Assembly method of positioning chock for ensuring gap at root parts butt jointing tubes in use for welding

A technology of root clearance and butt joints, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of base material damage on both sides of the groove, insufficient positioning rigidity, and difficulty in ensuring assembly clearance, etc., to achieve Easy operation for fixing removal, improved welding quality, and remarkable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The assembly method for ensuring the root clearance of pipe butt joints with positioning plugs for welding, including:

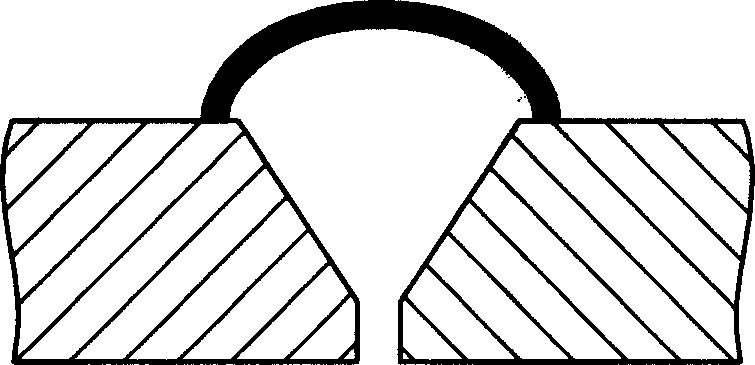

[0031] According to the pipe wall thickness δ=16mm, U-shaped groove can be used according to δ>15mm in Table 1 (see Figure 5 ), the joints of the two pipes are respectively processed into U-shaped grooves 1, the U-shaped groove 1 groove face angle β is 16°, and the root blunt edge P is 2.2mm;

[0032] The pipe is made of stainless steel, and the same material as the pipe is used to process the positioning plug 2 with the same size as the cross-section of the U-shaped groove 1;

[0033] According to the larger diameter of the pipe, four positioning plugs 2 are used for positioning, and the four positioning plugs 2 are arranged along the U-shaped bevel 1 of the pipe circumference in quarters, and the positioning plugs 2 are connected with the U-shaped grooves of the two pipe joints. The two sides of the groove 1 are fixed by argon tungsten arc welding...

Embodiment 2

[0036] The assembly method for ensuring the root clearance of pipe butt joints with positioning plugs for welding, including:

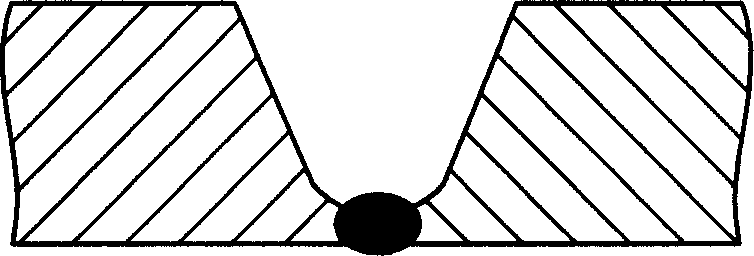

[0037] According to the pipe wall thickness δ=10mm, V-shaped groove can be used according to 3≤δ≤15m in Table 1 (see Figure 6 ), respectively process V-shaped grooves 4 at the butt joints of the two pipes, the included angle of the V-shaped grooves 4 is 60°, and the blunt edge P of the root is 1mm;

[0038] The pipe is made of stainless steel, and the same material stainless steel is used to process the positioning plug 5 with the same size as the cross-section of the V-shaped groove 4;

[0039] According to the small diameter of the pipe, three positioning plugs 5 are used for positioning, and the three positioning plugs 5 are arranged along the V-shaped bevel 4 of the pipe circle in three equal positions, and the positioning plugs 5 are connected with the outer circles of the two pipe joints. It is fixed by argon tungsten arc welding spot welding,...

Embodiment 3

[0042] The assembly method for welding the positioning plug to ensure the root gap of the pipe butt joint, including:

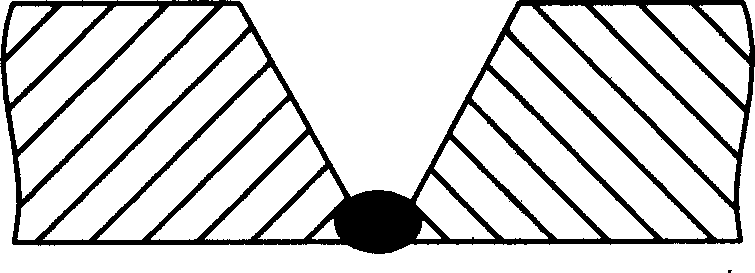

[0043] According to the pipe wall thickness δ=2.5mm, I-shaped groove can be used according to δ Figure 7 ), respectively process I-shaped grooves 7 at the butt joints of the two pipes;

[0044] The pipe material is copper-nickel alloy, and the same material copper-nickel alloy is used to process the positioning plug 8 with the same size as the section of the I-shaped groove 7;

[0045] According to the small diameter of the pipe, two positioning plugs 8 are used for positioning. Argon tungsten arc welding is fixed by spot welding, and the spot welding fixed weld seam 9 is 10mm long, ensuring that the root gap b=2mm meets the requirements of the process b=3±1mm;

[0046] Manual argon tungsten arc welding is used, starting from one point in order to weld the bottom weld seam, and welding to the positioning plug 8, and the spot welding fixed weld seam 9 at this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com