Bearing device with sensor and rolling bearing with sensor

A technology for rolling bearings and bearing devices, applied in bearing assembly, measuring devices, bearing components, etc., can solve the problems of increasing assembly man-hours, restricting miniaturization, increasing the number of parts and construction costs, and improving tensile strength, reducing assembly man-hours, The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

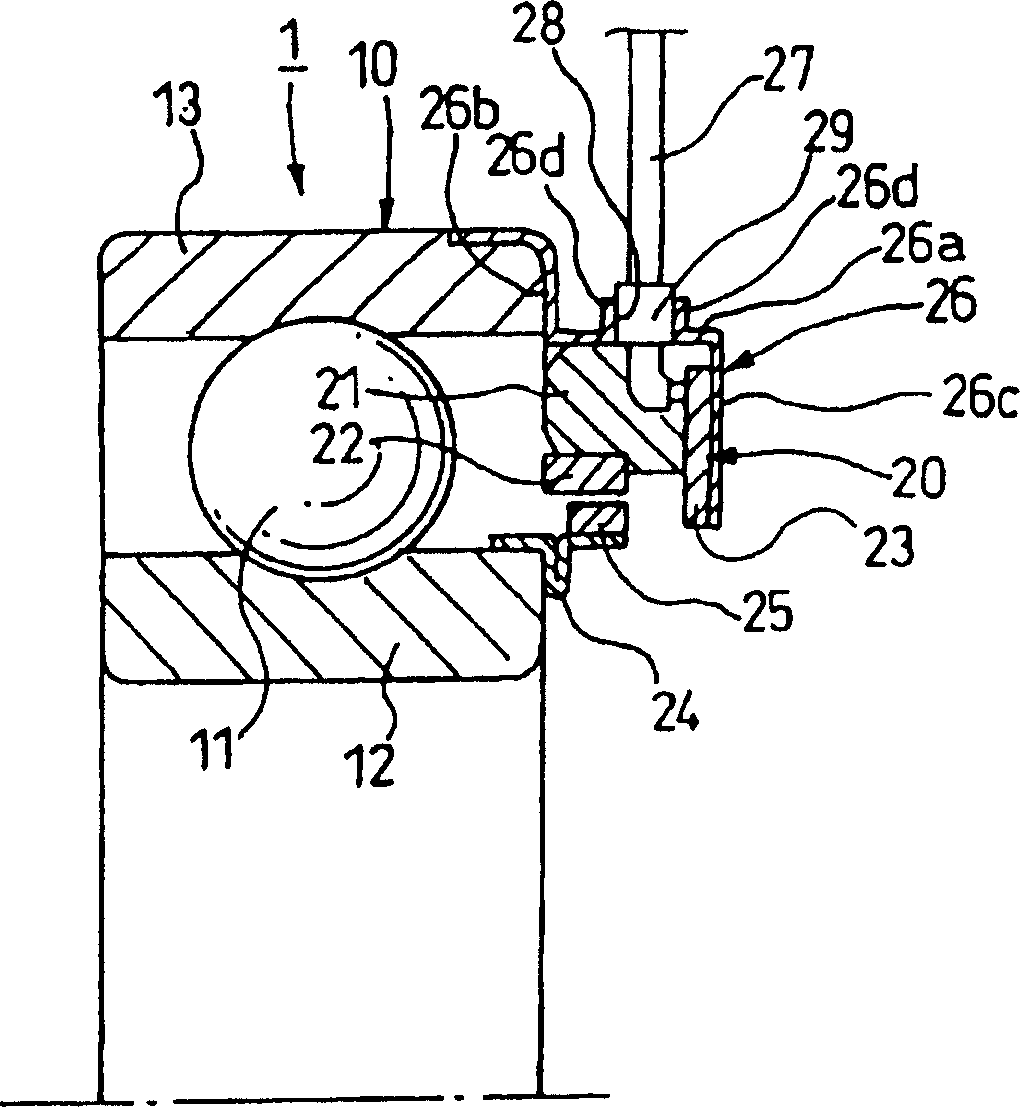

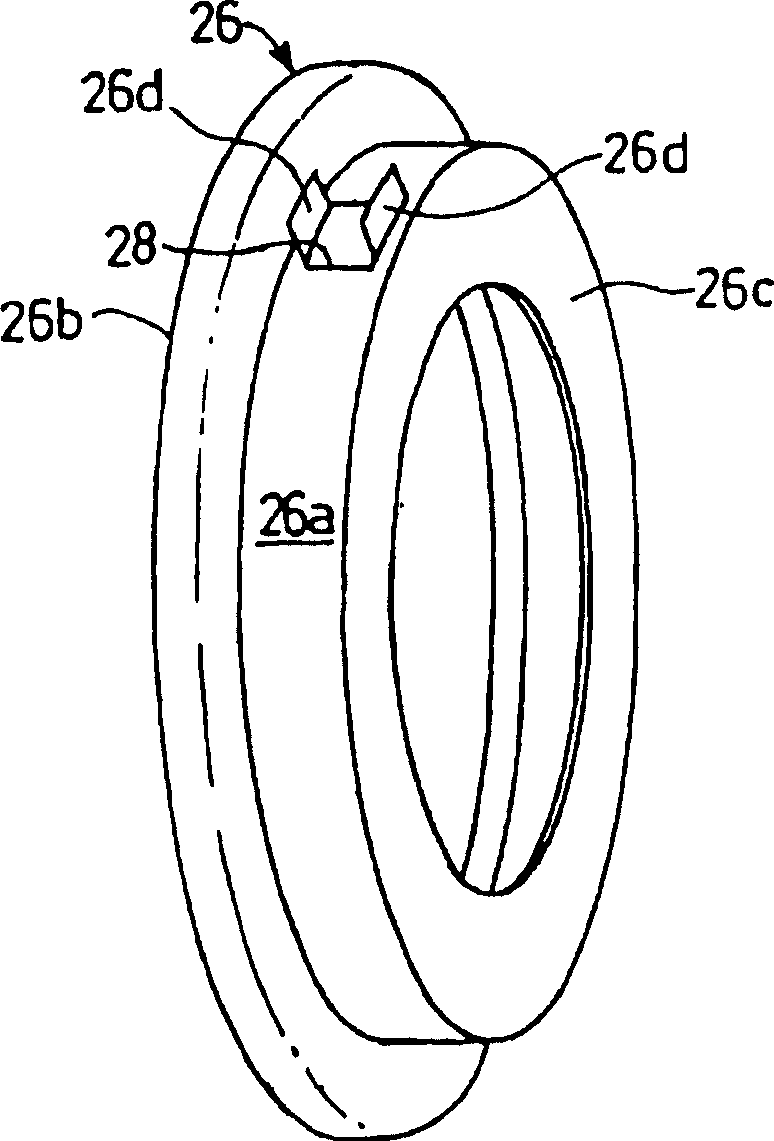

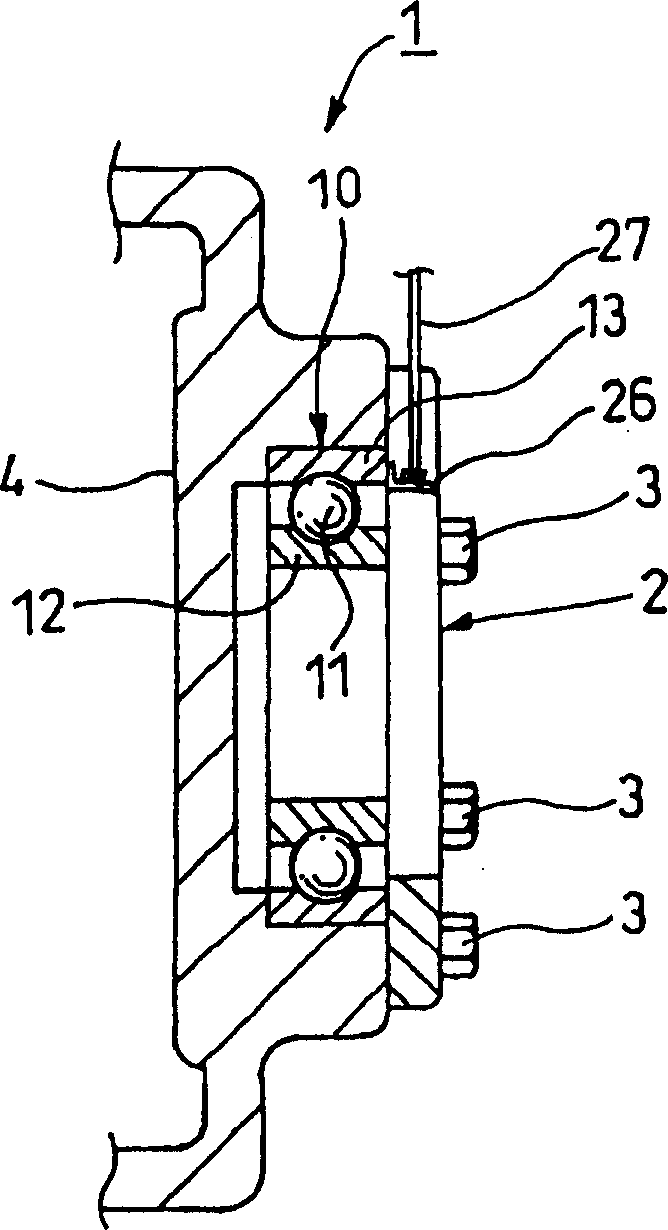

[0113] figure 1 It is a sectional view of main parts showing the first embodiment of the sensor-equipped bearing device of the present invention. figure 2 yes means figure 1 Perspective view of the sensor housing with sensor bearing assembly. image 3 yes means figure 1 The sectional view of the main part of the state where the bearing device with sensor is fixed on the bearing housing; Figure 4 yes image 3 right side view of Figure 5 yes means image 3 Diagram of the pressing part of the bearing unit with sensor.

[0114] Such as figure 1 As shown, the sensored bearing device 1 has a rolling bearing 10 . The rolling bearing 10 has an inner ring 12 as a rotating side ring, an outer ring 13 as a fixed side ring, and a plurality of rolling elements 11 rotatably interposed between the inner ring 12 and the outer ring 13 . The plurality of rolling elements 11 are held at equal intervals in the circumferential direction by cages not shown.

[0115] In addition, th...

no. 2 approach

[0134] Image 6 It is a perspective view for explaining the second embodiment of the sensor-equipped bearing device of the present invention. In addition, in the embodiment described below, the same code|symbol or equivalent code|symbol etc. is attached|subjected to the member etc. which have the structure and function equivalent to what already demonstrated, and description is simplified or omitted.

[0135] In the present embodiment, the protruding portion 31 of the sensor cover 30 is bent so as to protrude in the radial direction by forming a cutout portion of a part of the sensor cover 30 to form a single-leaf hinged door shape.

[0136] Other structures and functions are the same as those of the above-mentioned first embodiment.

no. 3 approach

[0138] Figure 7 It is a perspective view showing the sensor cover of the rolling bearing of the sensor-equipped bearing device according to the third embodiment of the present invention.

[0139] In the present embodiment, the protruding portion 41 of the sensor cover 40 is formed by bending a part of the sensor cover 40 to protrude in the radial direction toward the side (the side surface portion 40 c ) axially opposite to that of the second embodiment to form a single-leaf hinge. door shape.

[0140] Other structures and functions are the same as those of the above-mentioned first embodiment and second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com