Membrane washing box

A technology of film washing and box body, applied in the field of film washing box, can solve the problem of not being able to directly observe the motion state of the film, and achieve the effect of good positioning effect and good shading effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

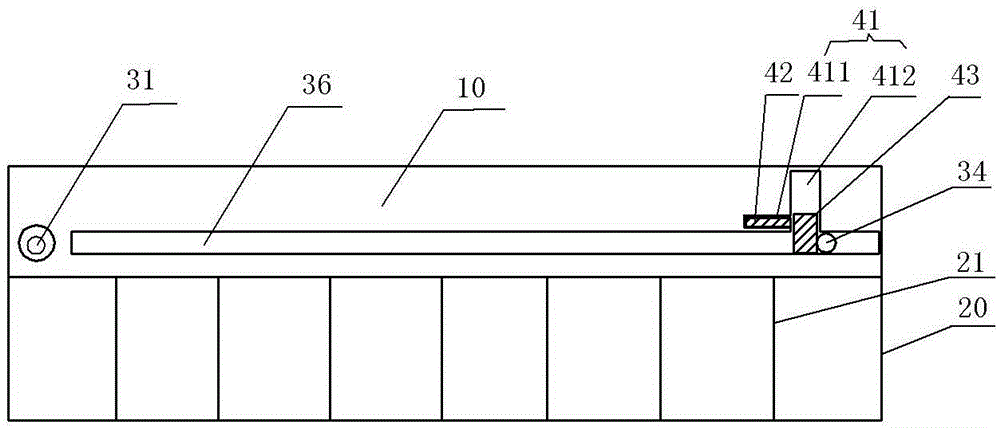

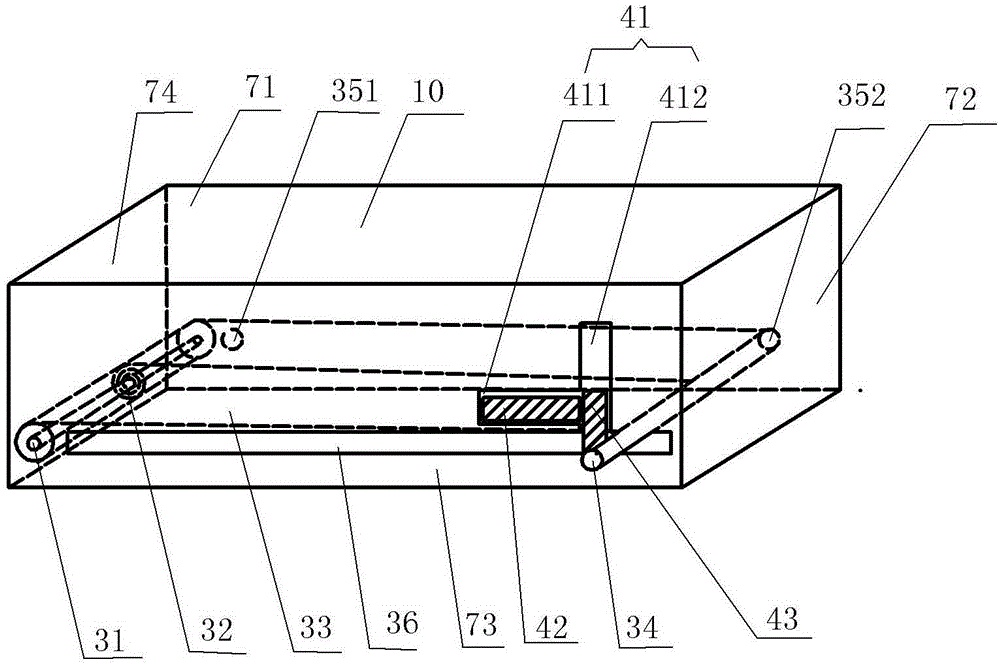

[0024] Embodiment one is basically as attached figure 1 And attached figure 2 Shown:

[0025] The film washing box includes a transparent box cover 10, a light-shielding box body 20, a light-shielding partition 21 and a water-shielding mechanism; the partition 21 is vertically fixed on the bottom surface of the box body 20; the water-shielding mechanism includes a roller 31 and a clockwork spring 32 , light-shielding waterproof membrane 33 and positioning rod 34; Lid 10 is cuboid shape, and the side wall of lid 10 is divided into successively connected A face, B face, C face and D face; Positioning holes 351 and light-shielding positioning holes 352, the initial positioning hole 351 is located at one end near the D surface, and the light-shielding positioning hole 352 is located at an end close to the B surface; the C surface is provided with a sliding groove 36, and the two ends of the sliding groove 36 are respectively connected with The D surface and the B surface are co...

Embodiment 2

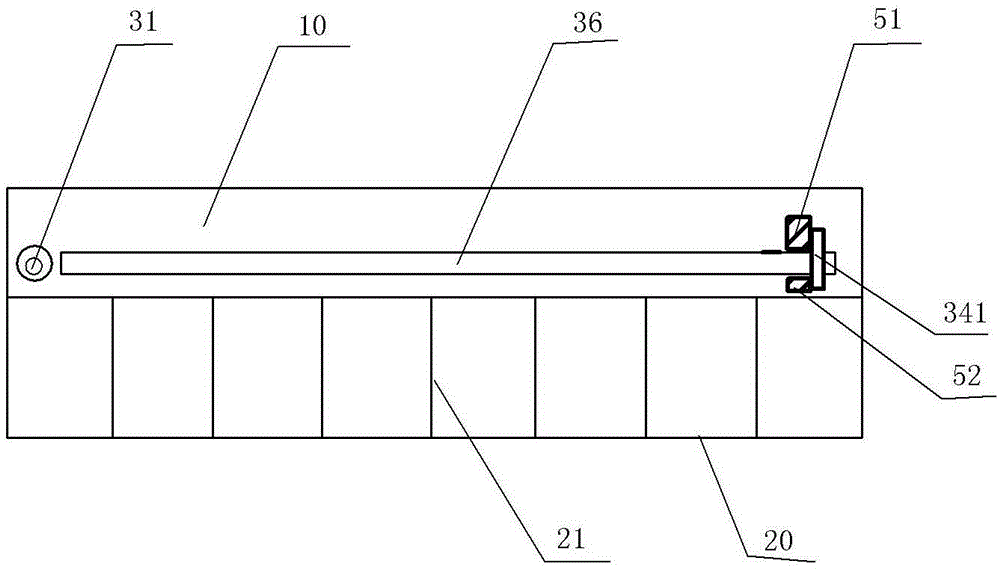

[0027] Embodiment two is basically as attached image 3 Shown:

[0028] The difference between this embodiment and Embodiment 1 is that the box cover 10 does not have a ╣╣-shaped chute 41, a horizontal slide bar 42 and a vertical slide bar 43, but an upper stopper 51 and a lower stopper 52 are provided; Block 51, lower block 52 and lid 10 are integrally formed; Upper block 51 is above slide groove 36 and is opposite to light-shielding positioning hole 352; Lower block 52 is below sliding groove 36 and is opposite to light-shielding positioning hole 352; The rod 34 is T-shaped and includes a handle 341 and a slide bar, and the handle 341 and the slide bar are fixedly connected.

[0029] During the pulling process of the positioning rod 34, the handle 341 is in the shape of "-". The handle 341 rotates along the rolling direction of the light-shielding waterproof film 33, and turns into a "│" shape, release the positioning rod 34, the positioning rod 34 is blocked by the upper ...

Embodiment 3

[0030] Embodiment three is basically as attached Figure 4 Shown:

[0031] The difference between this embodiment and Embodiment 1 is that the box cover 10 does not have a ╣╣-shaped chute 41, a horizontal slide bar 42 and a vertical slide bar 43, but is provided with an upper magnetic block 61, a lower magnetic block 62 and a magnetic strip 63; the upper magnetic block 61 is bonded on the slide groove 36 with glue and is opposite to the light-shielding positioning hole 352; the lower magnetic block 62 is glued to the following of the sliding groove 36 and is opposite to the light-shielding positioning hole 352; The magnetic block 61 and the lower magnetic block 62 attract each other.

[0032] In the initial state, the magnetic strip 63 is only attracted to the upper magnetic block 61 or the lower magnetic block 62 , and the magnetic strip 63 does not intersect with the sliding groove 36 . When needing shading, pull the positioning rod 34 through the upper magnetic block 61 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com