Base with ring-body and producing method

A manufacturing method and technology of the ring body, applied in the direction of electric solid state devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problems of cumbersome application, inability to provide comprehensive and complete solutions, and unstable product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

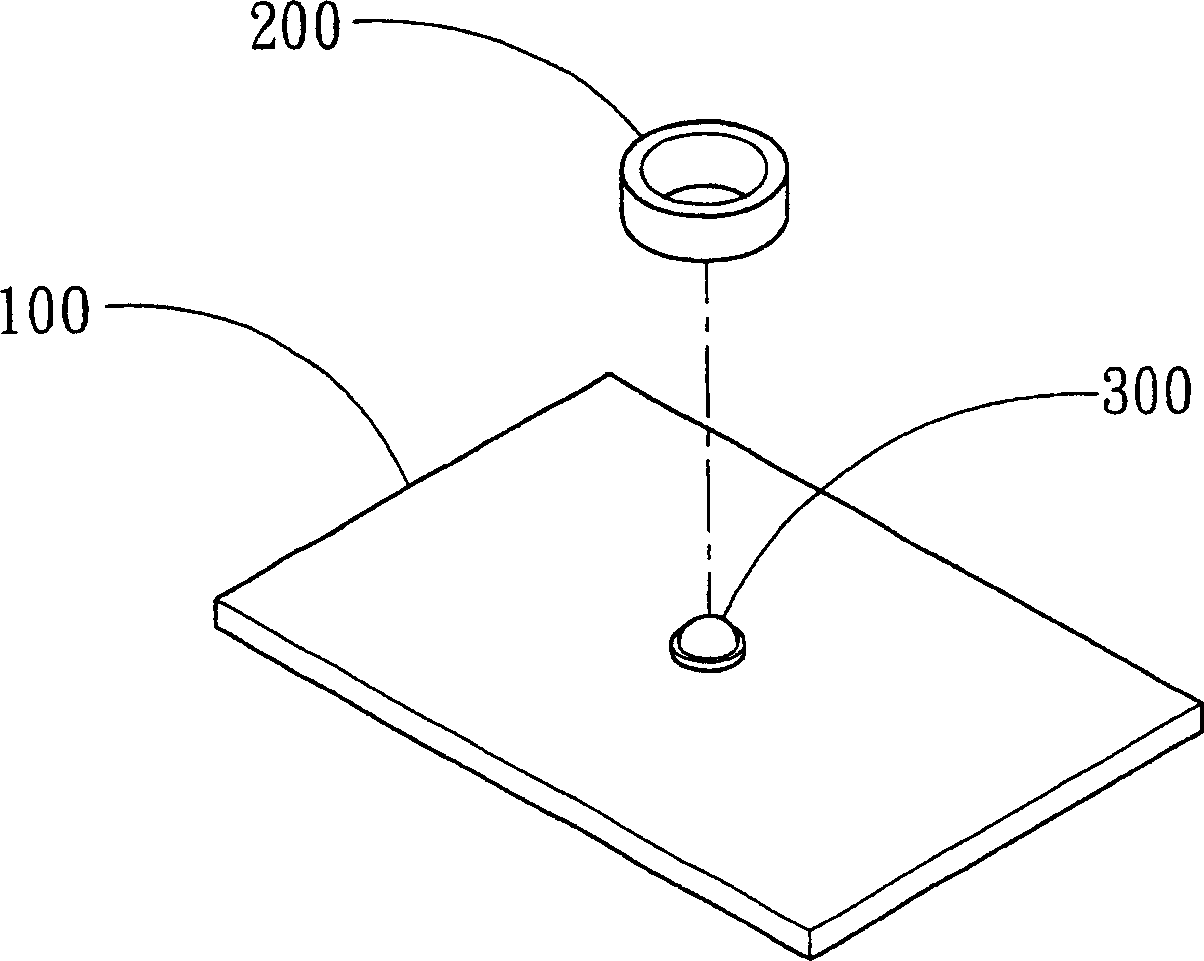

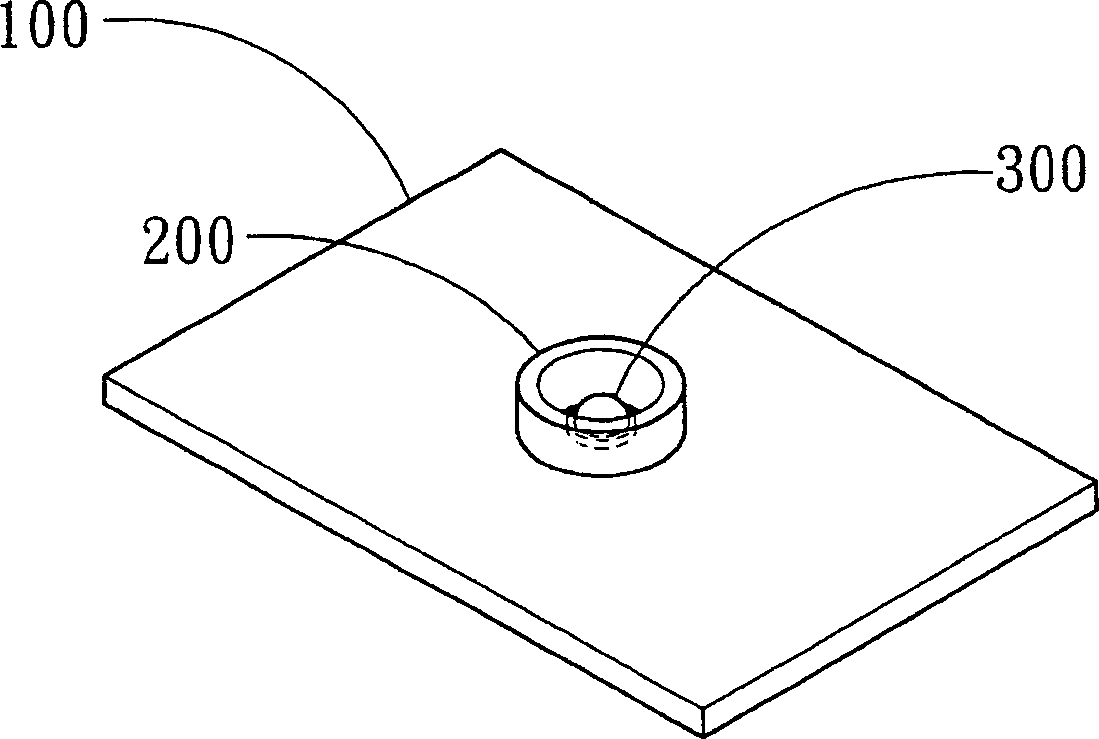

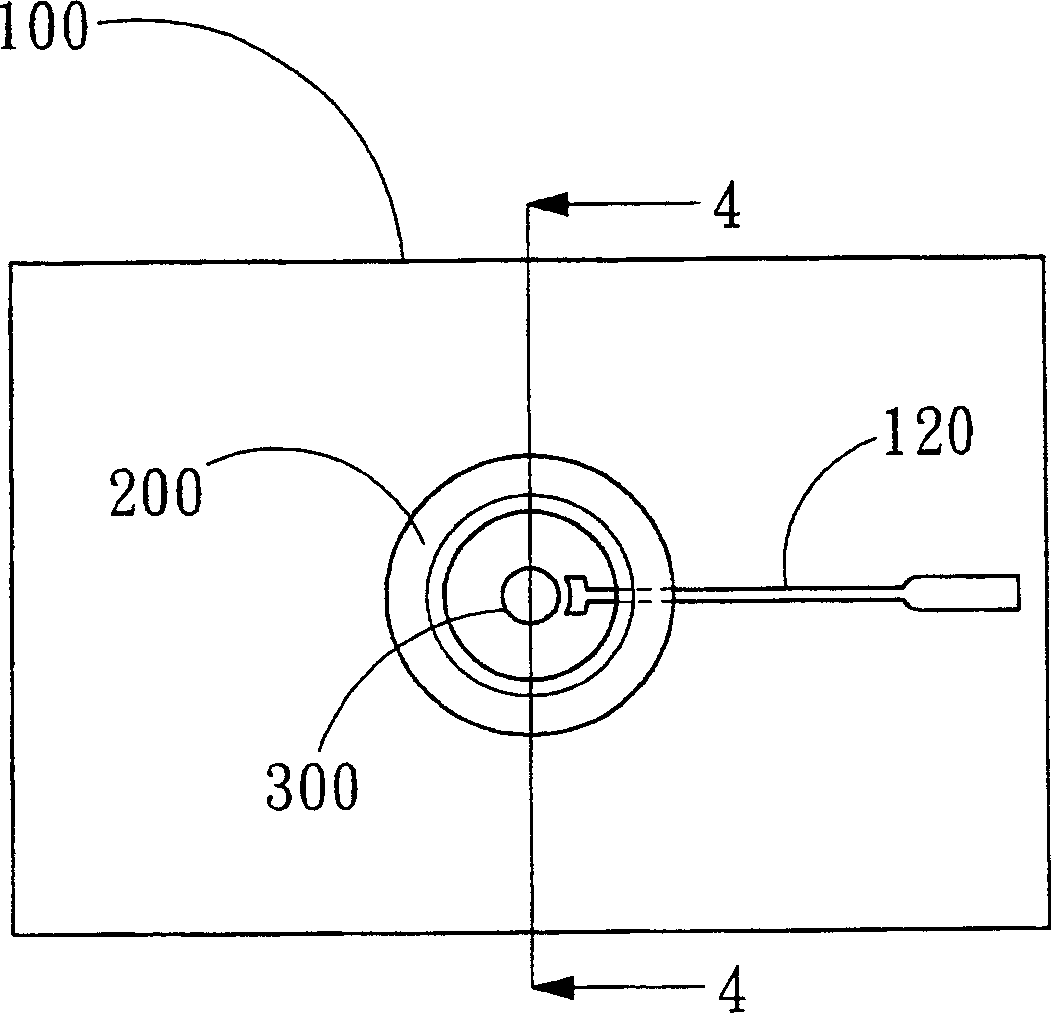

[0045] see figure 1 and figure 2 , figure 1 It is a three-dimensional exploded view of a preferred embodiment of the present invention, figure 2 It is a perspective view of a preferred embodiment of the present invention. The present invention provides a base with rings, which includes: a substrate 100 with an insulating layer 110 and a circuit layer 120; a ring 200 disposed on the surface of the substrate 100; a light emitting diode chip (LED, Light Emitting Diode) 300 is arranged on the surface of the substrate 100 surrounded by the ring body 200, and has an electrical connection relationship with the circuit layer 120 on the substrate 100, and the height of the ring body 200 on the substrate 100 is greater than the The height of the LED 300 above the substrate 100 ; and a light-transmitting colloid layer 400 made of light-transmitting material for covering the LED chip 300 and preventing the LED chip 300 from being in direct contact with the outside world.

[0046] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com