Integrative type direct-writing photo-etching method

A comprehensive, lithography technology, applied in the field of lithography, can solve the problems of long exposure time, slow processing speed and low resolution of a single wafer, and achieve the effect of improving the efficiency of exposure and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

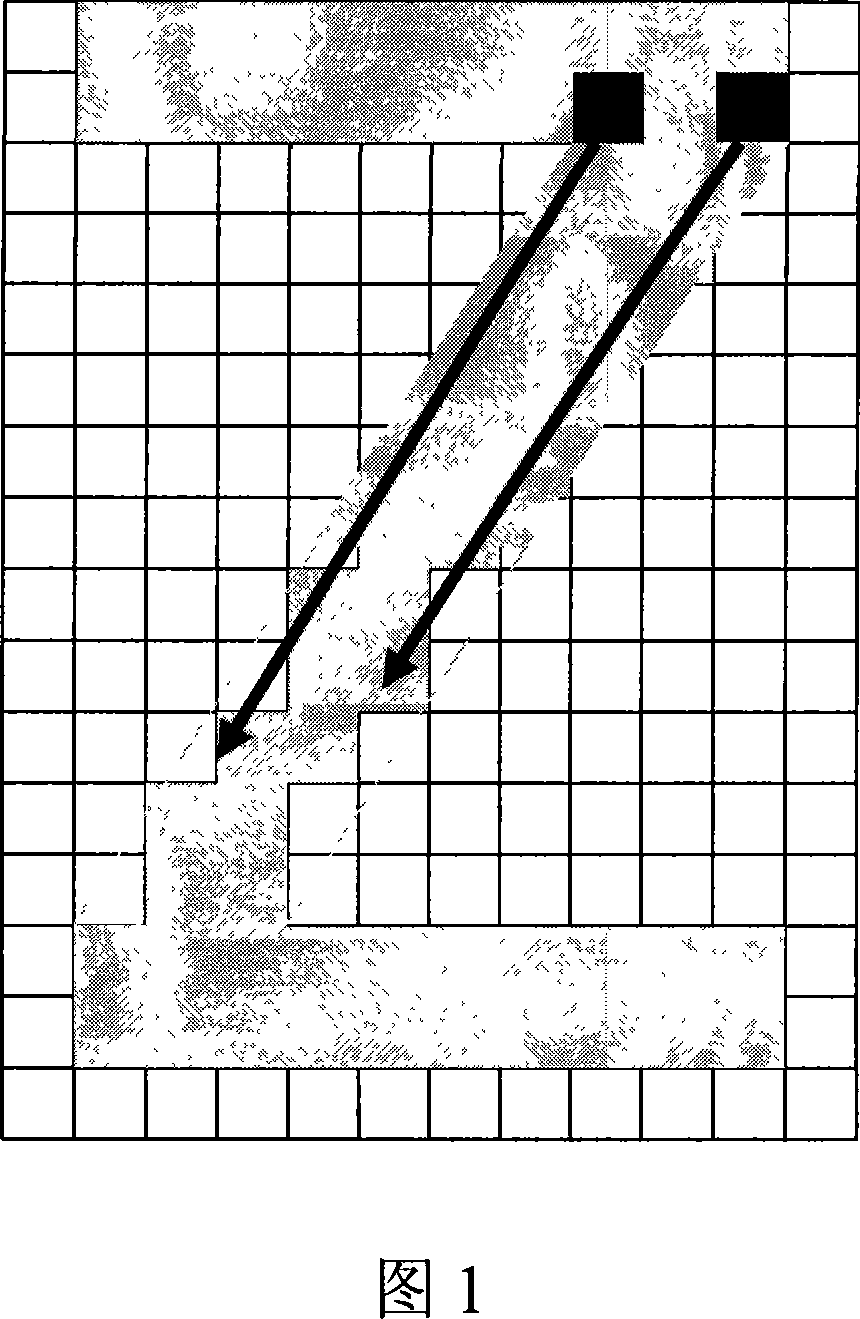

[0032] Referring to Fig. 1, adopt the method of the present invention photoetching Z word,

[0033] (1) First, generate a zigzag target exposure pattern on the photosensitive element placed on the precision mobile platform. Assuming that the spatial pattern generator has 16×12 pixels that can be transformed independently, assuming that the target zigzag pattern to be generated is located in the case of a projection lens with a certain target magnification, the size of the space corresponds to the pattern of the spatial pattern generator as shown in the figure 1(a).

[0034] (2), step-by-step direct writing lithography

[0035] In the case of the projection lens of the target magnification, carry out spatial positioning and focusing on the target exposure figure, determine the first exposure figure in the target exposure figure, as shown in Figure 1 (b), and perform exposure; obtain the target exposure figure Outside the outline, other spaces have been exposed;

[0036] (3),...

Embodiment 2

[0039] The quadrilateral is photoetched by the method of the present invention.

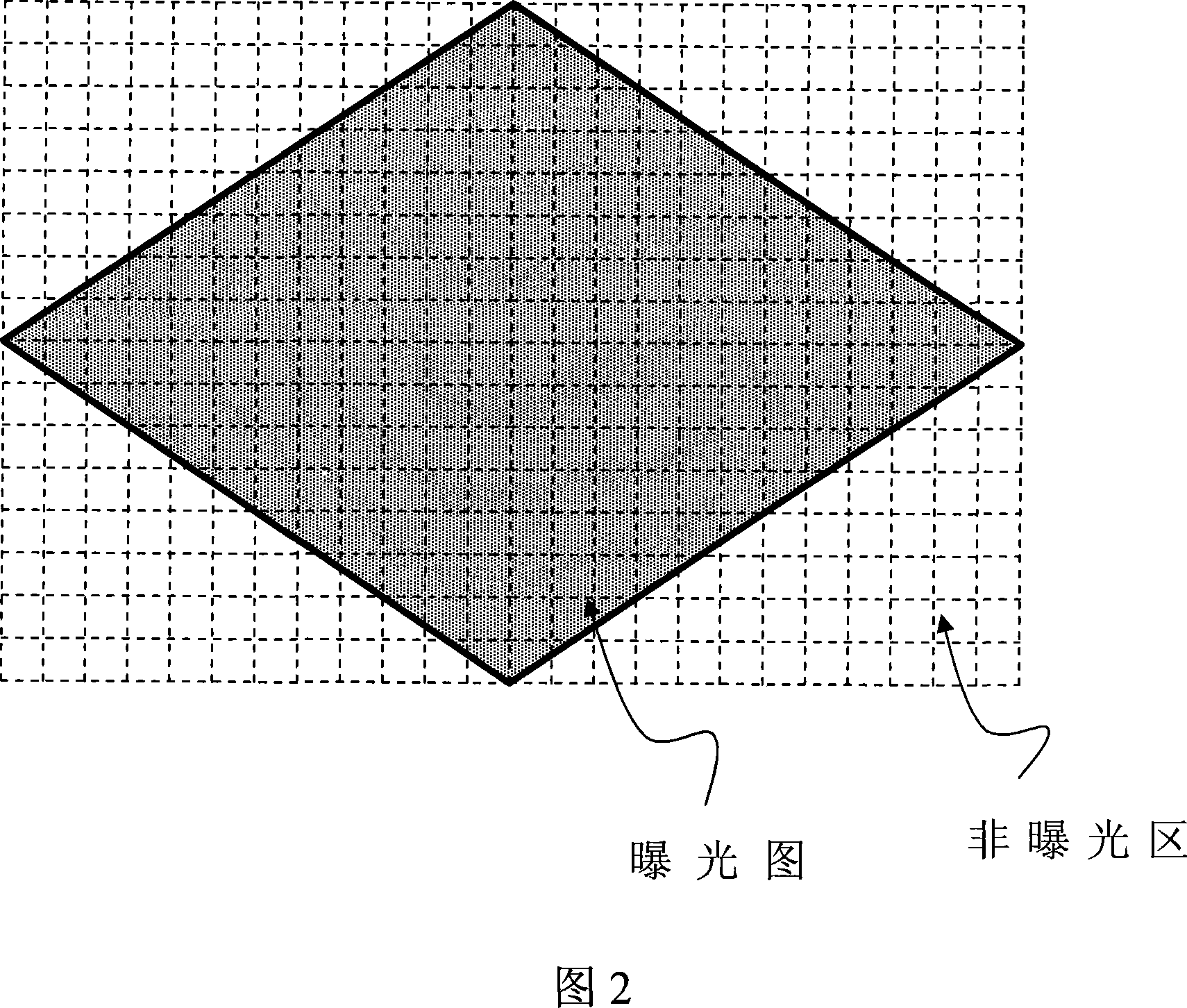

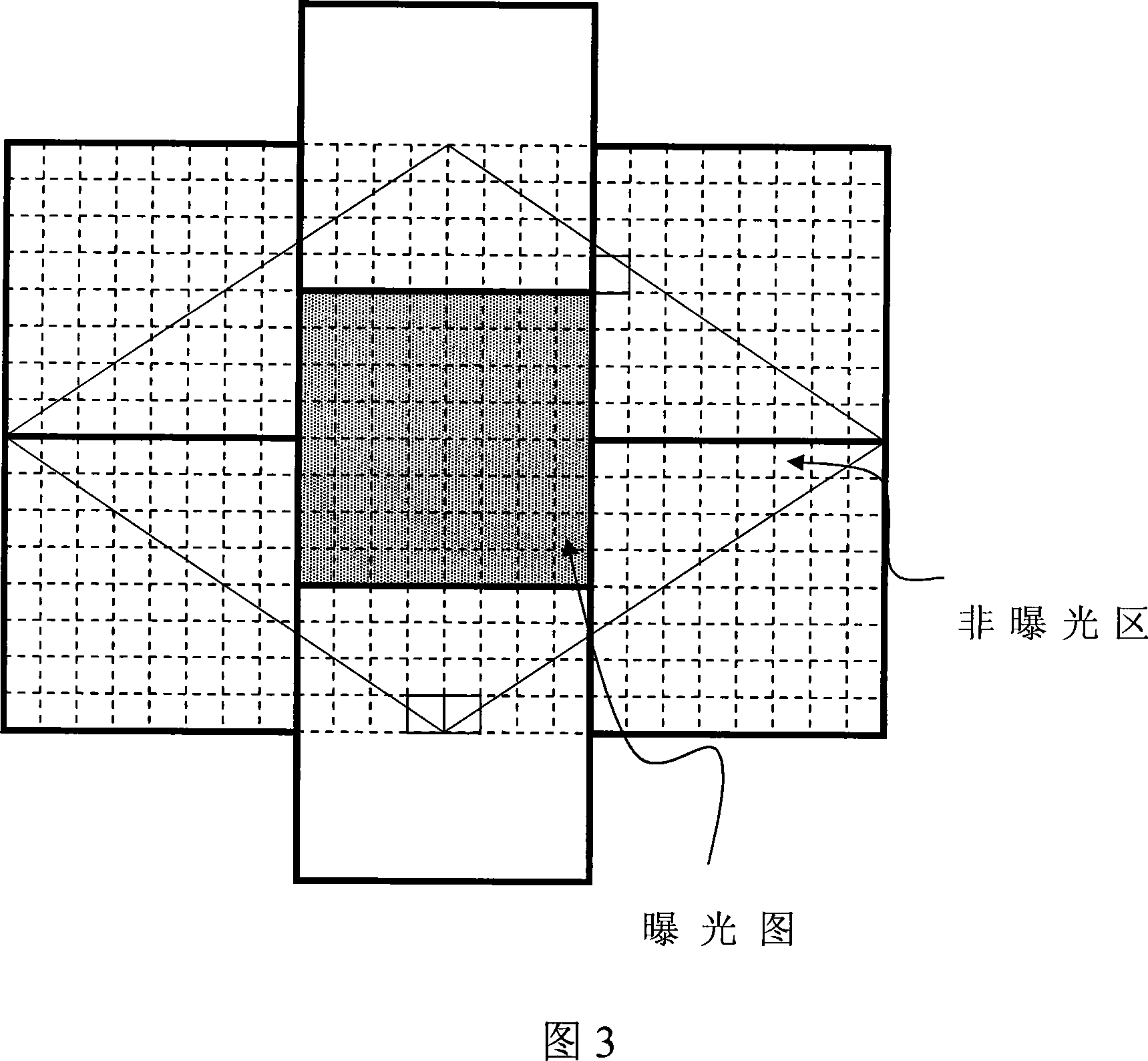

[0040] Fig. 2, Fig. 3, Fig. 4 and Fig. 5 schematically show the method of the quadrilateral exposure pattern produced by the integrated direct writing technique with step-by-step and continuous-type according to the present invention.

[0041] (1), assuming that the spatial pattern generator has 4×4 pixels that can be transformed independently, the space size of the target pattern to be produced corresponds to the pattern of the spatial pattern generator of 16×24 final resolution projections, as shown in the figure 2.

[0042] (2), step-by-step direct writing lithography

[0043] Assume further that as shown in Fig. 3, Fig. 4 and Fig. 5, there are two groups of projection lenses with the magnification of the final resolution and the magnification of one-half of the final resolution to choose from. In practice, those skilled in the art should understand that there may be two or more projection l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com