PCB back-drilling cover plate and preparation method thereof

A cover plate and back-drilling technology, applied in chemical instruments and methods, printed circuit manufacturing, other household appliances, etc., can solve the problems of high production cost of PCB back-drilling cover plates, poor positioning effect drilling accuracy, etc., and reduce drilling costs. Needle wear, good drilling depth control accuracy, easy drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

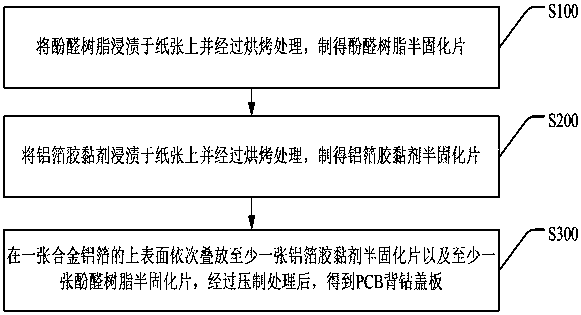

Method used

Image

Examples

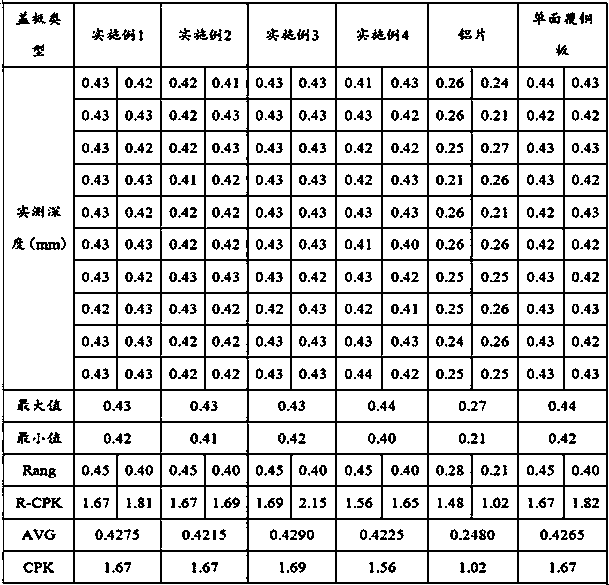

Embodiment 1

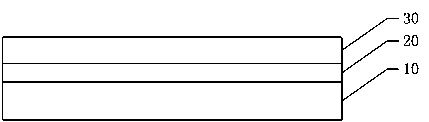

[0041] Take two phenolic prepregs, one impregnated polyaluminum foil adhesive prepreg and one single-sided roughened aluminum foil, press at 160°C and 20-25MPa pressure for 1 hour to obtain a single-sided aluminum foil-clad phenolic cover plate, phenolic resin insulation The thickness of the dielectric layer is 0.353mm, the thickness of the aluminum foil adhesive medium is 0.130mm, the thickness of the aluminum foil is 18μm, and the total thickness of the cover plate is 0.501mm.

Embodiment 2

[0043] Take a piece of phenolic prepreg, a piece of prepreg impregnated with aluminum foil adhesive, and a piece of aluminum foil with one-sided roughening treatment, and press it at a high temperature of 160°C and a pressure of 20-25MPa for 1 hour to obtain a single-sided aluminum foil-clad phenolic cover plate, phenolic resin insulation medium The thickness of the layer is 0.156mm, the thickness of the aluminum foil adhesive medium is 0.130mm, the thickness of the aluminum foil is 18μm, and the total thickness of the cover plate is 0.304mm.

Embodiment 3

[0045] Take five phenolic prepregs, one impregnated aluminum foil adhesive prepreg and one single-side roughened aluminum foil, press at 160°C and 20-25MPa pressure for 1 hour to obtain a single-sided aluminum foil-clad phenolic cover plate, phenolic resin insulation medium The thickness of the layer is 0.655mm, the thickness of the aluminum foil adhesive medium is 0.130mm, the thickness of the aluminum foil is 18μm, and the total thickness of the cover plate is 0.803mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com