Pipe laser welding machine

A laser welding machine and welding mechanism technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor welding effect, poor welding efficiency, high content of carbon and alloy elements, and achieve good welding effect, Good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments, but the present invention is not limited to the following specific embodiments.

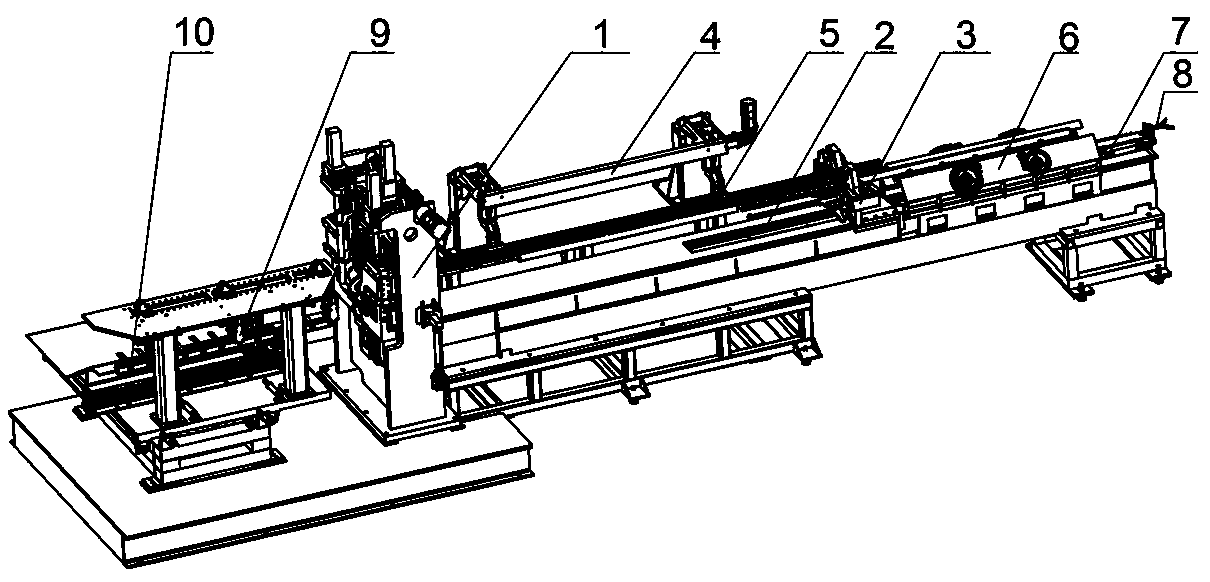

[0035] A pipe laser welding machine, including a controller, a feeding mechanism, a main engine, a material discharging mechanism, a safety protection mechanism and an auxiliary mechanism, and the main engine includes a frame 1 and a pre-positioning mechanism, a positioning mechanism and a welding mechanism arranged on the frame 1 ,in:

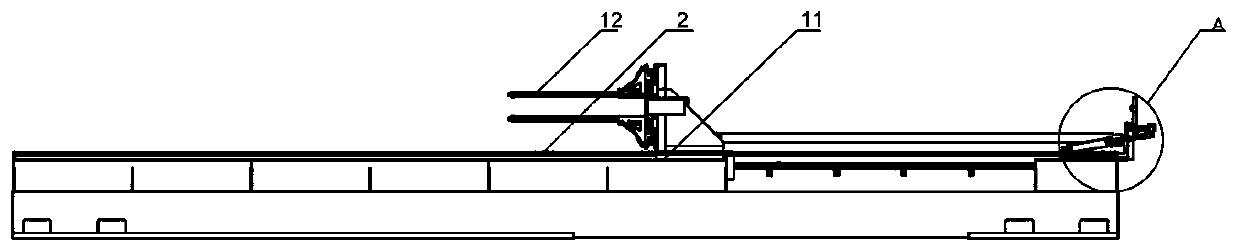

[0036] The feeding mechanism includes the feeding slide 2, the pre-feeding structure, the hanger 4, the pendant 5 and the pushing fixture 3, wherein:

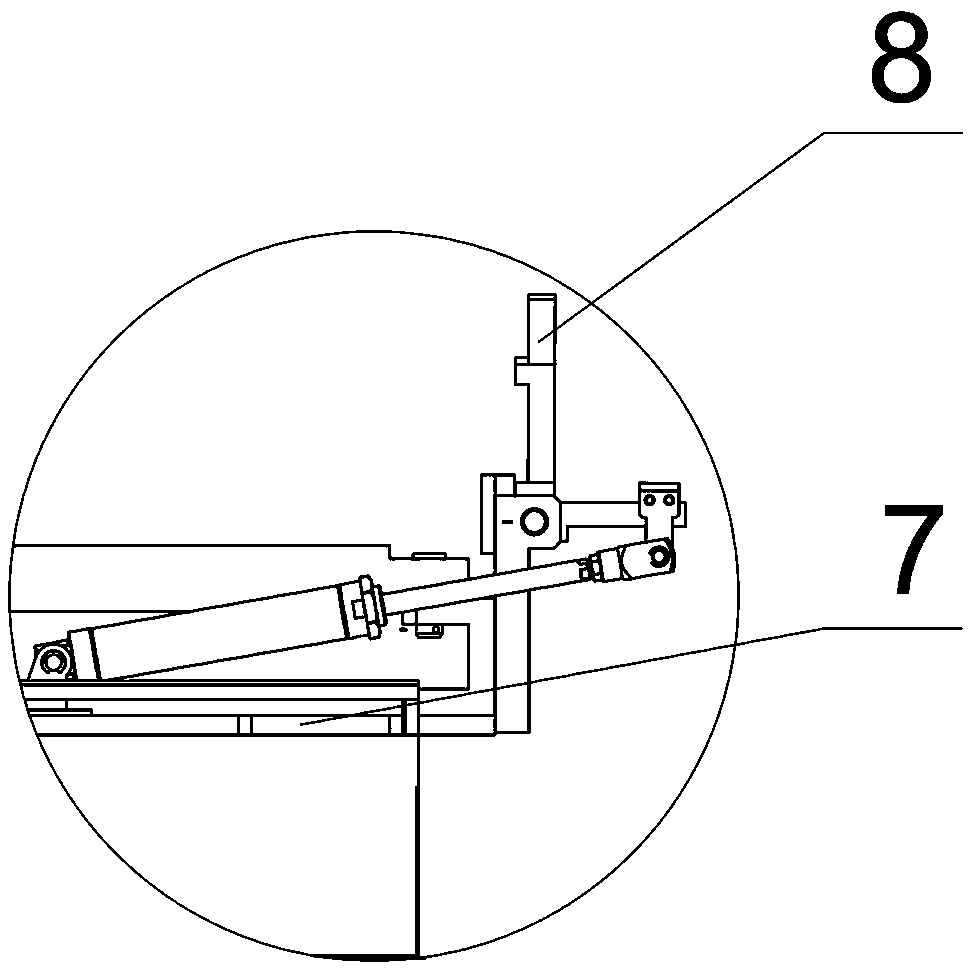

[0037] The pre-feeding structure includes a shift fork seat 7 slidingly connected on the feed slide 2, a telescopic rod, an L-shaped connecting rod, a shift fork 8 and a power mechanism. The shift fork seat 7 includes a horizontal part and a vertical part, and the L-shaped connection The rod corner position is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com