Preparation method of Ge-Sb-Se chalcogenide tapered fiber of different taper waists

A technology of ge-sb-se and tapered optical fiber, which is applied in the direction of cladding optical fiber, glass optical fiber, glass manufacturing equipment, etc., can solve the constraints of chalcogenide glass tapered optical fiber preparation efficiency and quality, volatile gas damage, and low mechanical strength and other problems, to achieve the effect of fine diameter, high nonlinear coefficient and good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: with Ge 15 Sb 22.5 Se 62.5 Taking the preparation of chalcogenide tapered optical fiber as an example, the preparation method includes the following steps:

[0029] 1) A columnar Ge with a size of Φ15 mm*70 mm wrapped with polyethersulfone resin on the surface 15 Sb 22.5 Se 62.5 The chalcogenide glass optical fiber preform is placed on the optical fiber drawing tower, and drawn at a stable and uniform speed at 450 ℃ under the protection of an inert gas atmosphere to form Ge 15 Sb 22.5 Se 62.5 Chalcogenide glass optical fiber;

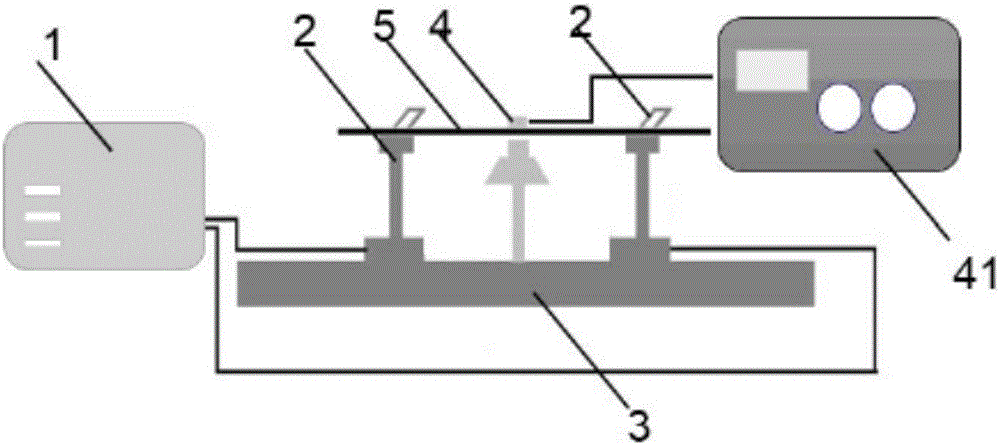

[0030] 2) Prepare a set of tapered device, such as figure 1 As shown, the taper device includes a stepper motor 1, a fixture 2, a three-dimensional translation stage 3 and a heating device 4, and the fixture 2 is used to clamp Ge 15 Sb 22.5 Se 62.5 Both ends of the chalcogenide glass optical fiber 5, the stepper motor 1 is used to control the Ge 15 Sb 22.5 Se 62.5 The tapering speed of the chalcogenide glass optical fi...

Embodiment 2

[0036] Embodiment 2: with Ge 15 Sb 20 Se 65 Taking the preparation of chalcogenide tapered optical fiber as an example, the preparation method includes the following steps:

[0037] 1) A columnar Ge with a size of Φ15 mm*70 mm wrapped with polyethersulfone resin on the surface 15 Sb 20 Se 65 The chalcogenide glass optical fiber preform is placed on an optical fiber drawing tower, and drawn at a stable and uniform speed at 420 ℃ under the protection of an inert gas atmosphere to form Ge 15 Sb 20 Se 65 Chalcogenide glass optical fiber;

[0038] 2) Prepare a set of tapered device, such as figure 1 As shown, the taper device includes a stepper motor 1, a fixture 2, a three-dimensional translation stage 3 and a heating device 4, and the fixture 2 is used to clamp Ge 15 Sb 20 Se 65 Both ends of the chalcogenide glass optical fiber 5, the stepper motor 1 is used to control the Ge 15 Sb 20 Se 65 The tapering speed of the chalcogenide glass optical fiber 5, the heating d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com