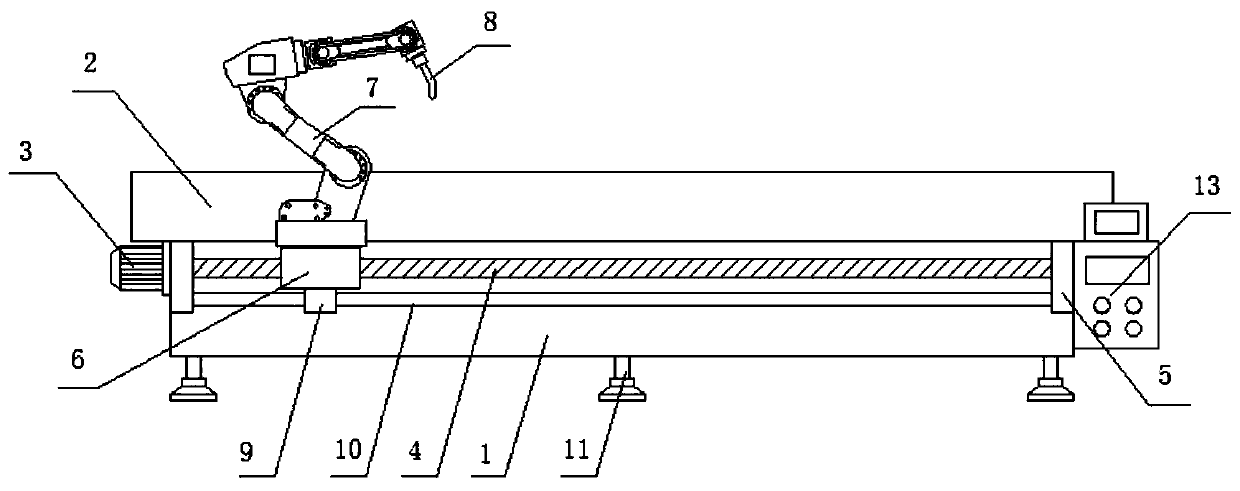

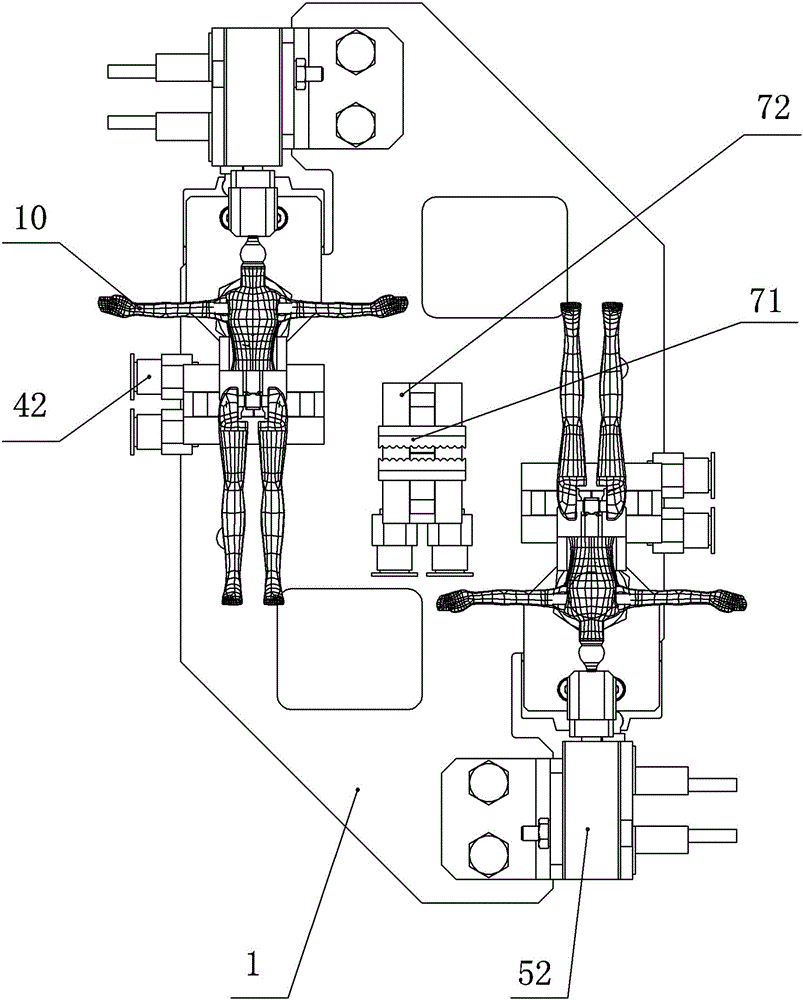

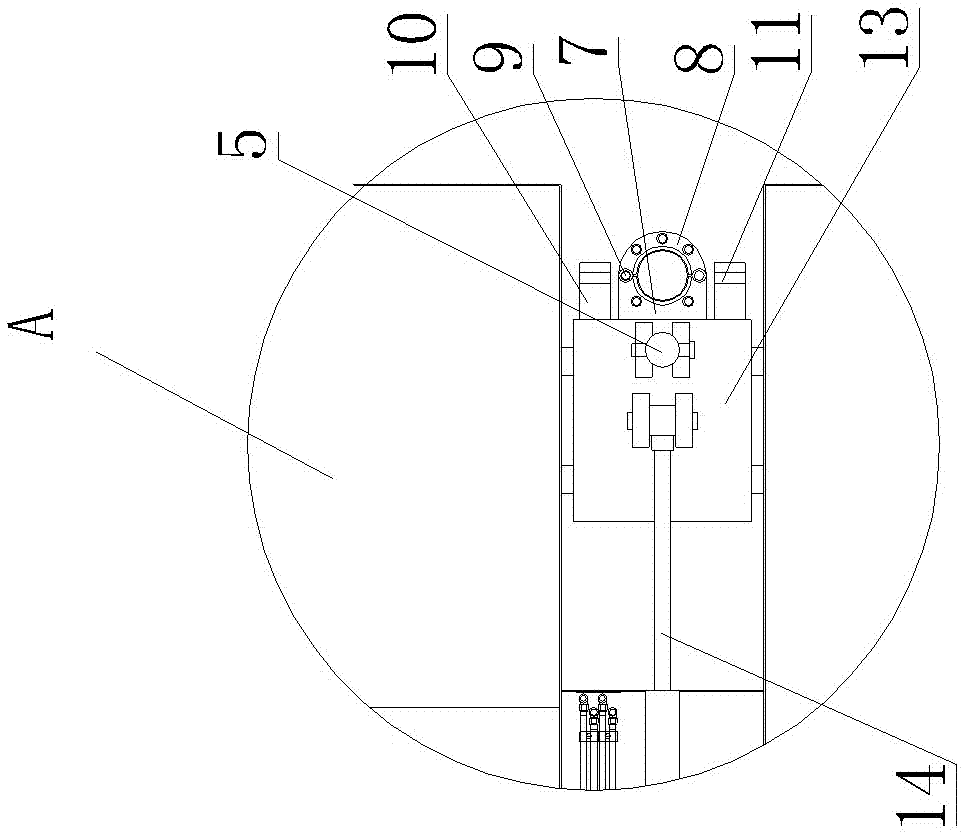

Robot welding production line

InactiveCN110369917AGood positioning effectImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeIndustrial engineering

The invention discloses a robot welding production line. The robot welding production line comprises a machine frame; a steel tube welding table is arranged on the upper side of the machine frame; a first clamping groove, a second clamping groove and a third clamping groove are formed in the upper side of the steel tube welding table; a screw rod is arranged on one side of the machine frame and isconnected to a sliding base in a threaded mode; a welding robot is arranged on the upper side of the sliding base through a rotating base; an electric welding head is arranged at one end of the welding robot; a PLC control cabinet is arranged at one end of the machine frame; and the input end of the welding robot is electrically connected to the output end of the PLC control cabinet. According tothe robot welding production line, through the first clamping groove, the second clamping groove and the third clamping groove, the steel tube can be clamped and placed, welding treatment can be carried out on the steel tube through the welding robot, the positioning effect on the steel tube is good, and therefore the welding efficiency can be improved.

Owner:中山博思德自动化设备有限公司

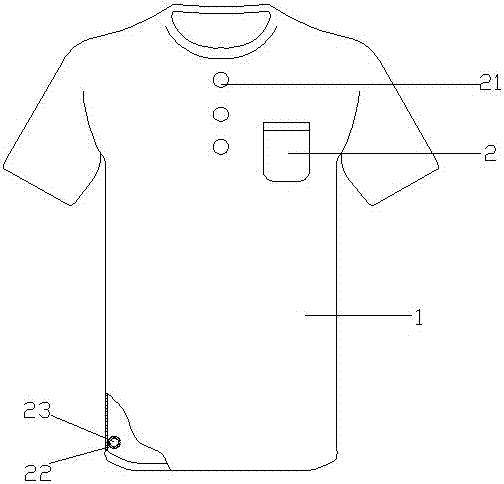

Children clothes with positioning function

The invention relates to the technical field of clothes, and discloses children clothes with a positioning function. The children clothes comprise a clothes body, a coat pocket is arranged on the front side of the clothes body, a water-proof cover is arranged on the portion, in the coat pocket, on the outer side of the clothes body, and a positioner is arranged in the water-proof cover; the positioner comprises a shell, a chip positioning cavity and a cell positioning cavity are formed in the shell, a GPS chip is arranged in the chip positioning cavity, a button cell for supplying power to the GPS chip is arranged in the cell positioning cavity, and a concave-convex button zipper is arranged at the opening end of the water-proof cover. When a child wears the clothes, an APP corresponding to the GPS chip is installed in a mobile phone of a parent, the specific position information of the child can be obtained in real time through the APP, and when the child is out of touch, the parent can quickly find the child through the positioning of the APP to the GPS chip; the water-proof cover has a water-proof protection effect on the positioner, and rainwater, perspiration and the like are prevented from entering the positioner.

Owner:湖州创库文化创意有限公司

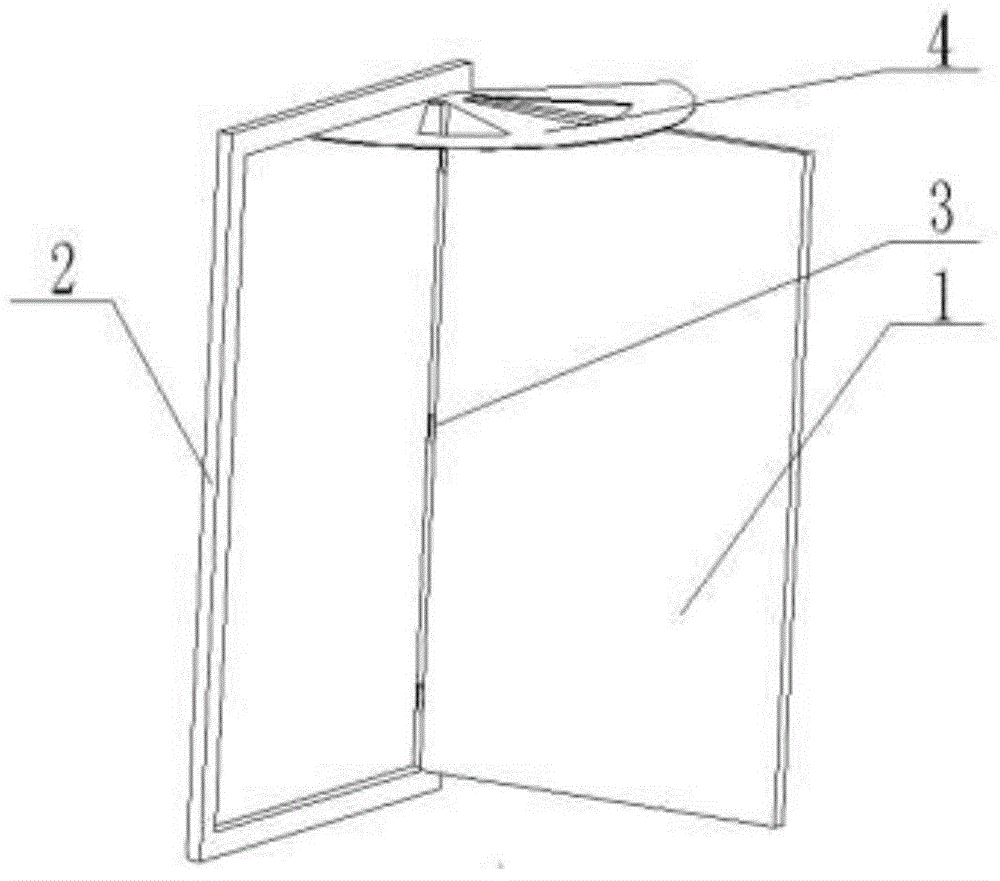

Electromagnetic positioning door

The invention relates to an electromagnetic positioning door which is characterized by comprising a door panel, a door frame, hinges, a fan-shaped positioning plate, a handle, a switch, a battery case, a battery, a wire, an iron core, a spring, a fixed spring piece, a conductive winding and a screw, wherein the iron core is wound with the conductive winding, the conductive winding, the switch and the battery are connected in series, and on-off of a current circuit is controlled by the switch mounted on the handle, so that a magnetic field generated in the middle of the conductive winding is controlled, and the door can be positioned at the preset opening angle. The problem that a conventional positioning door only has two positioning modes of completely opening and completely closing is solved, and various problems of the conventional positioning door are solved. The electromagnetic positioning door has the advantages of good positioning effect, small space occupation, wide application range, green and environment-friendly property and the like; the design mode for the conventional positioning door is changed, the conventional positioning door can be updated, and updating of the positioning door is promoted.

Owner:JIANGSU UNIV

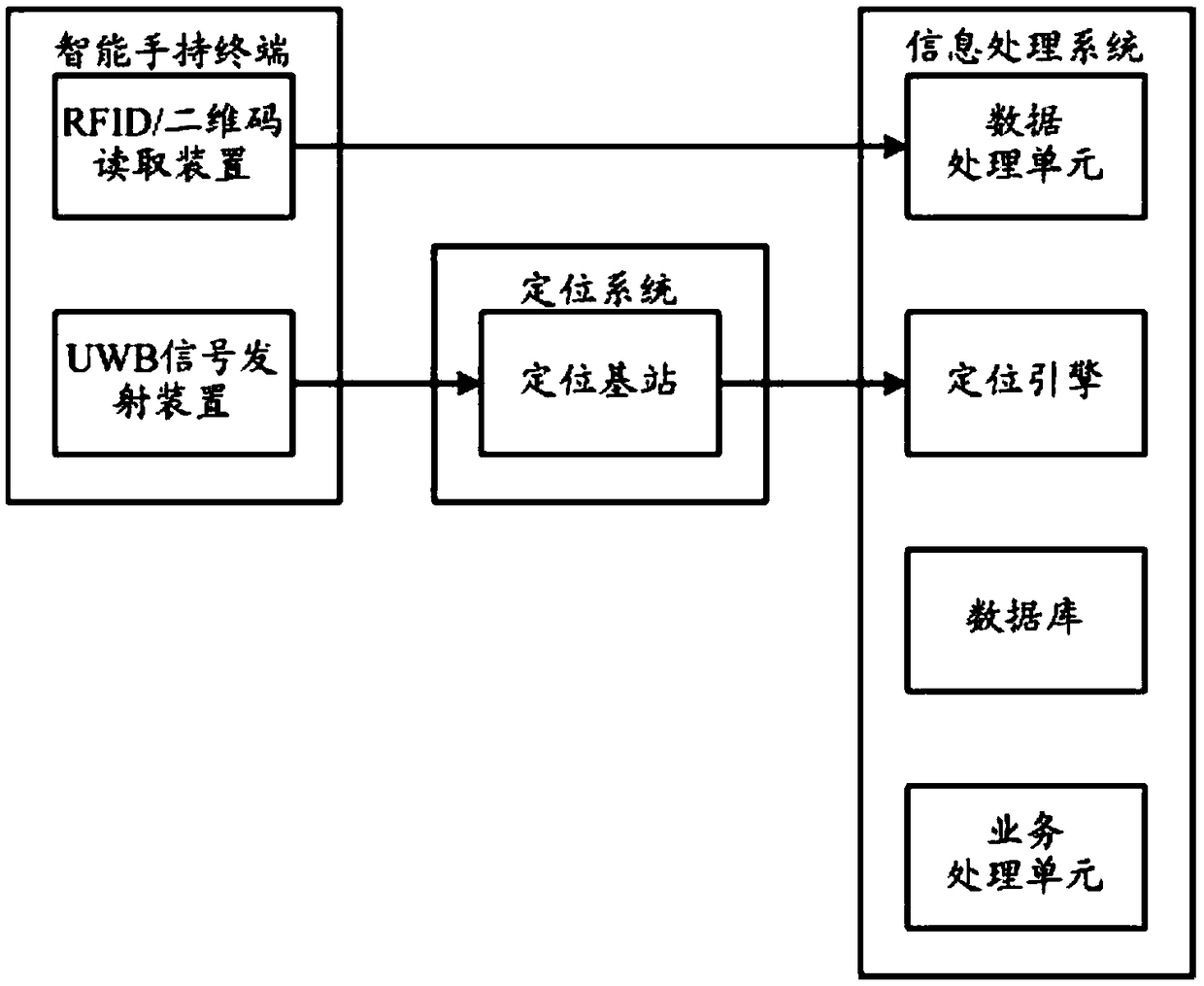

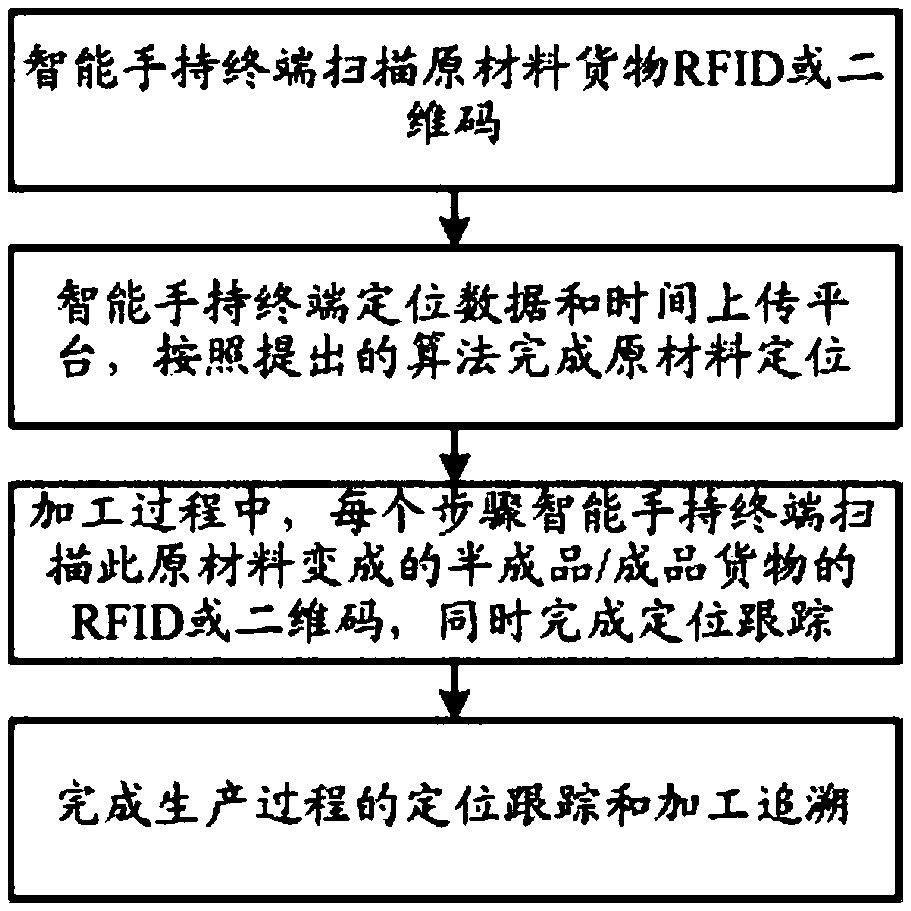

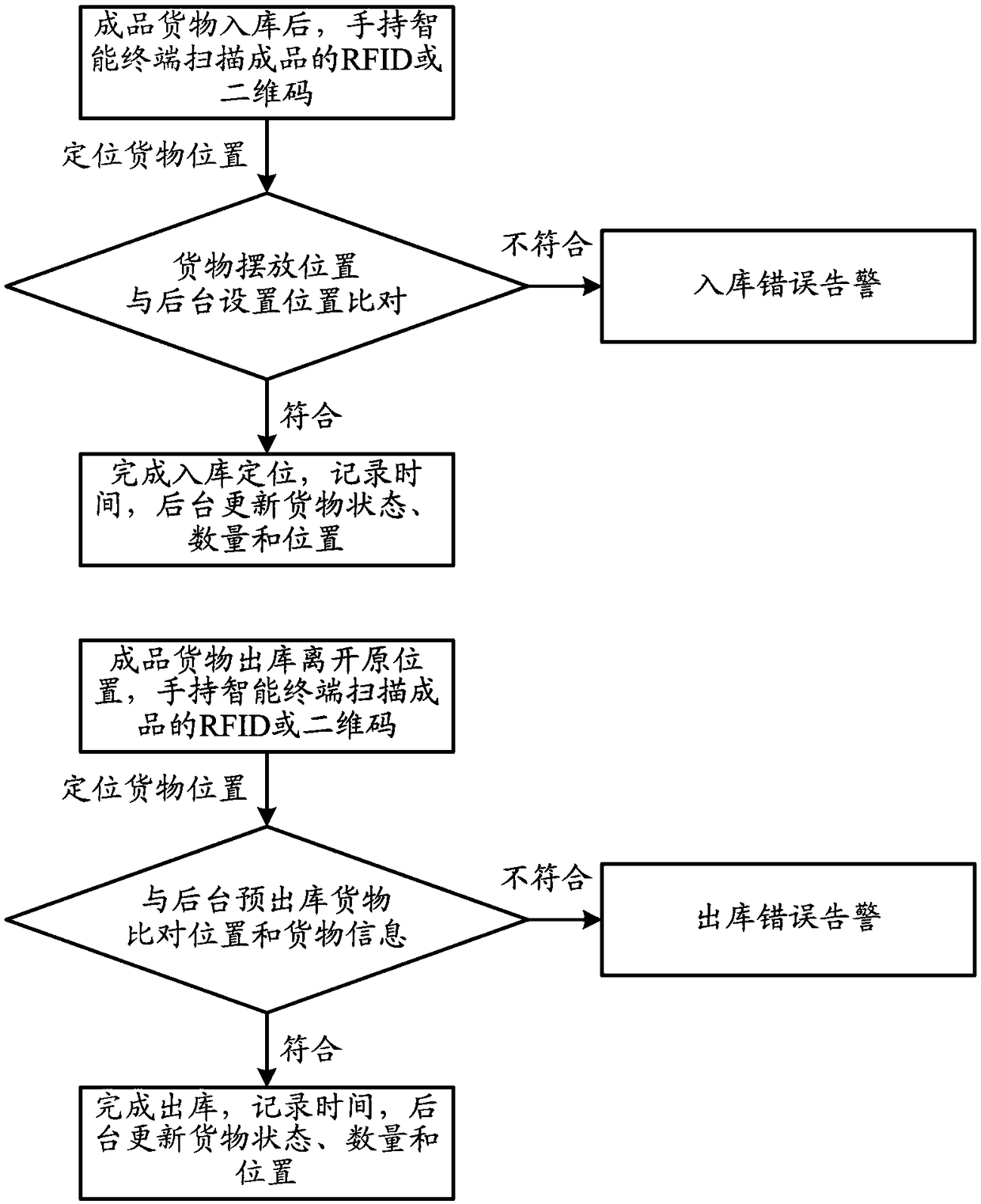

Intelligent Manufacturing Goods Location Tracking and Tracing Management System Based on UWB Technology

PendingCN109389343AReduce inefficiencies and errorsGood positioning effectLogisticsManagement systemEngineering

The invention relates to an intelligent manufacturing goods positioning tracking and tracing management system based on UWB technology, comprises a handheld terminal, a positioning system and an information processing system. The handheld terminal comprises an identification reading device and a UWB signal transmitting device. The identification reading device is used for reading the identification affixed on the goods to obtain the goods information and sending the goods information to the information processing system. The UWB signal transmitting device is used for transmitting a UWB signalto a positioning base station in the positioning system. The information processing system analyzes the UWB signal received by the positioning base station, obtains the position information of the handheld terminal, obtains the cargo position according to the positioning compensation mode, and maps and binds the cargo position and the cargo information. The invention can intelligently manage the goods in the production process and the warehouse and improve the efficiency.

Owner:SHANGHAI INTERNET OF THINGS +1

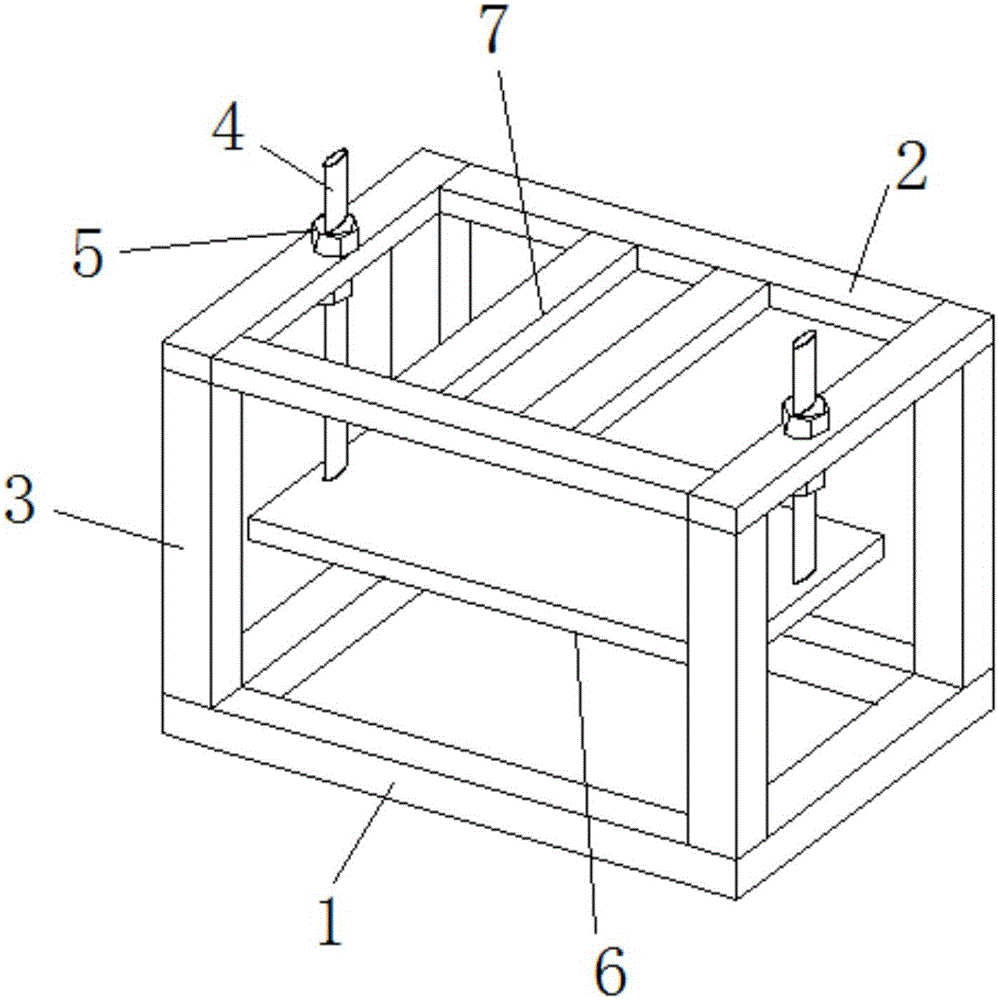

Storage battery installation mechanism

InactiveCN106058107ASimple structureGood positioning effectCell component detailsEngineeringPosition effect

The invention discloses a storage battery installation mechanism, which comprises a bottom frame, a top frame, vertical rods, screws, nuts, a storage battery supporting plate and positioning plates. The bottom frame and the top frame are arranged in parallel; the vertical rods are in vertical connection between the bottom frame and the top frame; the two screws are vertically inserted in right and left ends of the top frame, respectively and the bottom of the screws are in fixed connection with the storage battery supporting plate; the nuts are in threaded connection to the screw rods; and the positioning plates are in fixed connection with the top frame. The storage battery installation mechanism is convenient for disassembly and assembly of a storage battery, simple in structure and good in positioning effect and heat-dissipation effect.

Owner:NANJING JINLONG NEW ENERGY AUTOMOBILE RES INST

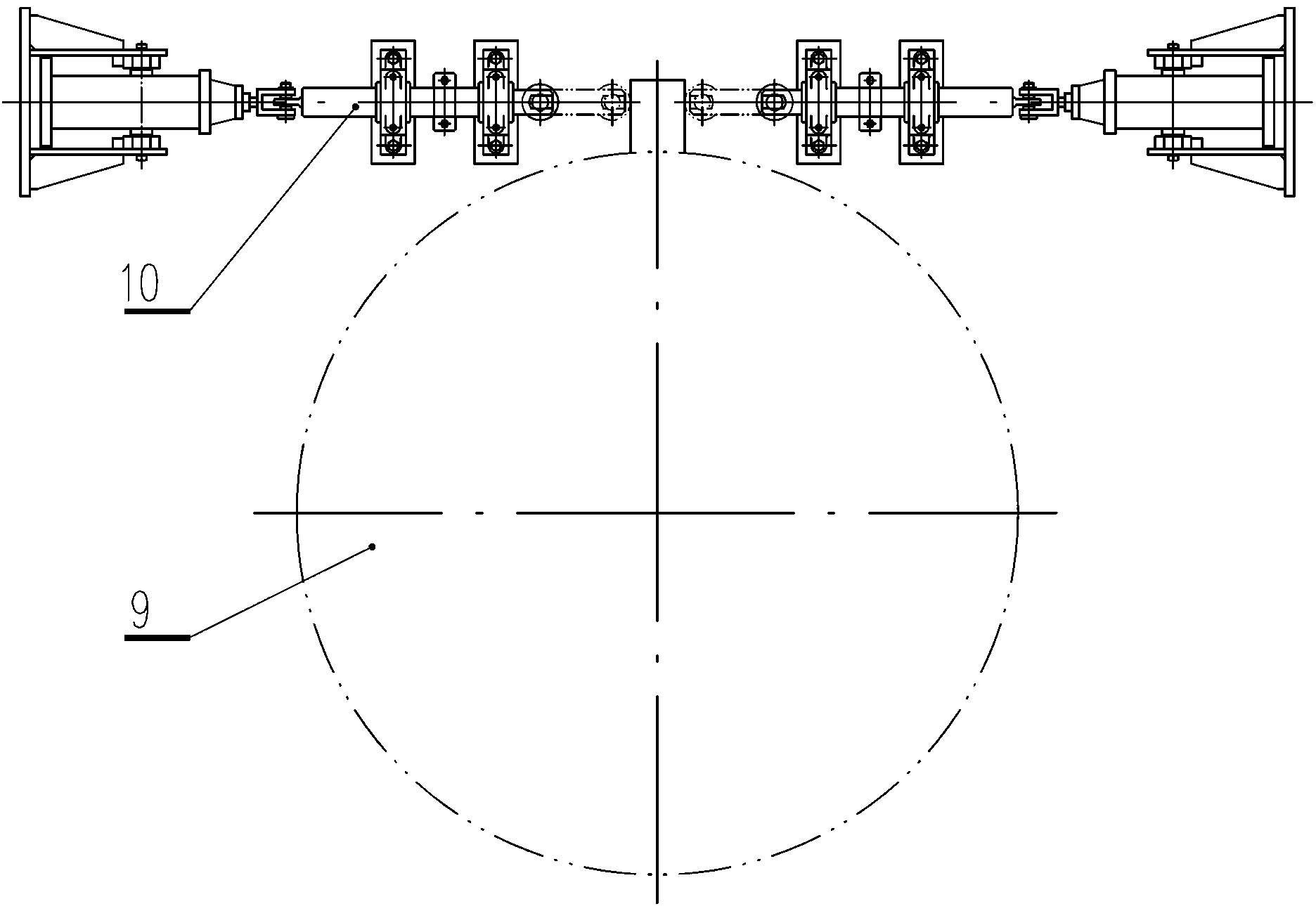

Welding jig for covering roller assembly connection block of hydraulic torque converter and process thereof

InactiveCN104308438AGood positioning effectStable and controllable position accuracyWelding/cutting auxillary devicesAuxillary welding devicesBatch productionEngineering

The invention aims to provide a process for welding a covering roller assembly of a hydraulic torque converter. The process is characterized in that the process can implement an upward welding and / or turning machining face and is favorable for machining and batch production, a connection block, a centering block and the covering roller assembly can be finished after being welded, and the problem of size precision is solved. The process comprises the following steps: a, stamping the covering roller assembly of the hydraulic torque converter; b, machining a positioning block which leaves some margin, c, welding the positioning block in the center of the outer surface of the covering roller assembly, d, welding the connection block on the outer surface of the covering roller assembly, e, clamping an inner side of the covering roller assembly and turning the connection block and the positioning block, and f, clamping the positioning block and turning and clamping an inner side of the covering roller assembly.

Owner:重庆红宇精密工业集团有限公司

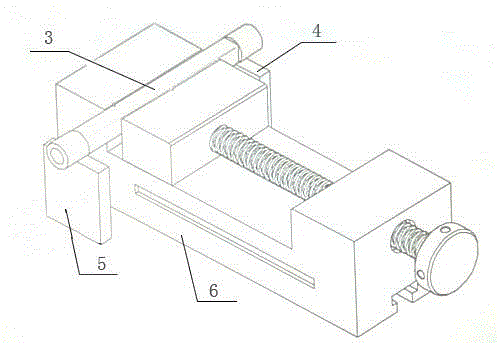

Slender and thin-walled step hole type inner-circle and outside-square structure finish machining method

The invention relates to a slender and thin-walled step hole type inner-circle and outside-square finish machining method, belongs to the technical field of non-ferrous metal finish machining in the field of machining and aims to provide a method for machining a thin-walled rod part which can machine high-precision stainless steel materials and adopts an inner-circle and outside-square semi-blind hole structure. According to the technical scheme, inner hole machining is realized according to the following steps: step 1, performing a rough turning process on an inner circle; step 2, performing half finished turning, finished turning and precision grinding processes on the inner circle in the step in sequence; step 3, performing artificial aging treatment on the excircle in the step 2; step 4, honing an inner hole by using a honing tool. Outside processing is performed according to the following steps: step 1, clamping a workpiece by adopting a combined clamp; step 2, positioning an outside square machining benchmark through a core shaft; step 3, performing line cutting on the outside square; step 4, performing artificial aging treatment on the outside square in the step 3; step 5, performing half fine grinding on the outside square; step 6, performing fine grinding on the outside square. The slender and thin-walled step hole type inner circle and outside structure precision machining method provided by the invention is applied to inner circle and outside square finish machining.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

Frock clamp for removal of waste of doll toy injection molding parts and use method

The invention provides a frock clamp for removal of waste of doll toy injection molding parts and a use method. A mounting plate is arranged on a mechanical arm and moves along with the mechanical arm. The mounting plate is provided with suction discs for adsorbing the doll toy injection molding parts from the back and tongs for clamping the doll toy injection molding parts from the two sides and further provided with material removal devices for opening water discharge openings in the necks of the doll toy injection molding parts so that waste can be discharged from the water discharge openings along with a water way. A waste clamp is arranged on a water outlet of the water way and can clamp and place waste. The frock clamp is simple in structure and high in automation degree; manual cooperation work is not needed, and working efficiency can be improved greatly; and classified discharge of different waste such as waste water and waste residues is facilitated, and treatment of different waste is facilitated.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

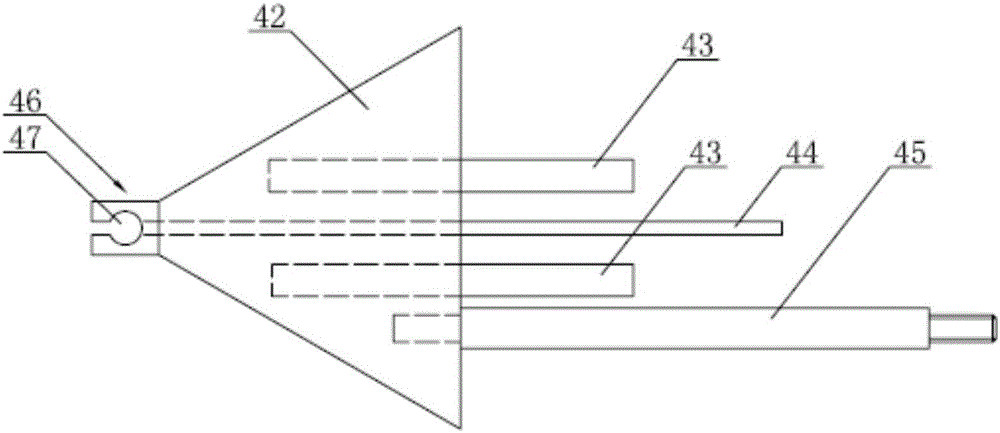

Preparation method of Ge-Sb-Se chalcogenide tapered fiber of different taper waists

ActiveCN105891942AGood positioning effectHigh precisionGlass optical fibreGlass making apparatusChalcogenideEngineering

The invention discloses a preparation method of a Ge-Sb-Se chalcogenide tapered fiber of different taper waists. The preparation method utilizes a specific and easy-to-operate tapering device to realize drawing of a Ge-Sb-Se chalcogenide tapered fiber, wherein during the tapering process, a first clamping plate and a second clamping plate of a clamp attached to each other under the magnetic force effect, and can compact the fiber through two soft rubber strips, so that the positioning effect of the fiber is good; and smooth operation of the tapering process can be guaranteed. Besides, as a stepping motor can control the tapering speed of the fiber and the heating area of a heating device is adjustable, the fiber areas with different lengths can be heated correspondingly and drawing of the Ge-Sb-Se chalcogenide tapered fiber of different taper waists can be realized; and as the temperature control accuracy of the heating device is 0.1DEG C and the three dimensional position of the heating device is adjusted by a three dimensional translation platform, the accuracy for heating the fiber can be improved. The preparation method of Ge-Sb-Se chalcogenide tapered fiber of different taper waists has the advantages of being simple in steps, being easy to operate, and being controllable in the external diameter of the taper area, wherein the diameter of the fiber core can be 700-2000Mum; the length of the taper area is 3-20mm; and the length of the taper area is greatly reduced relative to a traditional taped fiber.

Owner:NINGBO UNIV

Safety protection type anti-seismic noise-reduction electromechanical engineering equipment for building construction

InactiveCN112059779AImprove efficiencyGood positioning effectGrinding carriagesGrinding drivesElectric machineryEarthquake resistant

The invention discloses safety protection type anti-seismic noise-reduction electromechanical engineering equipment for building construction, and belongs to electromechanical engineering equipment. The equipment comprises a rack; a cutting device is fixedly installed on the right side of the top of the rack; a polishing device is fixedly installed in the middle of the top of the rack; a cleaningdevice is fixedly installed on the left side of the top of the rack; and protective bases are fixedly installed at the bottom and the top of the inner side of a rack body of the rack. According to theequipment, a second telescopic air cylinder of the polishing device is started, a polishing disc moves to a cutting opening of a cut object, meanwhile, a second rotating motor is started, the polishing disc rotates to polish the cut object, during polishing, the second telescopic air cylinder continues to stretch out and draw back, a first sliding block moves in a sliding rail, so that the polishing disc polishes the whole surface of the cutting opening of the cut object, the cut object is integrally polished, the efficiency is higher, the edge opening cannot injure people, and the cut objectis more attractive to use after being polished.

Owner:萧县威辰机电工程设备有限公司

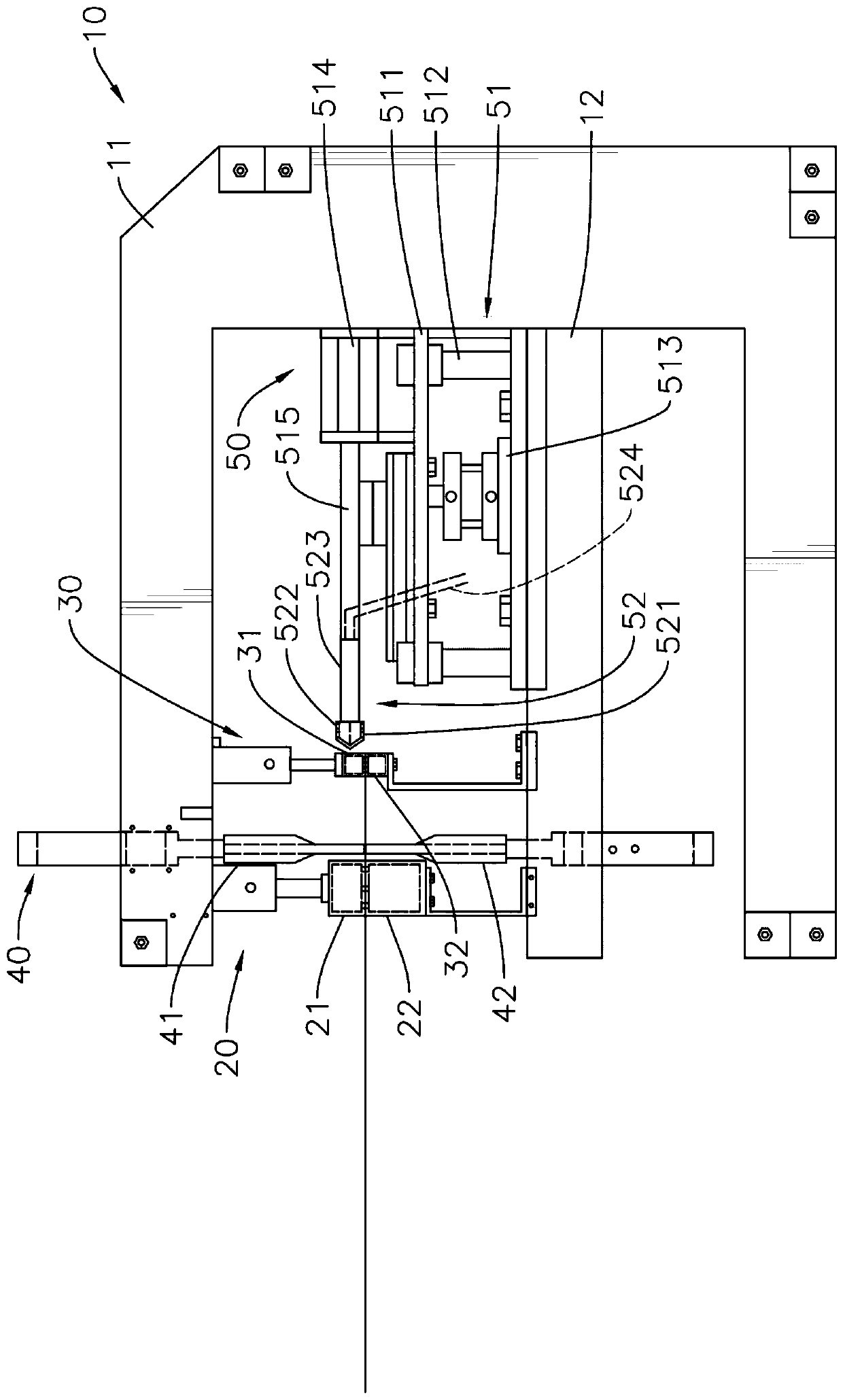

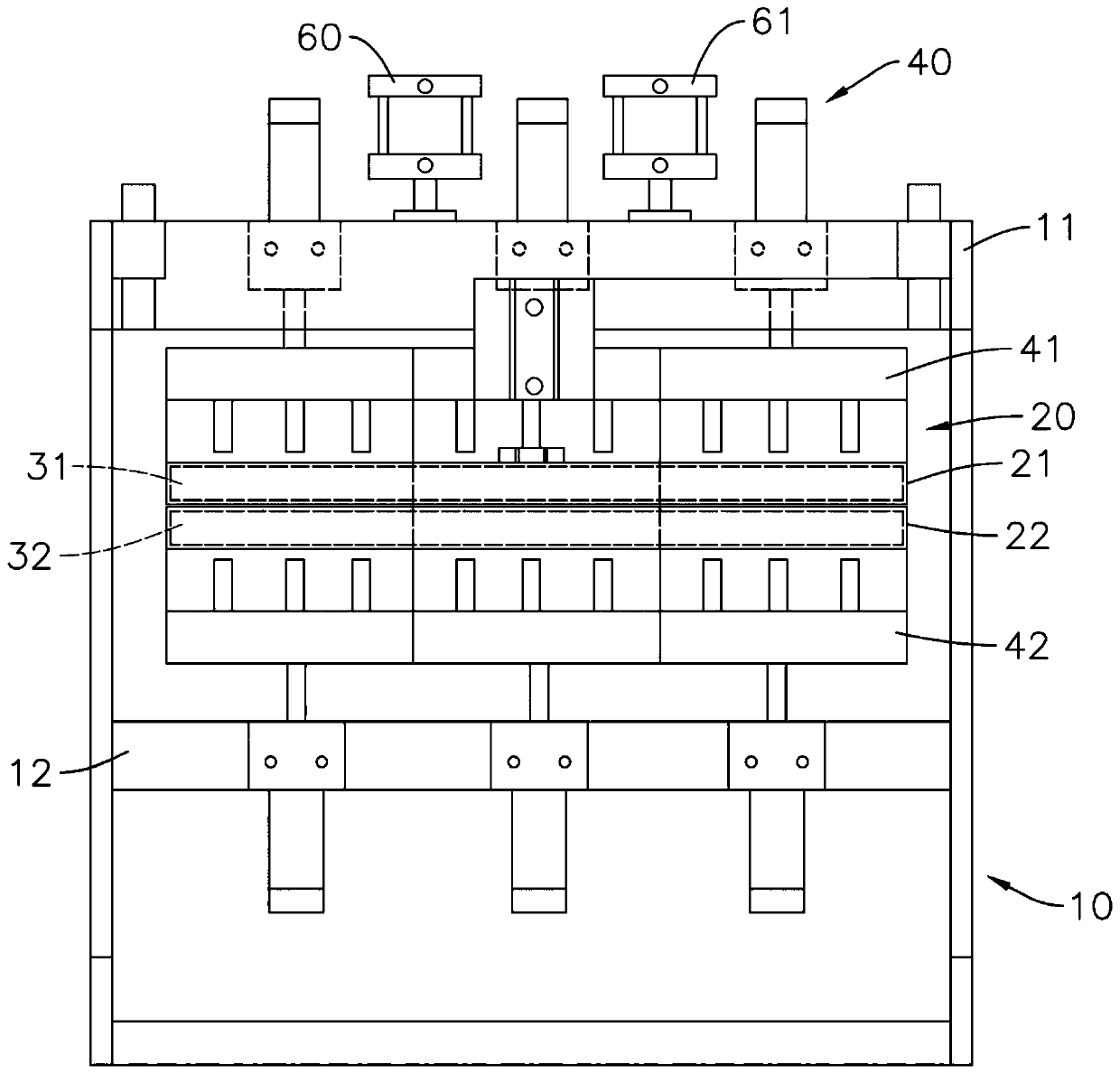

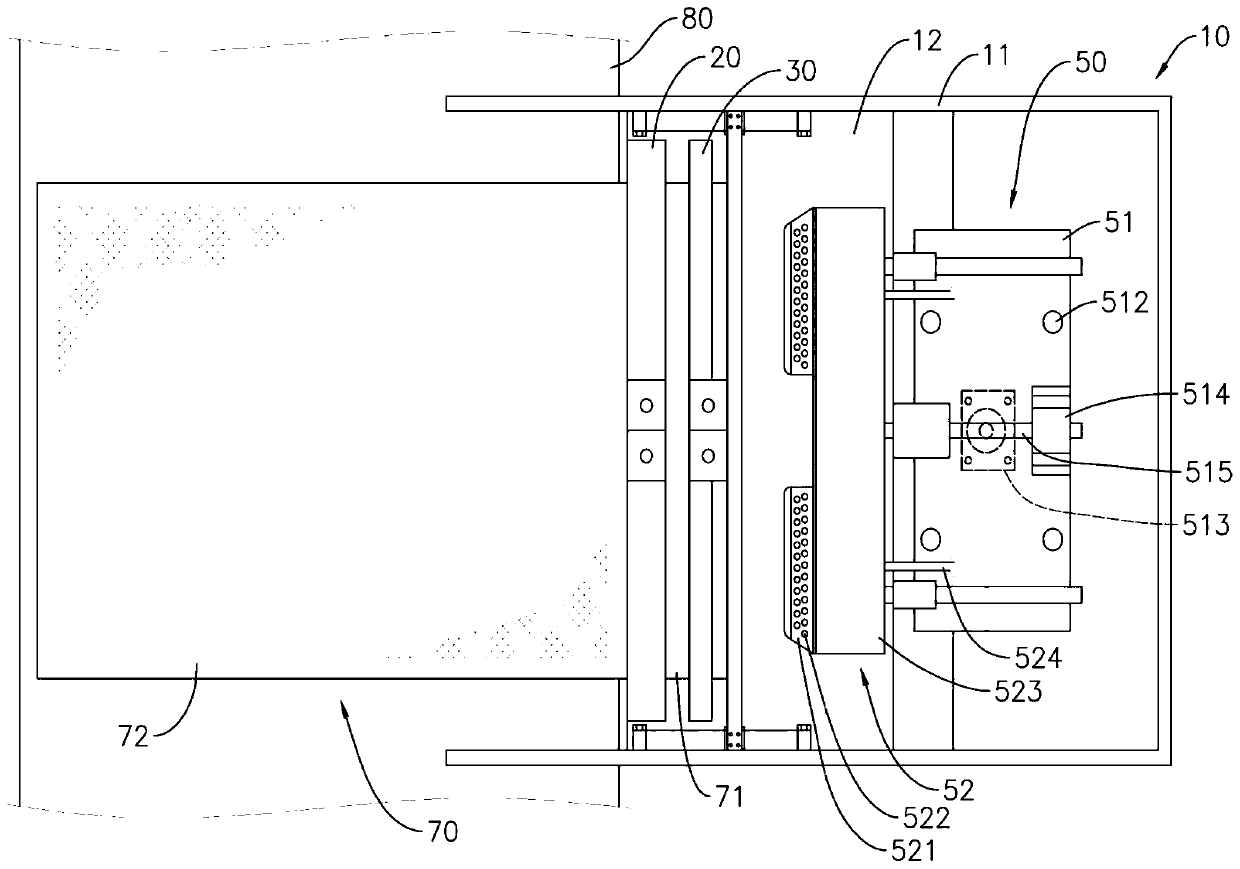

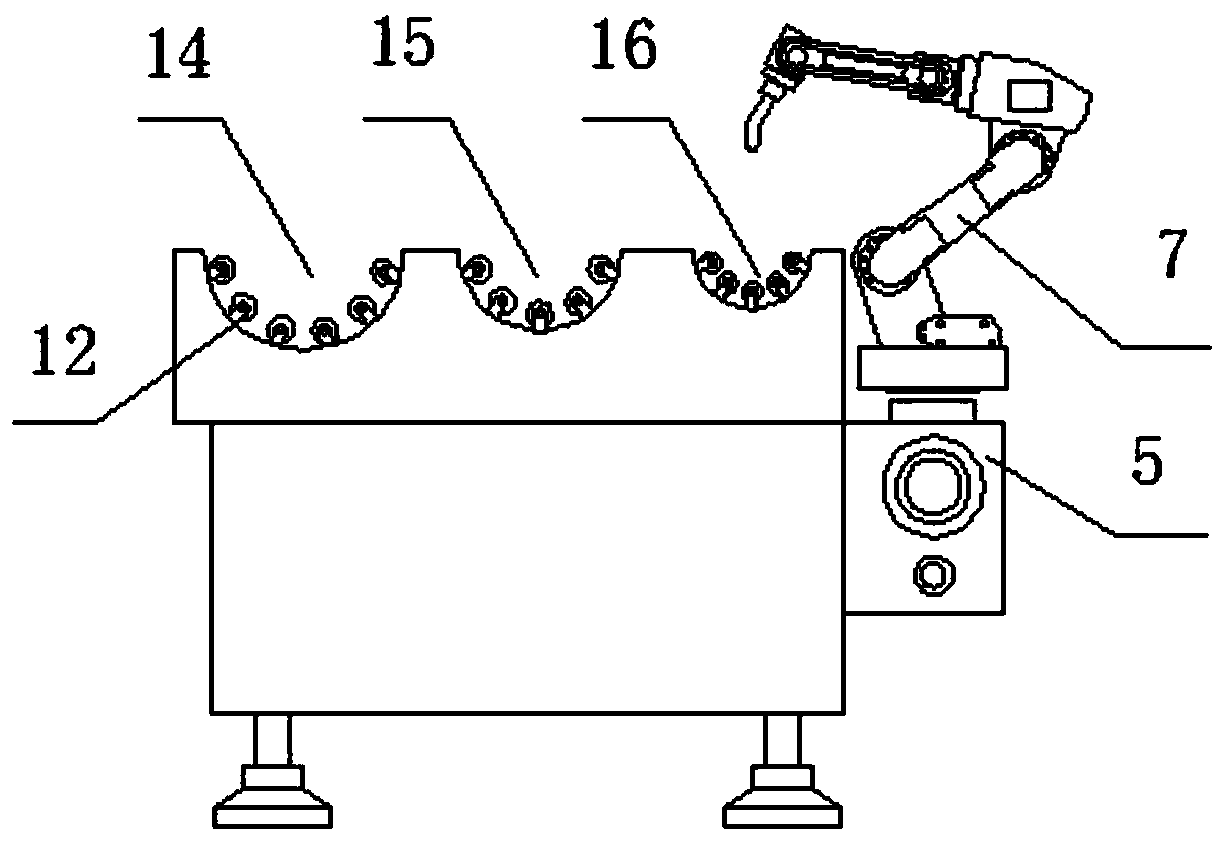

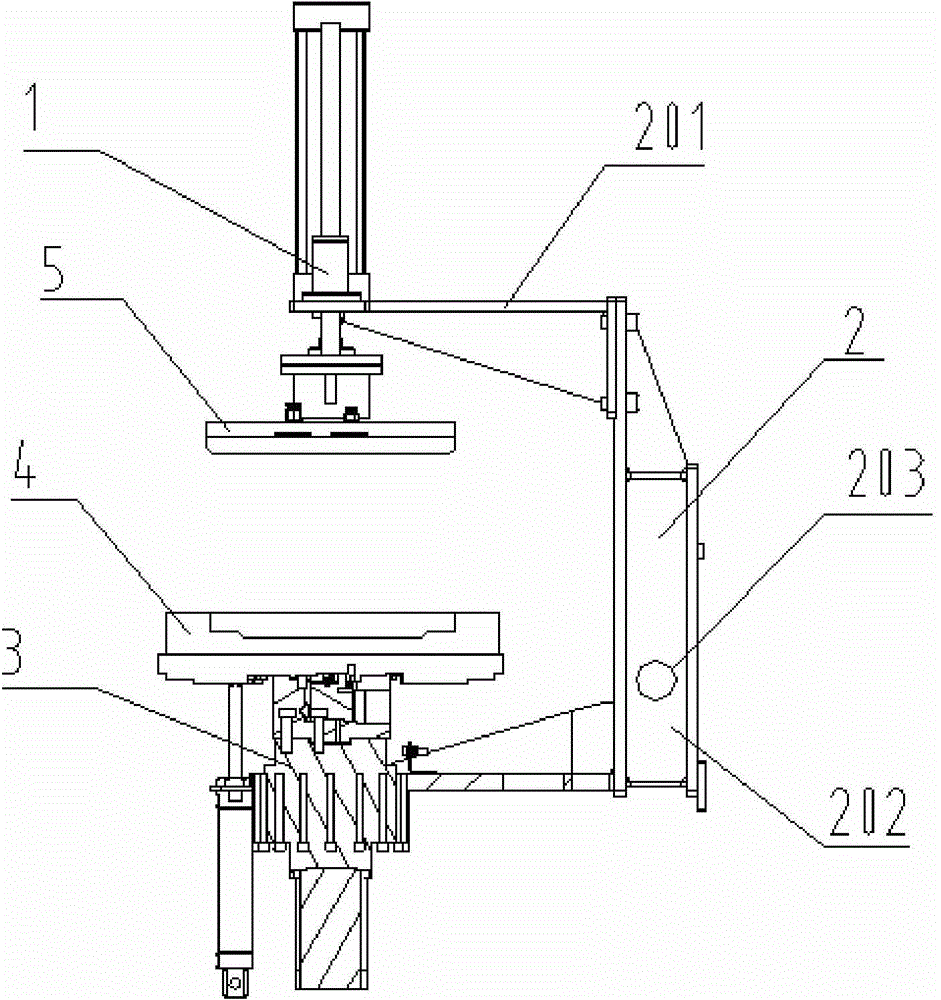

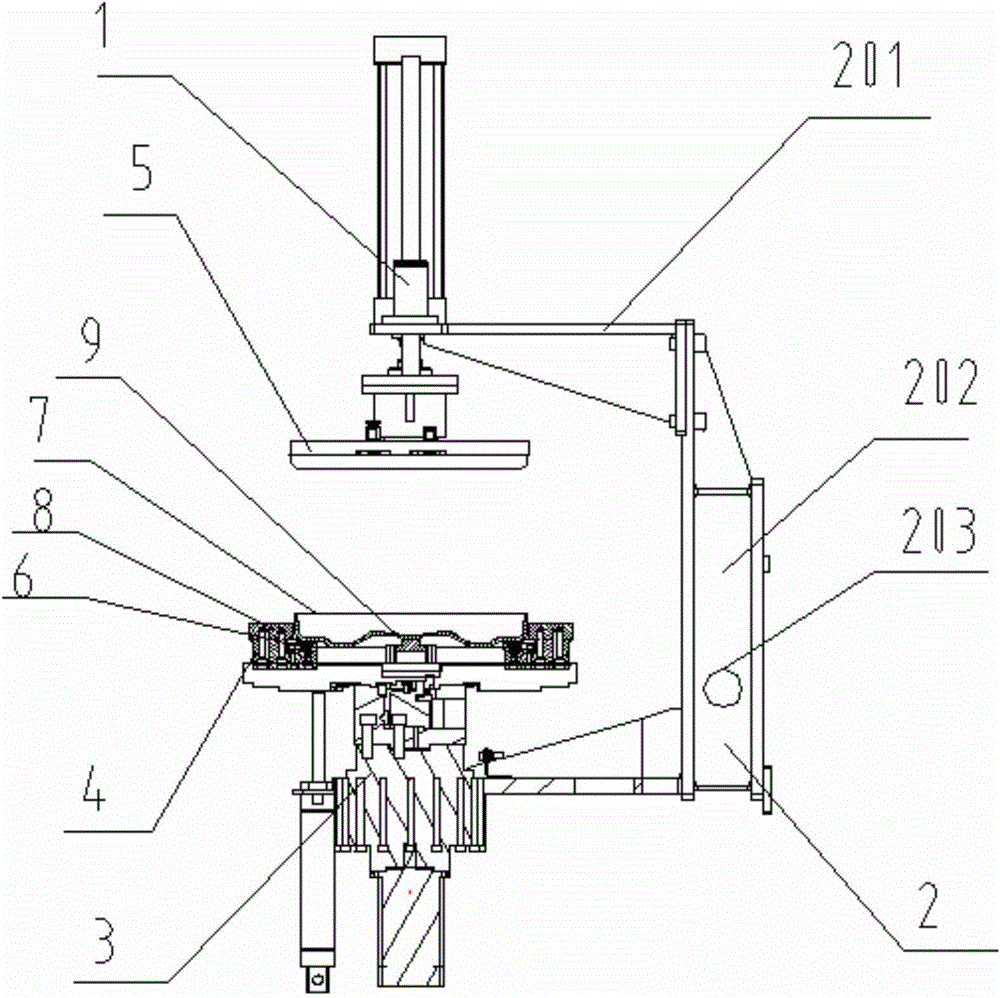

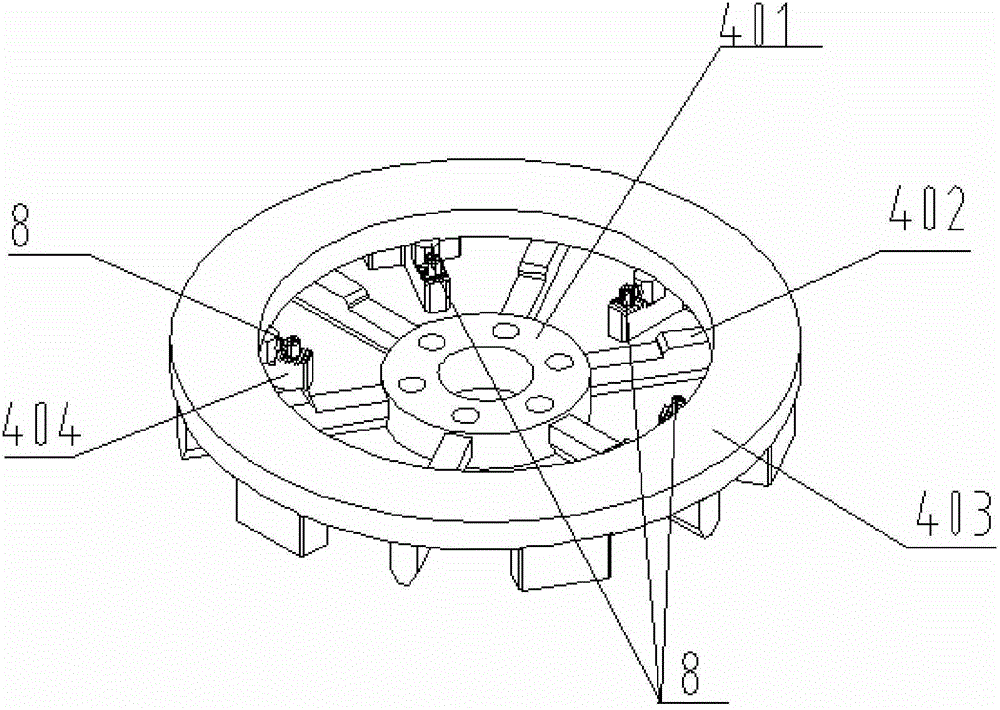

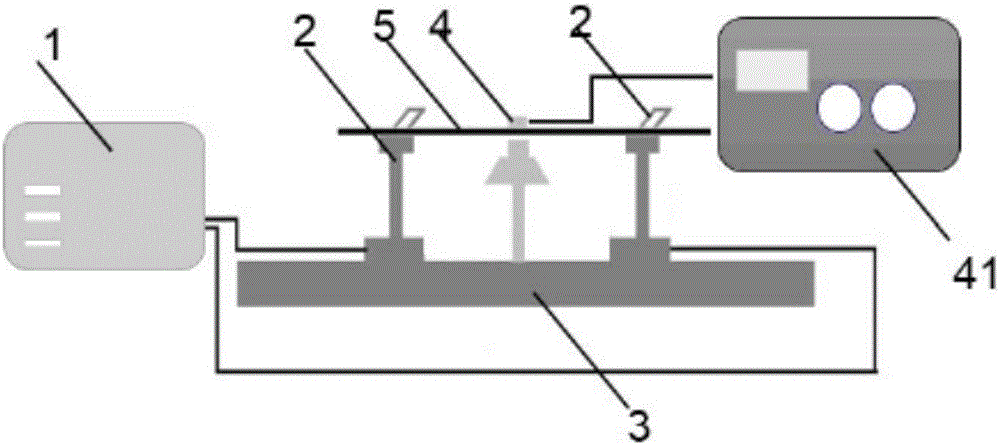

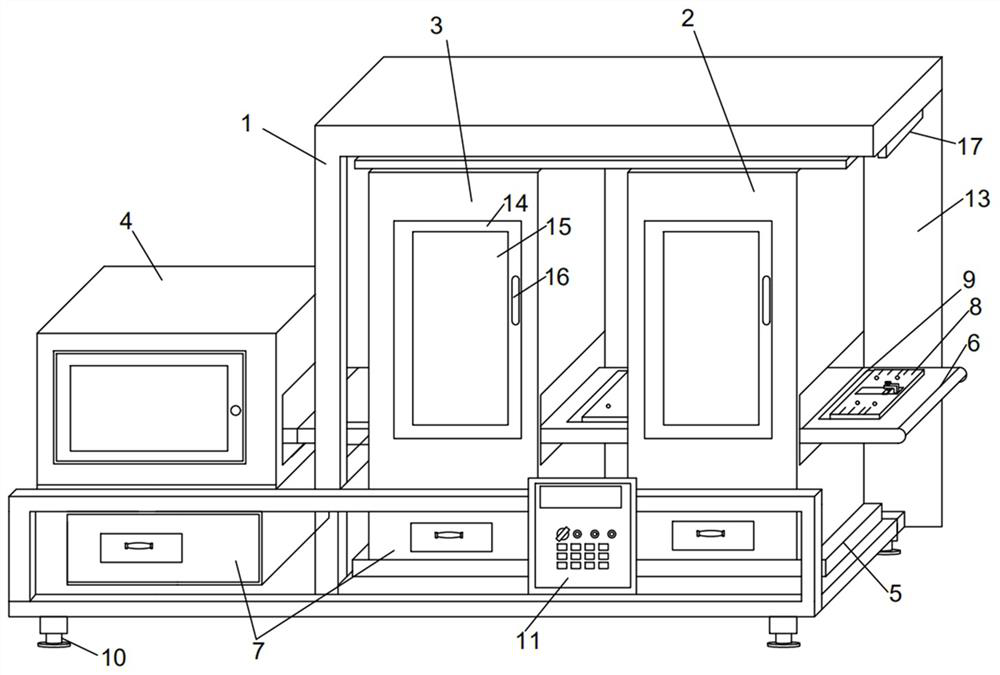

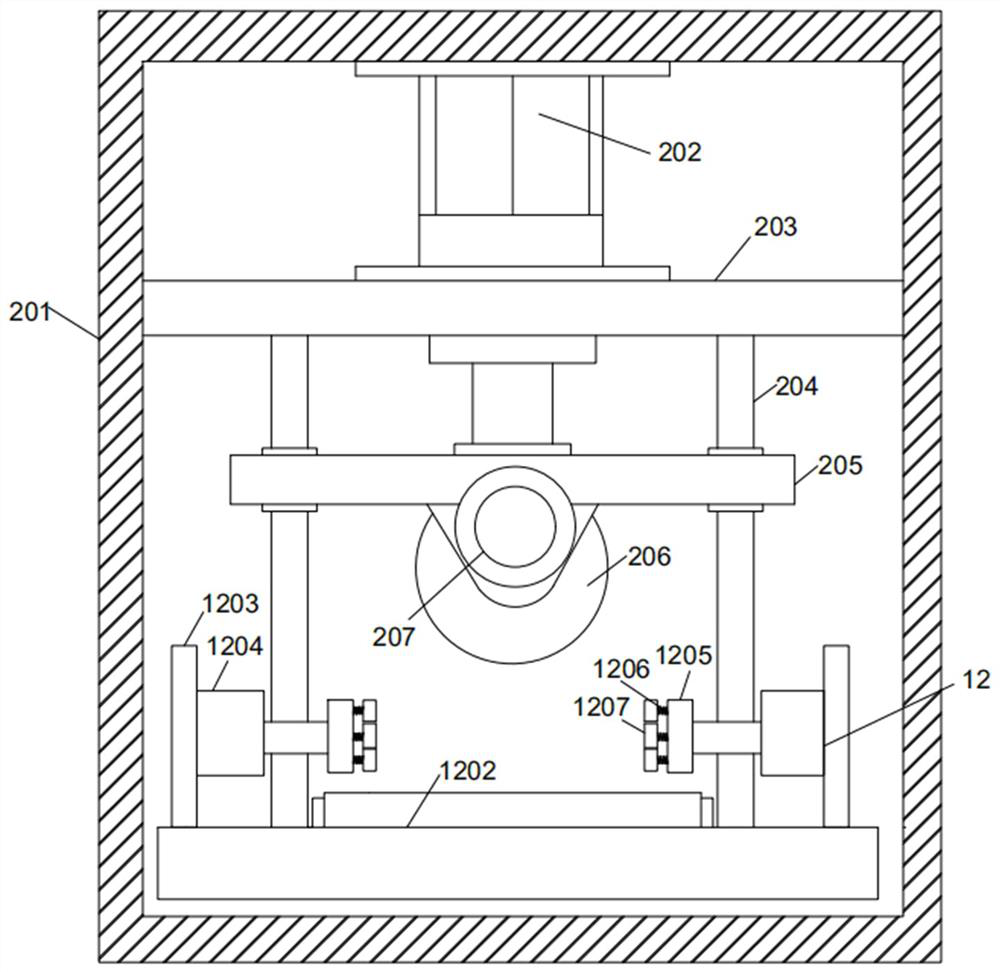

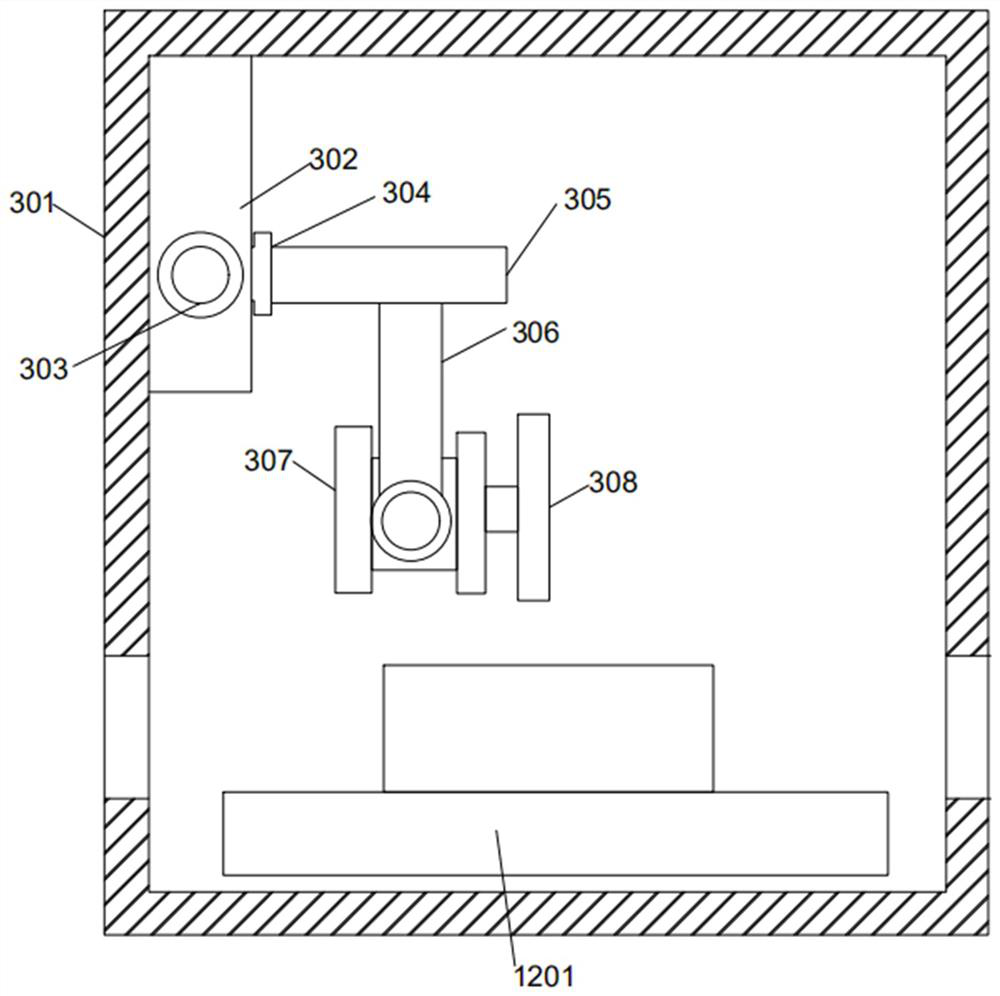

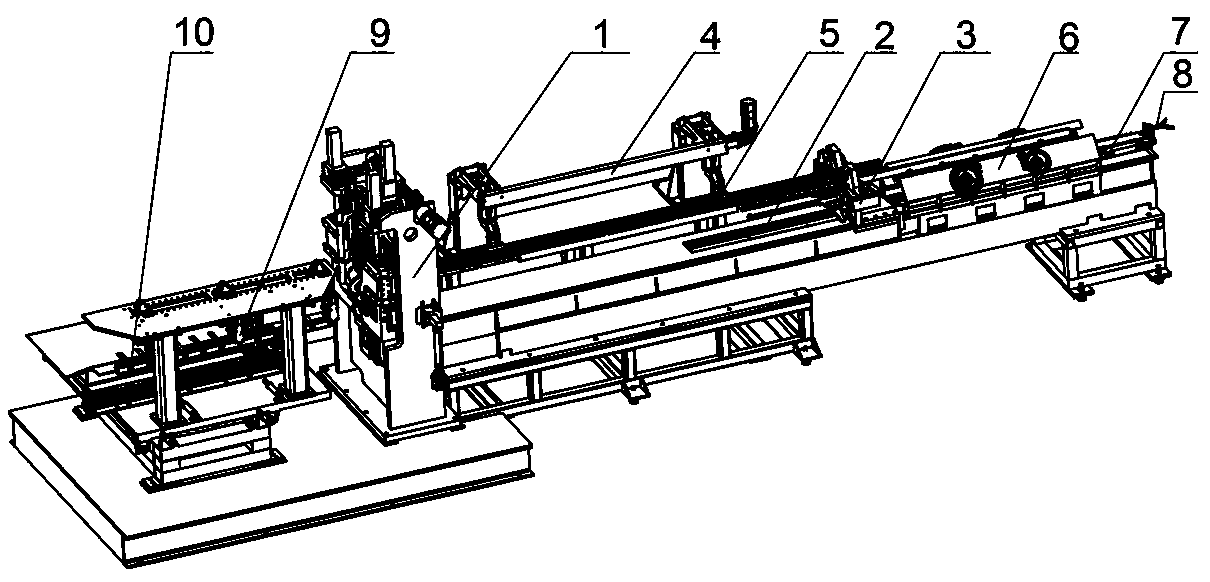

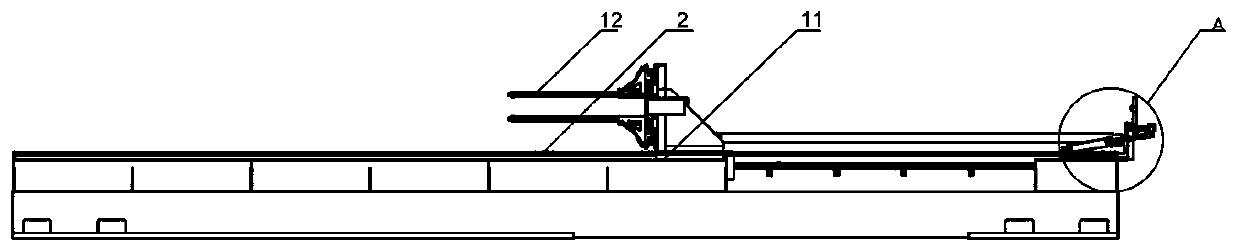

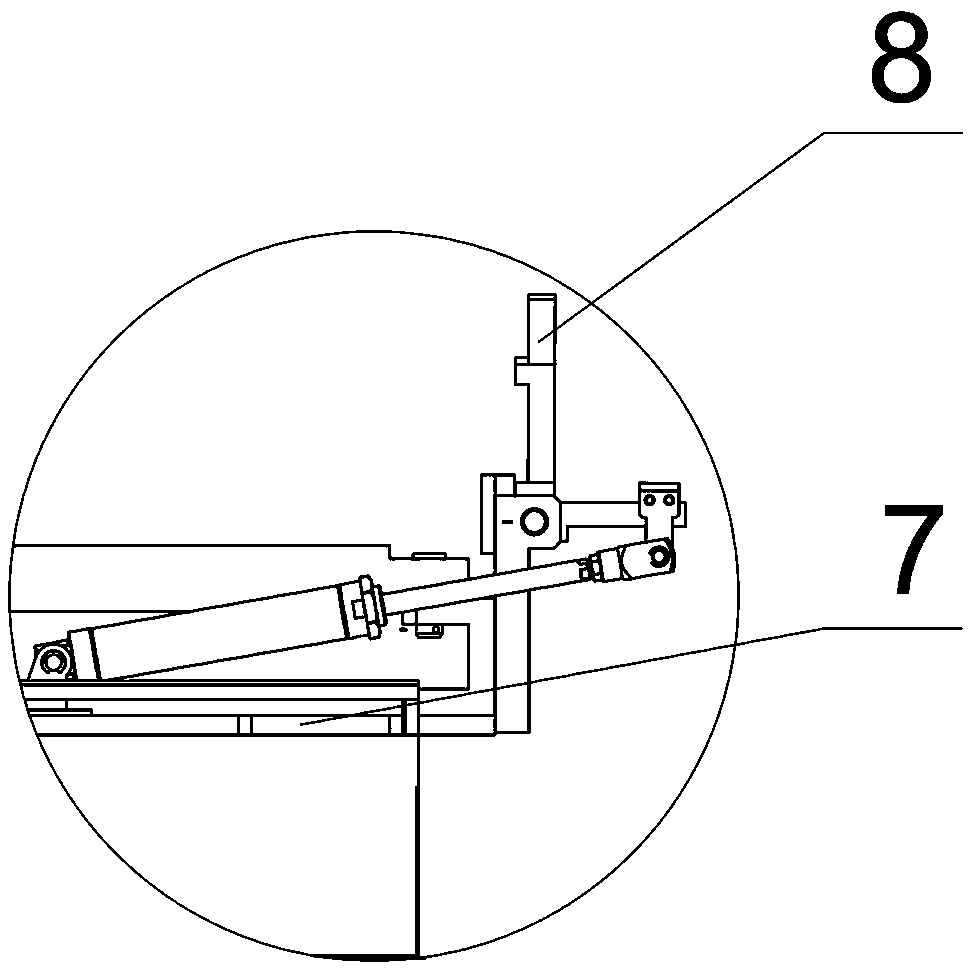

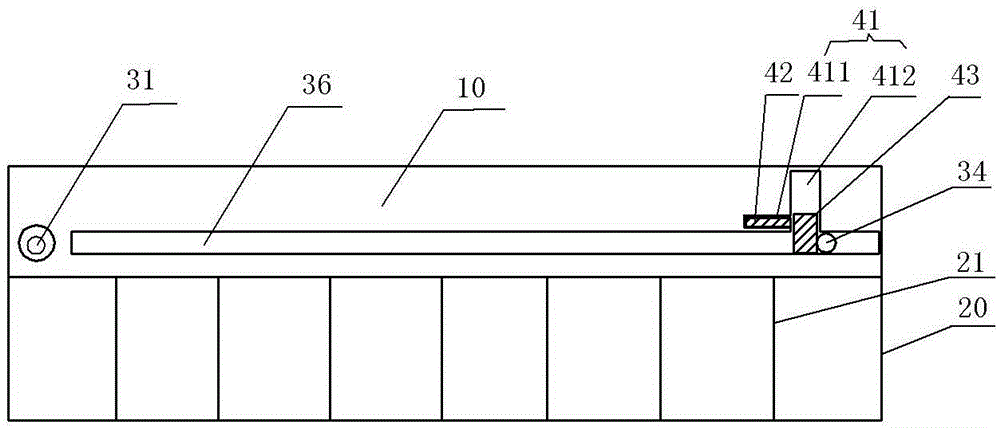

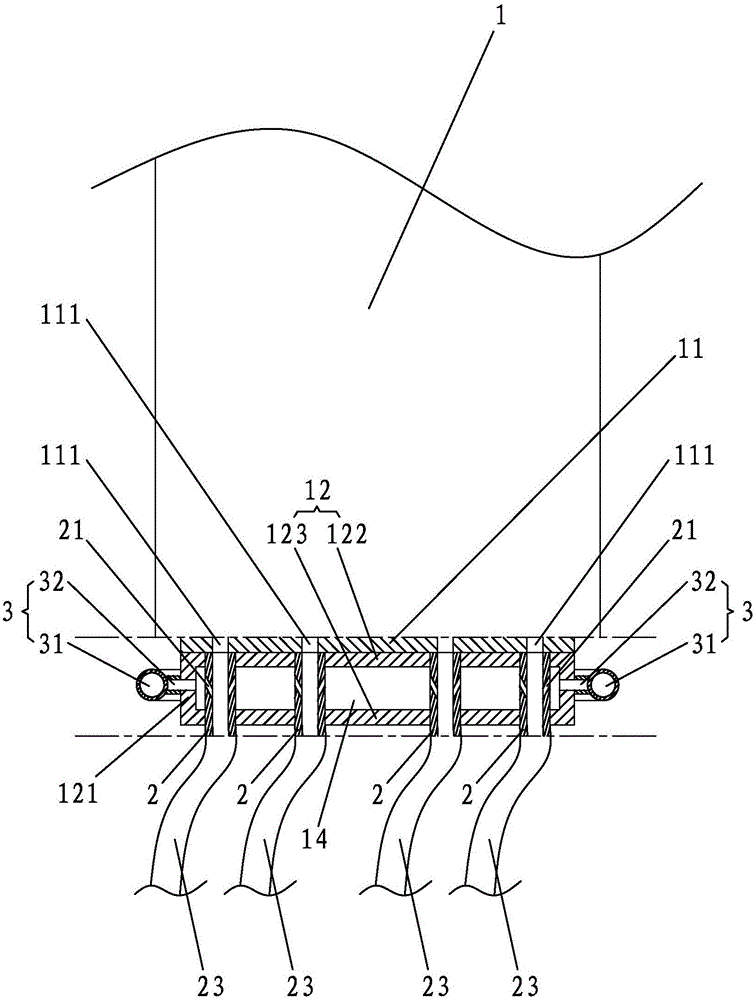

Pipe laser welding machine

ActiveCN111055016AGood positioning effectGood welding effectLaser beam welding apparatusPhysicsErbium lasers

The invention relates to the technical field of welding, in particular to a pipe laser welding machine which includes a controller, a feeding mechanism, a main machine, and a discharging mechanism. The main machine is provided with a positioning mechanism and a welding mechanism, the feeding mechanism, the positioning mechanism, the welding mechanism, and the discharging mechanism are all in signal connection with the controller, wherein the feeding mechanism includes a feeding slide platform (2) and a material pushing fixture (3) slidably connected to the feeding slide platform (2), and the material pushing fixture (3) is connected to the controller in a signal mode; the positioning mechanism includes a five-roller positioning mechanism, and the five-roller positioning mechanism is in signal connection with the controller; the welding mechanism includes a fiber laser and a welding head (26), and the fiber laser is in signal connection with the controller; and the discharging mechanismincludes a pipe outlet manipulator (9) and a pipe unloading device (10), and the pipe outlet manipulator (9) and the pipe unloading device (10) are all connected with the controller in a signal mode.The pipe laser welding machine is higher in welding efficiency and better in welding effect.

Owner:武汉大族金石凯激光系统有限公司

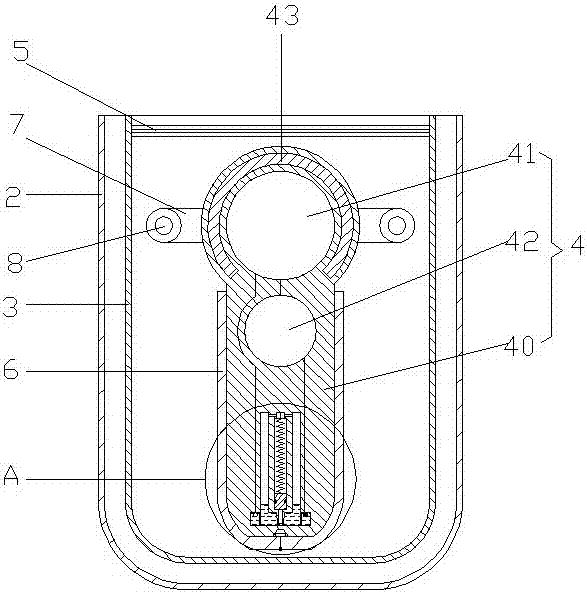

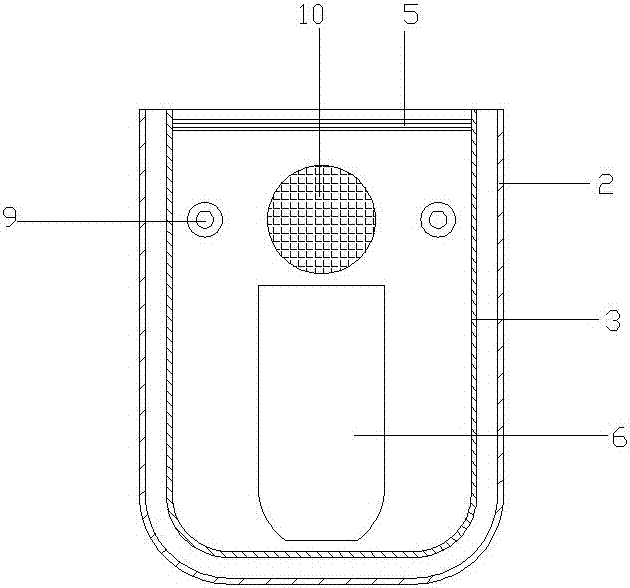

Membrane washing box

InactiveCN105181974AGood positioning effectGood shading effectSemi-permeable membranesBiological testingWestern blotEngineering

The invention discloses a membrane washing box which comprises a transparent box cover, a lightproof box body, lightproof partition plates and a waterproof mechanism. The partition plates are vertically fixed on the bottom face of the box body, the waterproof mechanism comprises a rolling shaft, a power spring, a lightproof waterproof membrane and a locating rod, the box cover is shaped like a cuboid, and the side wall of the box cover is provided with locating holes and a sliding groove; the rolling shaft is connected with the box cover in a rolling mode, and the axial direction of the rolling shaft is perpendicular to the sliding groove; the power spring is arranged on the rolling shaft in a sleeving mode, the lightproof waterproof membrane horizontally sticks to the power spring, the locating rod is fixedly connected with the outer endpoints of the power spring, one end of the locating rod is arranged in an initial or lightproof locating hole in a clamped mode, and the other end of the locating rod penetrates through the interior of the sliding groove. The membrane washing box can be used for biological experiments such as Western Blot of which membranes need to be washed.

Owner:CHONGQING KANGLE PHARMA

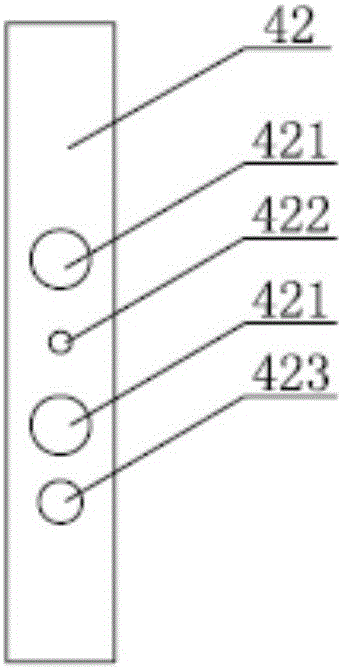

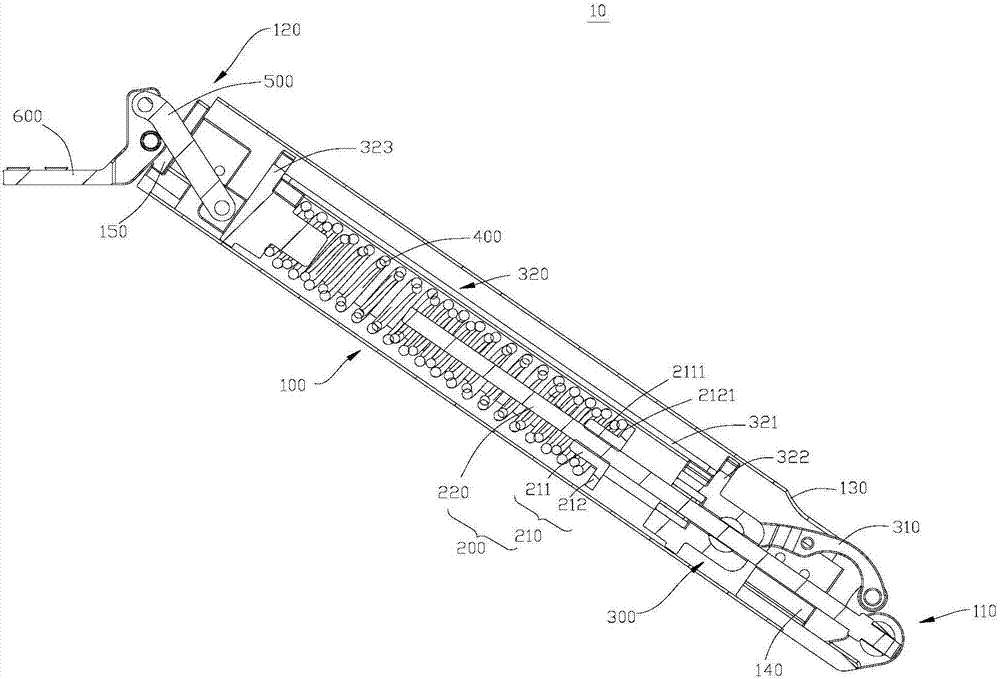

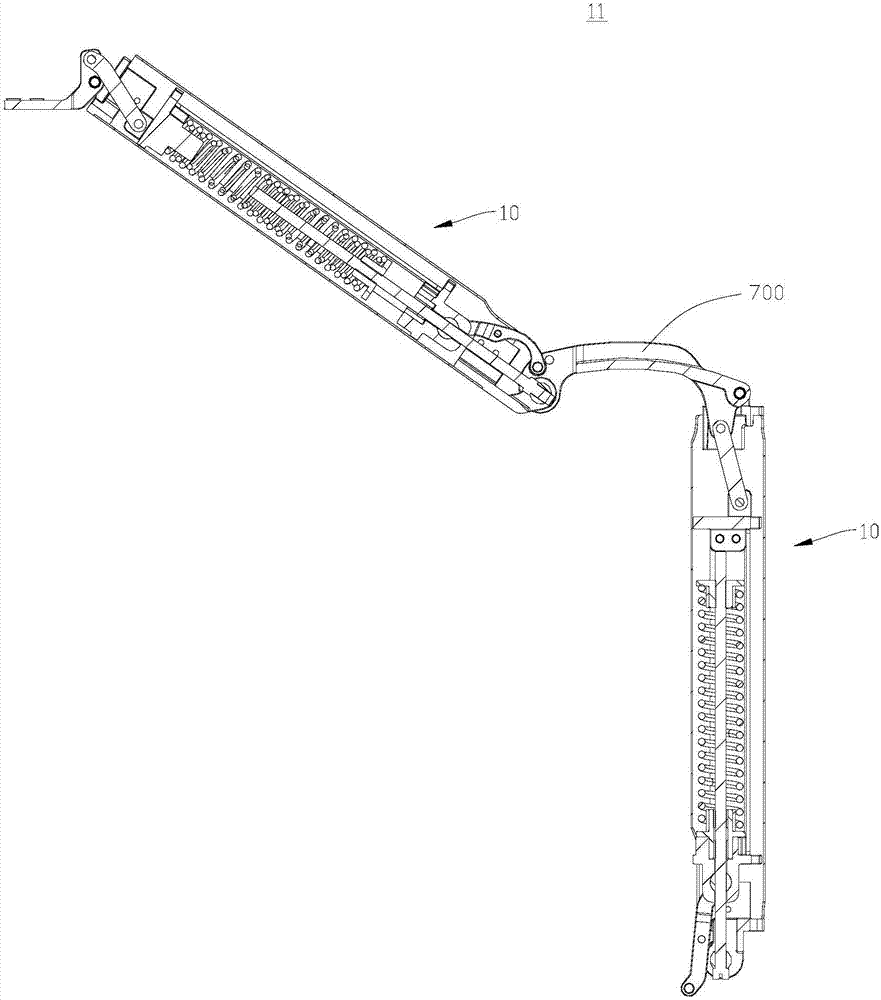

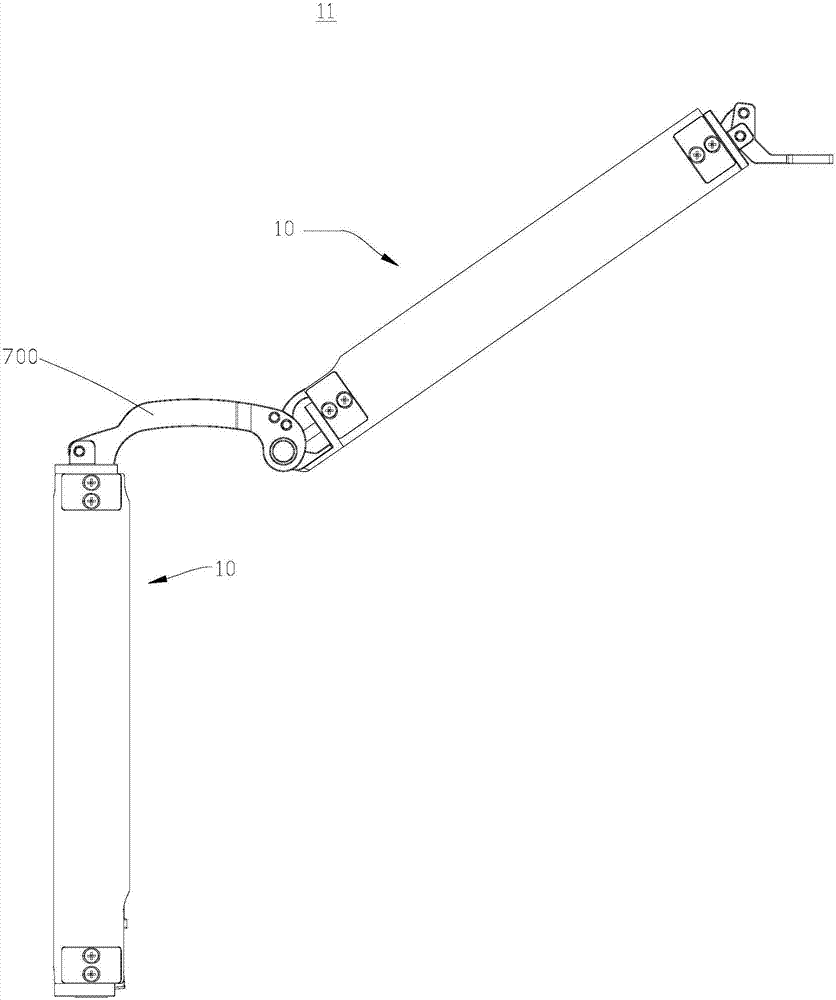

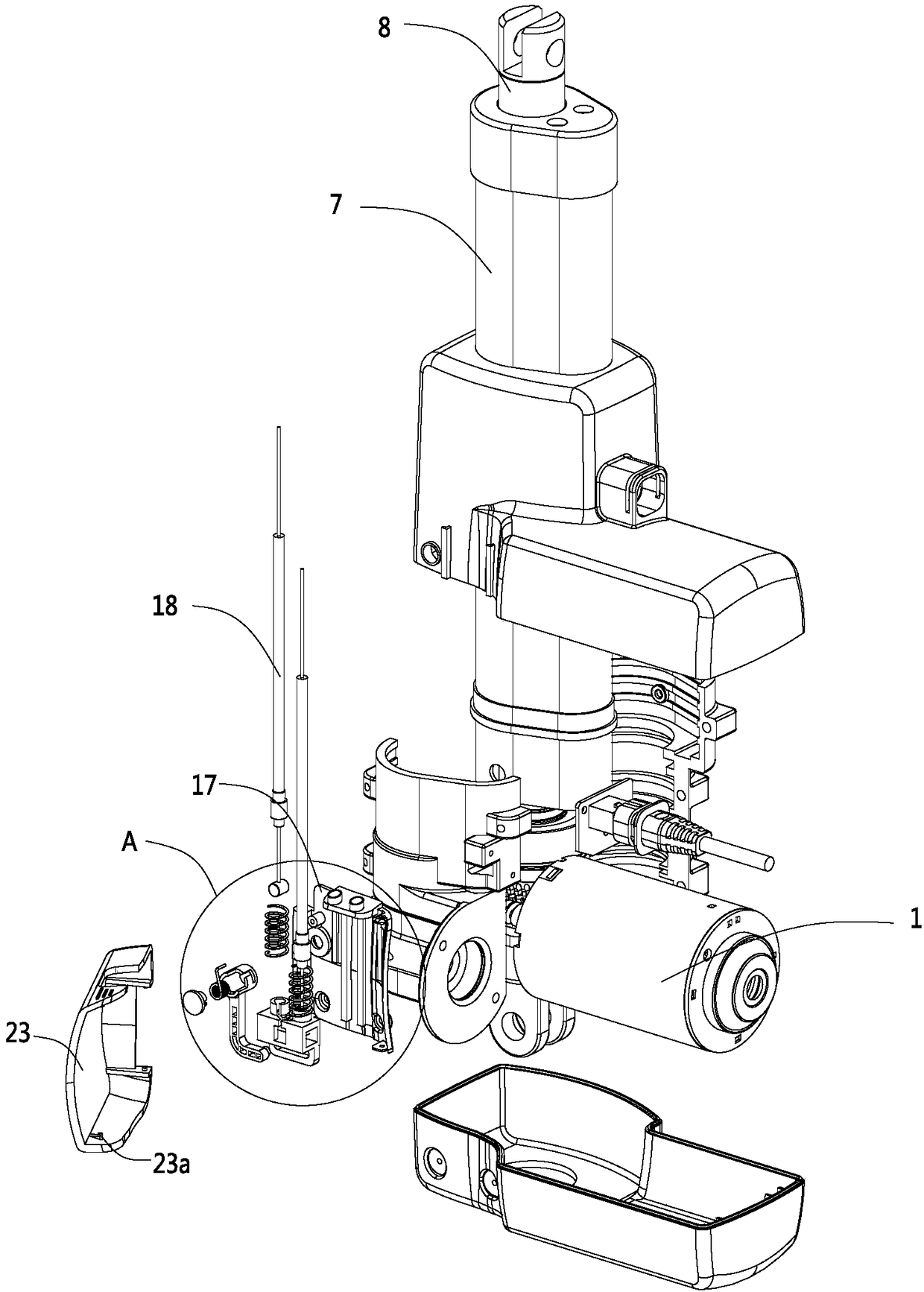

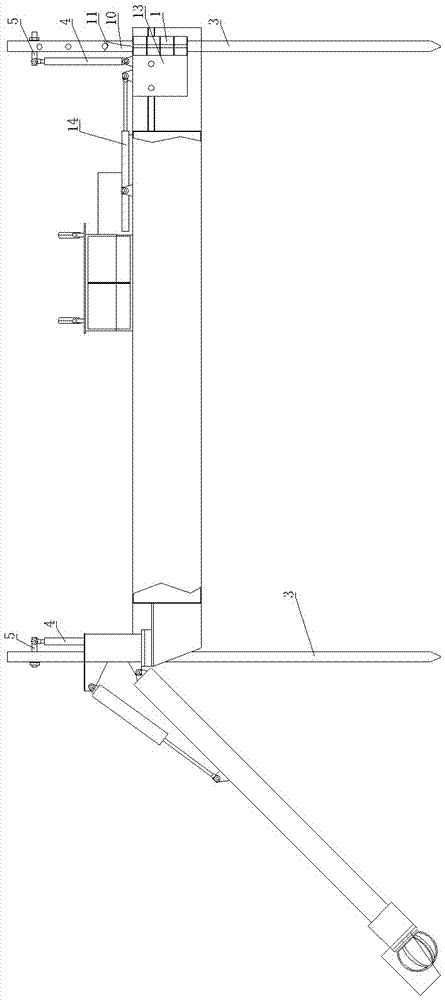

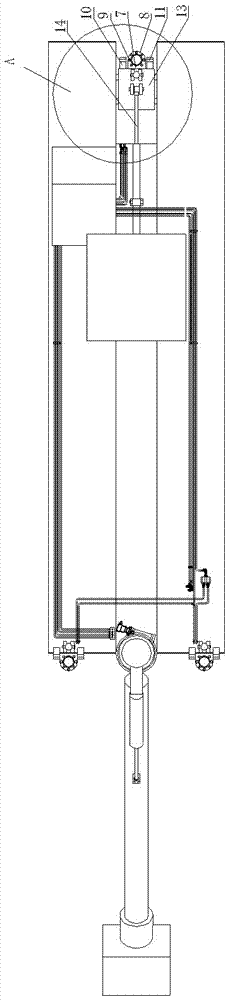

A TDP magic therapeutic instrument support arm, a support arm system and a TDP magic therapeutic instrument

The invention provides a TDP magic therapeutic instrument support arm, a support arm system and a TDP magic therapeutic instrument, and belongs to the field of medical instruments. The TDP magic therapeutic instrument support arm provide by the invention comprises an outer cylinder, a fixed part, a movable part and an elastic part. The fixed part is fixedly connected with the outer cylinder; the movable part is movably connected with the outer cylinder; and the elastic part is arranged between the movable member and the fixed member. The invention also provides the support arm system adopting the above TDP magic therapeutic instrument support arm. The invention also provides the TDP magic therapeutic instrument adopting the above support arm system. The TDP magic therapeutic instrument support arm, the support arm system and the TDP magic therapeutic instrument provided by the invention are relatively good in positioning effect and convenient for usage by users.

Owner:CHONGQING JIAJIALIN CENTURY MEDICAL INSTRUMENT CO LTD

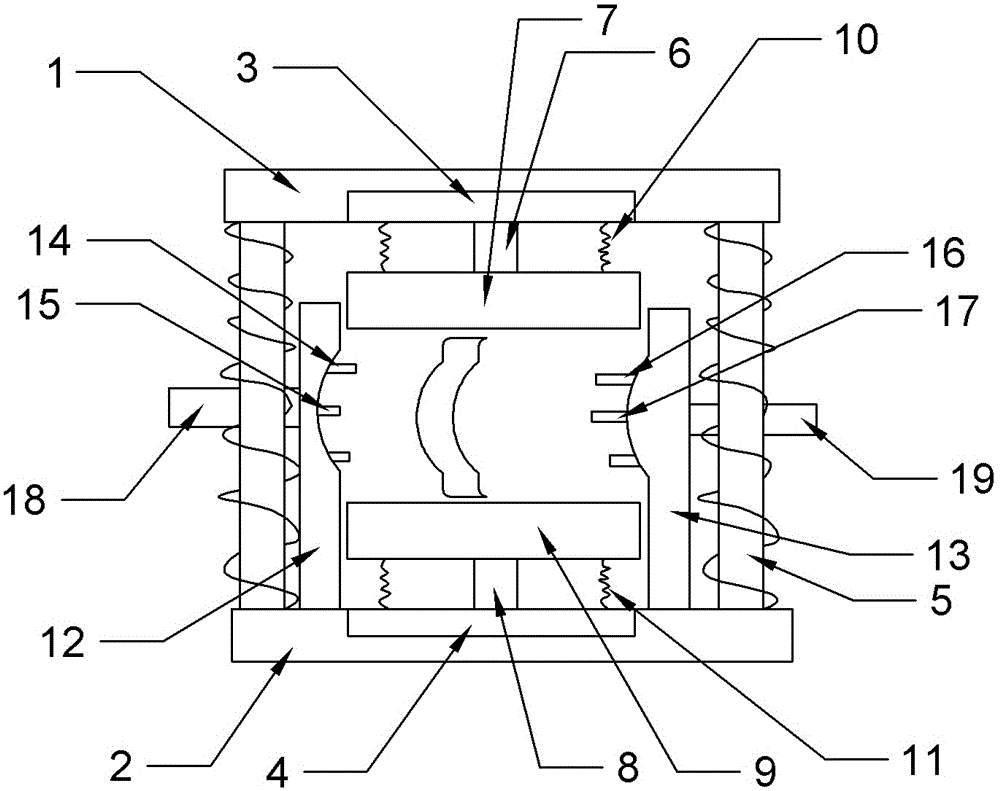

Spoke air hole machining mold

InactiveCN105057457AGood clamping effectGood positioning effectShaping toolsPerforating toolsSpokeLower face

The invention relates to the field of machining, in particular to a spoke air hole machining mold. The spoke air hole machining mold comprises an upper mold base, an upper mold body, a lower mold base and a lower mold body. The upper mold body and the upper mold base are connected in a matched manner. The lower mold body and the lower mold base are connected in a matched manner. An upper punch is arranged on the lower end face of the upper mold body. A lower punch is arranged on the upper end face of the lower mold body. A left elastic clamping plate and a right elastic clamping plate which are in sliding connection with the lower mold base are arranged on the lower mold base. Holes for the punches to penetrate are formed in the upper faces and the lower faces of the left elastic clamping plate and the right elastic clamping plate. The left elastic clamping plate is provided with a groove consistent with a spoke arc. A left protruding pin matched with a center hole of a spoke and left positioning pins matched with a spoke bolt hole are arranged on the upper face of the groove. The right elastic clamping plate is provided with a protruding groove matched with the left elastic clamping plate, and the groove is provided with right protruding pins and a right positioning pin. The spoke is vertically placed, the spoke is clamped and positioned through the left elastic clamping plate and the right elastic clamping plate, accordingly, vertical punching is carried out, and the spoke can be prevented from being abraded or deformed in the punching process.

Owner:CHONGQING DINGHAN MACHINERY

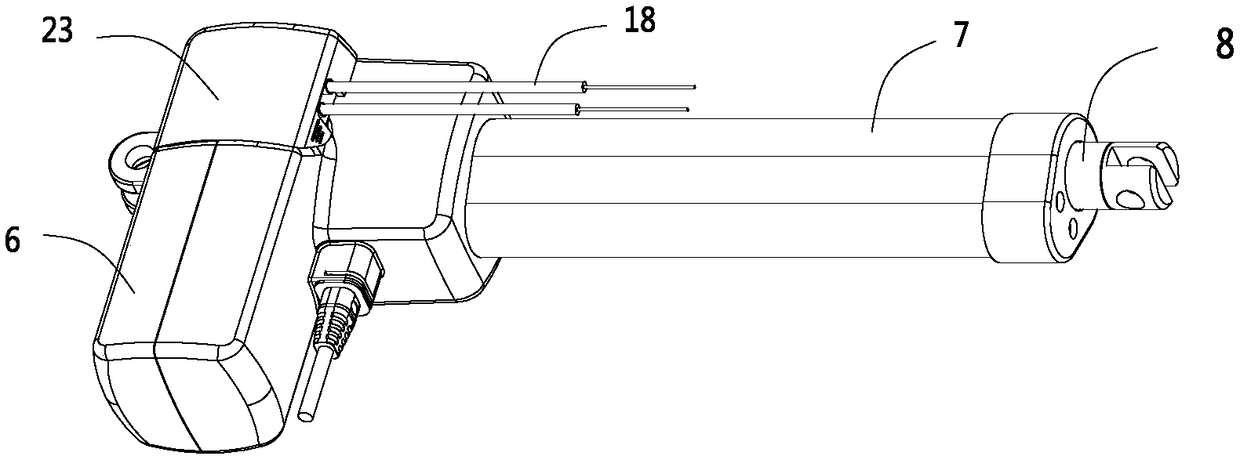

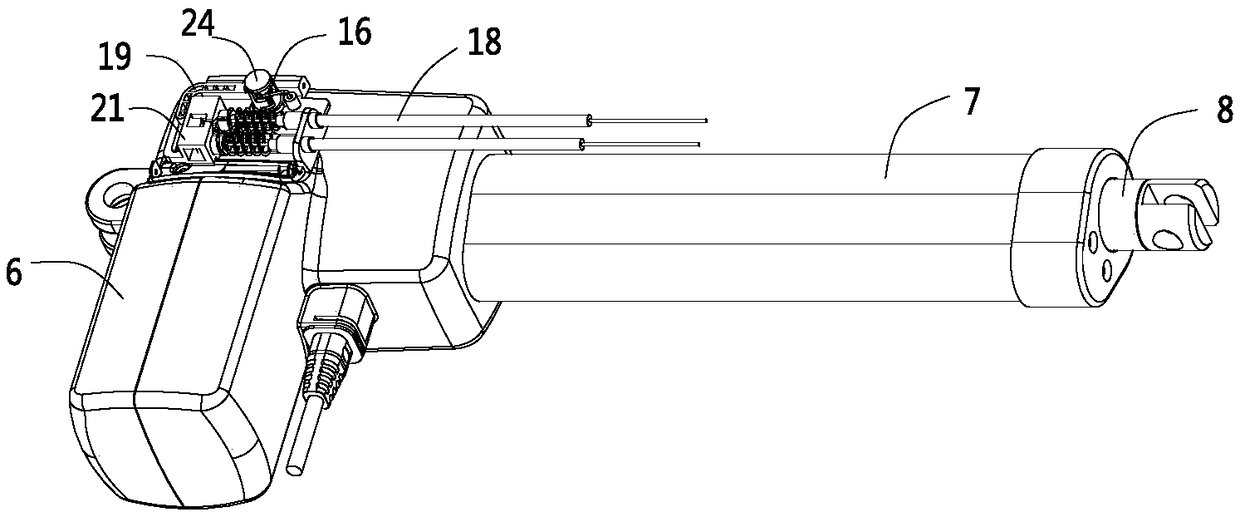

Linear actuator with compact structure

PendingCN108518466AGood positioning effectReduce space consumptionGearingGearing detailsLinear actuatorWorm drive

The invention discloses a linear actuator with a compact structure, and belongs to the technical field of linear transmission. The linear actuator with the compact structure comprises a transmission worm, a worm wheel, a lead screw and a nut. The transmission worm drives the worm wheel to rotate, the worm wheel rotate to drives the lead screw to rotate, and the lead screw rotate to drives the nutto move axially. A planetary gear assembly is arranged between the worm wheel and the lead screw, the planetary gear assembly comprises an inner gear ring, a sun gear, a planetary gear, and a planet carrier, the sun gear and the worm wheel rotate synchronously, and the planet carrier and the lead screw rotate synchronously. The linear actuator further includes a supporting seat arranged on one side of the rear end of the planetary gear assembly, a first sliding sleeve is installed on the supporting seat in a sleeving mode, a first limiting blocking ring is arranged at the tail end of the firstsliding sleeve, and the sun gear is installed in the first sliding sleeve in a sleeving mode and located between the first limiting blocking ring and the planet carrier or the lead screw. The linearactuator with the compact structure has the advantages of enabling the internal structure of the linear actuator to be more compact and less in occupied space.

Owner:NINGBO HAISHIKAI DRIVER TECH CO LTD

Forming method for insulating foam floor panel

The invention provides a forming method for an insulating foam floor panel. Process forms of traditional floor panel modules are broken through, a manipulator is used for achieving mechanical operation, the overturning and positioning effects are good, the efficiency is high, and safety and reliability are achieved. C-shaped steel reinforcing ribs are preheated, the butt fusion degree of a foam material and the C-shaped steel reinforcing ribs in the foaming process can be increased, and the butt fusion strength and quality are improved. Raw material particles can be stressed from outside to inside through the vacuumizing operation, and all the raw material particles and the C-shaped steel reinforcing ribs are combined more closely with adjacent raw material particles with high strength, so that the forming quality is further improved. Compared with the prior art, the forming method for the insulating foam floor panel is high in insulating foam floor panel forming efficiency, safe, reliable, high in butt fusion degree and high in tightness, so that a finished product is high in strength and good in quality; and the process is novel and reasonable, and the practicability is high.

Owner:FACKEL MACHINERY FUJIAN

Flame-retarding board material used for drilling and preparation method thereof

InactiveCN107877979AGood positioning effectGood chip removal effectLamination ancillary operationsLayered product treatmentHardnessHot pressing

The invention discloses a flame-retarding board material used for drilling and a preparation method thereof. The flame-retarding board material is produced from paper and flame-retarding resin in a hot-pressing manner with impregnation. In the invention, the flame-retarding board material is 0.2-0.5 mm in thickness, is less than 1% in warping degree, is 84-92 shore D in hardness and is V1-V0 in flame-retarding level. The main resin material of the board material is phenolic resin, which has moderated hardness, density and strength and belongs to thermosetting resin, so that during drilling, adrill can easily drill the board material, thus achieving excellent positioning effect. The board material has good chip discharge effect and can avoid fracture of the drill. Due to addition of a flame-retarding agent, flame-retarding effect of the resin is reinforced, so that the flame-retarding board material can reach the V0 flame-retarding level.

Owner:烟台柳鑫新材料科技有限公司

Rotary table positioning device

InactiveCN103013540AHigh positioning accuracyGood positioning effectCoke quenchingLinear driveEngineering

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

Positioning device for dredger

InactiveCN106892058AWidely applicableGood positioning effectSoil-shifting machines/dredgersAnchoring arrangementsElectrical and Electronics engineeringPiston rod

The invention provides a positioning device for a dredging ship, which can solve the problems of poor positioning effect and poor stability of the positioning mechanism of the existing dredging ship. The positioning column on the hull is characterized in that: an oil cylinder is installed on the hull, the front end of the piston rod of the oil cylinder is fixedly connected with a connecting key, and the positioning column is provided with a keyway matching the connecting key, so The connection key is inserted into the key groove and locked by a locking pin inserted on the connection key to connect the oil cylinder and the positioning column.

Owner:WUXI TONGCHUANG FIBERGLASS BOAT FACTORY

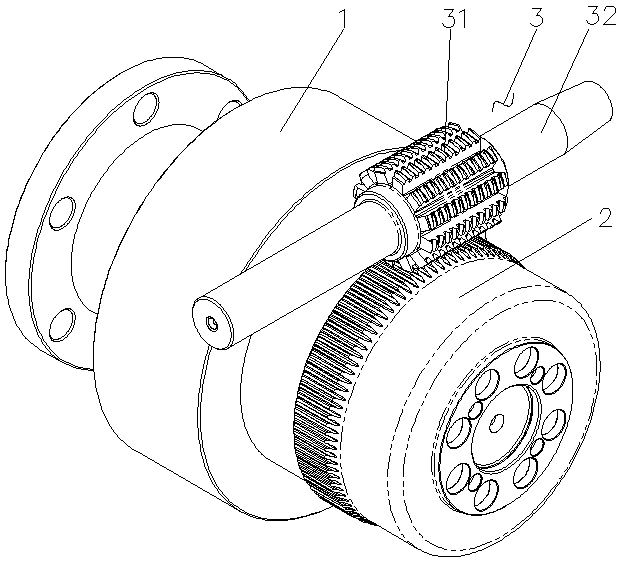

Hobbing tool of harmonic reducer flexible wheel

PendingCN109794654AImprove gear hobbing accuracyGood positioning effectGear-cutting machinesGear teethEngineeringHarmonic

The invention discloses a hobbing tool of a harmonic reducer flexible wheel. The hobbing tool comprises a hydraulic expansion tool installed on a gear hobbing machine, an expansion part is arranged onthe front part of the hydraulic expansion tool, a harmonic reducer flexible wheel body sleeves the expansion part, hydraulic oil is introduced into the hydraulic expansion tool to make the expansionpart tightly expand theharmonic reducer flexible wheel body, a hobbing cutter is arranged on the upper part of the harmonic reducer flexible wheel body, and the hobbing part of the hobbing cutter is located on the upper part of the harmonic reducer flexible wheel body and conducts hobbing. In the way, according to the hobbing tool of the harmonic reducer flexible wheel, the hobbing accuracy can beimproved, the positioning effect is good, the structure is simple, and use is convenient.

Owner:WUXI HENGYITONG MACHINERY CO LTD

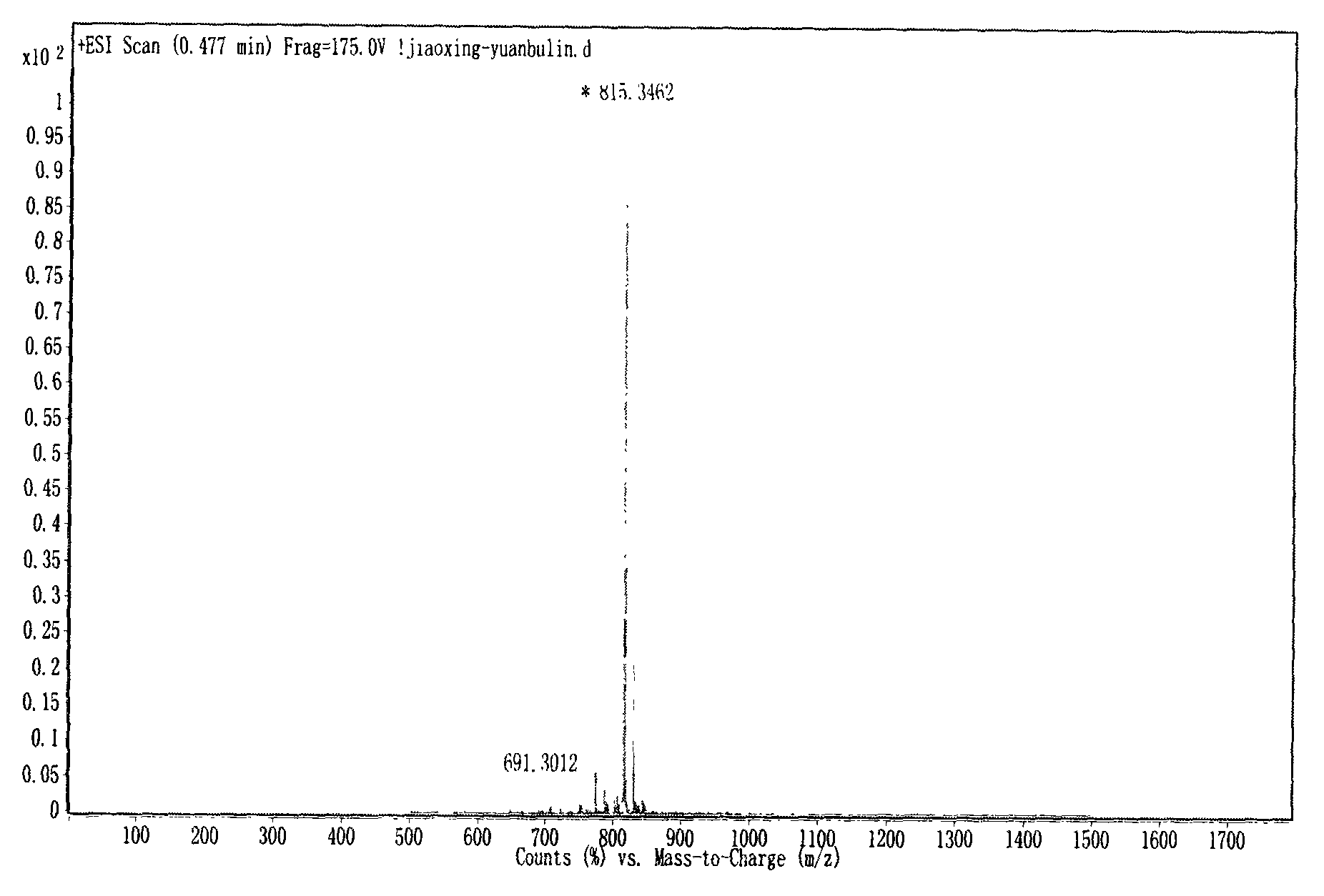

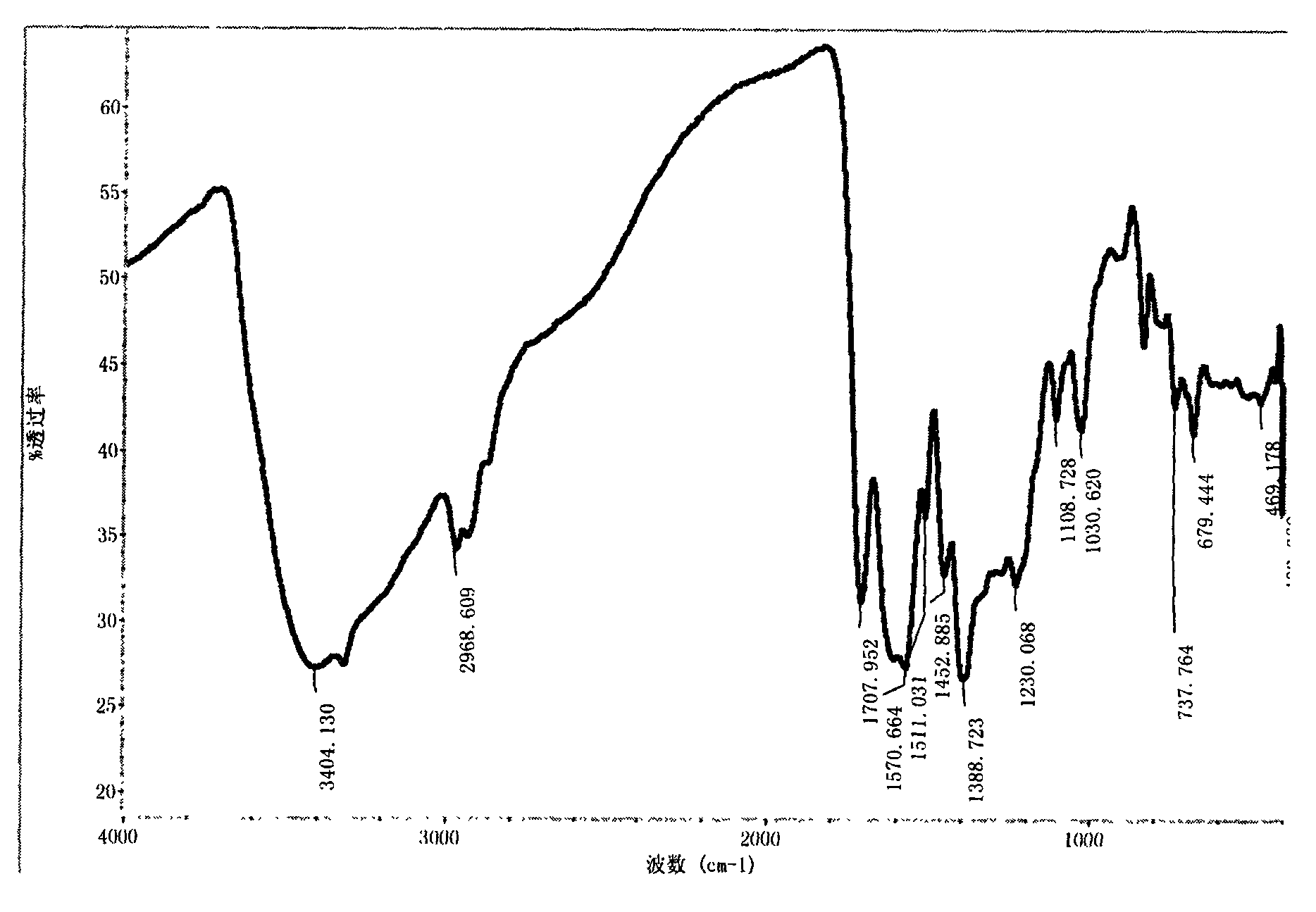

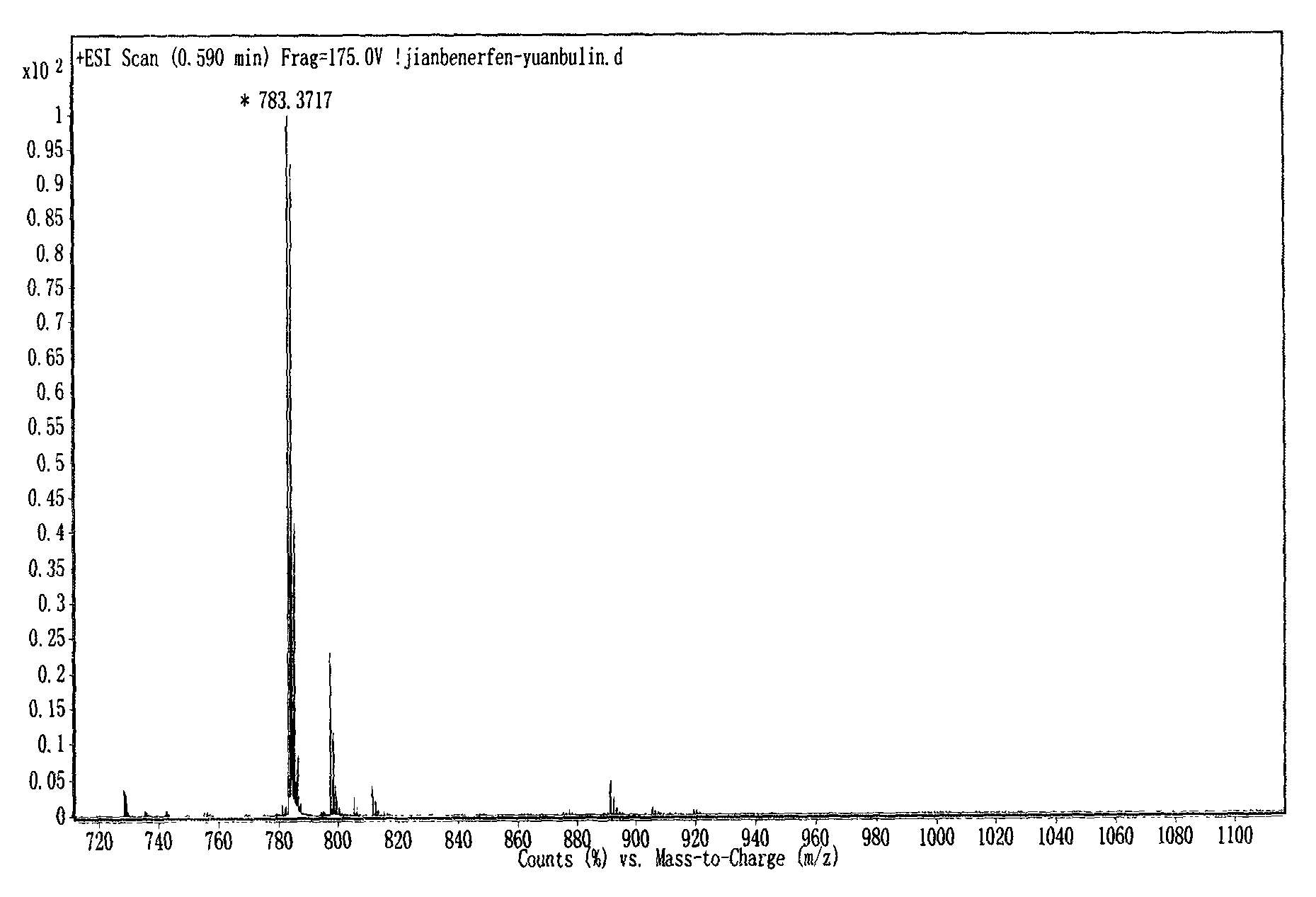

Novel protoporphyrin derivative and preparation method thereof

The invention discloses a novel protoporphyrin derivative and a preparation method thereof. The novel protoporphyrin derivative has a structure represented as follows. The novel protoporphyrin derivative has a good in-vivo orientation effect and a good biological utilization degree, can be used in research and development of anti-oxidation drugs. The preparation method is simple, is easy to operate, is free of a catalyst, is green and environmental-protective, is suitable for industrial production and is wide in application prospect.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com