Preparation method for samarium-doped cerium oxide solid electrolyte powder

A solid electrolyte, cerium oxide technology, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, circuits, etc., can solve problems such as adverse effects of electrolyte materials, improve product uniformity and consistency, and facilitate the process flow Controlled, easily granular effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

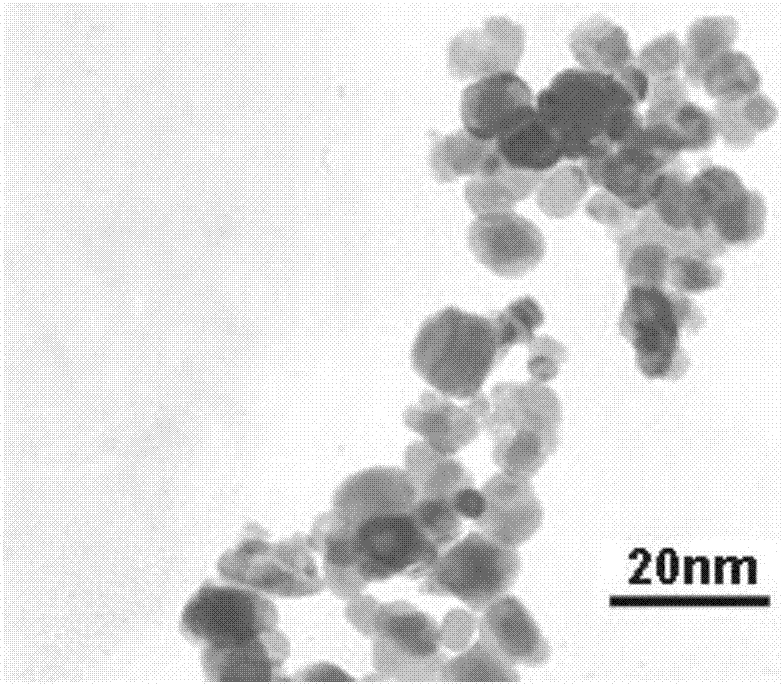

Embodiment 1

[0037] Prepare SDC powder as follows:

[0038] (1) Ce(NO 3 ) 3 ·6H 2 O is dissolved in deionized water to make a cerium nitrate solution with a concentration of 1mol / L;

[0039] (2) Sm(NO 3 ) 3 ·6H 2 O is dissolved in deionized water and is made into the samarium nitrate solution that concentration is 1mol / L;

[0040] (3) Mix cerium nitrate solution and samarium nitrate solution according to the volume ratio of 4:1, and dilute with deionized water until the sum of Ce and Sm metal ion concentrations is 0.05mol / L, to obtain A solution;

[0041] (4) dissolving ammonium carbonate with deionized water to form a 0.05mol / L ammonium carbonate solution, adding dispersant BYK180 to it, and the concentration reaches 0.2g / L to obtain solution B;

[0042] (5) Dissolve citric acid, oxalic acid and ammonium chloride into solution with deionized water, citric acid concentration 0.08g / L, oxalic acid concentration 0.2g / L, ammonium chloride concentration 0.15g / L, obtain C solution;

[00...

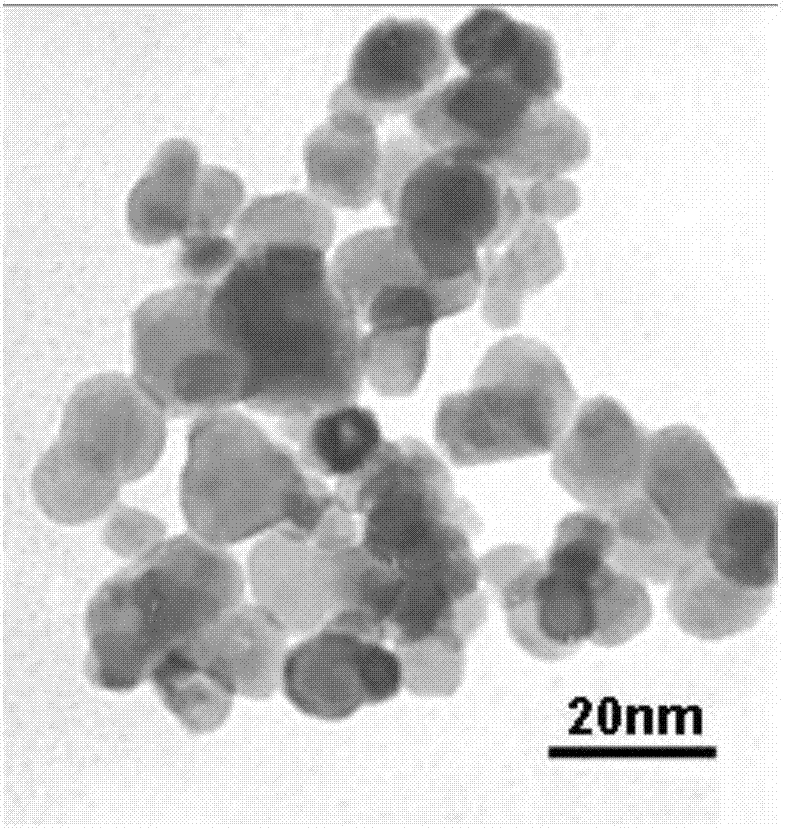

Embodiment 2

[0047] Prepare SDC powder as follows:

[0048] (1) Ce(NO 3 ) 3 ·6H 2 O is dissolved in deionized water to make a cerium nitrate solution with a concentration of 1mol / L;

[0049] (2) Sm(NO 3 ) 3 ·6H 2 O is dissolved in deionized water and is made into the samarium nitrate solution that concentration is 1mol / L;

[0050] (3) The cerium nitrate solution and the samarium nitrate solution are mixed according to the volume ratio of 4:1, and diluted with deionized water until the concentration of Ce and Sm metal ions is 0.05mol / L to obtain the A solution;

[0051] (4) Ammonium carbonate was dissolved in deionized water to form a 0.05mol / L ammonium carbonate solution, and the dispersant BYK182 was added therein until the concentration reached 0.25g / L to obtain solution B;

[0052] (5) Dissolve citric acid, oxalic acid and ammonium chloride into solution with deionized water, citric acid concentration 0.1g / L, oxalic acid concentration 0.25g / L, ammonium chloride concentration 0.16...

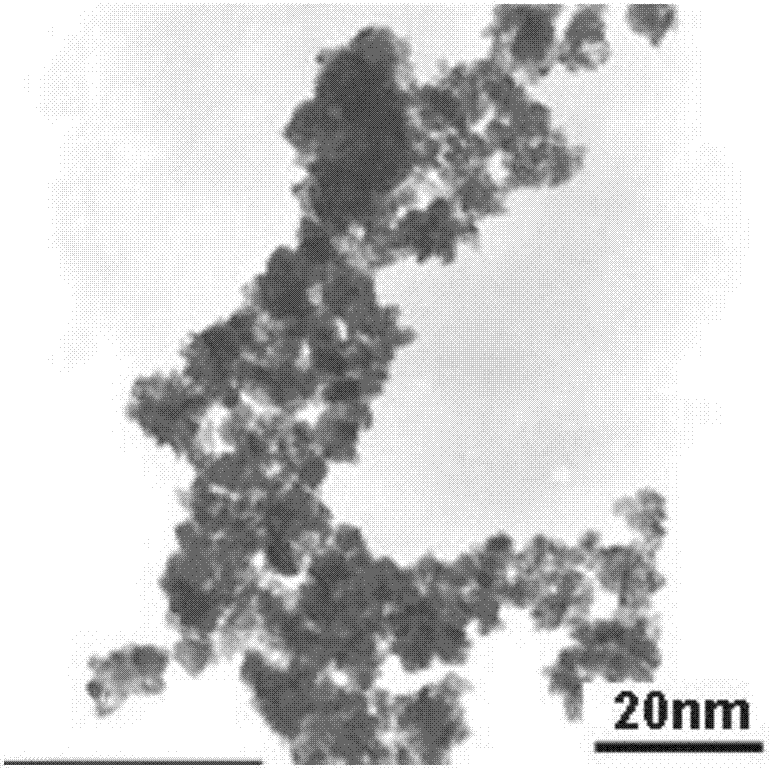

Embodiment 3

[0057] Prepare SDC powder as follows:

[0058] (1) Ce(NO 3 ) 3 ·6H 2 O is dissolved in deionized water to make a cerium nitrate solution with a concentration of 1mol / L;

[0059] (2) Sm(NO 3 ) 3 ·6H 2 O is dissolved in deionized water and is made into the samarium nitrate solution that concentration is 1mol / L;

[0060] (3) Mix cerium nitrate solution and samarium nitrate solution according to the volume ratio of 4:1, and dilute with deionized water until the sum of Ce and Sm metal ion concentrations is 0.05mol / L, to obtain A solution;

[0061] (4) Ammonium carbonate was dissolved in deionized water to form a 0.05mol / L ammonium carbonate solution, and the dispersant BYK190 was added therein until the concentration reached 0.3g / L to obtain solution B;

[0062] (5) Dissolve citric acid, oxalic acid and ammonium chloride into solution with deionized water, citric acid concentration 0.12g / L, oxalic acid concentration 0.27g / L, ammonium chloride concentration 0.18g / L, obtain C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com