Step-by-step projection photo-etching machine double set shifting exposure ultra-sophisticated positioning silicon chip bench system

A silicon wafer stage, projection light technology, applied in microlithography exposure equipment, photolithography process exposure devices, optics, etc., can solve the problems of system positioning accuracy, system complexity, double-stage collision, etc., and reduce adverse effects. , the effect of improving exposure efficiency and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

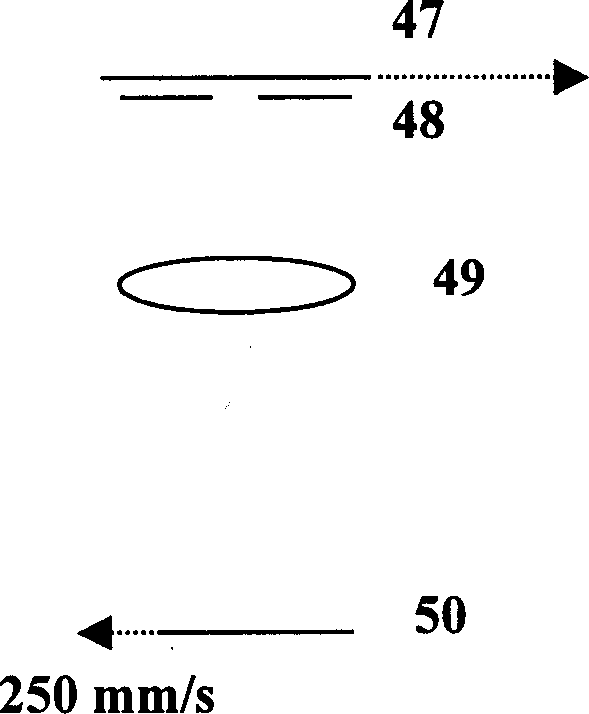

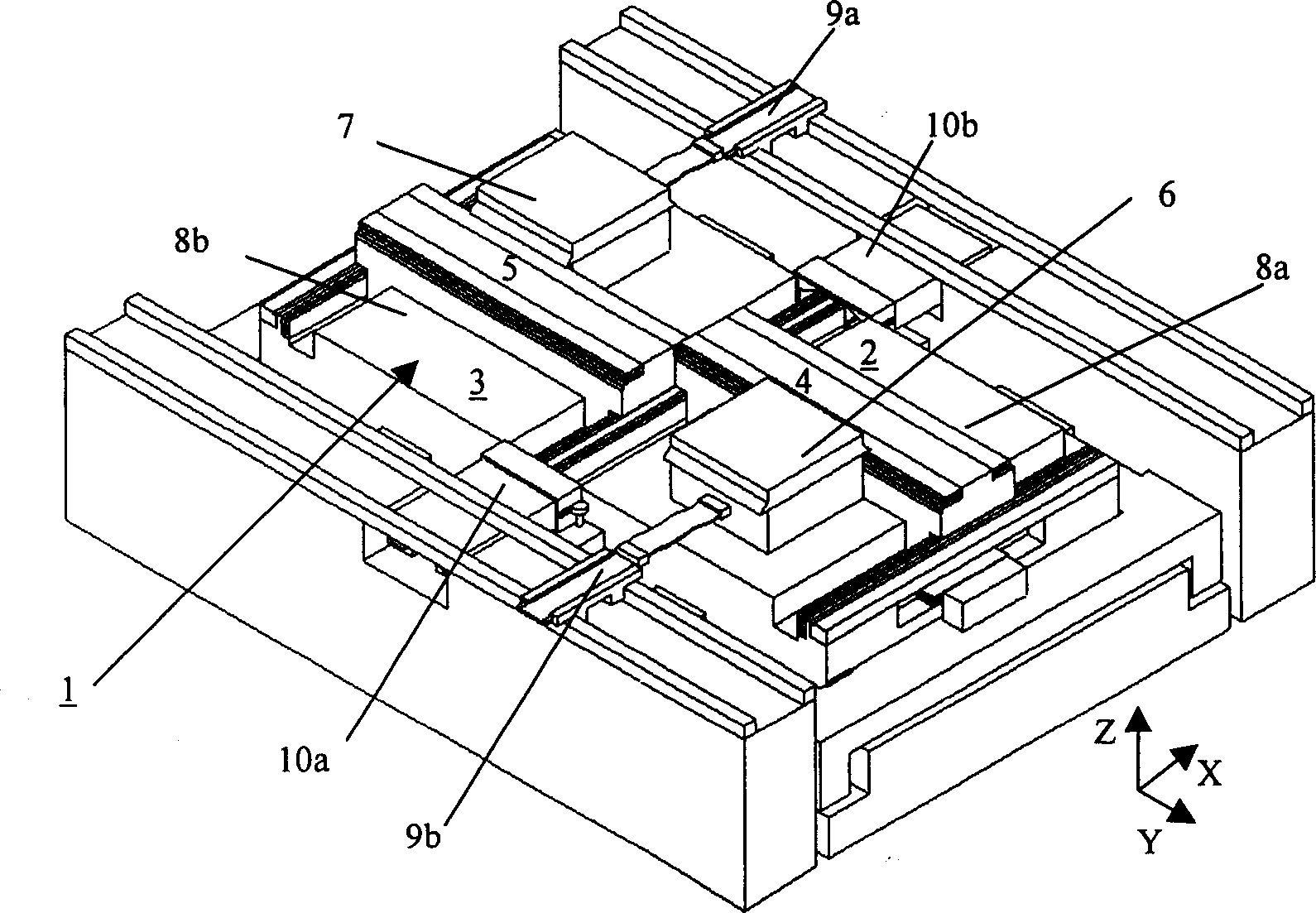

[0052] figure 2 Shows the status of the entire system at work. At this time, the double-sided buttable linear guide rails 4, 5 and the silicon wafer carrying device 6, 7 complete the set action at the exposure station and the silicon wafer pretreatment station respectively, and the bridging devices 10a, 10b are in the non-bridging position and will not Interference with the Linear Way unit. The cable tables 9a, 9b are driven by their driving devices, so that the cables on the silicon wafer carrying device keep moving synchronously with the silicon wafer carrying device.

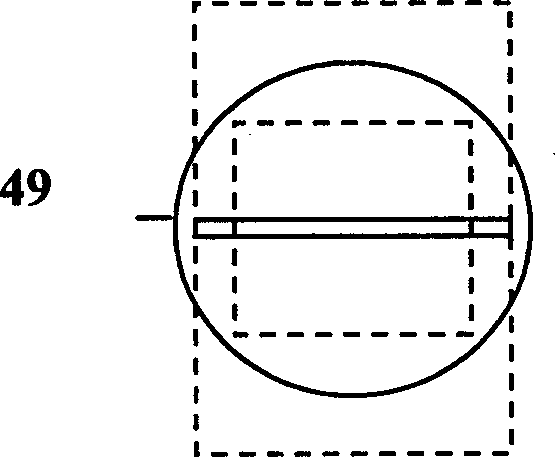

[0053] image 3 It shows the situation when the system is working in the switching state. First, the double-sided buttable linear guide units 4, 5 and the wafer carrying devices 6, 7 enter the exchange position P together. 1 ,P 2 , at this moment, the double-sided linear guide rails 4, 5 are accurately docked. Then the bridging device is driven by its driving device to move toward each other along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com