Production process method of infrared cut-off filters

A production process, infrared cut-off technology, applied in the direction of filter, glass production, manufacturing tools, etc., can solve the problems of low production efficiency, easy to appear scratches or damage, easy to damage, etc., and achieve the effect of good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

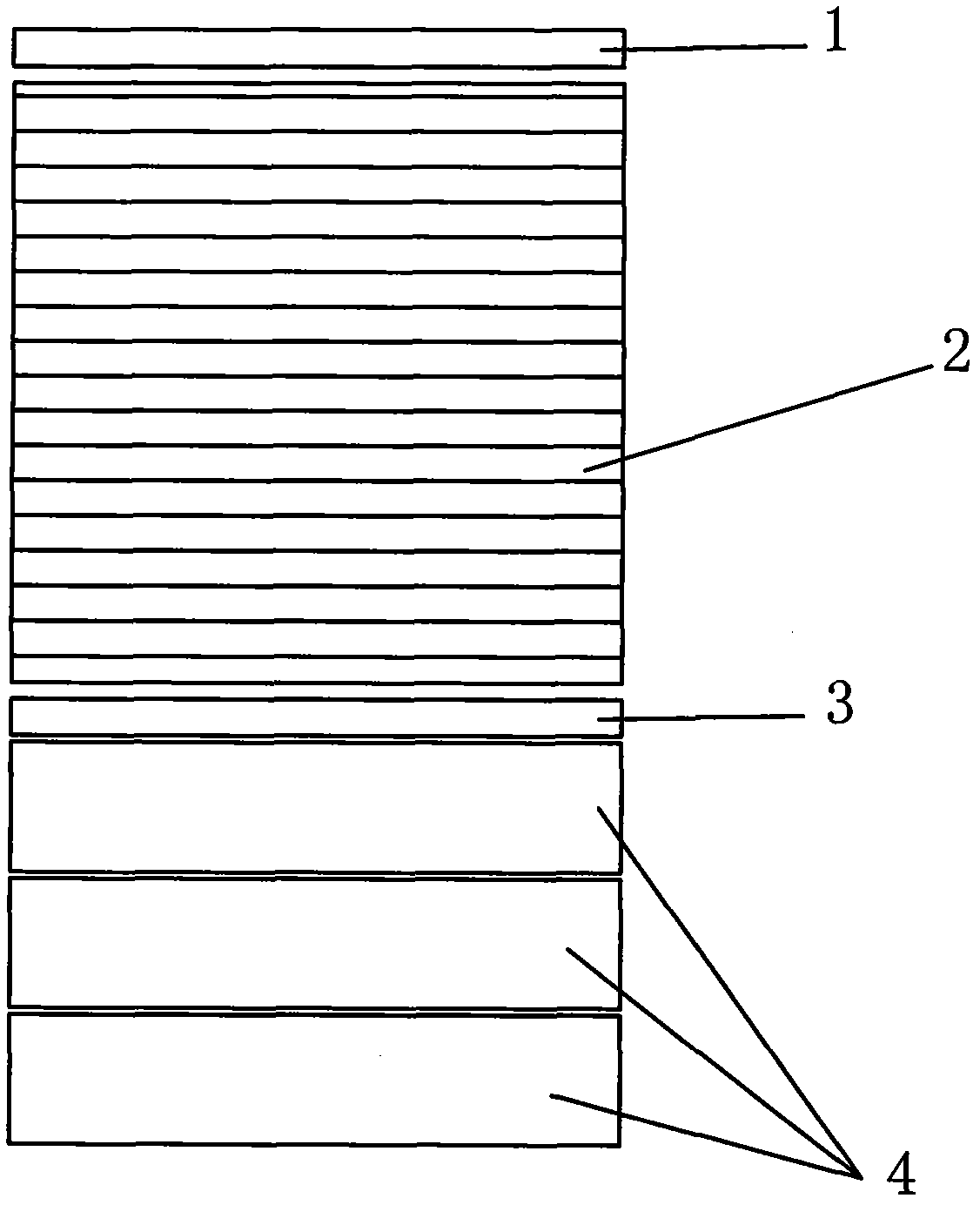

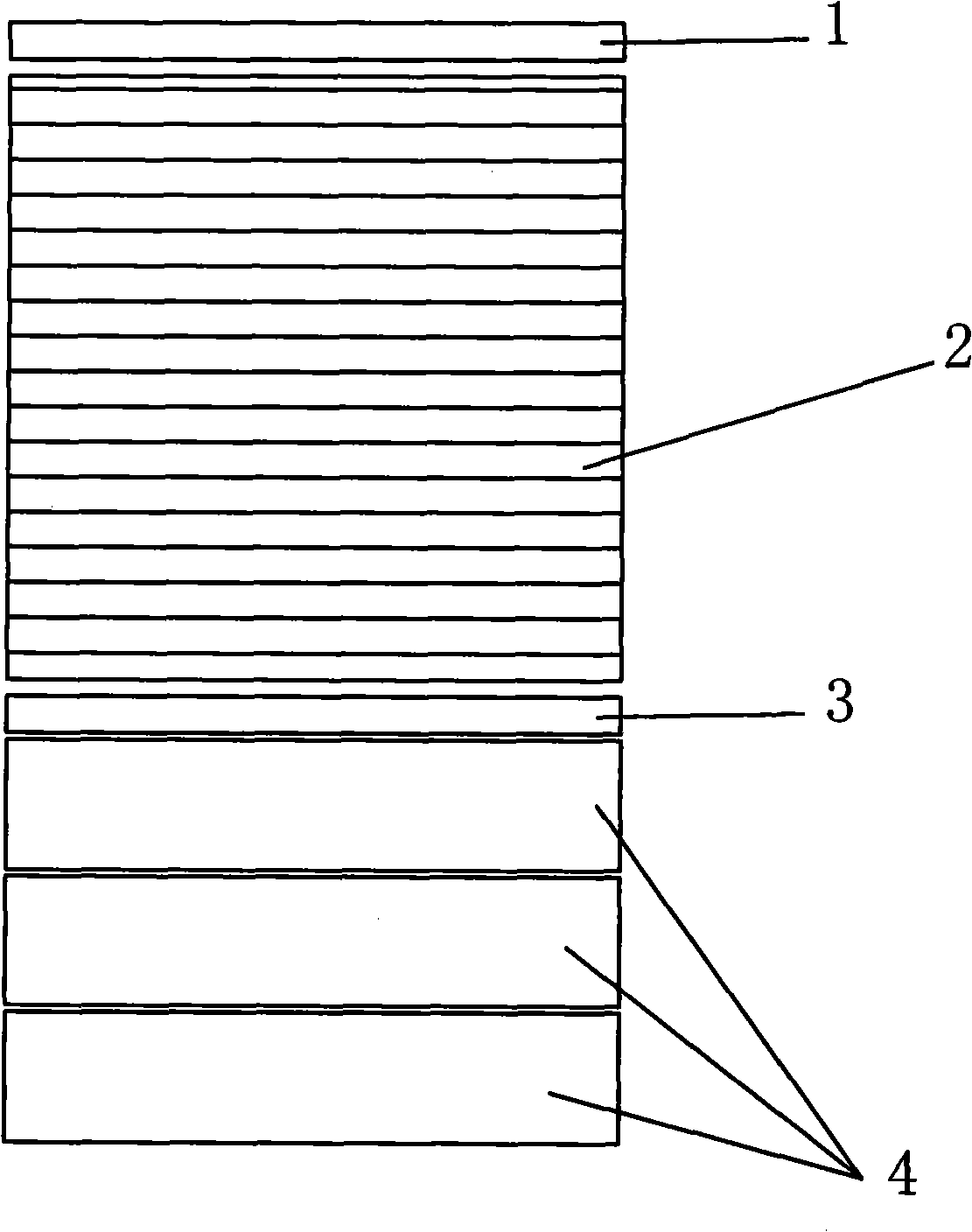

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The production process method of the infrared cut-off filter of the present invention comprises the following steps: 1) glass sheet coating;

[0023] 2) glue the multi-layer glass sheets together;

[0024] 3) Cutting the multilayer glass sheets glued together;

[0025] 4) rounding the multi-layer glass sheets;

[0026] 5) Foamed glass sheets after coating;

[0027] 6) Cleaning of glass sheets after coating;

[0028] 7) The glass sheet after coating is dried;

[0029] 8) Put the cut lenses into the injection molding board for packaging,

[0030] In the step 2), yellow wax is used for gluing between the glass sheets. It has been verified by experiments that the gluing effect of yellow wax with a concentration of 8:1 is the best. Heat the yellow wax to 118°C-120°C, put the jig into the yellow wax, manually move the glass vertically in the yellow wax, after a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com