Elastic plug structure

An elastic and top-pressing technology, applied in the direction of bolts, etc., can solve the problem of low reliability of the positioning structure, and achieve the effects of good positioning effect, reliable positioning and high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

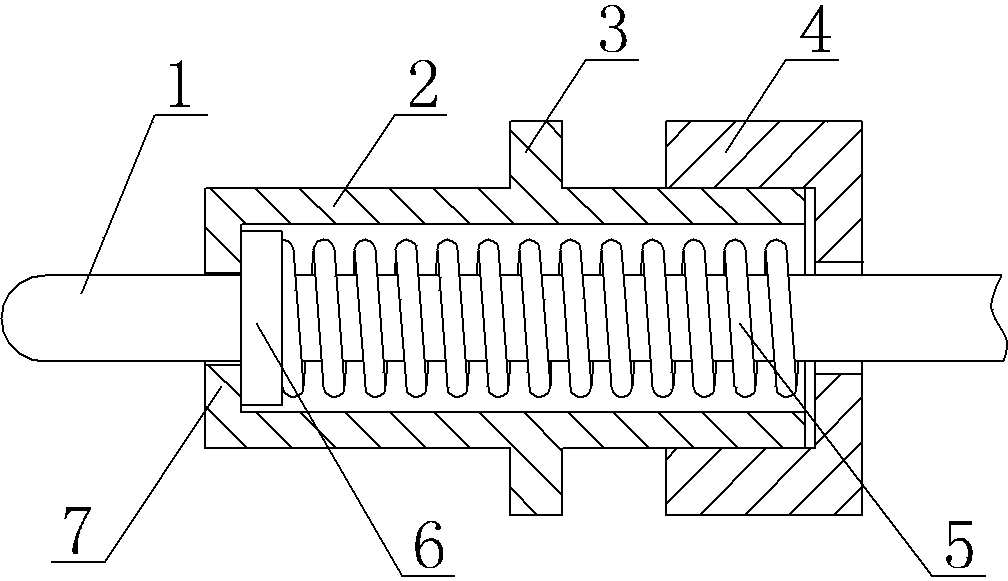

[0008] An embodiment of an elastic plug structure, in figure 1 Among them, the fixed sleeve body 2 is inserted with a telescopic plug 1, and the two ends of the telescopic plug 1 protrude from the two ends of the fixed sleeve body 2 respectively. The front end of the fixed sleeve body 2 has an inward-turned retaining edge 7, and the outer peripheral surface of the telescopic plug 1 is protruded with a collar 6, and the collar 6 is press-fitted with the retaining edge 7. A locking nut 4 is provided, and the rear end of the locking nut 4 has a turning edge, and the turning edge is press-fitted with the rear end surface of the fixed sleeve body 2 . The retractable head 1 is sleeved with a return spring 5, the front end of the return spring 5 presses on the collar 6, and the rear end of the return spring 5 presses on the turning edge.

[0009] A fixed convex ring 3 is arranged on the outer peripheral surface of the fixed sleeve body 2 , and there is a distance between the fixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com