A special-shaped ceramic brick forming mold and its preparation method

A technology for molding molds and ceramic tiles, which is applied in the direction of ceramic molding machines, molds, mold auxiliary parts, etc., can solve problems such as inability to process, difficult to achieve control, and affect decorative effects, so as to enhance wear resistance, facilitate processing, and reduce effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

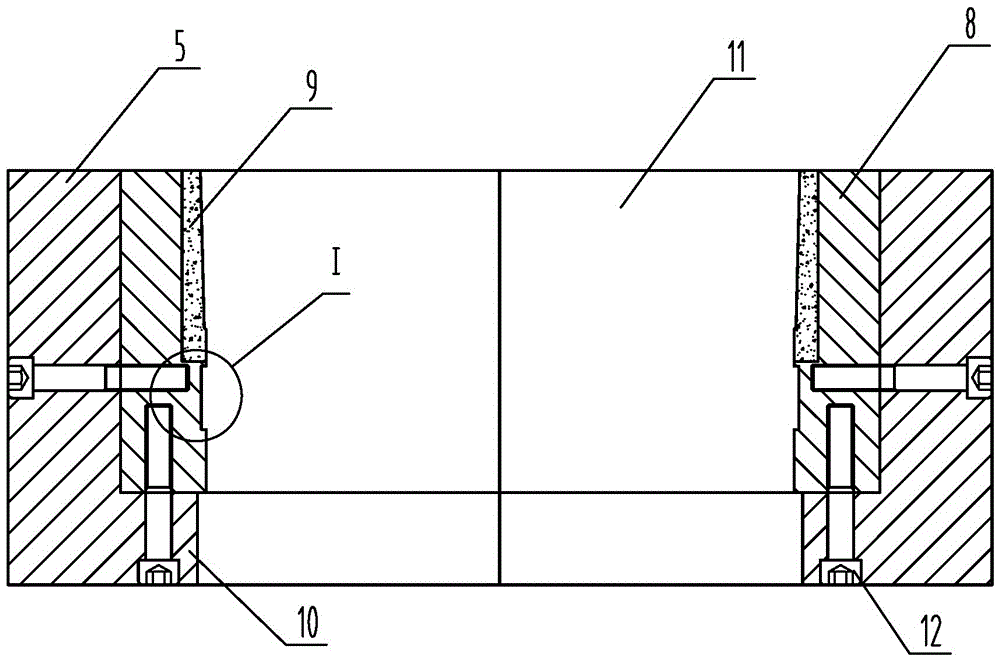

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] In the present invention, the corresponding up and down positions in use are defined as up and down; the side close to the center of the cavity 11 is defined as the inside, and the other side away from the center of the cavity 11 is defined as the outside.

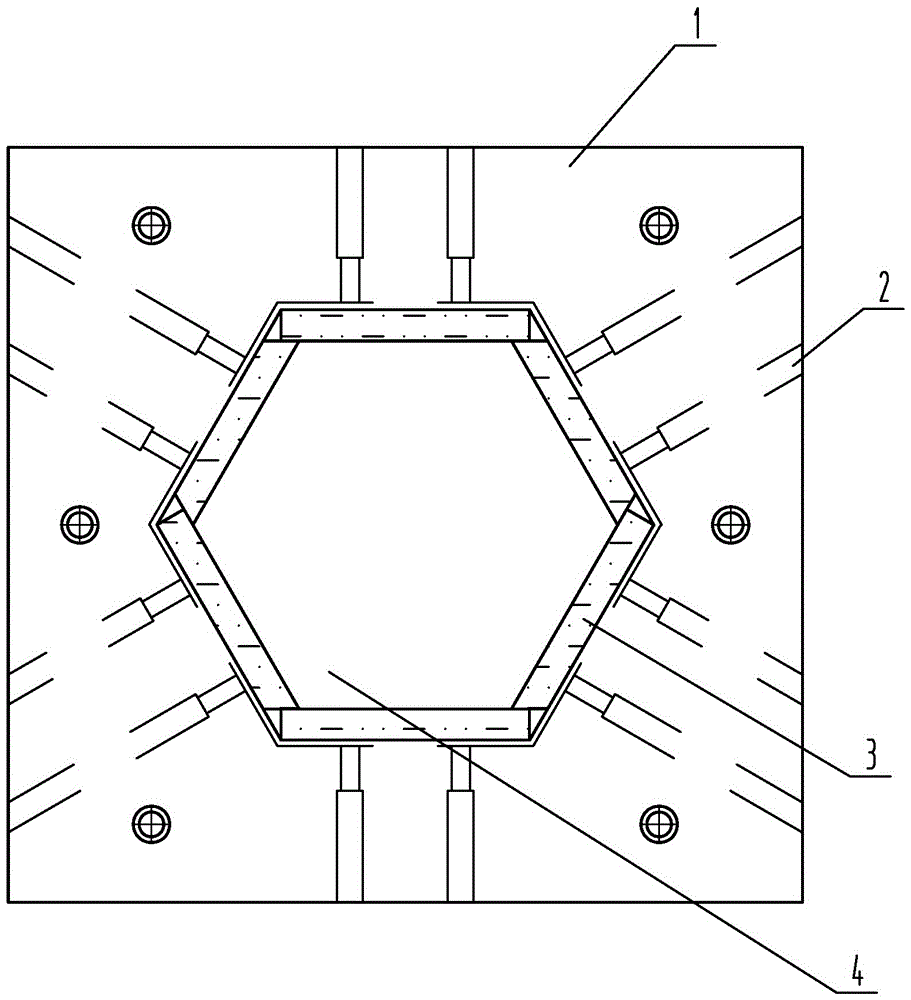

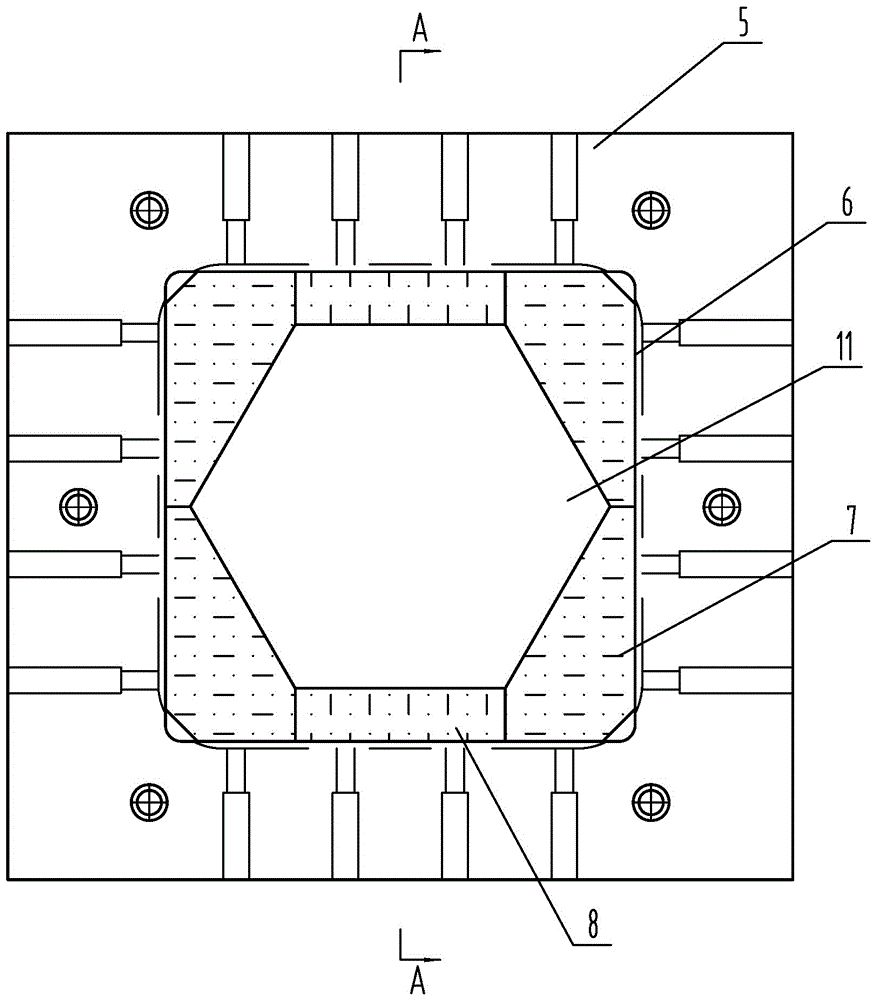

[0039] In this specific embodiment, a regular hexagonal ceramic tile forming mold is taken as an example.

[0040] Such as figure 2 As shown, the present invention has a quadrilateral inner chamber 6 with a cross section on the middle frame 5, wherein each corner of the quadrilateral is a right angle, and a corner block 7 is installed at the included corner of two adjacent side walls of the inner chamber 6. , the side length of the hypotenuse of the corner block 7 is equal to the side length of the regular hexagonal ceramic brick, and the side wall where the hypotenuse of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com