Carbon black polymer combined counter electrode of dye-sensitized nano crystal solar battery and preparation method thereof

A technology for solar cells and dye sensitization, applied in the field of preparation of the pair of electrodes, can solve problems such as low electrocatalytic activity, and achieve the effects of broad application prospects, easy control, and easy bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

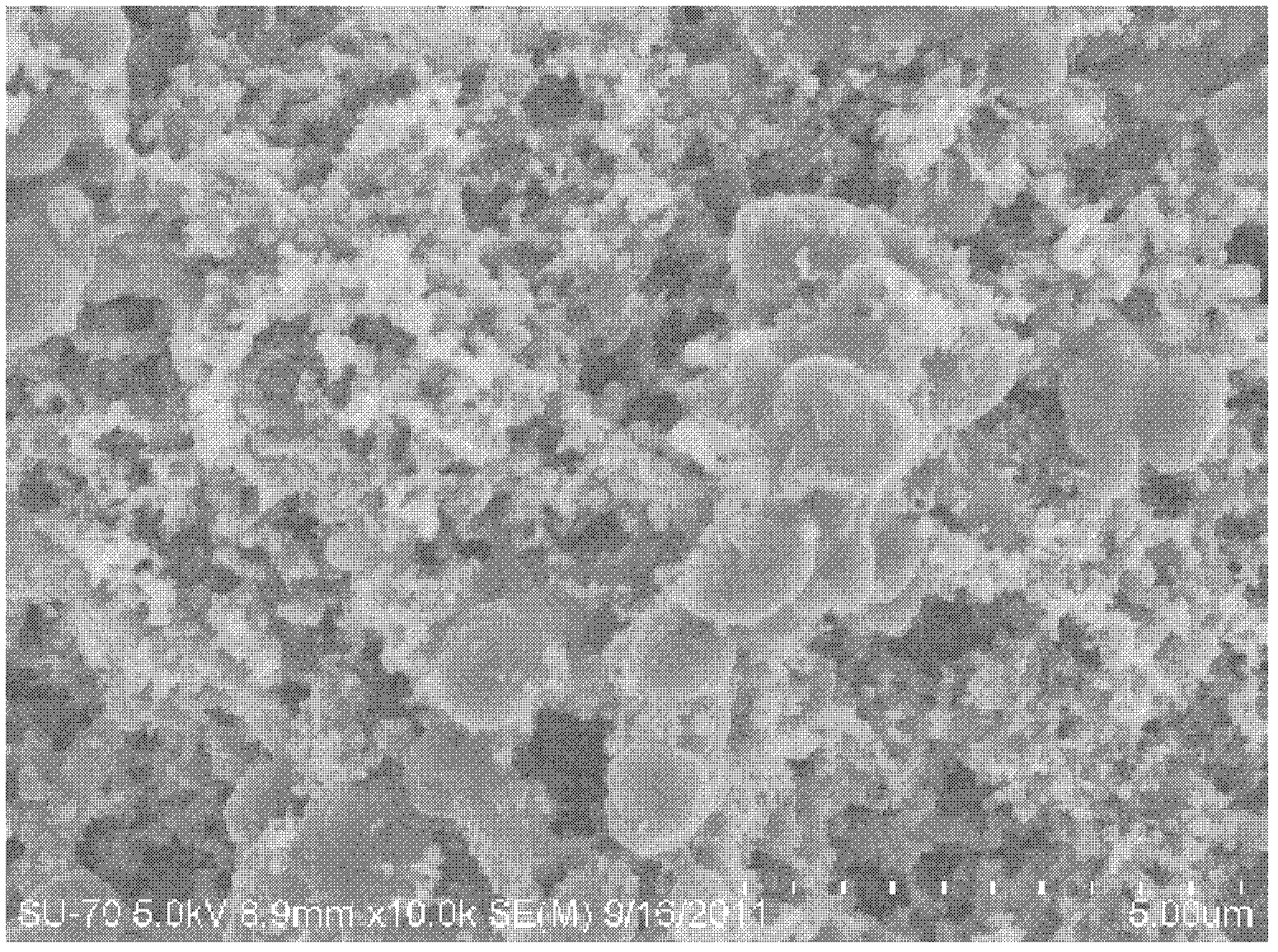

Embodiment 1

[0032] 1) Mix propylene carbonate (PC) and ethylene glycol dimethyl ether (DME) in a volume ratio of 7:3, and weigh 6g in total; add 0.05g polyoxyethylene (PEO), 0.05g polytetrafluoroethylene Vinyl hexafluoropropylene fluoride (P(VDF~HFP)); 80°C water bath (2 hours), until completely dissolved;

[0033] 2) add carbon black 0.04g wherein again, and silane coupling agent WD50 (H 2 NCH 2 CH 2 CH 2 Si(OC 2 h 5 ) 3 ) 0.1g, as an adhesive, magnetically stirred for 12h, and configured into carbon slurry;

[0034] 3) Coating on the substrate conductive glass by knife coating method, and heat-treating in a drying oven at 100°C for 12 hours, a composite carbon counter electrode with a film thickness of 13.70 μm and a sheet resistance of 551.8Ω / □ can be obtained.

[0035] The composite carbon counter electrode prepared above is used as the counter electrode of the dye-sensitized nanocrystalline solar cell, and the short-circuit current of the assembled battery is 9.83mA / cm 2 , th...

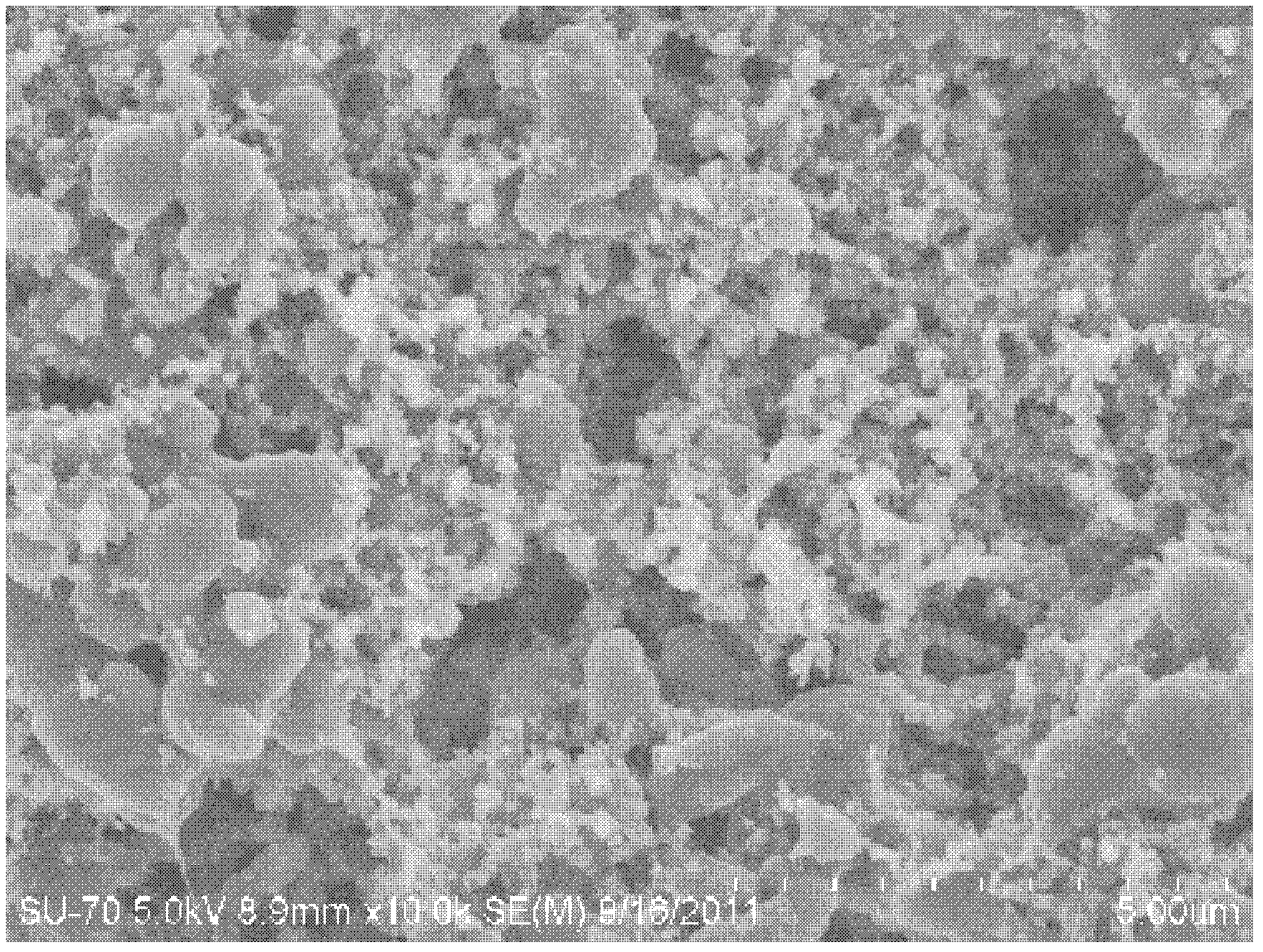

Embodiment 2

[0037] 1) Mix propylene carbonate (PC) and ethylene glycol dimethyl ether (DME) in a volume ratio of 7:3, and weigh 6g in total; add 0.05g polyoxyethylene (PEO), 0.05g polytetrafluoroethylene Vinyl hexafluoropropylene fluoride (P(VDF~HFP)); 80°C water bath (2 hours), until completely dissolved;

[0038] 2) add carbon black 0.07g wherein again, and silane coupling agent WD50 (H 2 NCH 2 CH 2 CH 2 Si(OC 2 h 5 ) 3 ) 0.1g, as an adhesive, magnetically stirred for 12h, and configured into carbon slurry;

[0039] 3) Coating on the substrate conductive glass by doctor blade method, heat treatment in a drying oven at 100°C for 12 hours, a composite carbon counter electrode with a film thickness of 16.79 μm and a sheet resistance of 166.9Ω / □ can be obtained.

[0040] The composite carbon counter electrode prepared above is used as the counter electrode of the dye-sensitized nanocrystalline solar cell, and the short-circuit current of the assembled battery is 9.51mA / cm 2 , the op...

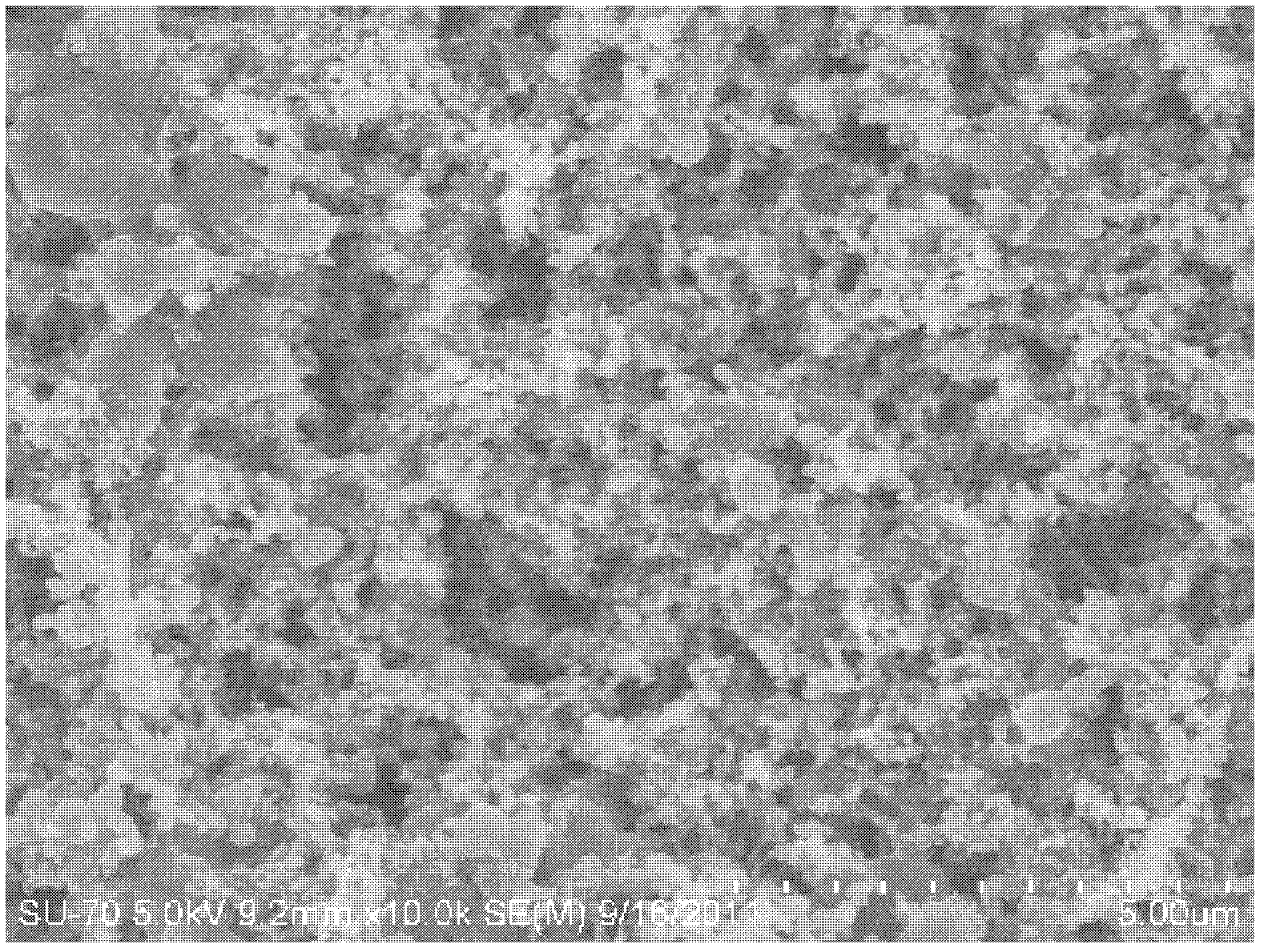

Embodiment 3

[0042] 1) Mix propylene carbonate (PC) and ethylene glycol dimethyl ether (DME) in a volume ratio of 7:3, and weigh 6g in total; add 0.05g polyoxyethylene (PEO), 0.05g polytetrafluoroethylene Vinyl hexafluoropropylene fluoride (P(VDF~HFP)); 80°C water bath (2 hours), until completely dissolved;

[0043] 2) add carbon black 0.10g wherein again, and silane coupling agent WD50 (H 2 NCH 2 CH 2 CH 2 Si(OC 2 h 5 ) 3 ) 0.1g, as an adhesive, magnetically stirred for 12h, and configured into carbon slurry;

[0044] 3) Coating on the substrate conductive glass by knife coating method, and heat-treating in a drying oven at 100°C for 12 hours, a composite carbon counter electrode with a film thickness of 17.28 μm and a sheet resistance of 136.6Ω / □ can be obtained.

[0045] The composite carbon counter electrode prepared above is used as the counter electrode of the dye-sensitized nanocrystalline solar cell, and the short-circuit current of the assembled battery is 10.94mA / cm 2 , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com