Slender and thin-walled step hole type inner-circle and outside-square structure finish machining method

A slender, stepped hole technology, applied in the field of non-ferrous metal finishing, can solve the problems of difficult honing process and difficult processing of blind holes, and achieve the effects of good positioning effect, improved machining accuracy and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

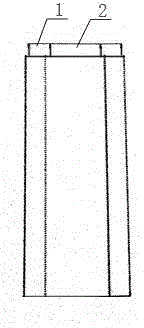

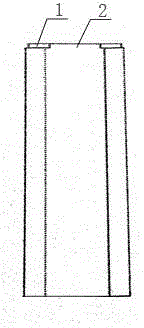

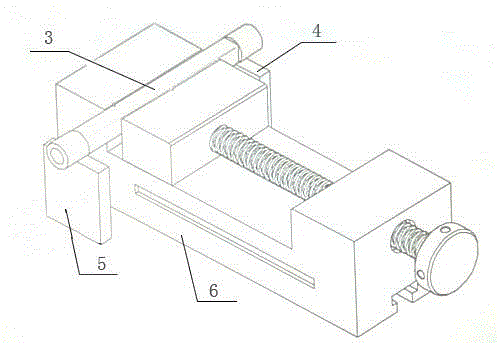

[0035] like Figure 1-Figure 4 As shown, the finishing method of the slender, thin-walled stepped hole inner circle and outer square structure, the inner hole processing is carried out according to the following steps:

[0036] The first step is to execute the rough turning process on the outer circle, and increase the margin of the outer circle by 2mm in the rough turning process;

[0037] In the second step, semi-finishing, finishing, and fine-grinding are performed sequentially on the outer circle after the first step;

[0038] The third step is to perform artificial aging treatment on the outer circle after the second step, the aging temperature is 125 degrees, and the time is 6 hours;

[0039] The fourth step is to use the honing tool to honing the inner hole;

[0040] The fifth step, the car spindle;

[0041] The sixth step, semi-finishing the outer circle;

[0042] The seventh step is to finely grind the outer circle;

[0043] Foreign processing is carried out acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com