Spoke air hole machining mold

A technology for processing molds and spokes, which is applied in the field of mechanical processing, can solve the problems of large punch force, deformation of spokes, wear of spokes, etc., and achieve the effects of small moving distance, avoiding wear and tear, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

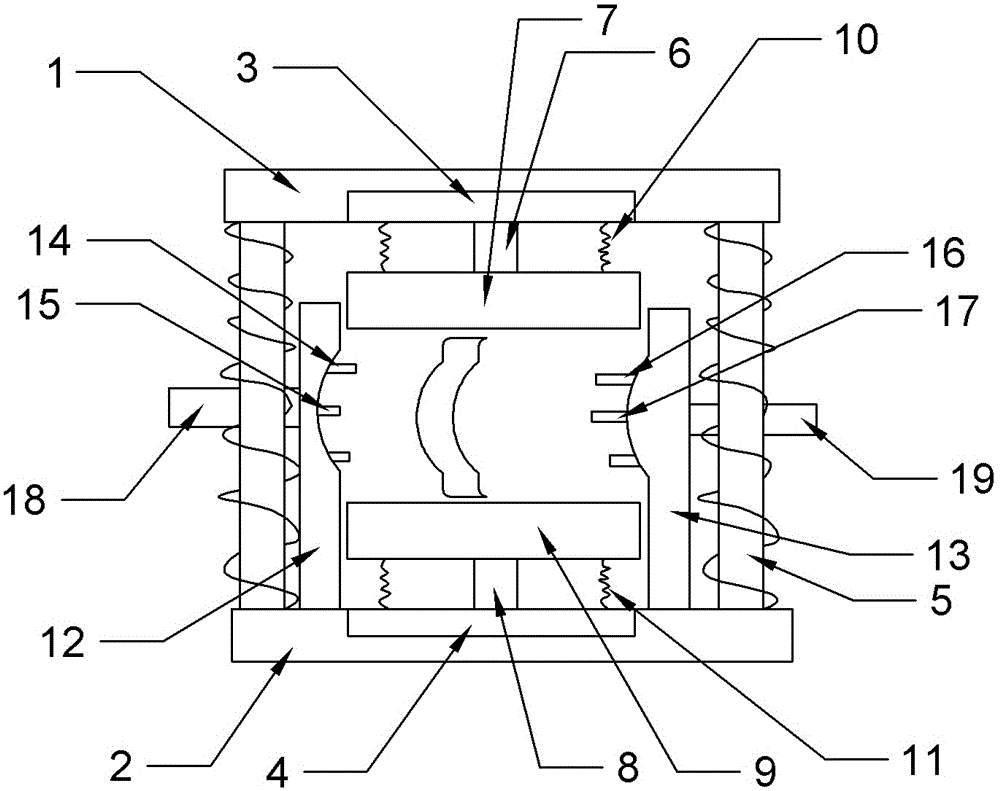

[0017] Such as figure 1 As shown, a spoke air hole processing mold includes an upper mold base 1, a lower mold base 2, an upper mold 3, a lower mold 4 and a guide column 5 for stamping, and the upper mold base 1 is located above the lower mold base 2, The upper mold 3 is fixedly connected with the depression on the lower end surface of the upper mold base 1, the lower mold 4 is fixedly connected with the depression on the upper end surface of the lower mold base 2, the guide columns 5 are located on both sides of the lower mold base 2, and the upper mold 3 is provided with a The guide hole that guide post 5 cooperates, and the guide post 5 on both sides is covered with stage clip above, is used for the guide of punching. The lower end of the upper die 3 is provided with an upper punch 6, and the upper punch 6 passes through the first elastic plate 7 positioned below the upper die 3, and the upper end of the lower die 4 is provided with a lower punch 8, and the lower punch 8 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com