Patents

Literature

40results about How to "No reduction in productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of replacing lime with limestone for slagging and producing steel in oxygen top blown converter

The present invention belongs to the field of steel production, and relates to a method of replacing lime with limestone for slagging and producing steel in an oxygen top blown converter. The invention is characterized in that the limestone is directly added during slagging in the steel production process. The added batch number is increased and the amount of each batch of material is reduced. Namely the lime is added by 1-3 times for slagging formerly, and when the limestone is added for slagging, the limestone is added by 4-8 times. The adding amount of each time, calculated according to the CaO therein, is 1 / 2-1 / 3 of lime added formerly and is for preventing the condensing and incrusting at the metal surface in the furnace in the early period of converting. The adding amount of limestone, calculated according to CaO therein, accounts for 30%-100% of adding amount of lime in the batch. The method of the invention has the main advantages of elimination of lime calcining procedure or reduction of production scale, reduction of cost required for operating the calcining device and reducing the discharged pollution, prevention of heat waste caused by cooling the lime after calcining, low sulfur content in the lime generated in the oxygen top blown converter, and benefit for restraining resulfurization of melted iron in the steel production process.

Owner:UNIV OF SCI & TECH BEIJING

Production method and application of high-efficient cellulase mixture

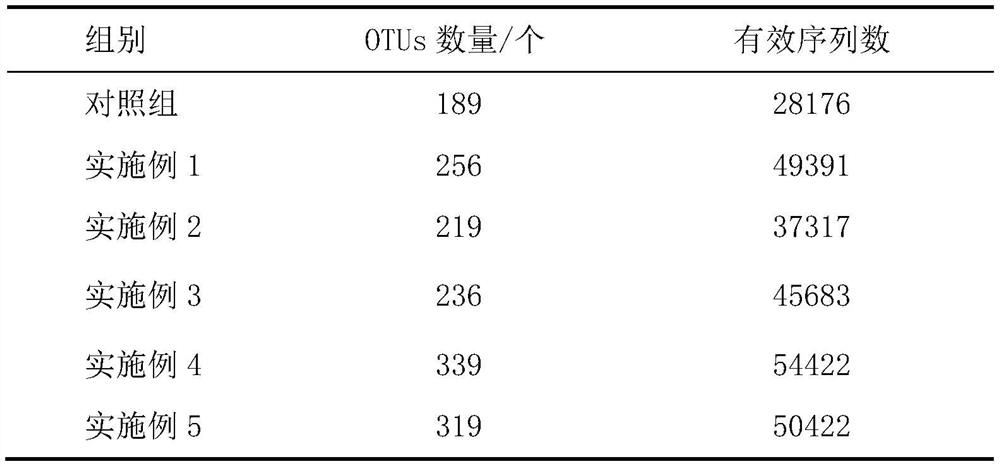

PendingCN105420217AReduce fermentation costsNo reduction in productivityMicroorganism based processesEnzymesControl mannerCellulase

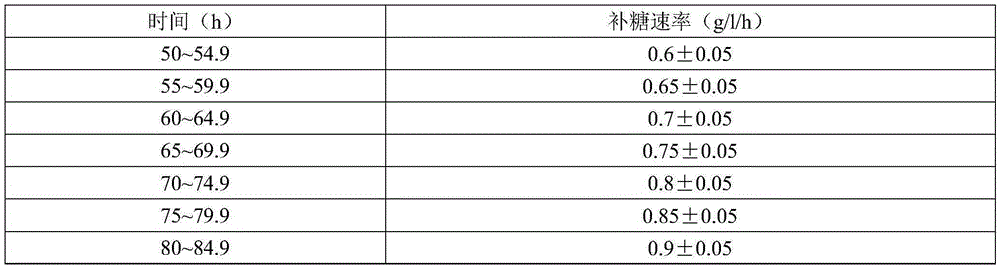

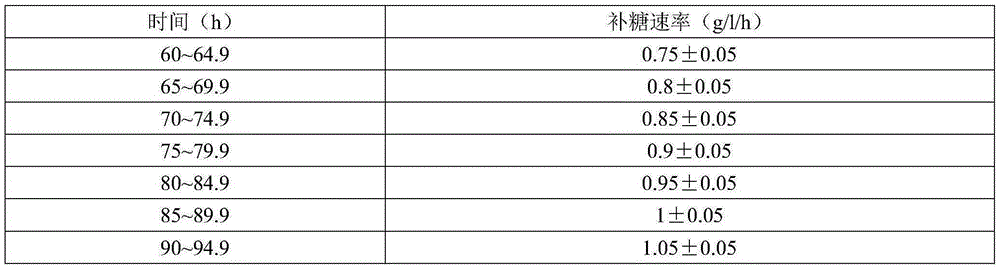

The invention relates to a production method and application of a high-efficient cellulase mixture. Through performing fermentation by using a non-soluble carbon source, not only can fermentation cost of cellulase be saved, but also the production of the cellulase is effectively induced; a reducing sugar control measure is adopted, so that the repression effect of a carbohydrate is reduced, and the production capacity of the cellulase is improved; in addition, a novel material-making up control manner is built through combining the non-soluble carbon source with a material-making up component and a material-making up rate process, so that matching of all components of the produced cellulase mixture is optimized while the yield (production capacity) of the cellulase is promoted, and the activity of the cellulase is improved by not less than 50 percent.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

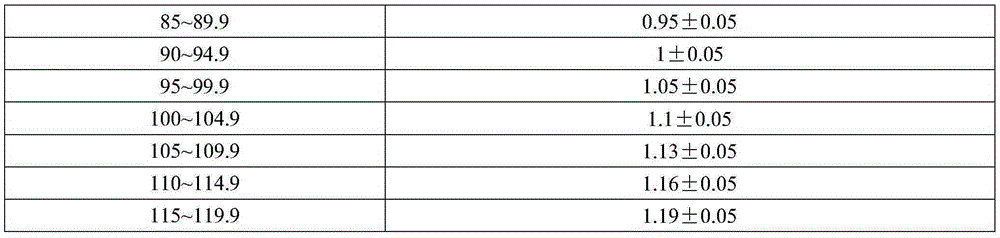

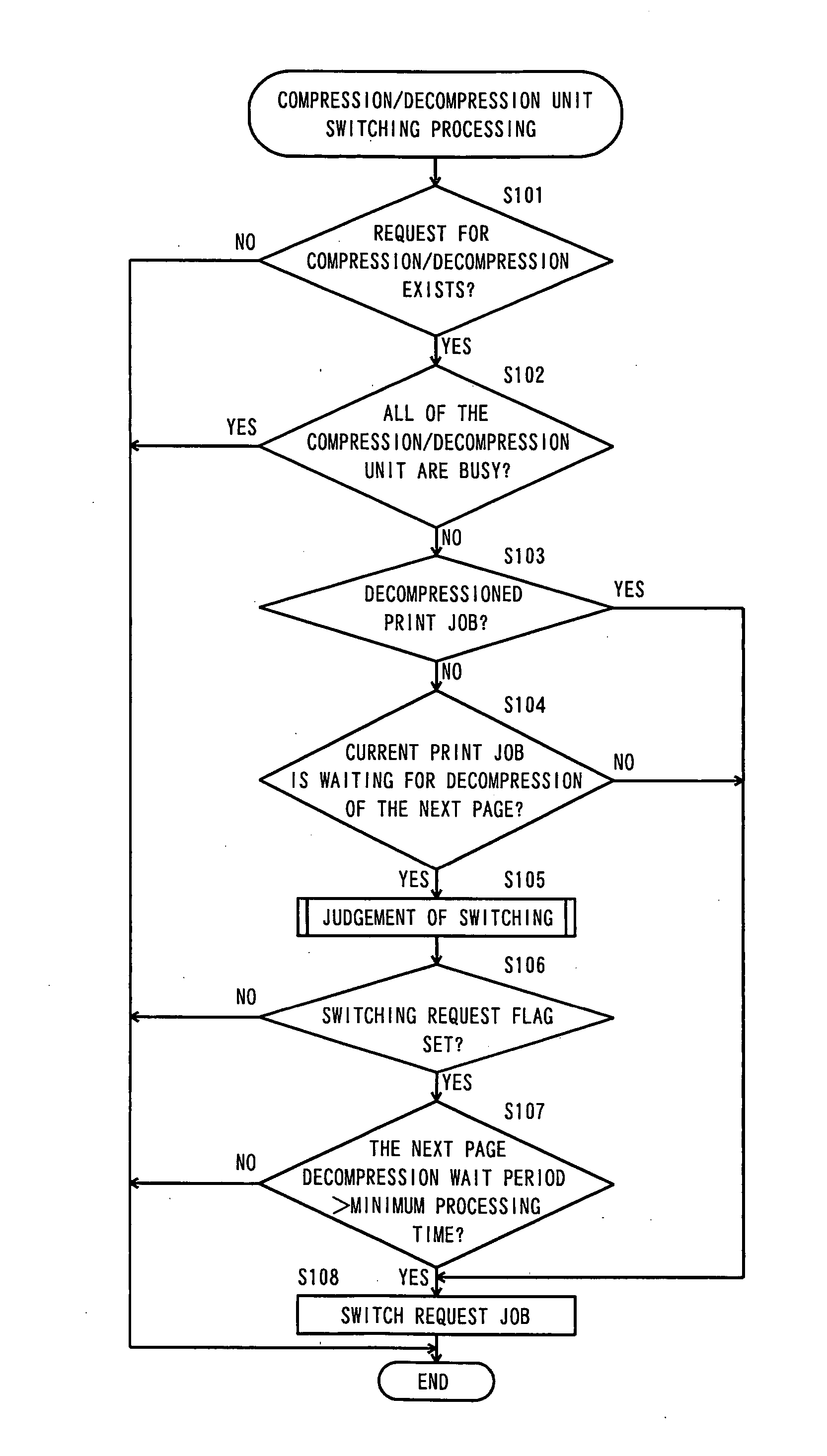

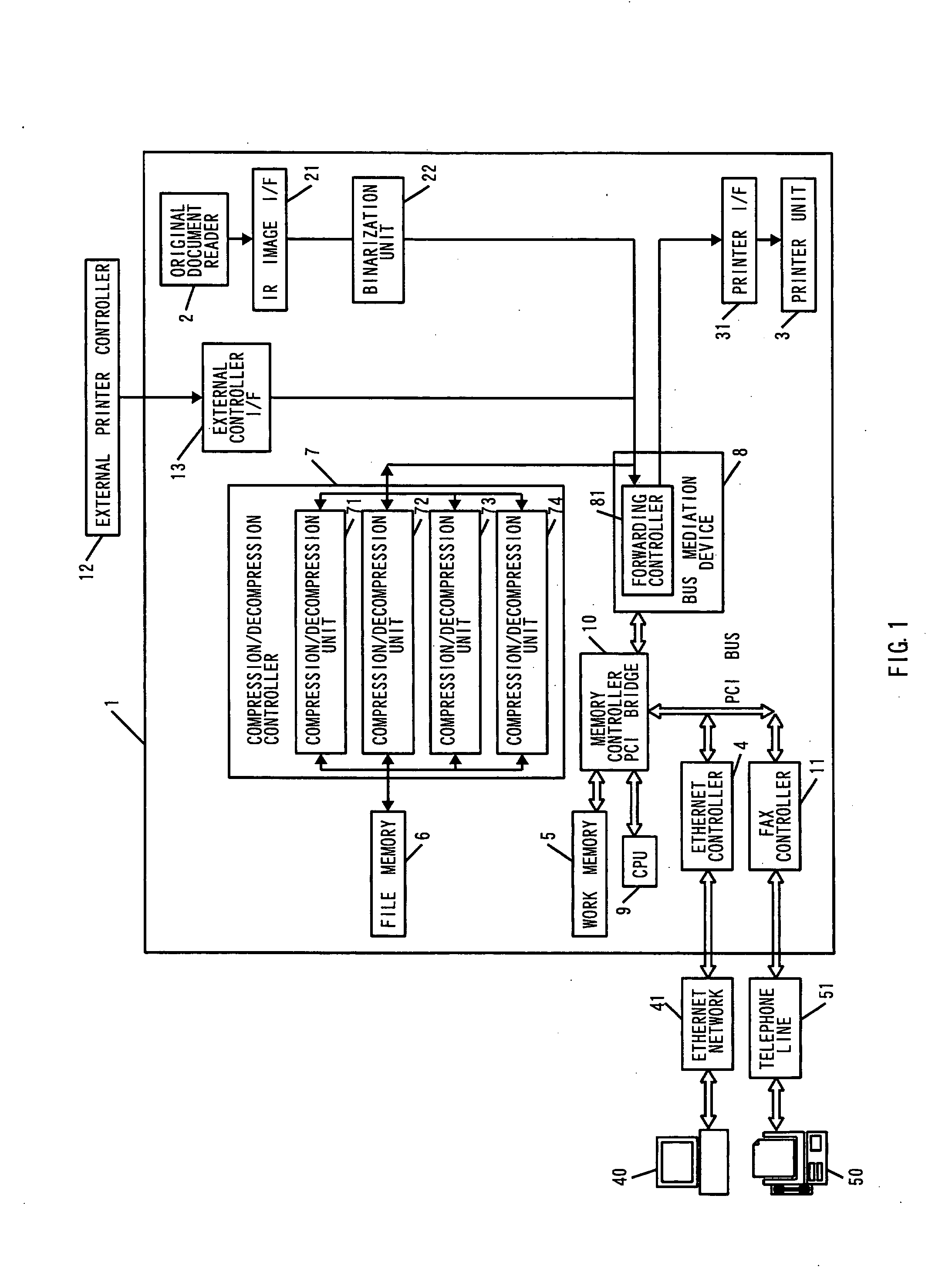

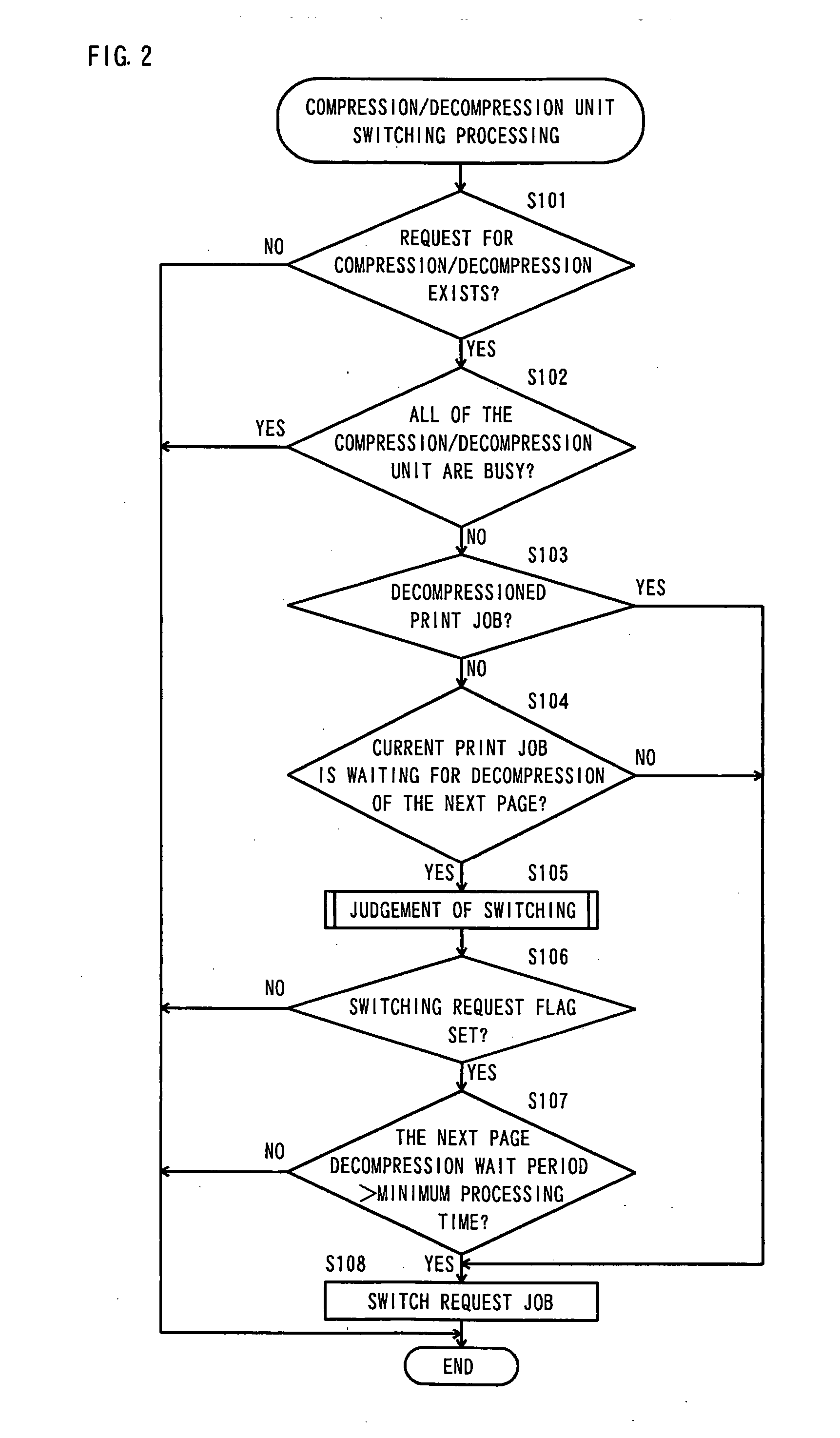

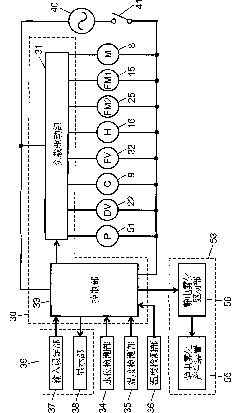

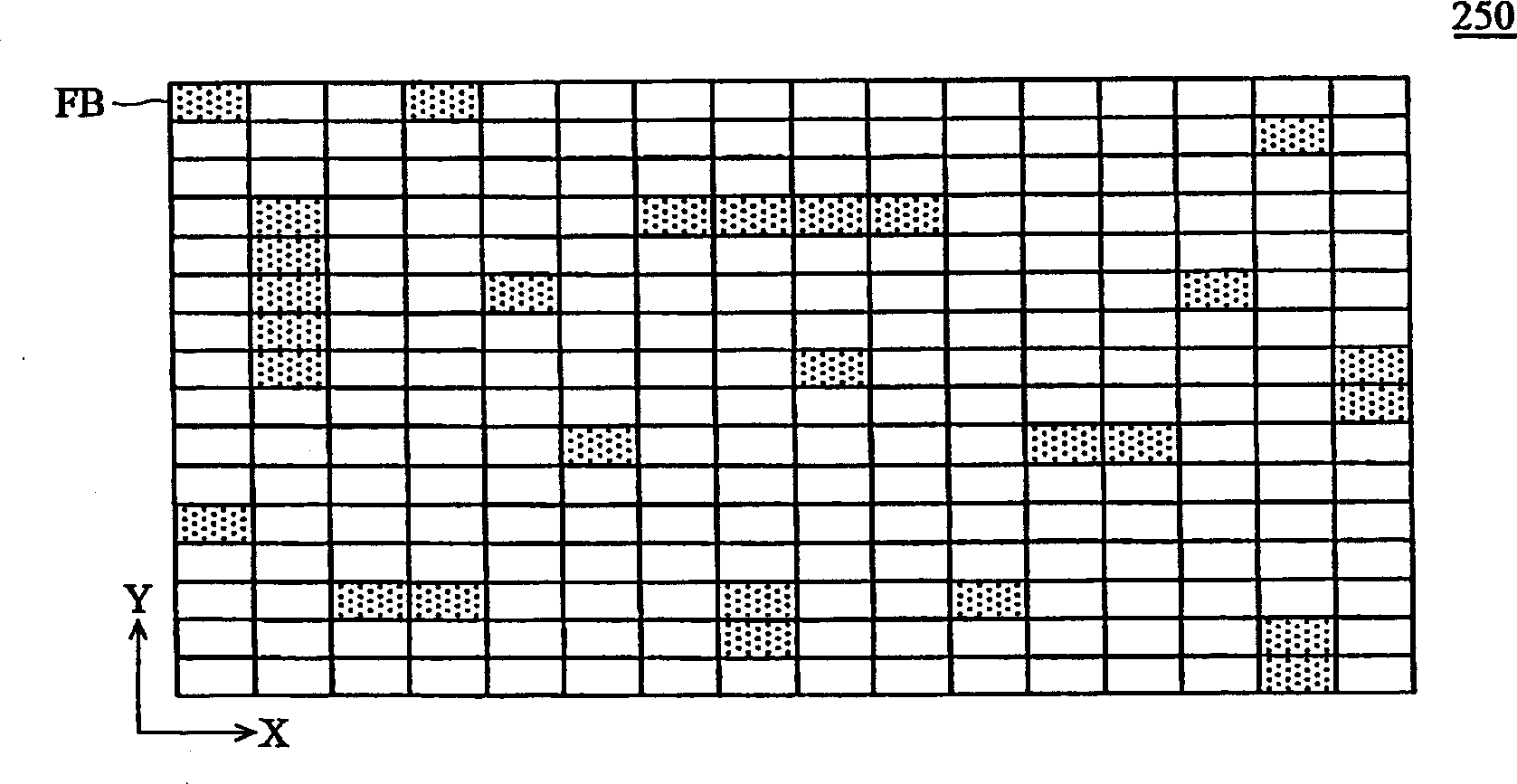

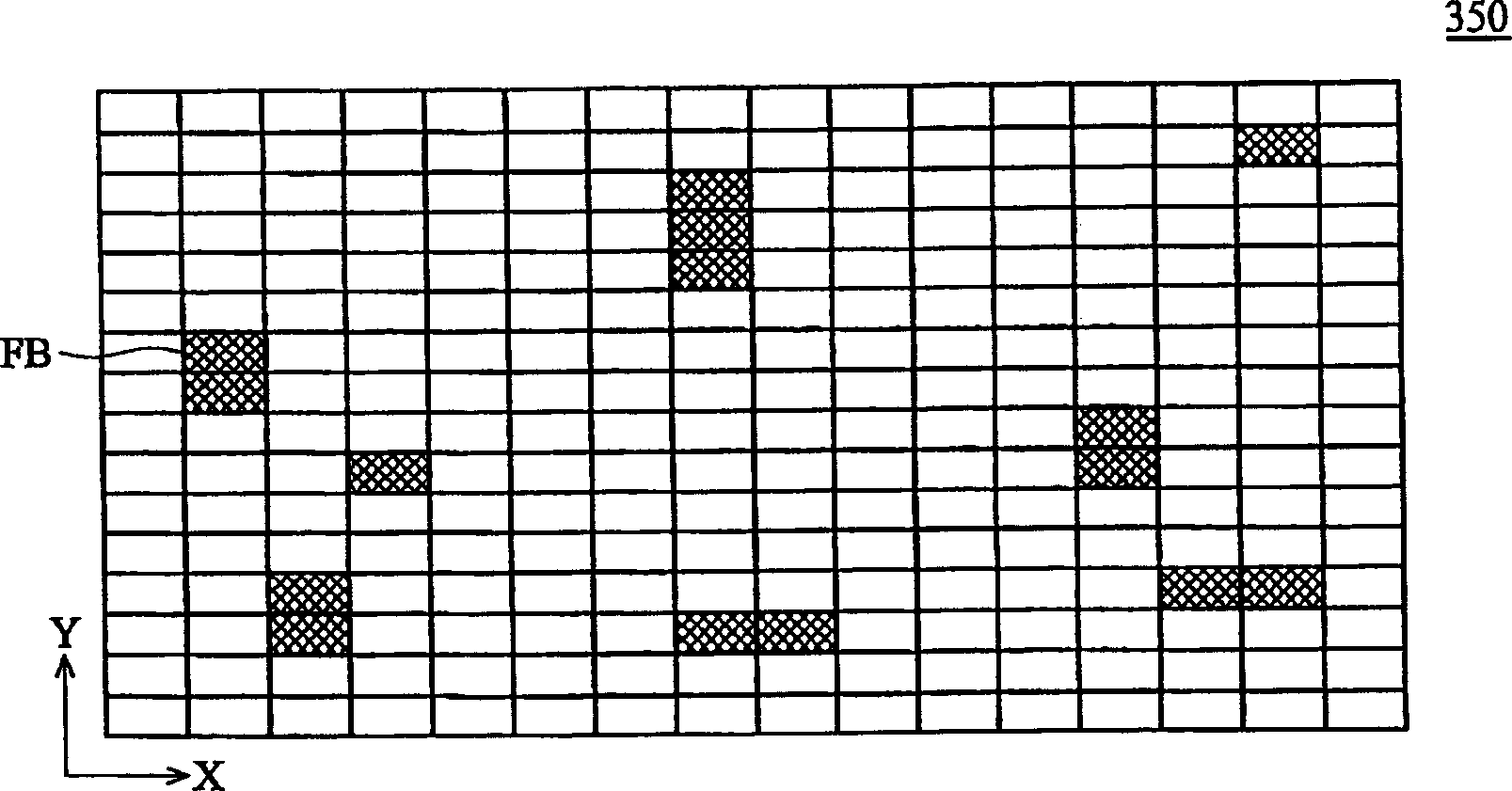

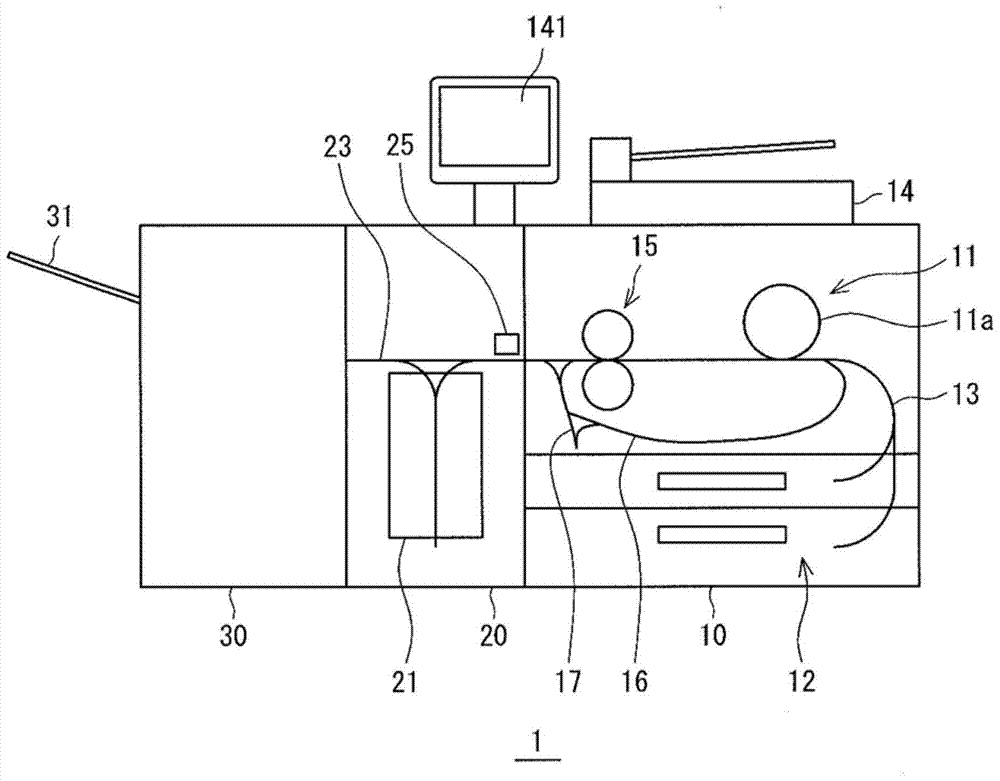

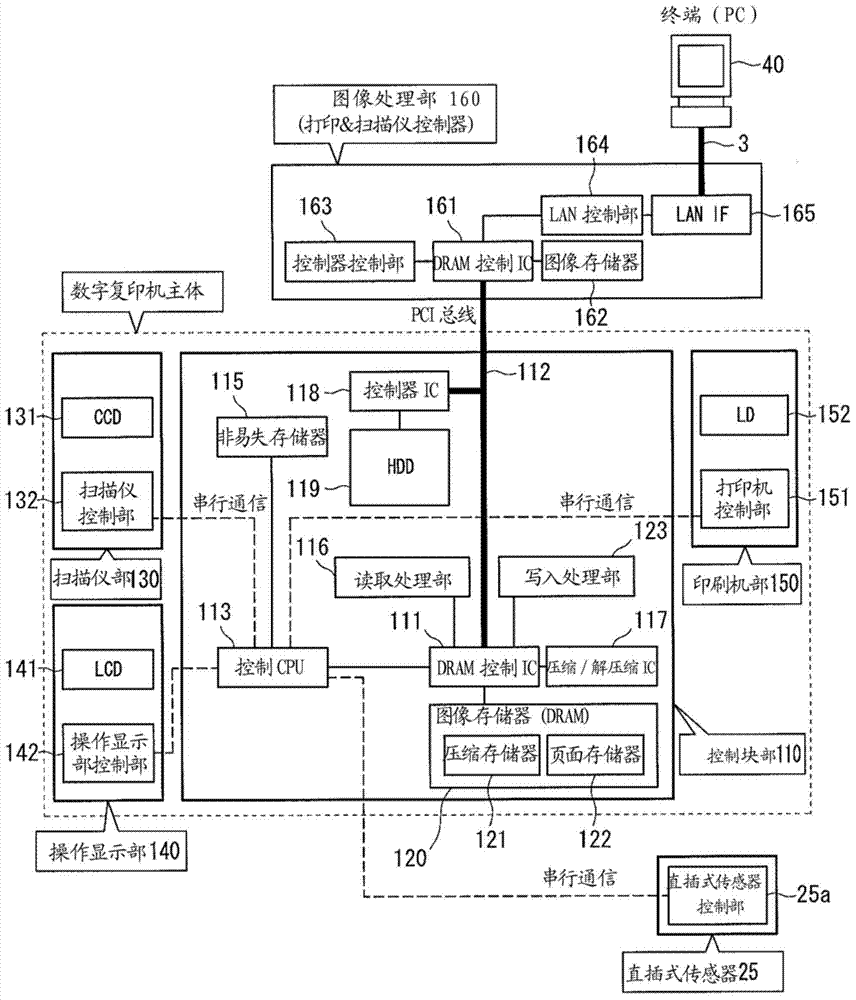

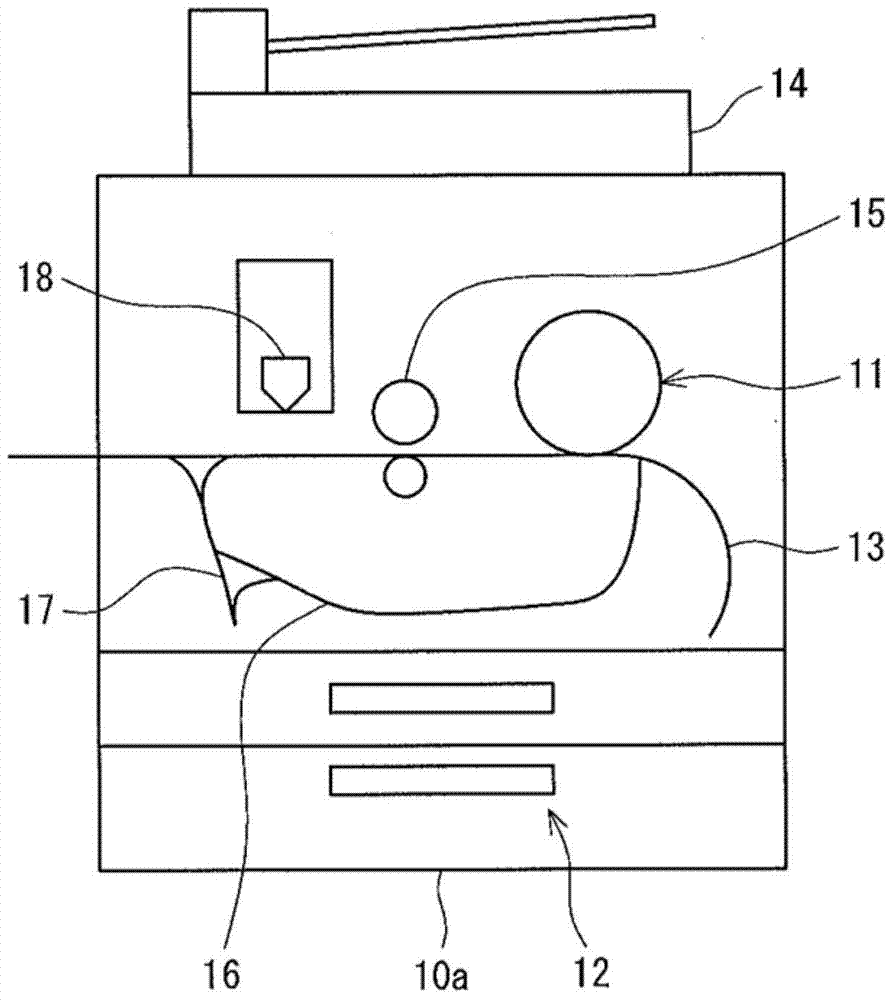

Data processing apparatus

InactiveUS20050044549A1Improve processing efficiencyReduction in productivityMultiprogramming arrangementsOther printing apparatusWaiting periodData request

When a request for compression or decompression of data for a next job is issued while processing of an current job is underway by one or more compression / decompression unit[s], the minimum processing time for the next-job data is compared with the processing wait period between pages of the current job. It is determined based on the results of this comparison whether or not compression or decompression of the next-job data is to be permitted. Based on this determination, control is carried out regarding whether or not compression or decompression of the next job by the compression / decompression unit[s] between pages of the current job is to be executed.

Owner:KONICA MINOLTA BUSINESS TECH INC

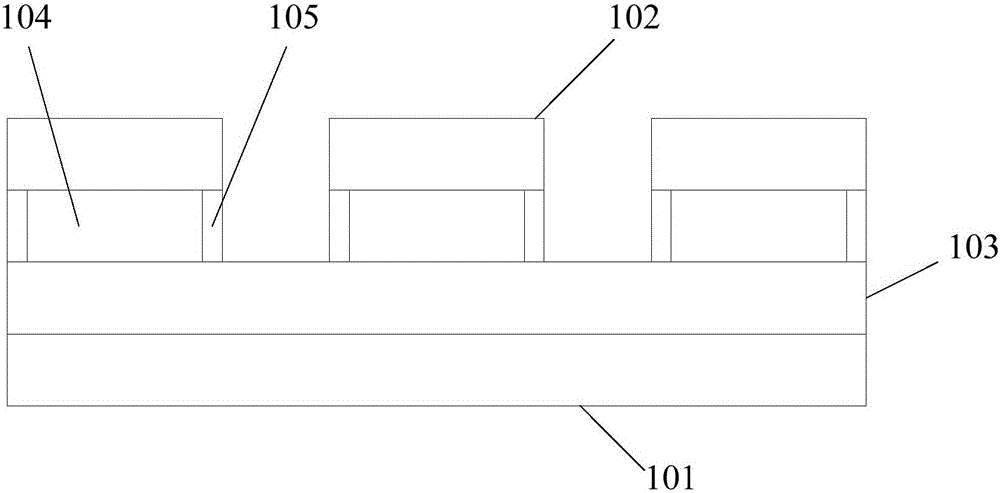

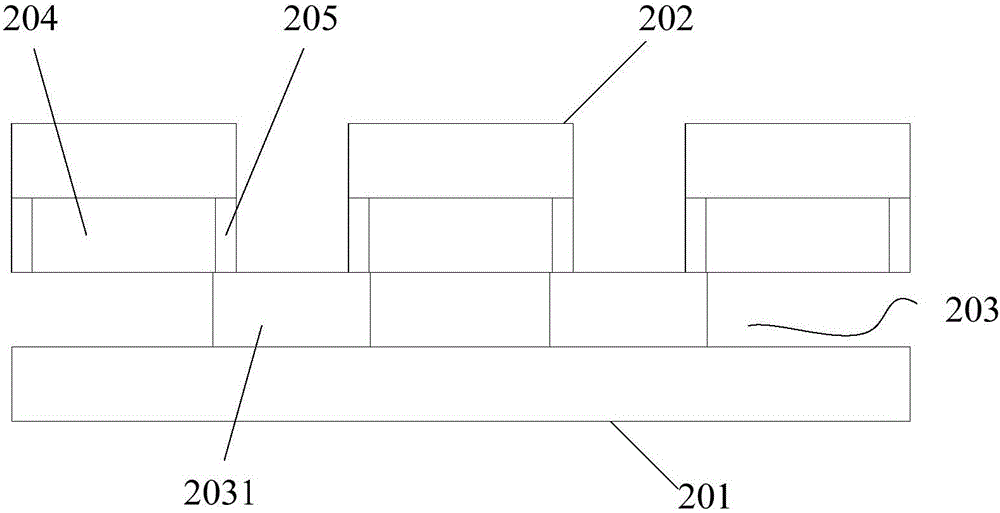

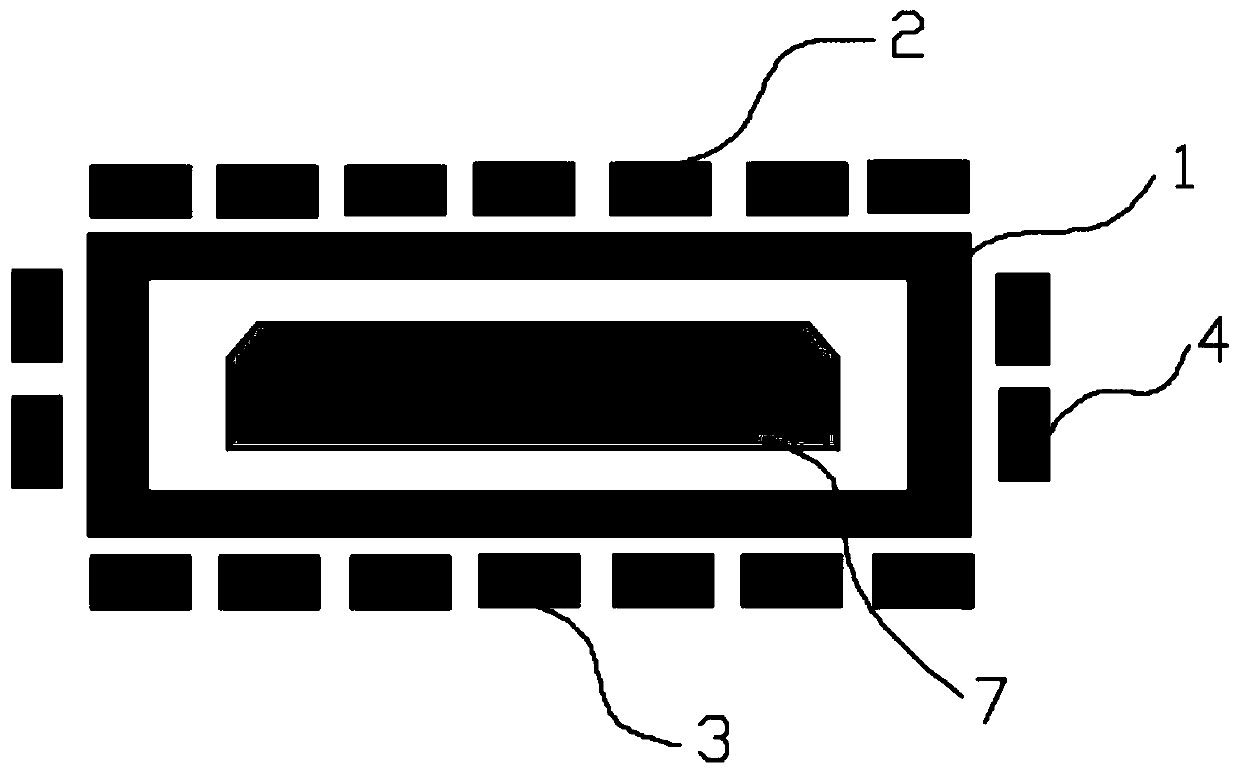

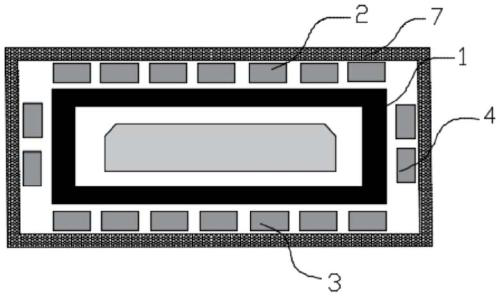

Array substrate, display panel and display device

ActiveCN105097847AImprove electrostatic protection abilityAvoid damageStatic indicating devicesSemiconductor/solid-state device detailsDisplay deviceEngineering

The invention provides an array substrate, a display panel and a display device. The array substrate comprises a first conductive pattern and a second conductive pattern which form a GND (Ground) protection circuit, wherein the first conductive pattern comprises a plurality of first conductive line segments which are arranged at intervals; the adjacent first conductive line segments are connected through the second conductive pattern; insulating layers are spaced between the first conductive line segments and the second conductive pattern; and the first conductive line segments and the second conductive pattern are connected through penetrating through via holes of the insulating layers. Meanwhile, the invention provides the display panel, comprising the array substrate provided by any one embodiment of the invention. Furthermore, the invention further provides the display device comprising the array substrate provided by any one embodiment of the invention.

Owner:BOE TECH GRP CO LTD +1

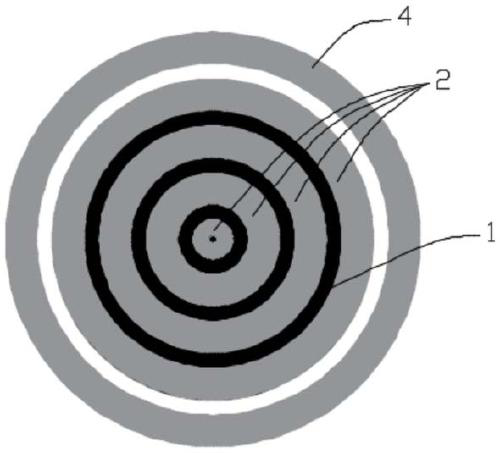

Annealing treatment method and device for reducing internal stress of crystal

ActiveCN111074348AReduce radial stressAchieve Axial Temperature GradientPolycrystalline material growthAfter-treatment detailsRadial stressCrucible

The invention provides an annealing treatment method for reducing the internal stress of a crystal. The annealing treatment method comprises the following steps: (1) a preparation stage: putting the crystal to be annealed into a crucible, vacuumizing the crucible, and introducing inert gas; and (2) a heating stage: heating the crucible by using a heating device, and in the heating process, respectively controlling the heating temperatures of a plurality of first heating rings concentrically arranged above the crucible in the heating device so that the crucible forms a radial temperature gradient. The heating temperature of a plurality of first heating rings of the heating device is controlled, the crucible forms the radial temperature gradient, the radial temperature gradient different from or opposite to the radial temperature gradient during crystal growth can be obtained and radial stress of the crystal can be remarkably reduced. The heating temperature of the first heating ring below the crucible and the heating temperature of the third heating ring on the side face of the crucible are controlled, the axial temperature gradient of the crucible is achieved, the axial temperaturegradient different from or opposite to the axial temperature gradient of the crystal in the growth process can be obtained and basic elimination of residual thermal stress can be achieved.

Owner:SICC CO LTD

Feed mulberry and feed ramie mixed complete materials for beef cattle

InactiveCN106036051ANo reduction in productivityReduce dosageFood processingAnimal feeding stuffBiotechnologyWeight gaining

The present invention discloses to feed mulberry and feed ramie mixed complete materials for a beef cattle, and relates to the technical field of feeds. The mixed complete materials consist of the following raw materials in percentages by mass: 10-15% of feed mulberry powder, 0-10% of feed ramie powder, 0-5% of pennisetum purpureum powder, 0-5% of sweet sorghum powder, 40-50% of corn flour, 0%-15% of soybean meal, 5%-15% of wheat bran, 5%-12% of dry distillers' grains, and 3%-8% of beef cattle premixes. The raw materials are crushed, the crushed raw materials are screened, the screened raw materials are mixed, the mixed raw materials are stirred evenly, the beef cattle premixes are added, an appropriate amount of an antioxidant is added, the mixture is stirred evenly to obtain the mixed materials, the mixed materials are granulated into granular materials, the granular materials are finally cooled, and the cooled granular materials are dried to obtain the finished products. The feed is mainly used for the breeding and fattening of the beef cattle in a growing and fattening period, can significantly reduce the use amount of grain protein powder and reduce the culturing costs under the conditions of ensuring no reduction of production performance of the beef cattle, can also balance the structure of daily grains, and reaches the effects of improving daily weight gains, improving slaughtering rates, and shortening the fattening effects in a fattening cycle.

Owner:湖南德人牧业有限公司 +1

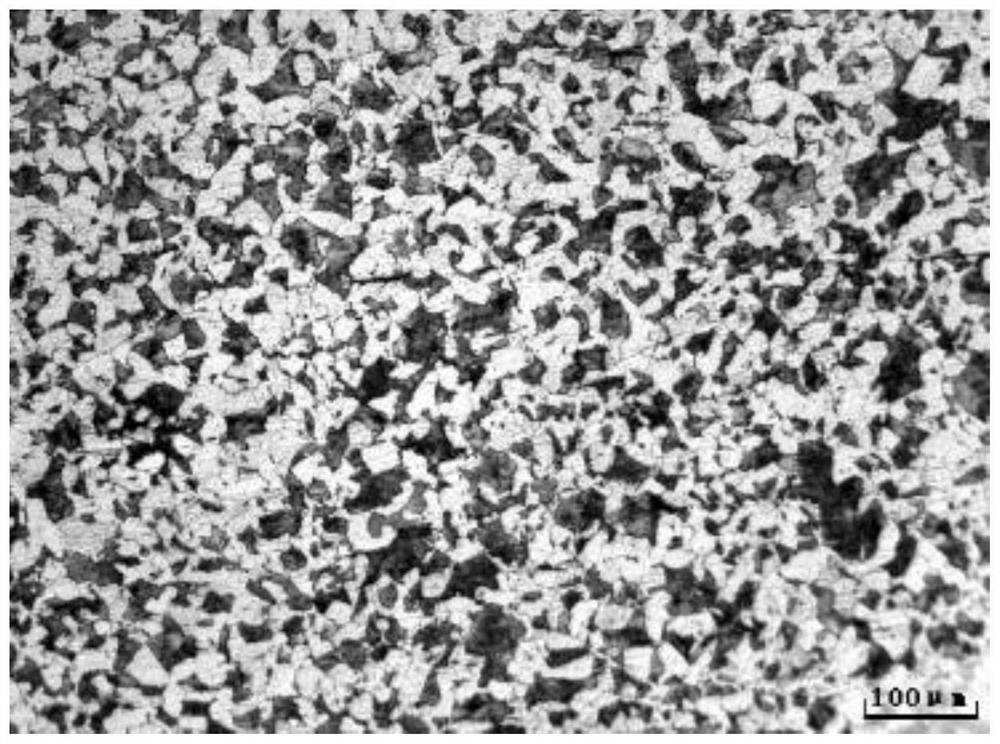

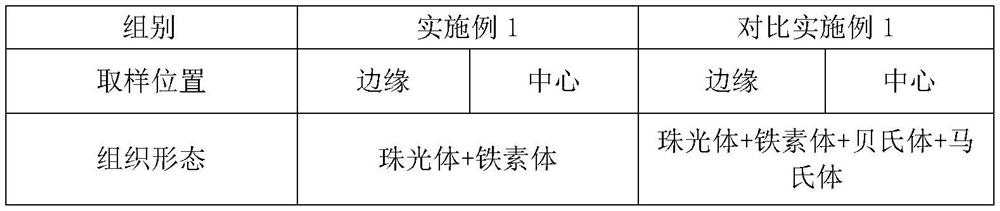

Rolling process of improving 38CrMoAl steel rolling state structure

InactiveCN110180893AImprove uniformityRefined grain sizeTemperature control deviceMetal rolling arrangementsMetallurgyNucleation

The invention discloses a rolling process of improving a 38CrMoAl steel rolling state structure. The rolling process is characterized by comprising the following steps of 38CrMoAl steel blank selection, steel blank heating, steel blank rough rolling, steel blank medium rolling, steel blank finish rolling and steel cooling. The rolling process of improving the 38CrMoAl steel rolling state structurehas the following advantages that a relatively low final rolling temperature is controlled, so that the surface temperature of a rolled piece is lower than a temperature of a core portion in the process, the steel core portion obtains a relatively large compressive stress in the rolling process, the structure uniformity is greatly improved, and crystal grains are further refined; the final rolling temperature is lowered to be close to the actual critical phase change point Ar3, a phase change from gamma to alpha is promoted, and a nucleation site of ferrite is increased, so that a structure morphology of a product is ferrite and pearlite structures in a balanced state; and the rolling process is green and environmentally friendly, does not pollute the environment, is capable of lowering the cost and increasing the benefit and particularly has important significance of controlling the online structure and the performance of medium-low carbon alloy structural steel.

Owner:XINING SPECIAL STEEL +1

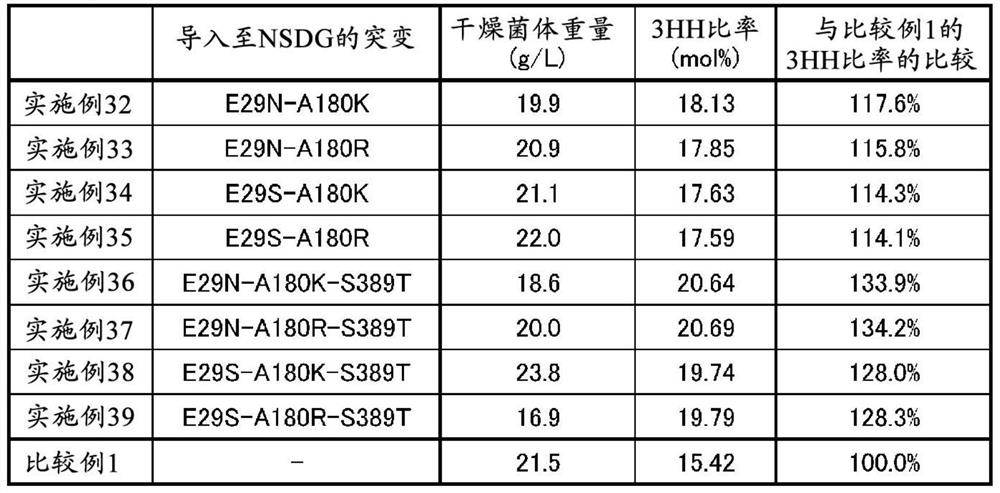

Mutant polyhydroxyalkanoic acid synthase, gene and transformant thereof, and method for producing polyhydroxyalkanoic acid

A mutant polyhydroxyalkanoic acid synthase having an amino acid sequence that shows 85% or higher sequence identity with an amino acid sequence represented by SEQ ID NO: 1 and is such that at least one amino acid from among amino acids 27-33, 39, 56, 106, 129, 144, 165, 170, and 172-187 from the N-end of the amino acid sequence represented by SEQ ID NO: 1 is substituted by another amino acid.

Owner:KANEKA CORP

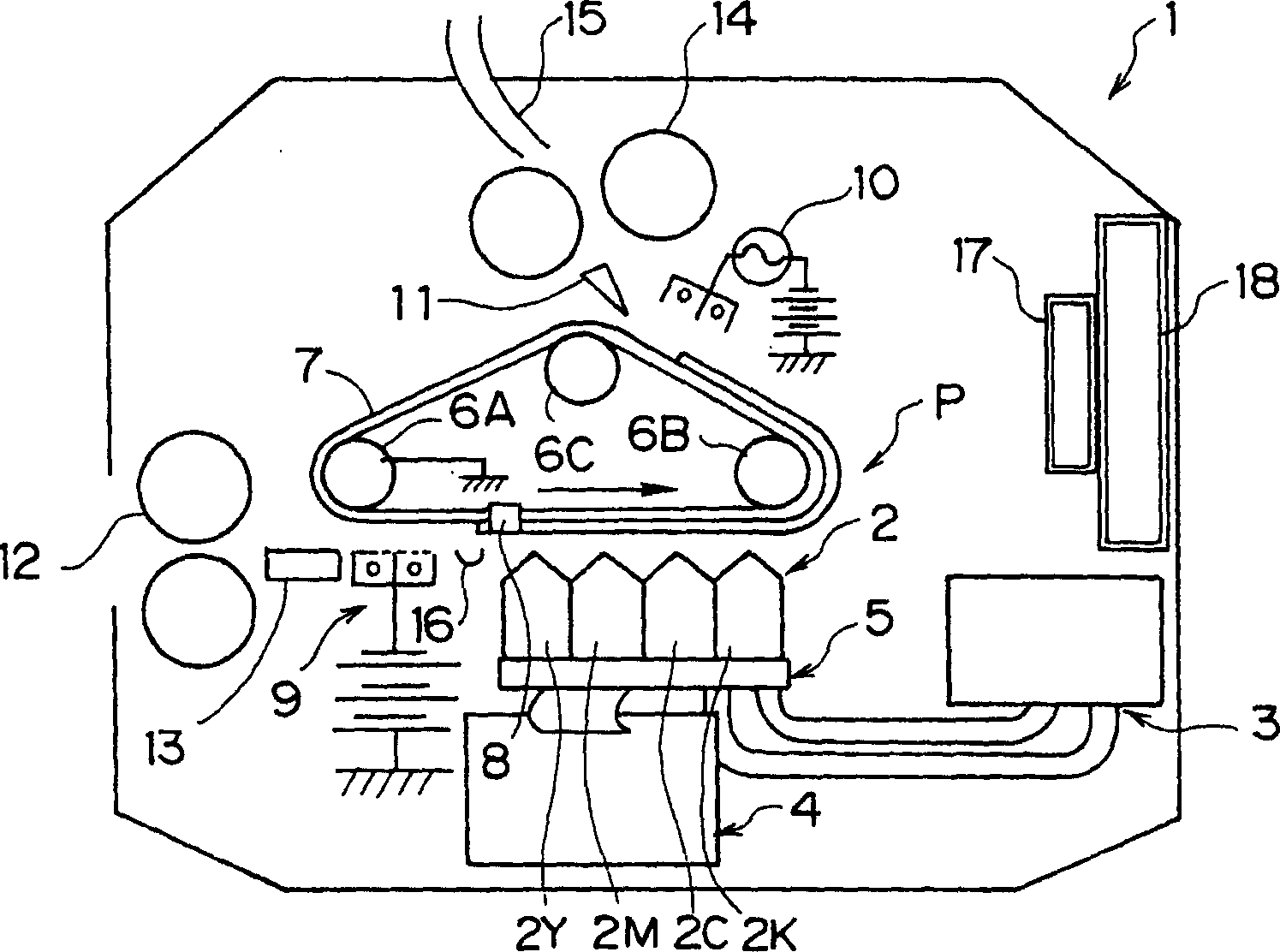

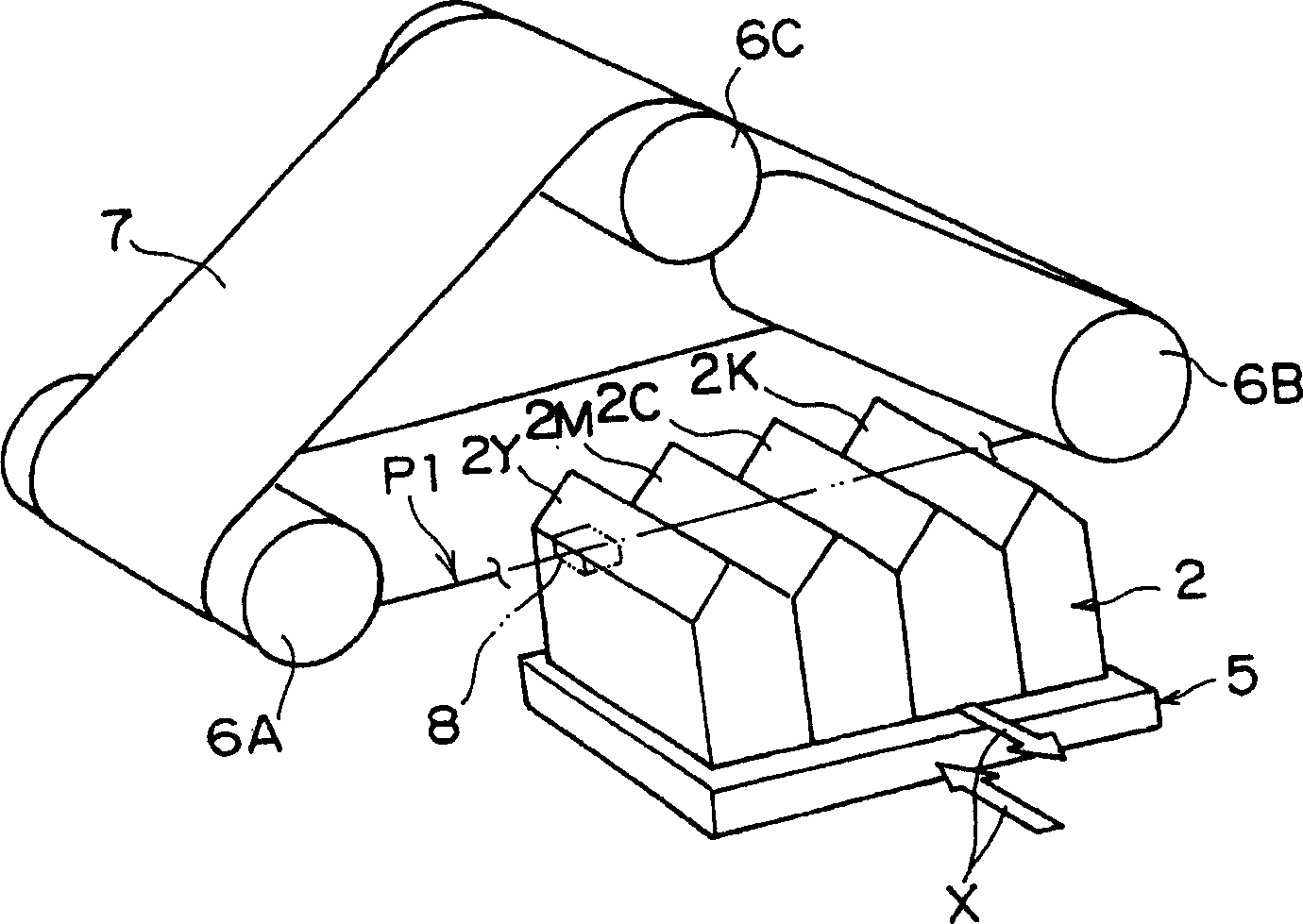

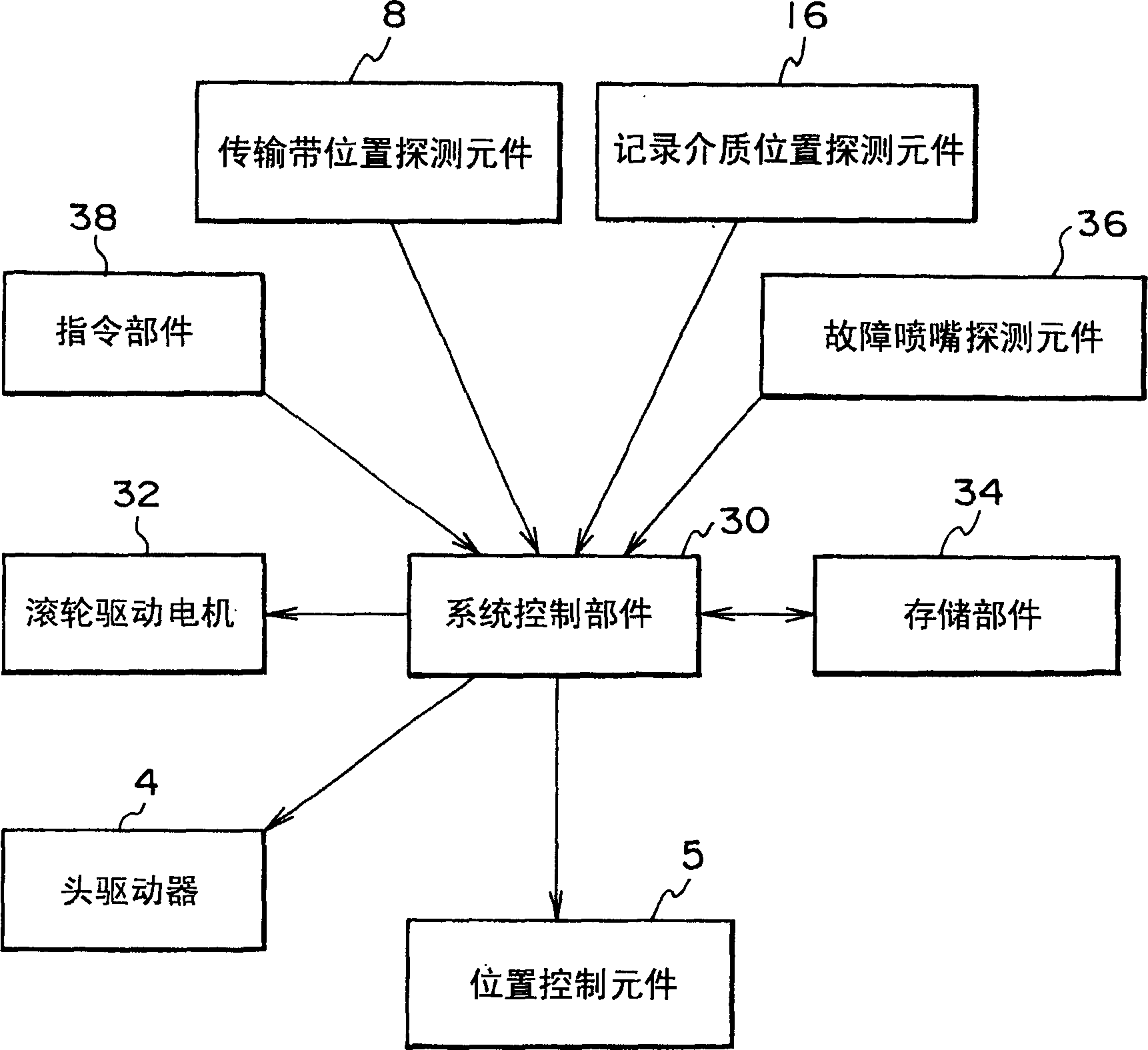

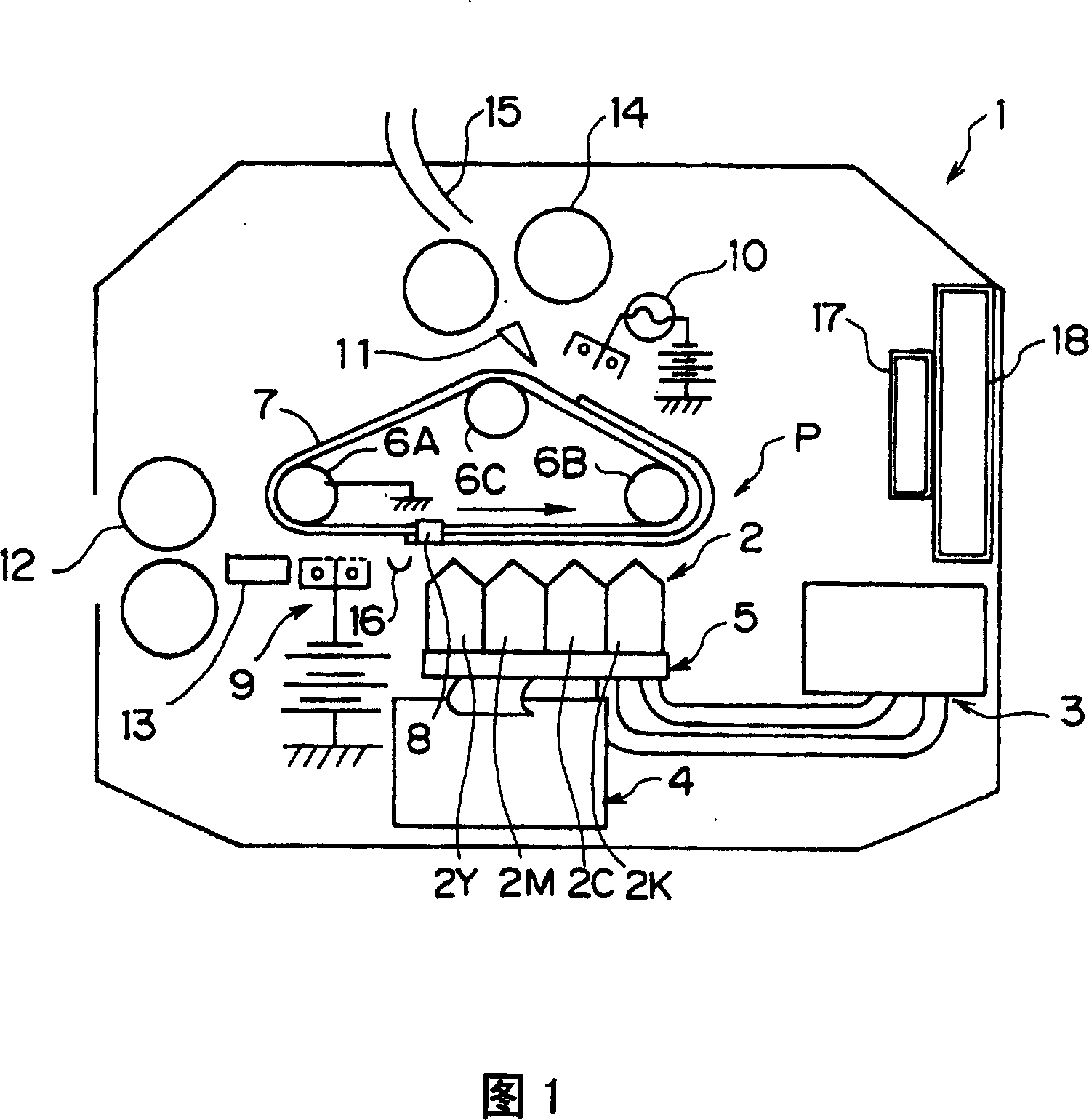

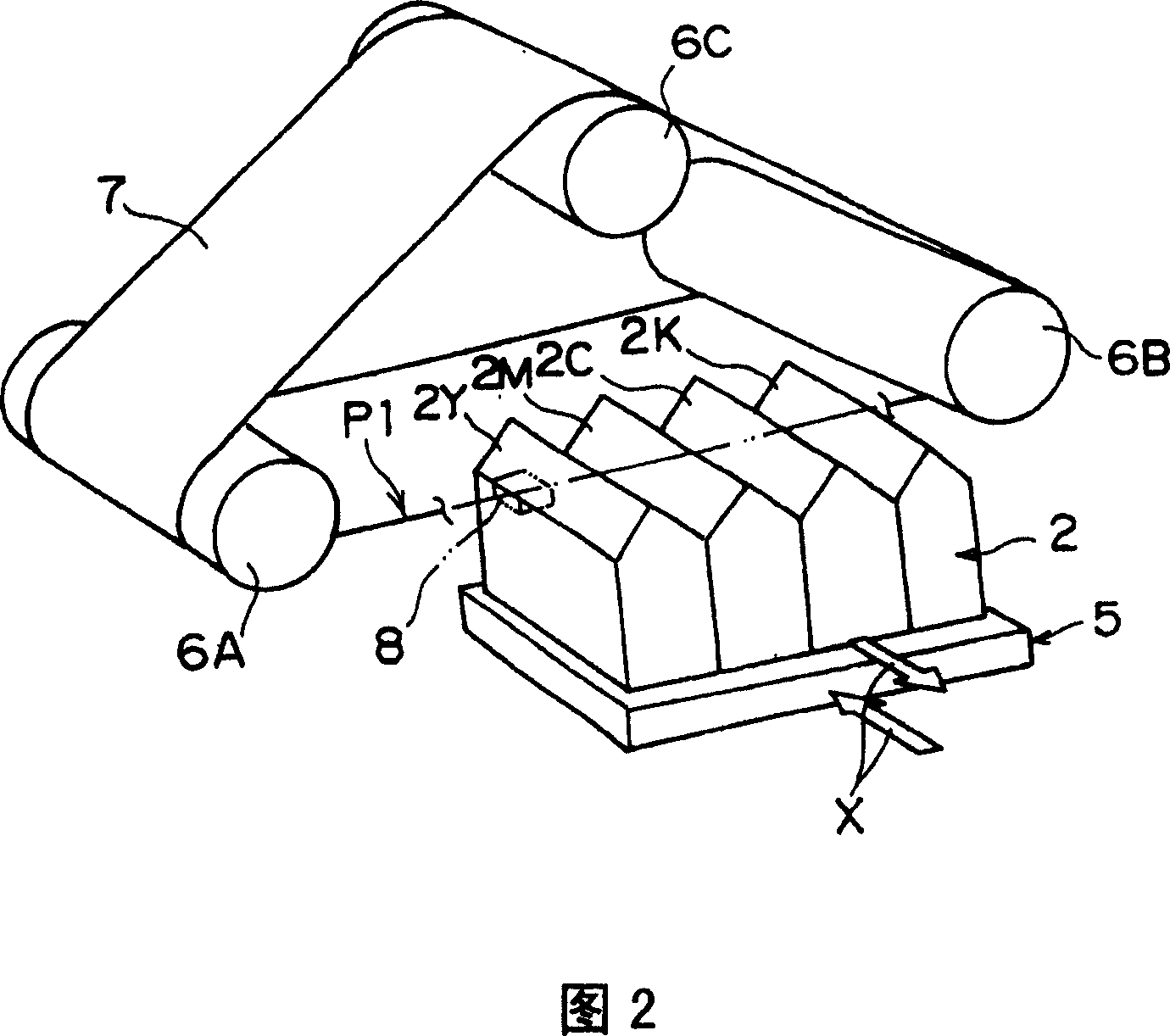

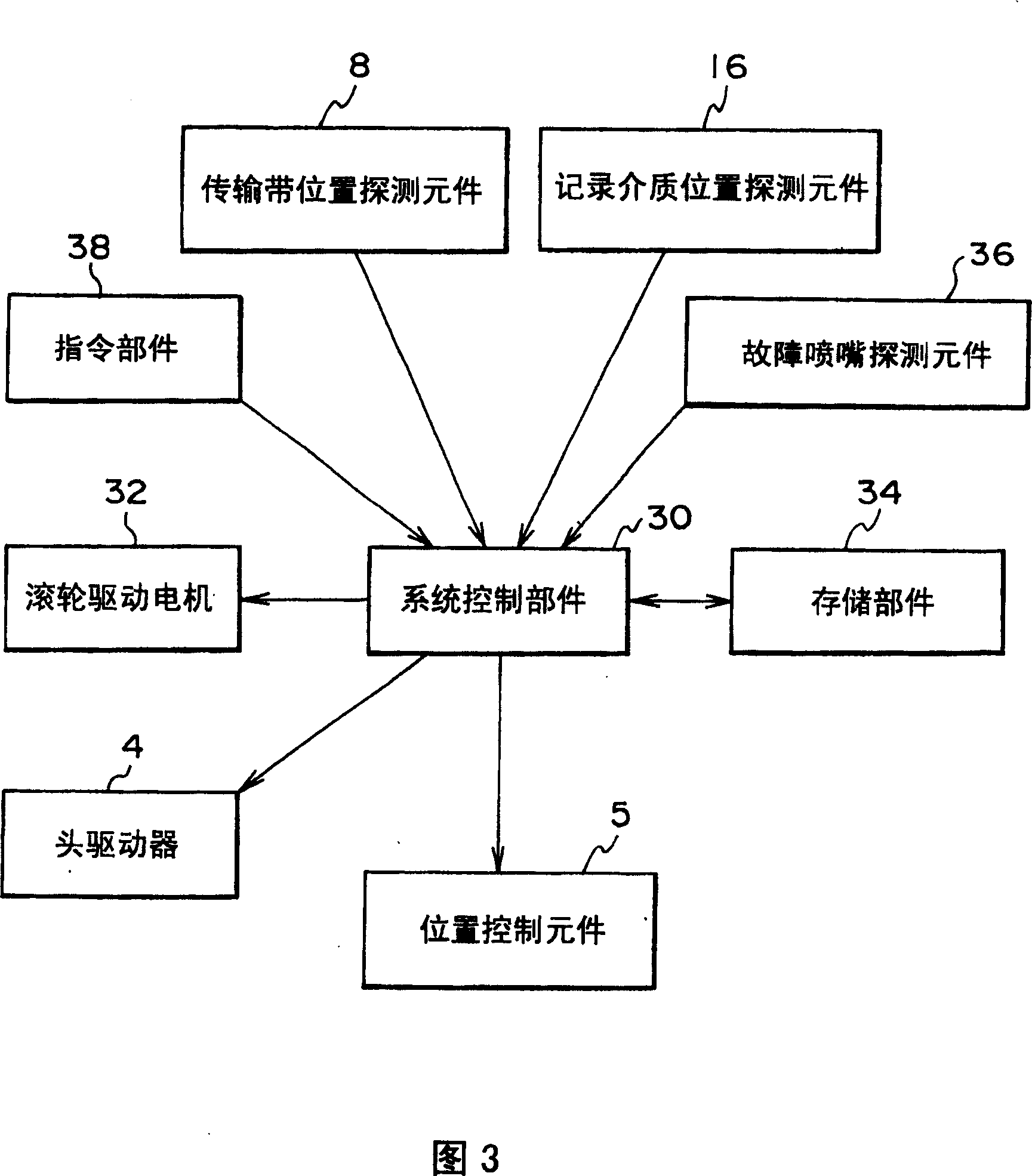

Ink-jet recording device and recording method

InactiveCN1470381AQuality improvementNo reduction in productivityInking apparatusOther printing apparatusEngineeringPosition control

An inkjet recording device and inkjet recording method capable of forming a high quality image with a simple structure. A transport belt position detection component detects a position of an end portion of a transport belt and outputs the detected position to a system control section. A recording medium position detection component detects a position of an end portion of a recording medium and outputs the detected position to the system control section. A position control component is capable of moving on the basis of instructions from the system control section for movement across a transport direction.

Owner:FUJIFILM CORP

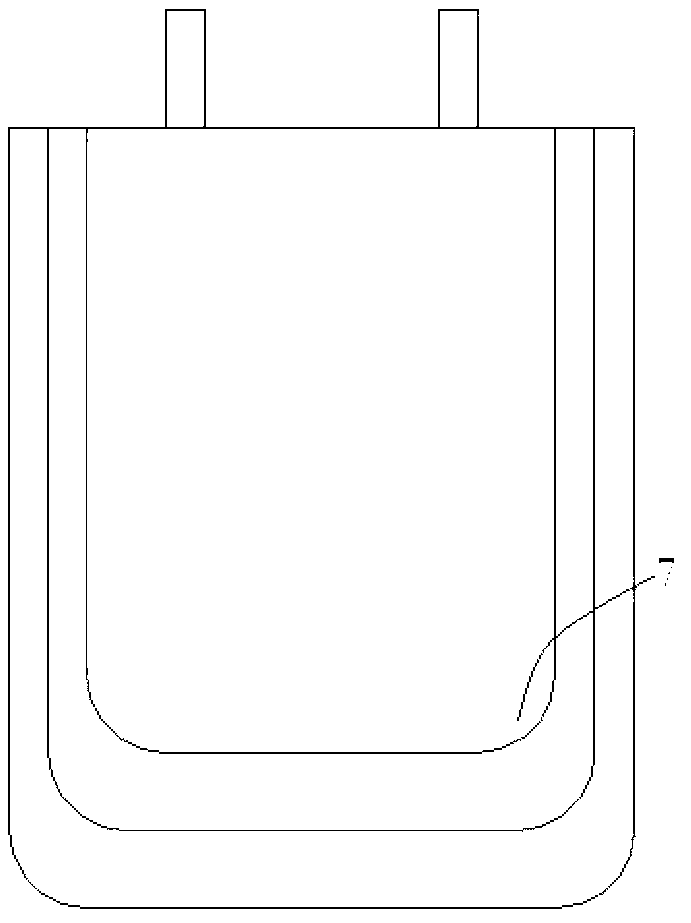

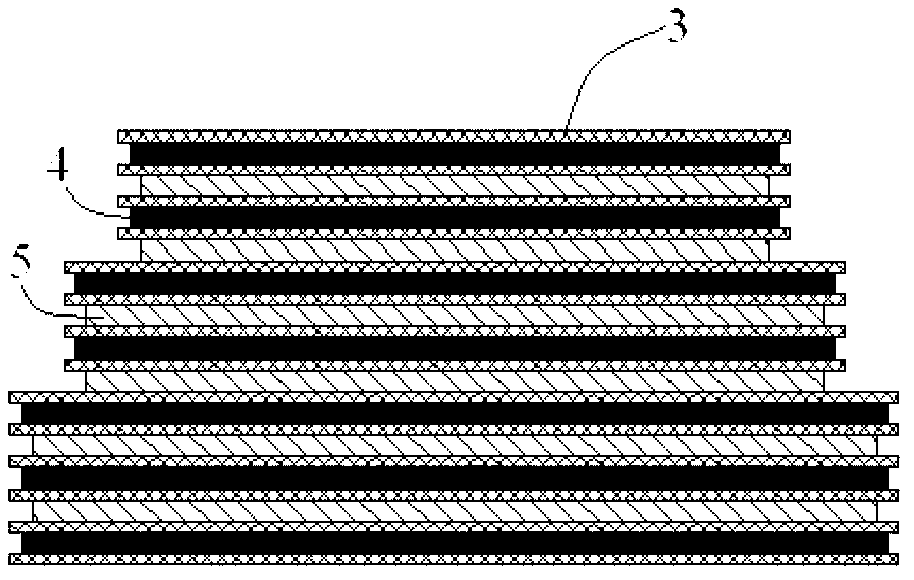

Method for preparing lithium ion cell

ActiveCN103346354ARealize continuous moldingNo reduction in productivityFinal product manufactureElectrolyte accumulators manufactureState of artPole piece

The invention discloses a method for preparing a lithium ion cell. The method comprises the following steps: 1) coating: coating along the unwinding direction of a current collector coil stock, wherein the number of coating areas is one or multiple, and two side edges of each coating area have uncoated areas as tab forming parts; 2) compacting; 3) pole piece cutting and forming; 4) preparing single cells and half cells; 5) step-like naked cell stacking; and 6) hot-press forming. Compared with the prior art, the method for preparing the lithium ion cell realizes the continuous forming of fillets and tabs and ensures fluency of production and high efficiency through the reasonable arrangement of the coating areas and the uncoated areas, and the production efficiency cannot be greatly reduced due to the special shape of the cell, so that the method is especially suitable for producing various lithium ion battery cells matched with irregular space shapes.

Owner:DONGGUAN AMPEREX TECH +1

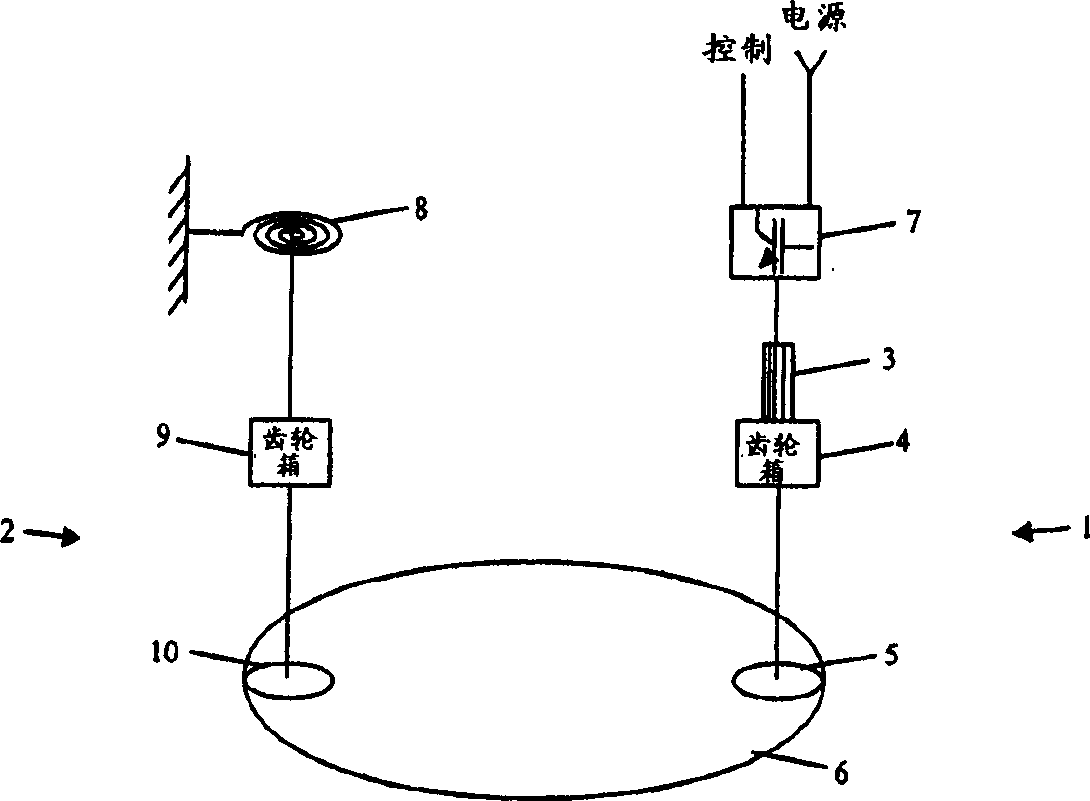

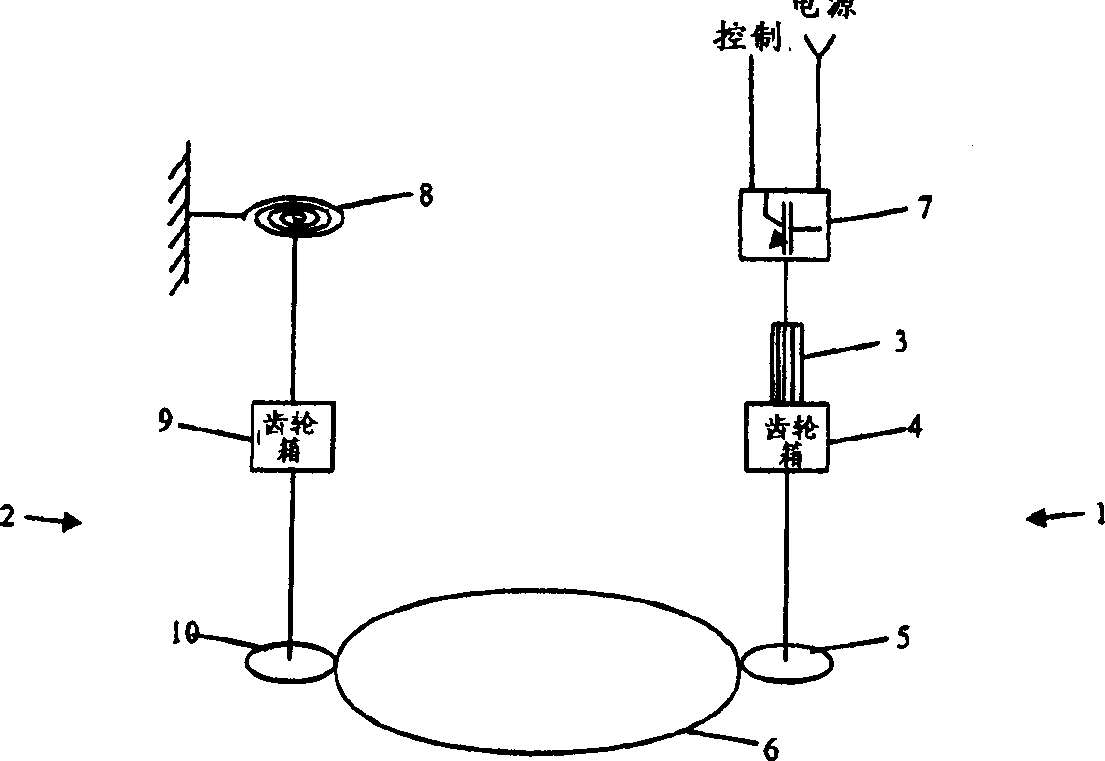

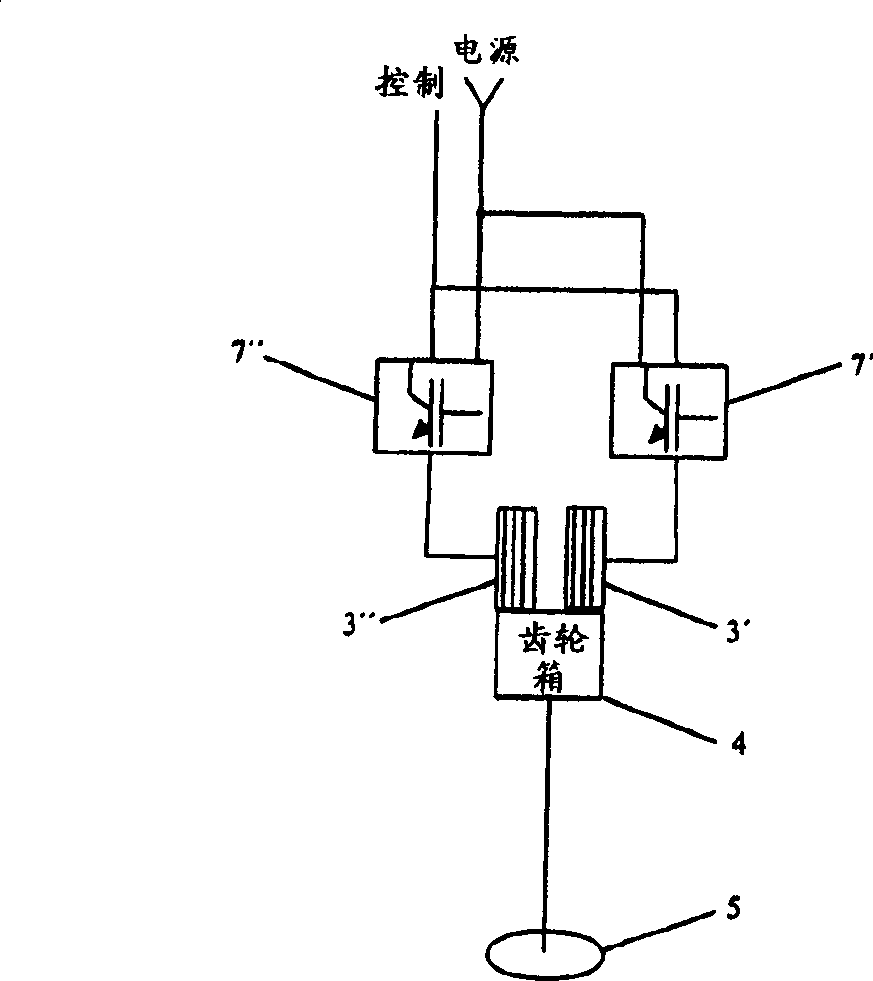

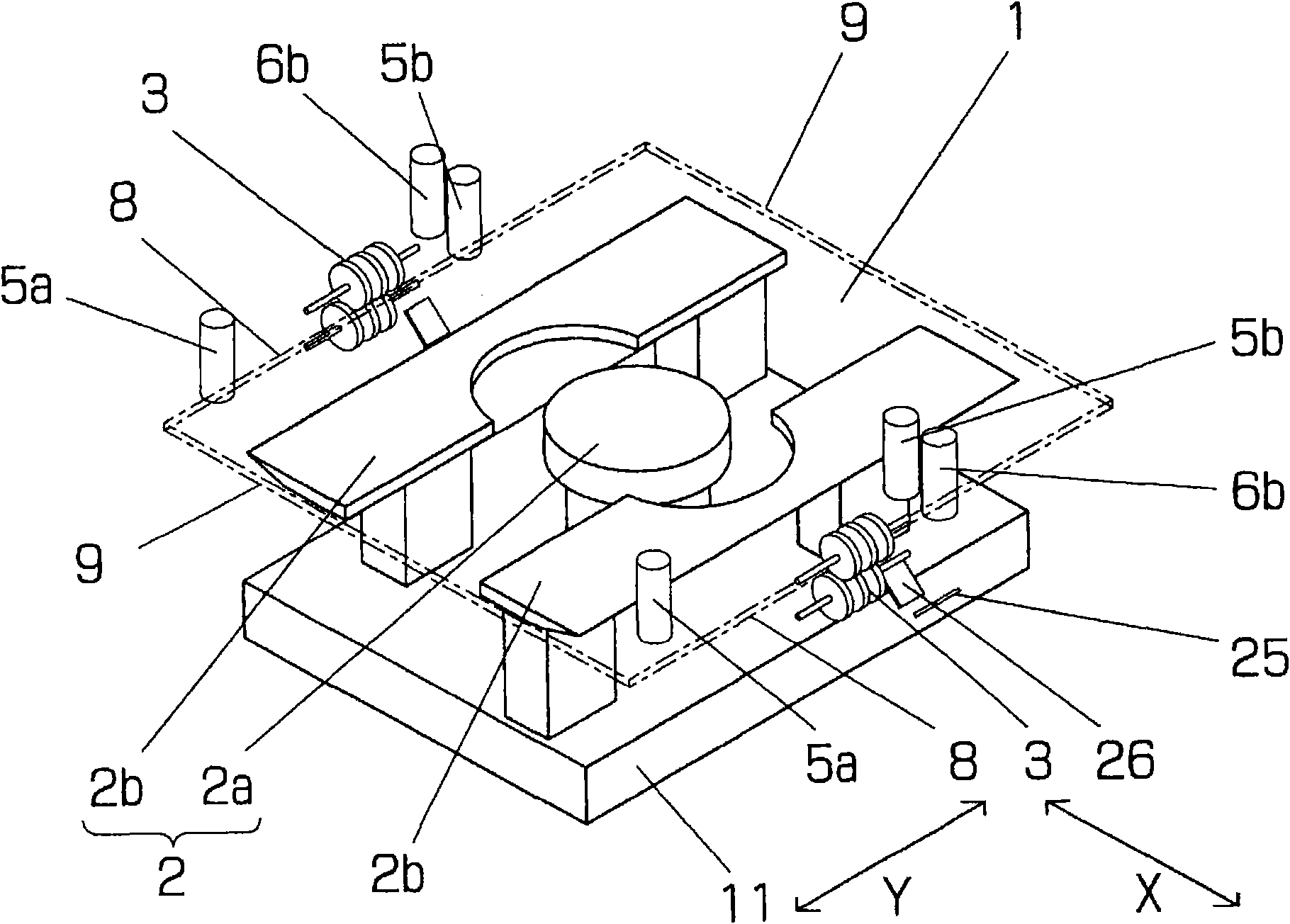

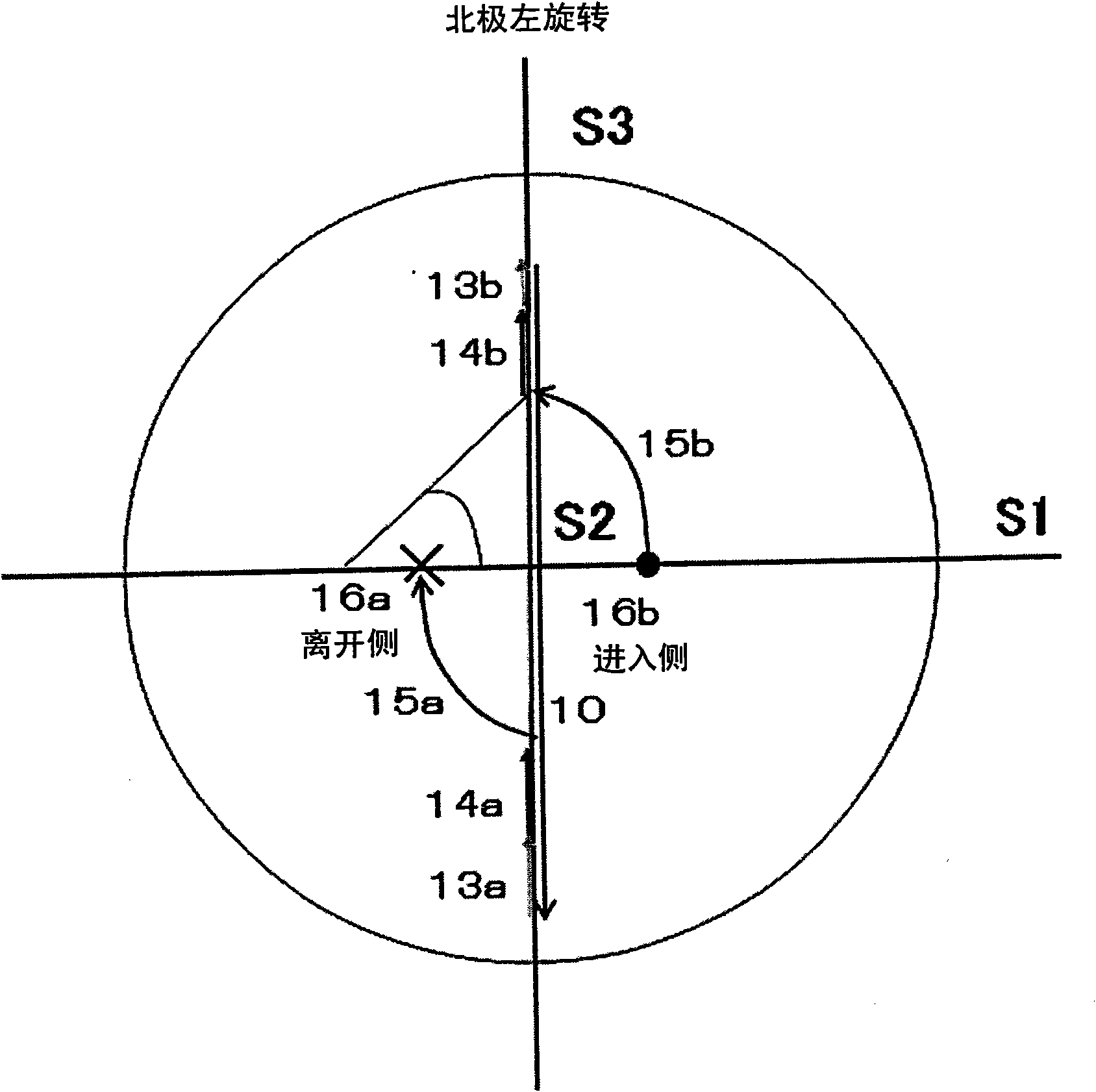

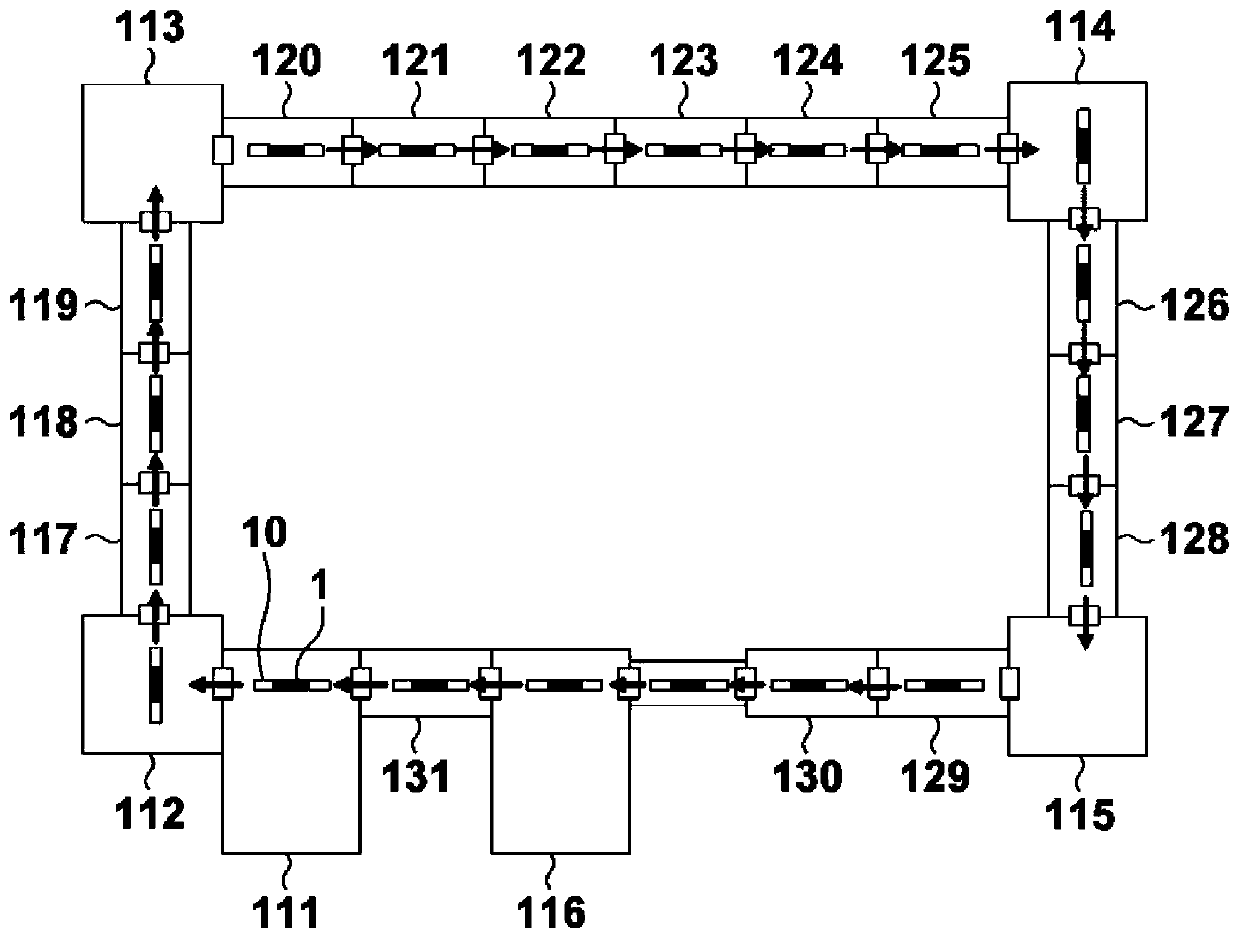

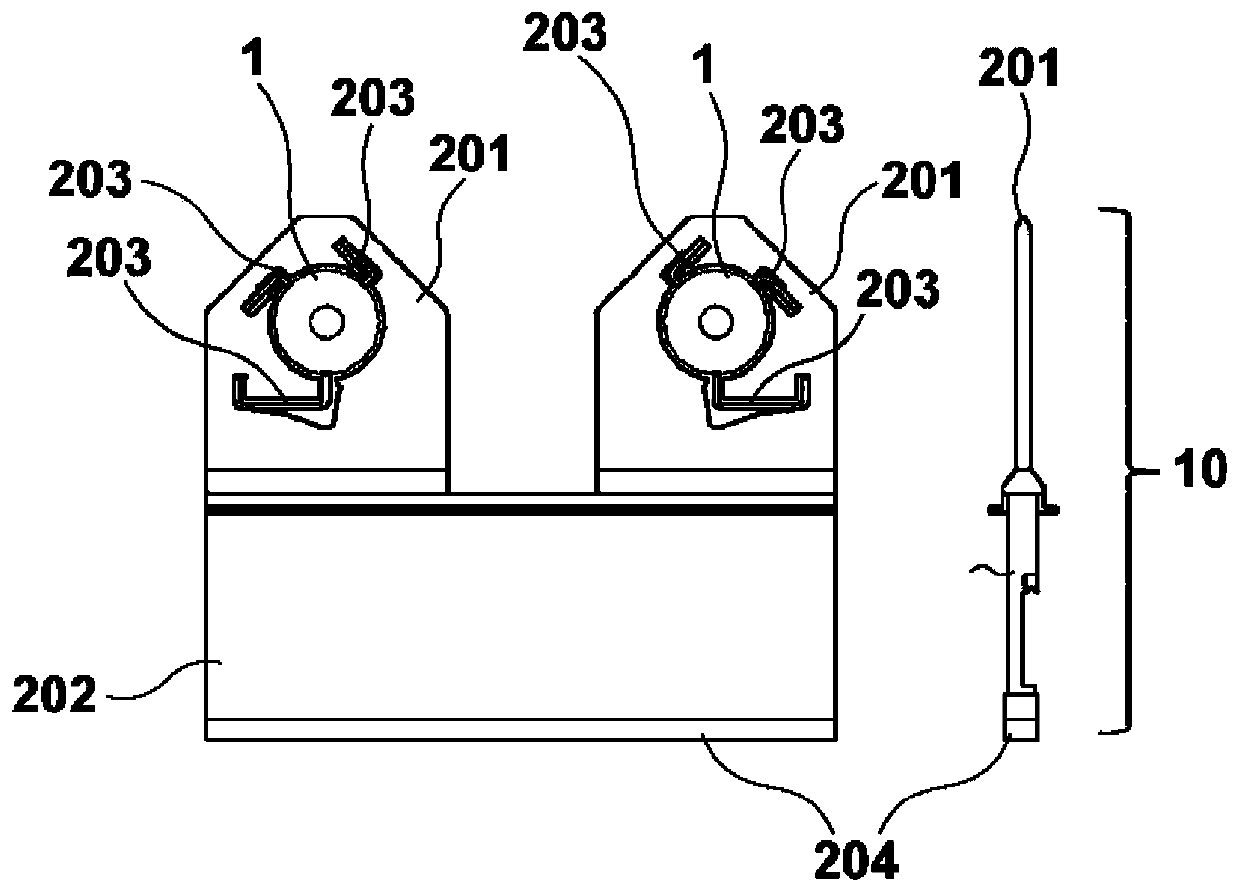

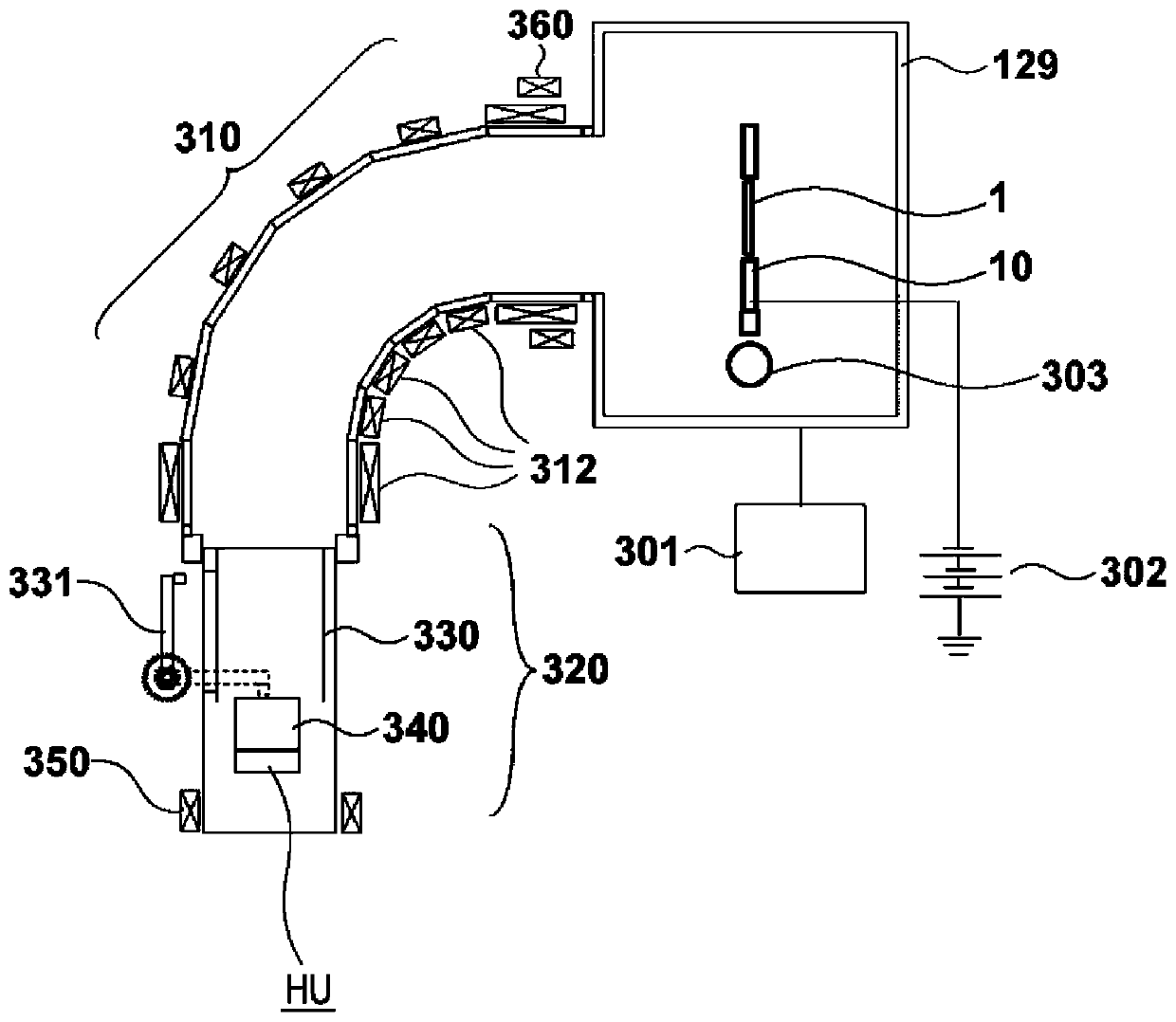

Pitch drive system for a wind turbine

InactiveCN1782369AAvoid downtimeNo reduction in productivityWind motor controlMachines/enginesControl theoryTurbine

A pitch drive system for a wind turbine is provided, comprising an adjustment drive (1) for adjusting the pitch of rotor blades of the wind turbine during normal operation, the adjustment drive comprising at least one drive chain ( 3, 4, 5); and an emergency drive (2) for tilting a rotor blade in an emergency, said emergency drive comprising at least one drive chain (8, 9, 10), wherein the emergency drive At least one transmission chain (8, 9, 10) of (2) is independent of at least one transmission chain (3, 4, 5) of the adjustment drive (1).

Owner:GENERAL ELECTRIC CO

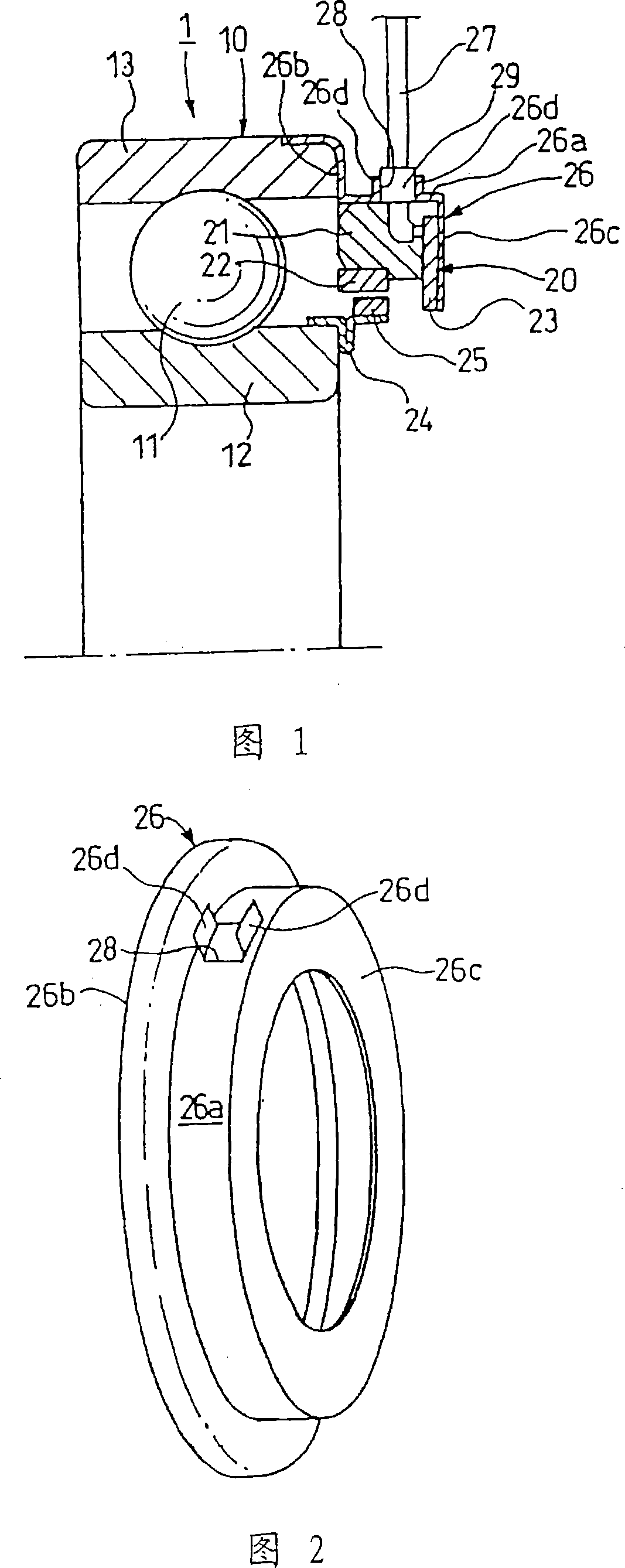

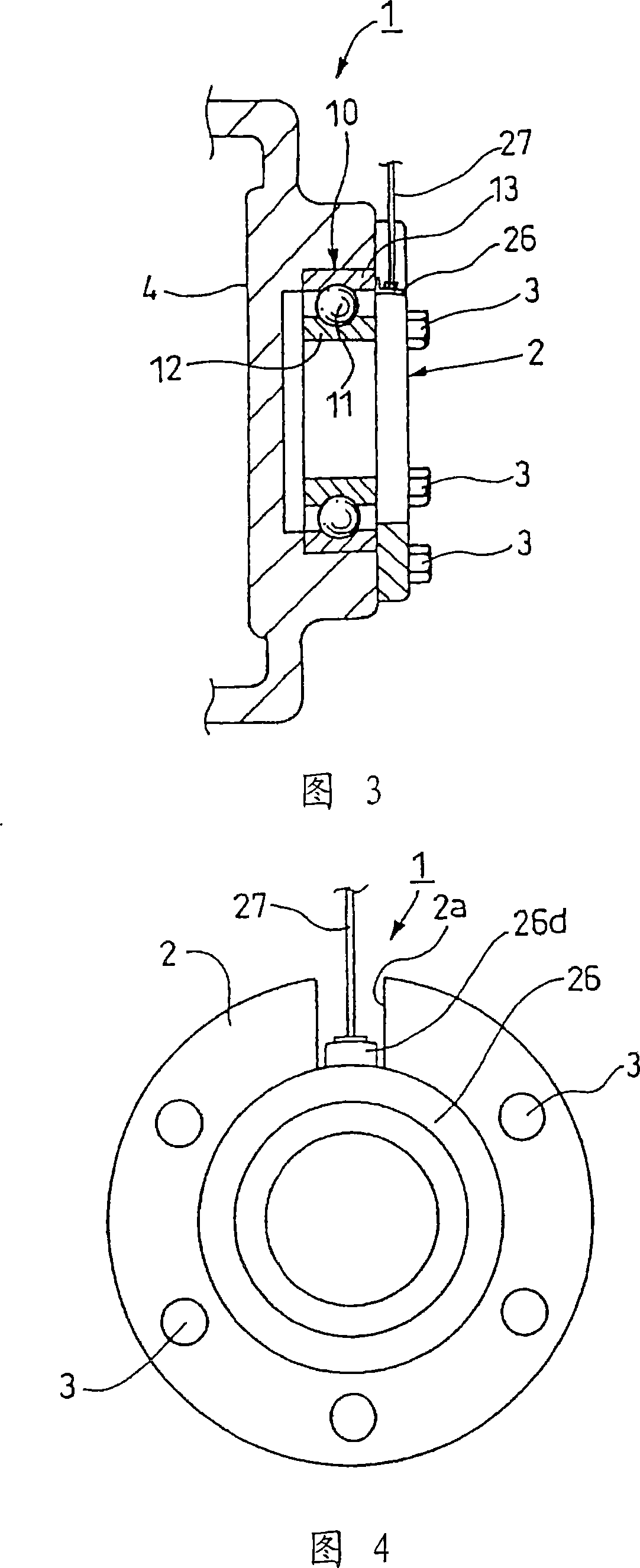

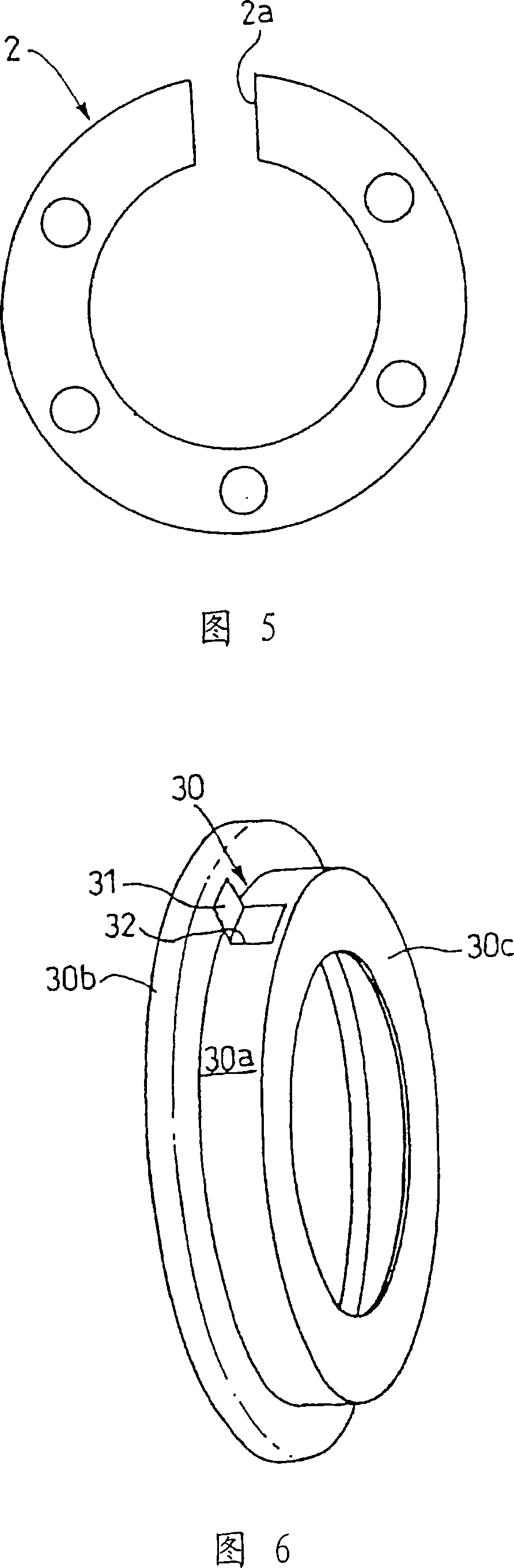

Bearing device with sensor and rolling bearing with sensor

InactiveCN101187404APrevent rotationSimple structureBearing assemblyLinear/angular speed measurementRolling-element bearingEngineering

The present invention relates to a bearing apparatus with a sensor and a rolling bearing with a sensor used to movers such as automobiles or railway carriers, facility machines of equipment, or machine tools. One of the embodiments comprises a sensor detecting conditions of the rolling bearing, a ring-shaped sensor cover housing the sensor therein and secured to a stationary-side bearing ring, and a ring shaped presser member secured to a bearing housing provided outside in a radius direction of the sensor cover, or secured to a shaft, and an opening portion is provided at a decided portion of the sensor cover, and projections standing toward a side of the presser member are furnished in the circumference of the opening portion, the presser member is defined with cutouts for inserting the projections, and the cutouts are arranged with the projections.

Owner:NSK LTD

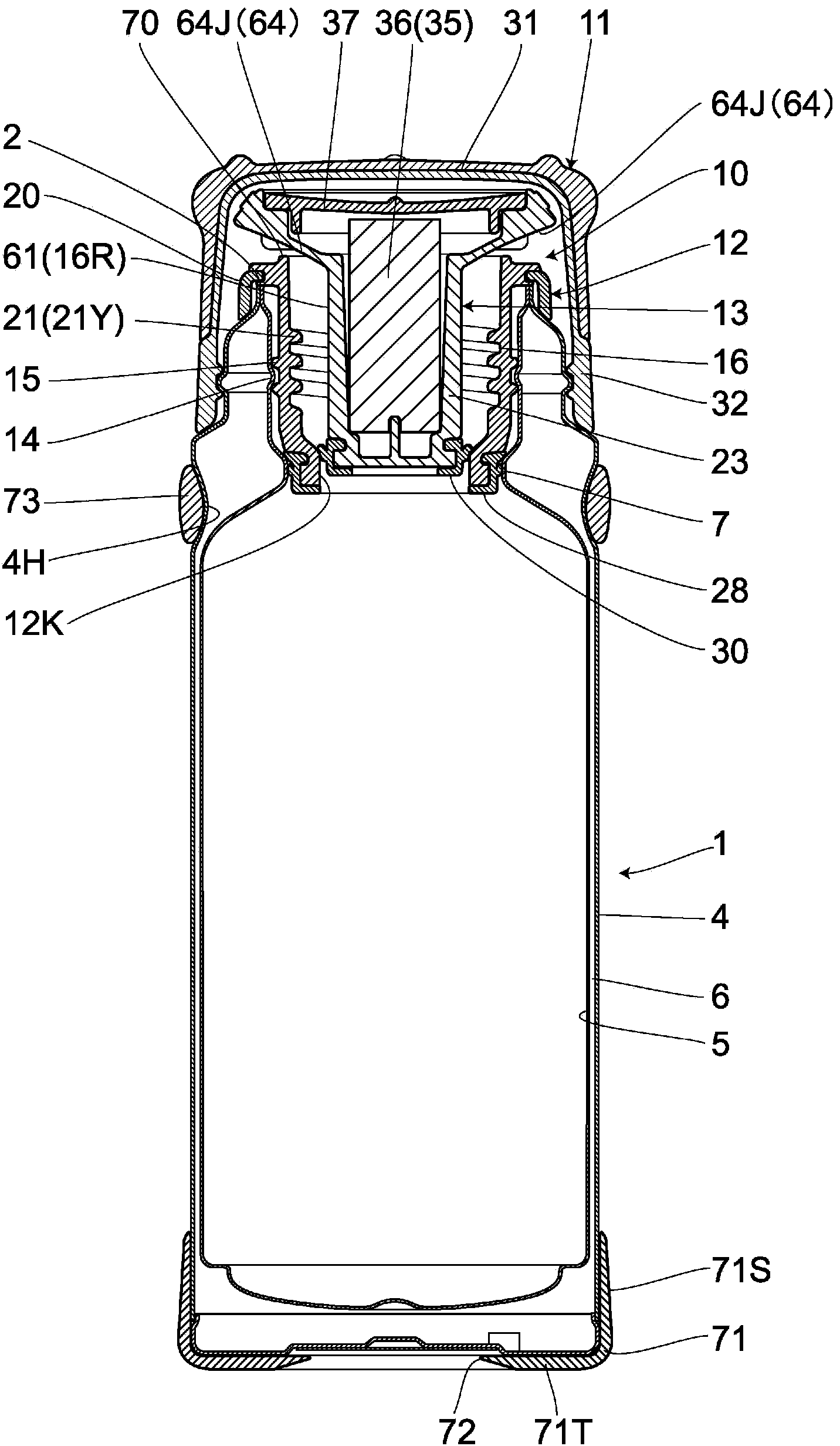

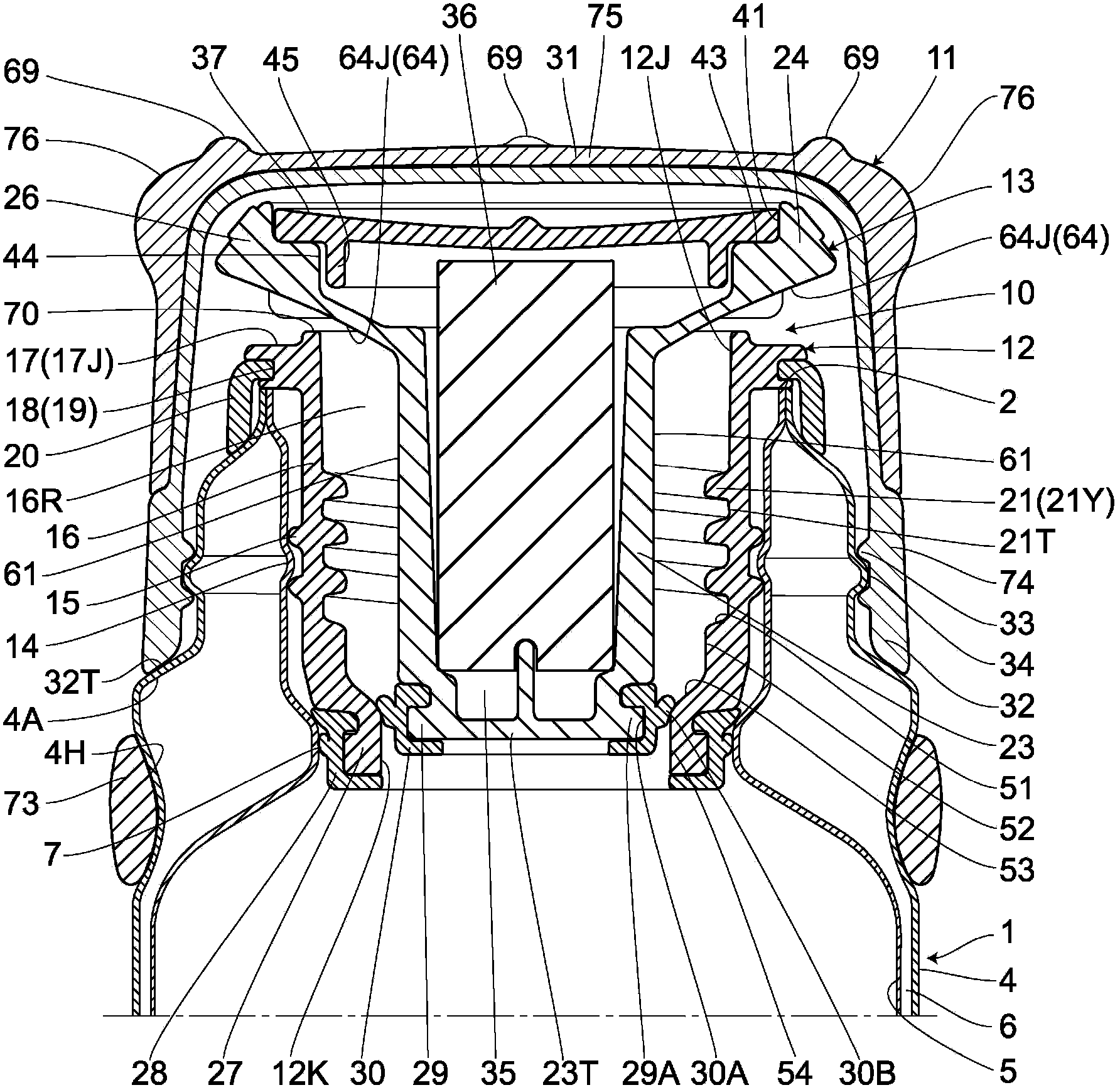

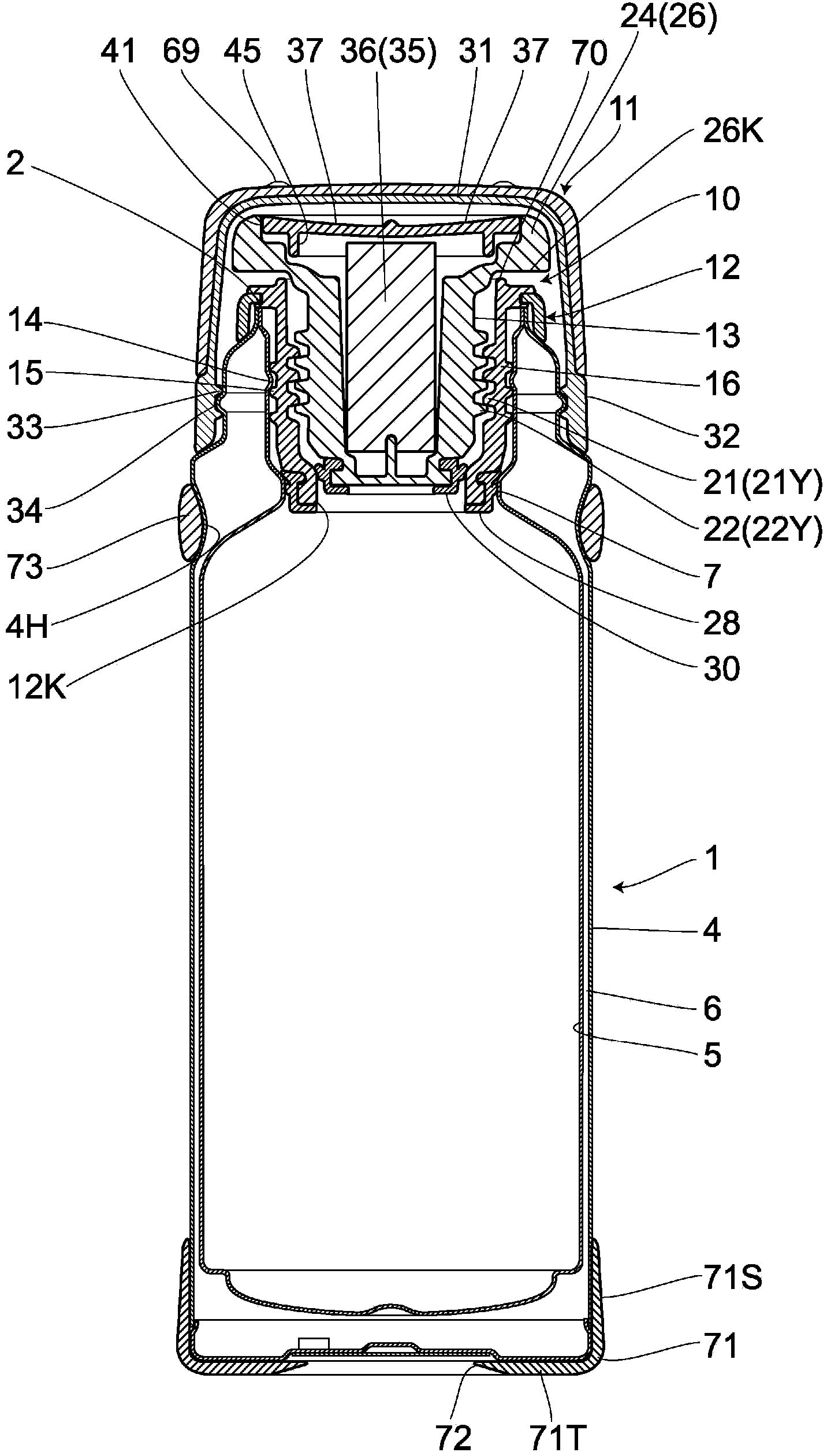

Plug assembly for beverage container

ActiveCN104108520AStable tightening stateSteady injectionNon-pressured vesselsDrinking vesselsEngineeringMechanical engineering

Provided is a plug assembly for a beverage container, exhibiting a favorable pourability without hindering a compactness. The assembly includes: an outer plug (12) fitted into an upper opening of a container body (1) and having an outflow passage (16R) therein; and an inner plug (13) fitted into an upper opening section of the outer plug (12). Provided on the inner circumferential surface of the outer plug (12) is a female screw (21) having a thread continuous in the radial direction and used to attach the inner plug (13). Provided on the outer circumferential surface of the inner plug (13) is a male screw (22) corresponding to the female screw (21). Flow passages (61) are formed by vertically cutting out at least a part of the male screw (22), and provided on the upper regions of the flow passages (61) are control walls (64J) linearly slanting upward and outward. A stable screwed state can be consistently maintained regardless of the locations of the flow passages (61).

Owner:THERMOS LLC +1

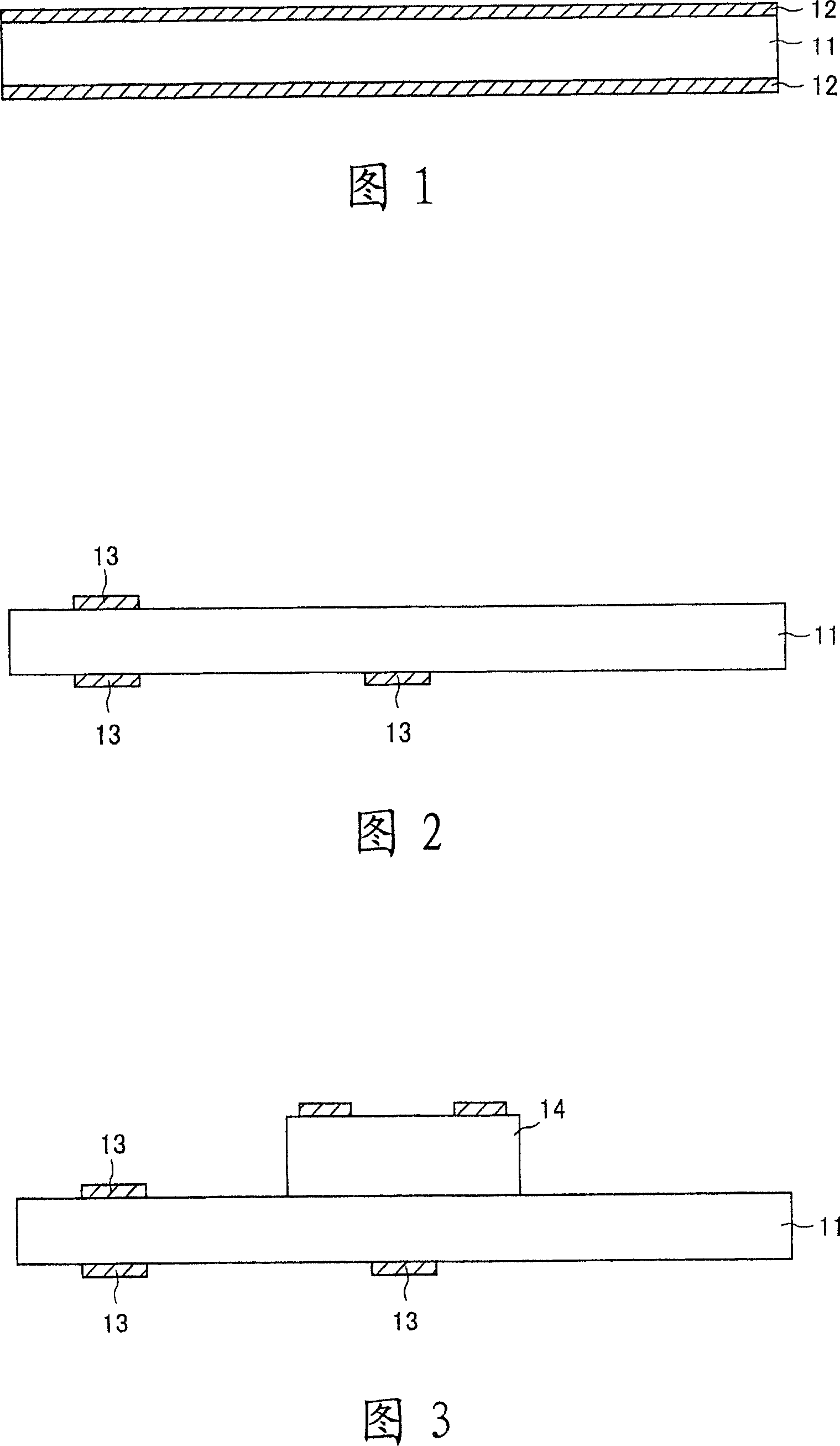

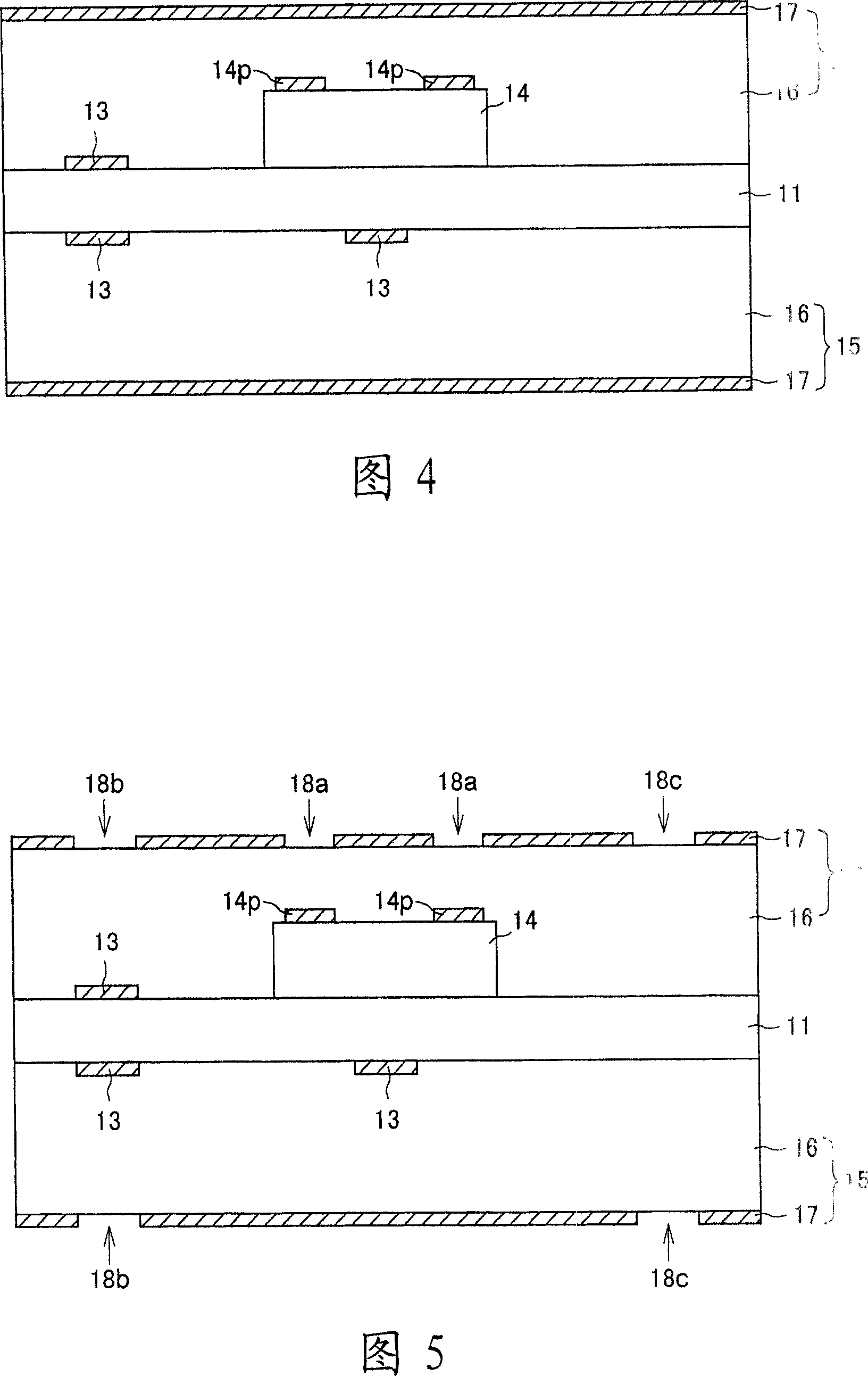

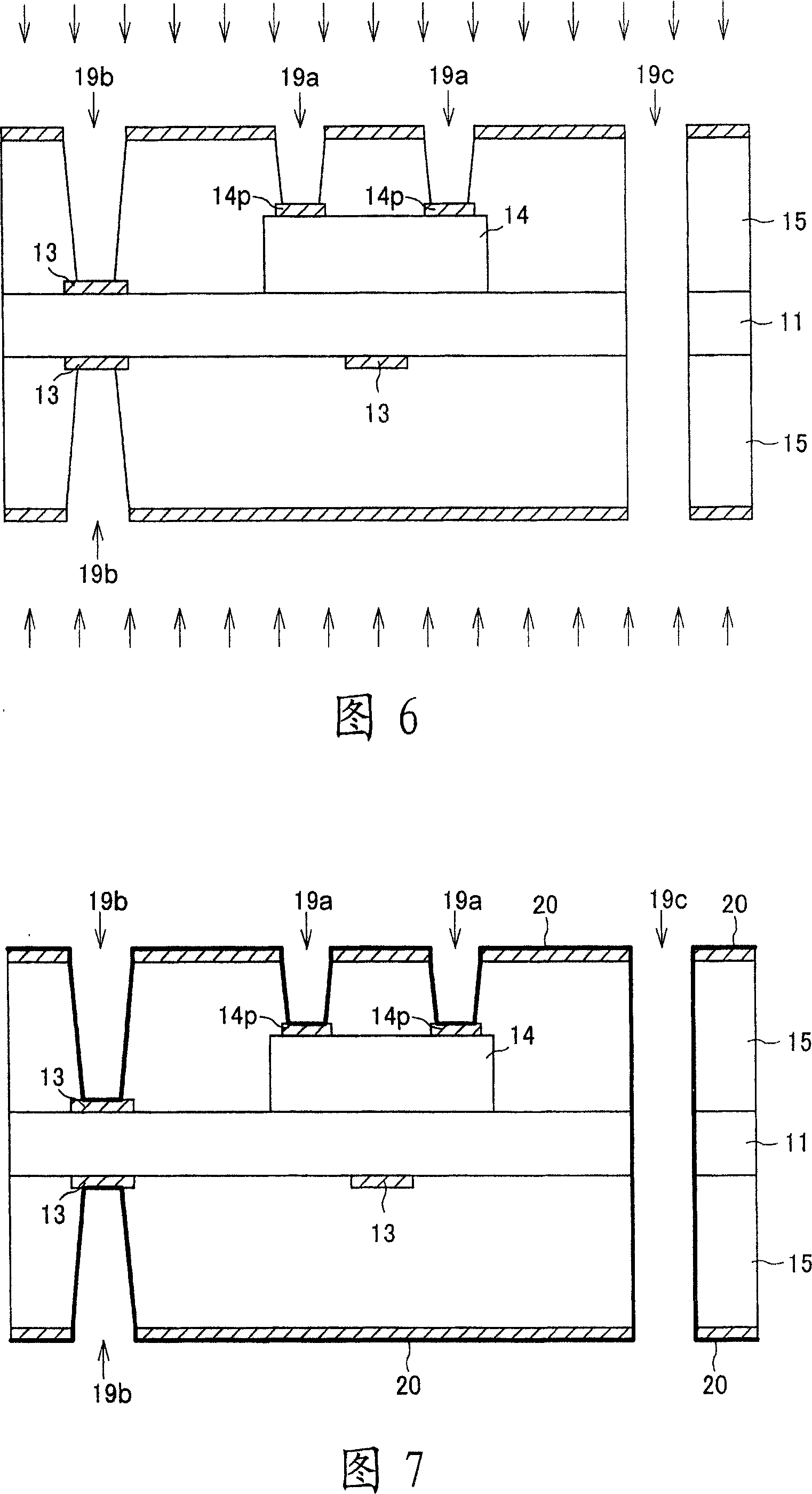

Method for manufacturing ic-embedded substrate

InactiveCN1988120AWon't hurtNo reduction in productivityPrinted circuit assemblingSemiconductor/solid-state device detailsEtchingCopper foil

The invention provides a method for manufacturing an IC-embedded substrate without generating damages on a semiconductor IC chip embedded in a resin layer due to heating and weighting (stress), and is able to manage increase and finely spaced of number of pad electrodes. Firstly, a copper foil (12) disposed on either side of the core substrate (11) is selectively removed by photolithography and etching, whereby a conductor pattern (13) comprising wiring and lands is formed on the core substrate (11). Next, after a semiconductor IC chip (14) is mounted face up in a prescribed region on the core substrate (11), it is embedded in a resin sheet (16). Then, a copper foil (17) formed on a surface of the resin sheet (16) is selectively removed by shape-maintained machining, as as to form a mask pattern for forming an aperture. Thereafter, the aperture is formed by a sand-jetting processing in which the copper foil (17) applied with shape-maintained machining is used as the mask.

Owner:TDK CORPARATION

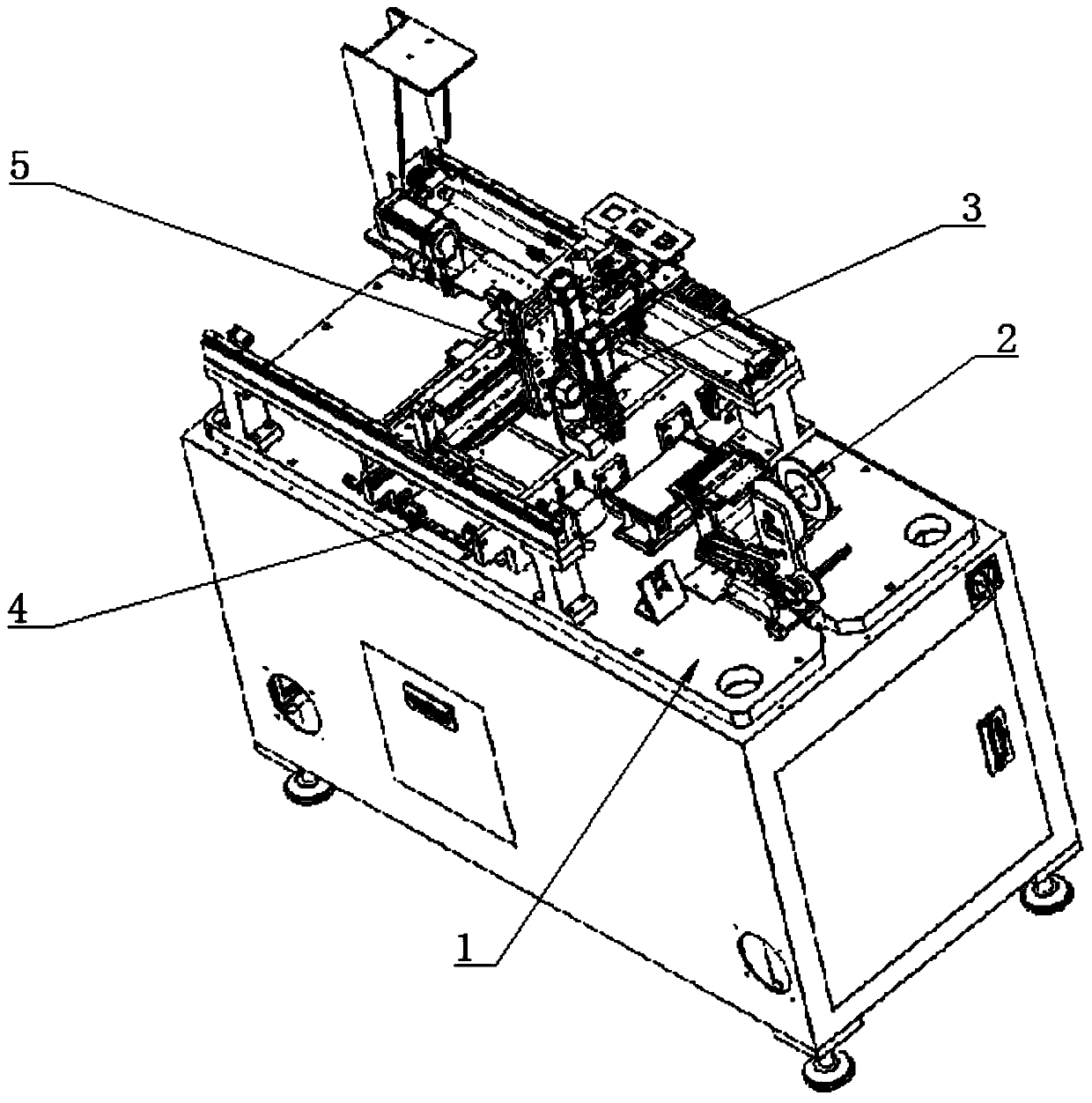

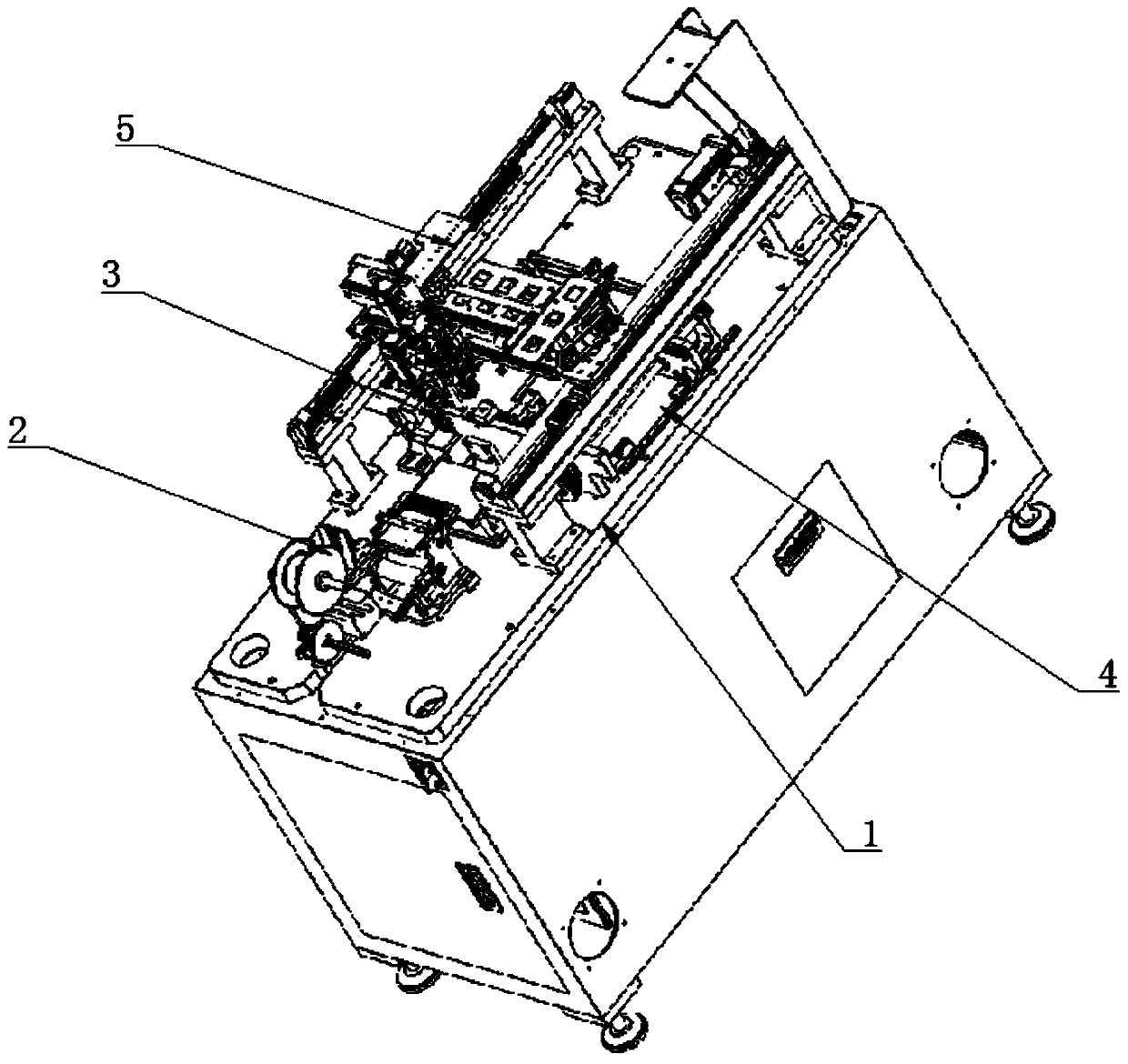

Automatic labeling machine

PendingCN110654669ASpeed up biddingImprove work efficiencyLabelling machinesProcess engineeringIndustrial engineering

The invention discloses an automatic labeling machine. The automatic labeling machine comprises a labeling machine table. An automatic label feeding device, a label suction nozzle device, a moving rail device and a marking device are mounted on the labeling machine table. Through integral use of the above devices, the automatic labeling machine can automatically and quickly discharge labels when implementing automatic labeling operation, can protect suction nozzles against damage when bearing a certain impact force or protect products against damage by the suction nozzles bearing a certain impact force, can achieve the quick adjusting function on different specifications of products during operation, can find damaged or tainted labels in time during operation, thereby improving the production quality and production efficiency of labeling automatic production.

Owner:苏州朗翔机电设备有限公司

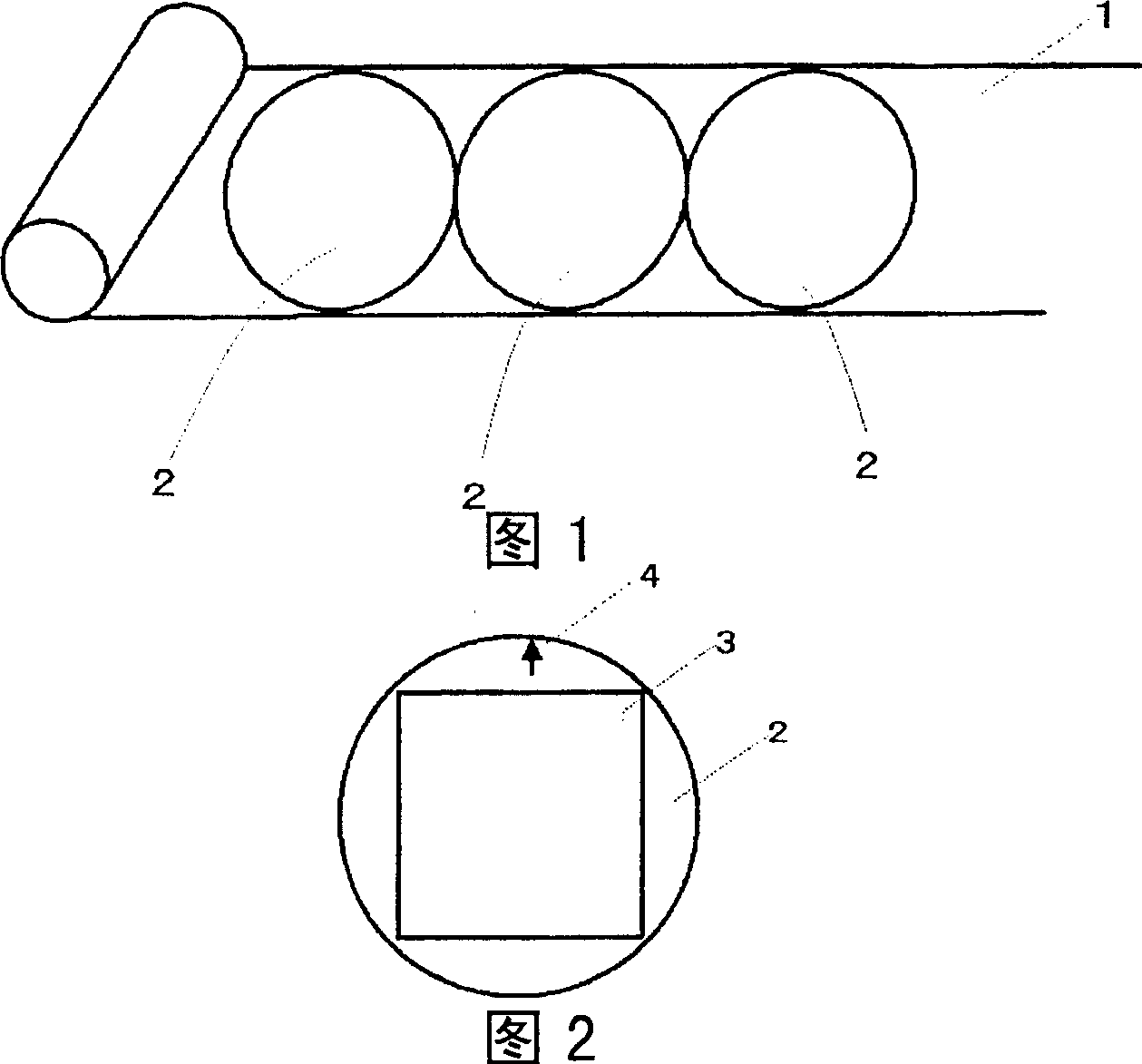

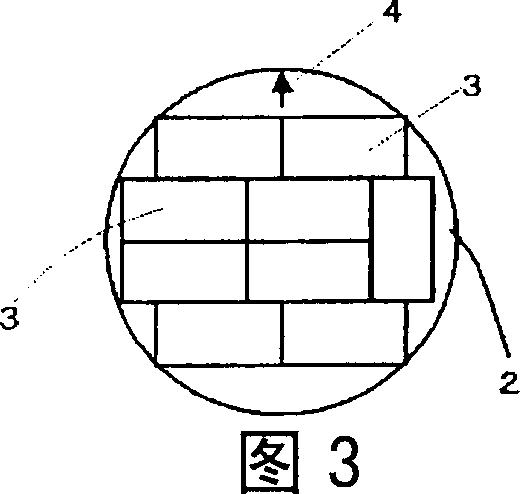

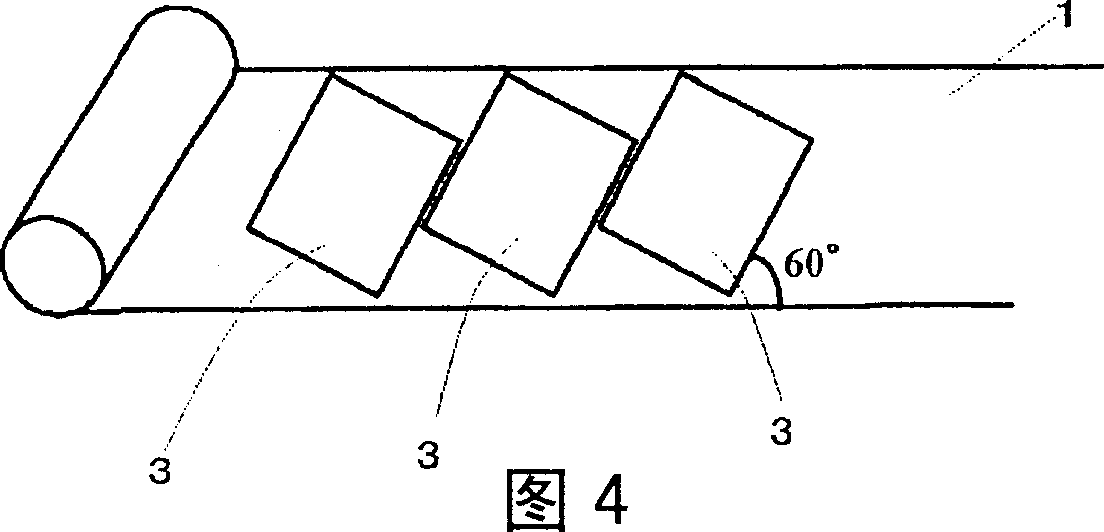

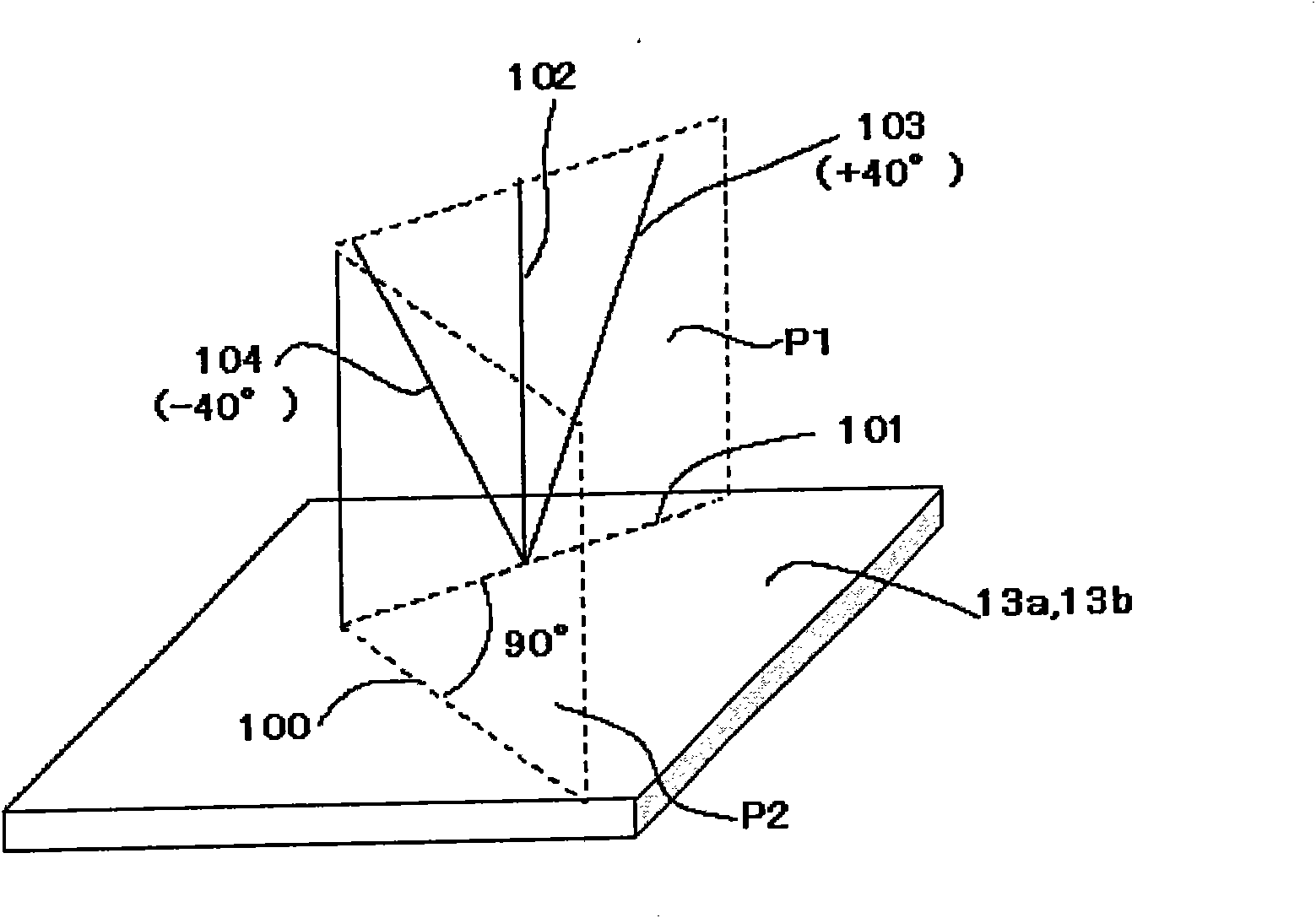

Optical member, method of manufacturing the same, and image display device applying the same

InactiveCN1947041AIncreased Design FreedomNo reduction in productivityPolarising elementsNon-linear opticsOptical axisDisplay device

A highly versatile optical member machined into a circular shape for eliminating the effect of optical axis unique to optical members is disclosed which is capable of facilitating stock control without lowering production efficiency. An optical member having a higher degree of freedom in design can be provided by employing such a production method wherein a long optical member is machined into a circular shape and then the circular optical member is machined into a desired shape so that the optical axis can be adjusted finely even after machining of the long optical member.

Owner:NITTO DENKO CORP

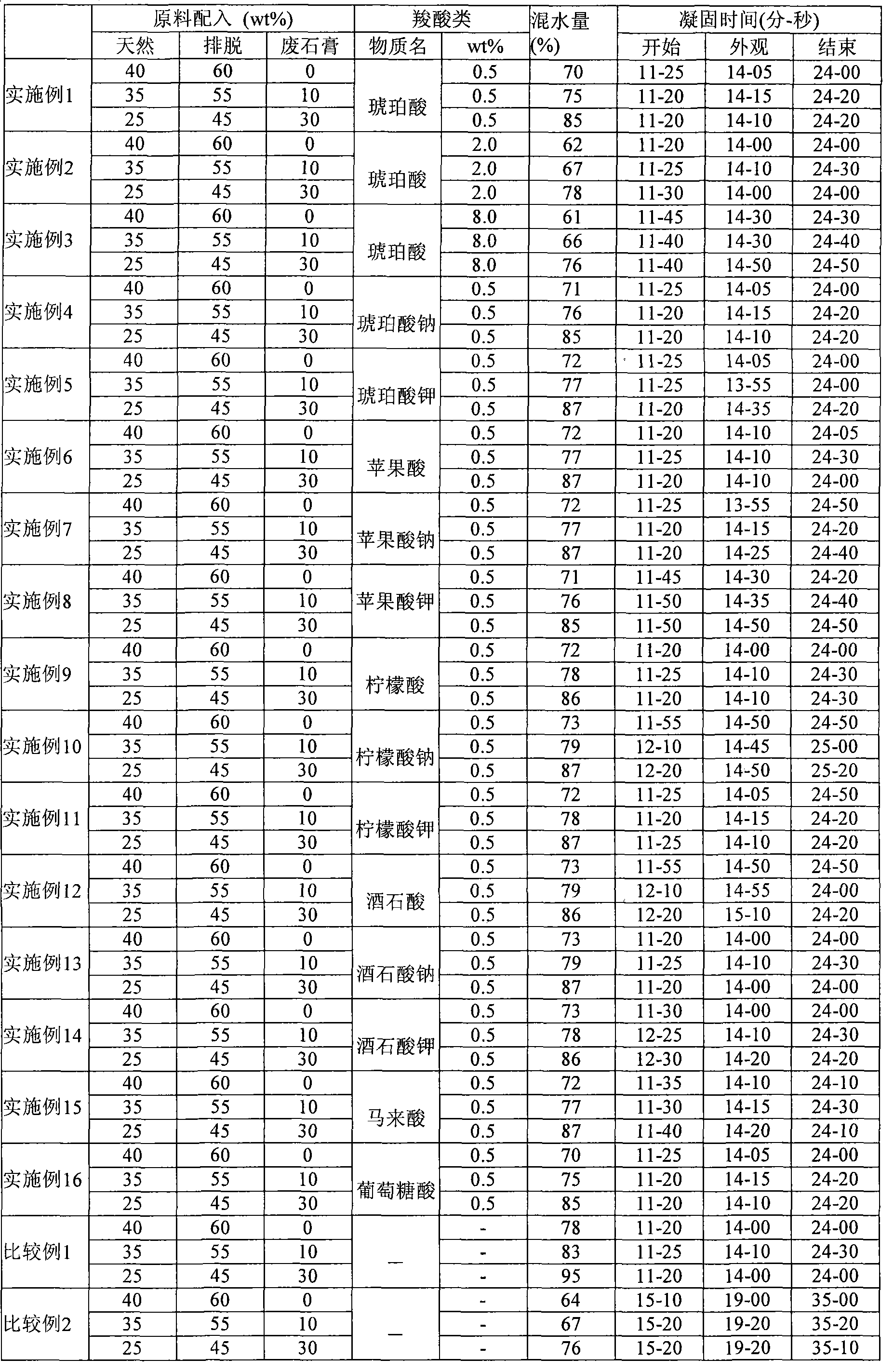

Process for producing calcined gypsum and gypsum board

InactiveCN101479209ALess water mixingThe setting time will not be prolongedSolid waste managementCalcium/strontium/barium sulfatesCarboxylic acidGypsum

The invention provides a process for calcined-gypsum production which attains a reduction in the amount of water to be mixed and does not prolong setting time. A raw-material gypsum is calcined after a carboxylic acid is incorporated thereinto, whereby calcined gypsum can be obtained which necessitates a smaller amount of water to be mixed therewith and needs no prolonged setting time. Even when recycled gypsum, which leads to an increase in the amount of water to be mixed, is used in a large amount as a raw material for gypsum, the calcined gypsum produced by the process is reduced in the amount of water to be mixed therewith and needs no prolonged setting time. Consequently, ordinary gypsum boards can be produced without lowering the productivity thereof.

Owner:YOSHINO GYPSUM CO LTD

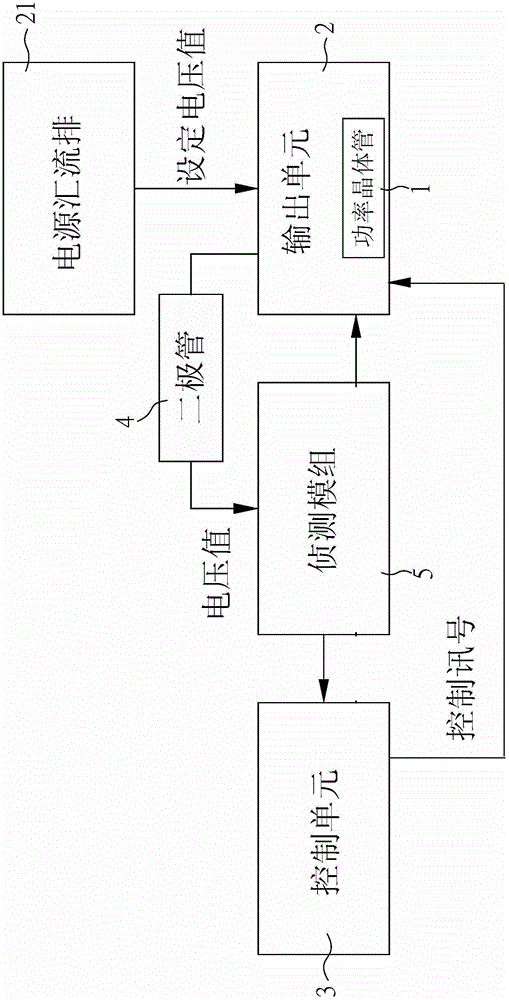

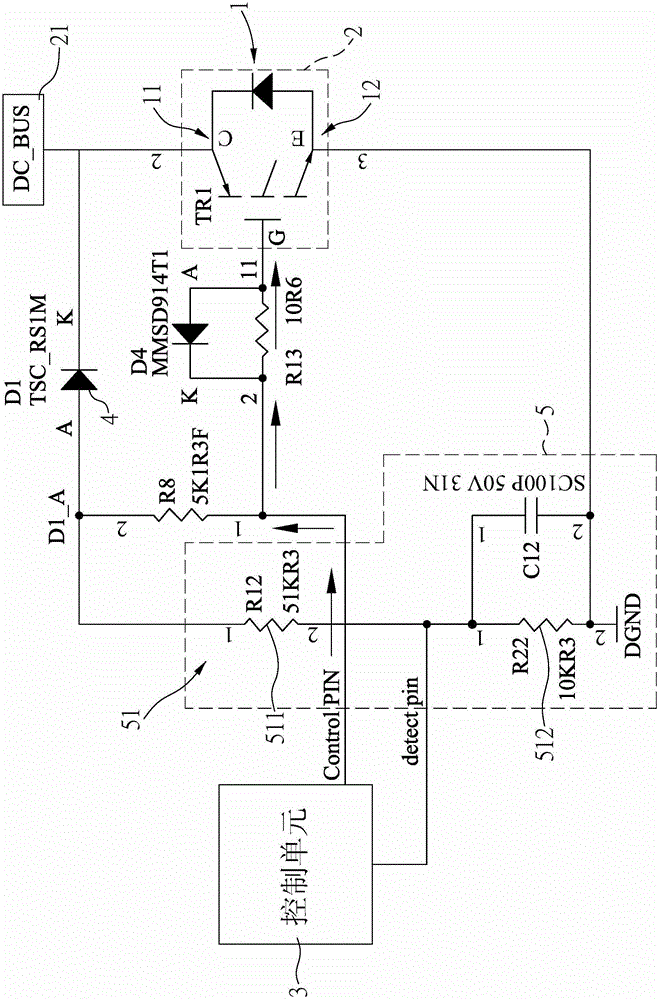

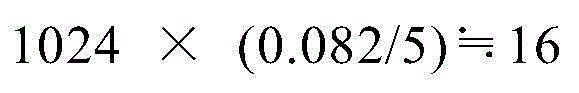

Protecting and detecting circuit for power transistor

InactiveCN105098731AAvoid harmNo reduction in productivityEmergency protective circuit arrangementsInternal resistanceControl signal

The present invention discloses a protecting and detecting circuit for a power transistor. The circuit includes: an output unit, a control unit, a diode, and a detecting module. The power transistor generates a first voltage due to an internal resistance, and generates a second voltage after voltage crossing via the diode. The second voltage is divided by a voltage division circuit of the detecting module and then is transferred to the control unit, a digital analogue converter converts the second voltage from an analogue signal into a comparison value of a digital signal, and an accident that the control unit cuts off a control signal results in a failure to actuate when the comparison value is larger than a limit value.

Owner:PRECISION MACHINERY RES & DEV CENT

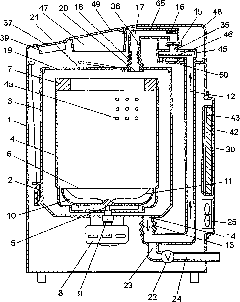

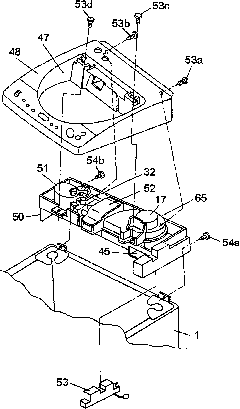

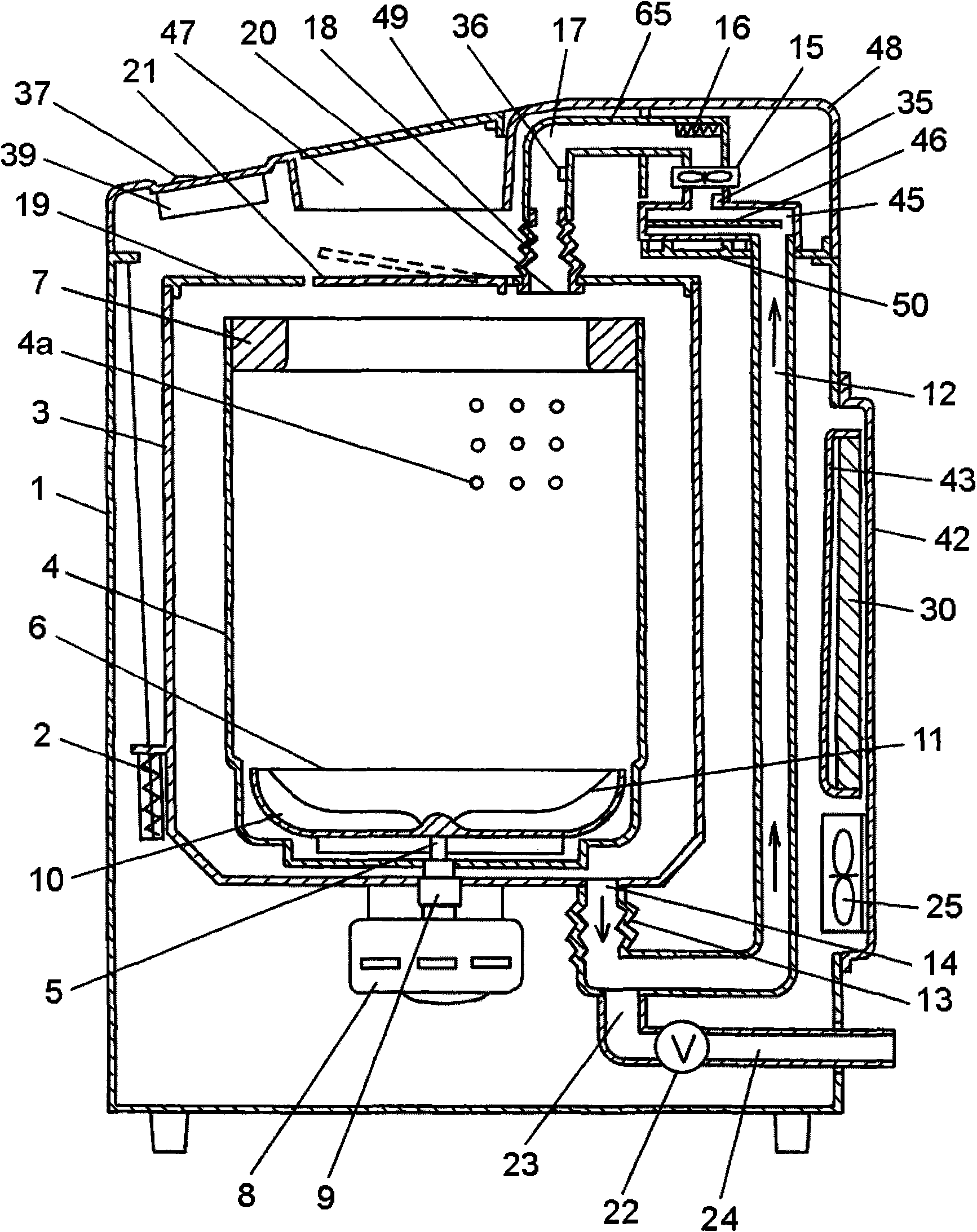

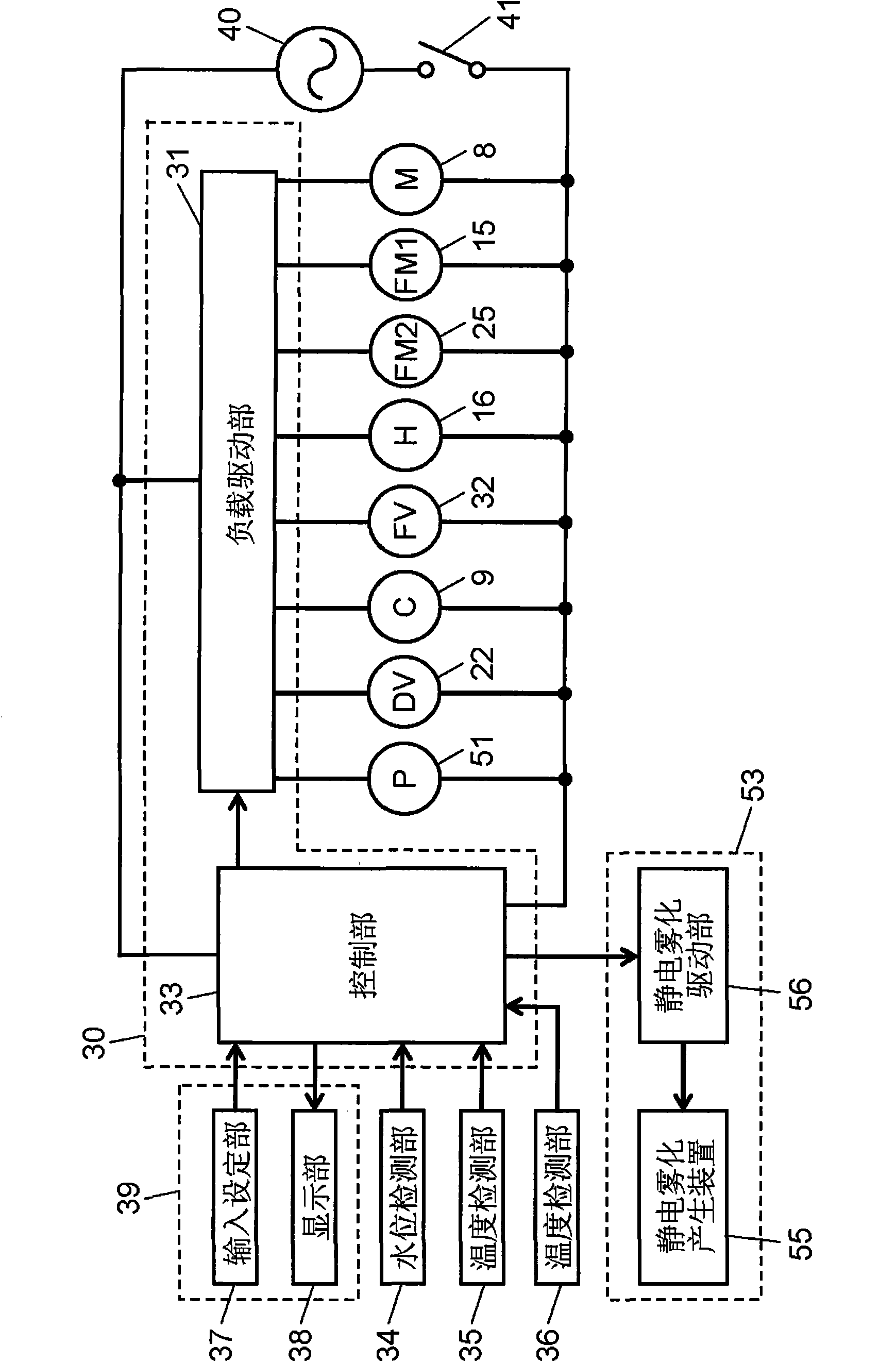

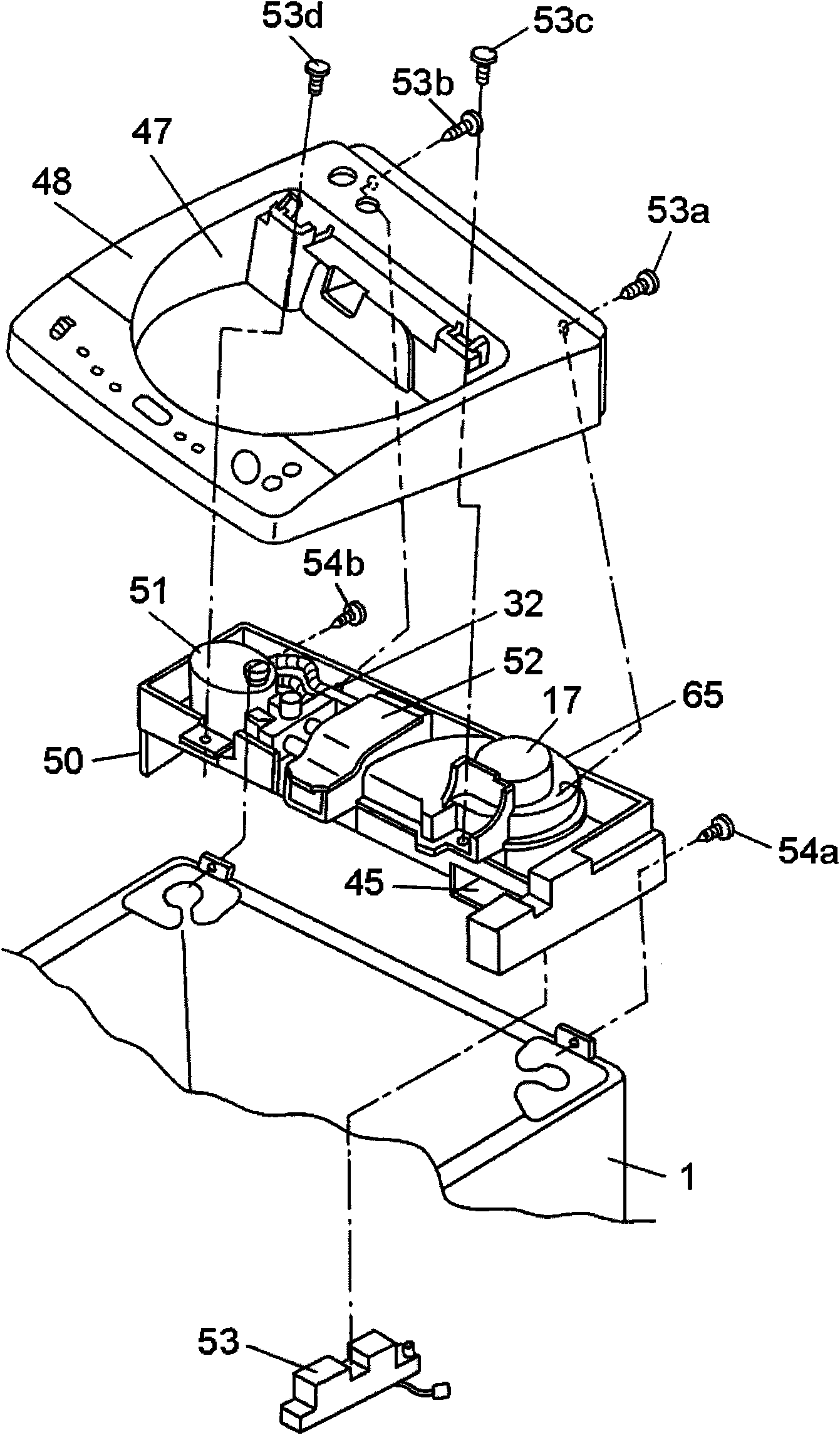

Washing machine

ActiveCN102191650ANo reduction in productivityCheap manufacturingOther washing machinesWashing machine with receptaclesFiberEngineering

The present invention provides a washing machine which comprises the following components: a wave wheel (6) which is provided at an inside part of the bottom of an internal tank (4) for mixing clothes; an upper frame (48) which is provided at the upper part of a housing (4); an air supply part (65) which is provided with an air injection port (20) that supplies air into the internal tank (4); anda static atomization generation unit (53) which is provided in the upper frame (48) and is provided with a static atomization generation device (55) that generates electrified particle water through static atomization. The static atomization generation unit (53) discharges the electrified particle water from the upper part into the internal tank (4) by means of the air injection port (20) in a sterilization deodorization step, thereby deeply and reliably penetrating into the inner part of the fiber of the clothes by the electrified particle water which is discharged into the internal tank (4)from the upper part for sterilization and deodorization.

Owner:PANASONIC CORP

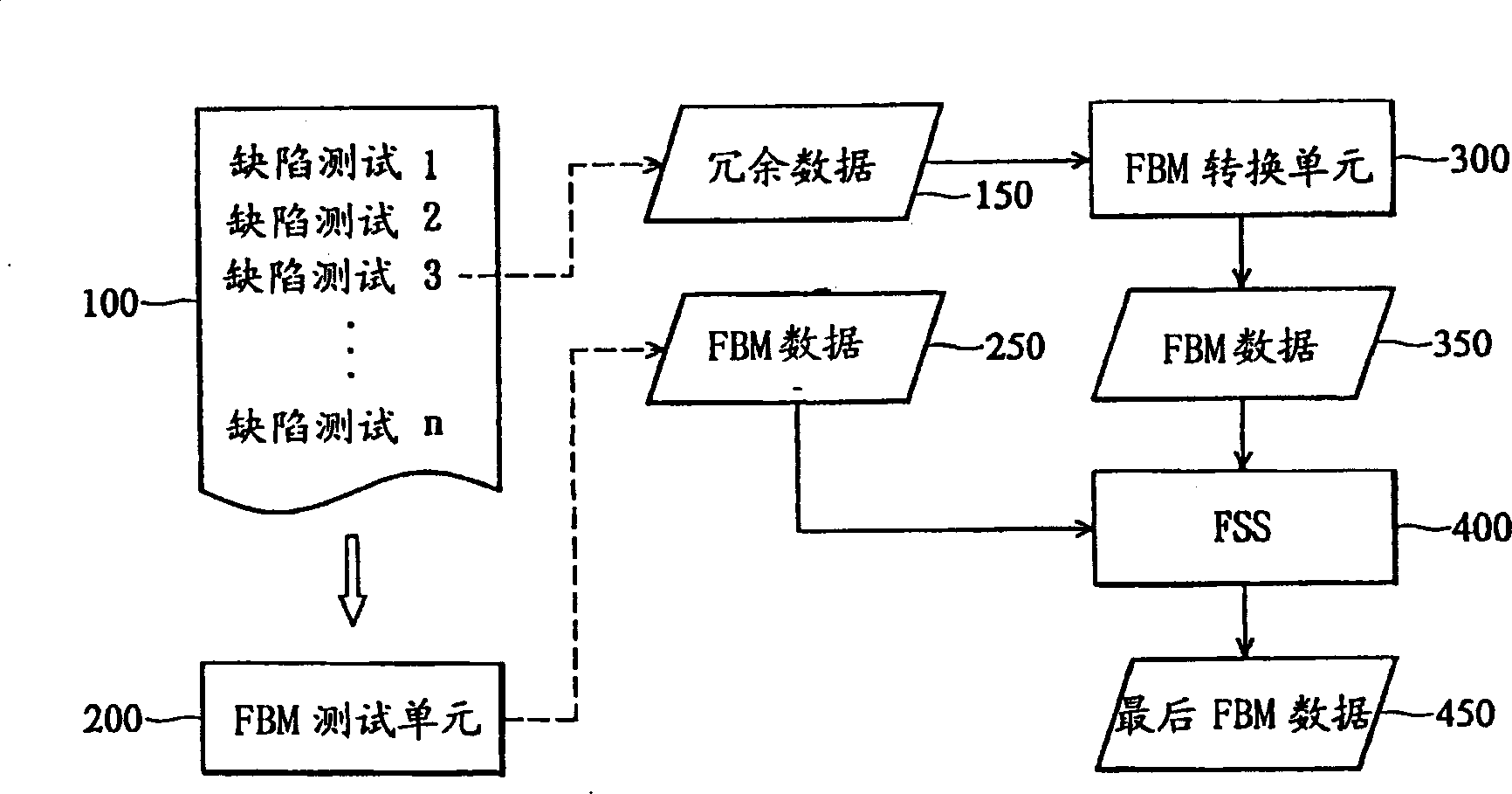

Method and system for inspecting semiconductor defect

InactiveCN1855411AShorten test timeImprove yieldSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationElectrical conductorSemiconductor

The invention is designed for use in testing defect of wafer in a process of manufacturing semiconductor and comprises the following steps: executing an operation for testing defect and getting its redundant information; executing an operation for testing the abnormal state and getting a first bad bit-mapping; the redundant information is converted to a second bad bit-mapping; comparing the first bad bit-mapping with the second bad bit-mapping to generate a third bad bit-mapping.

Owner:POWERCHIP SEMICON CORP

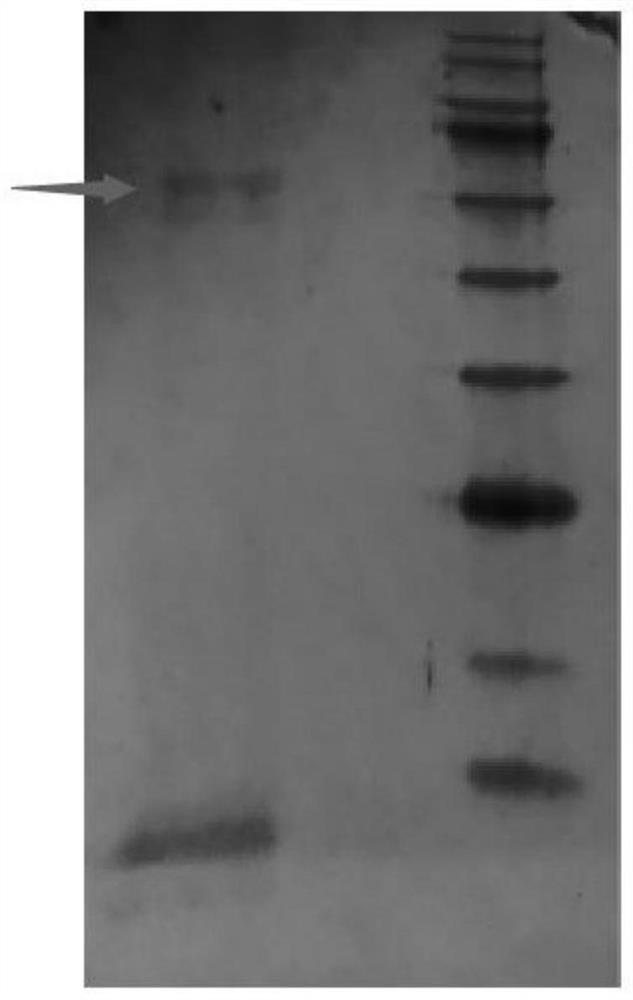

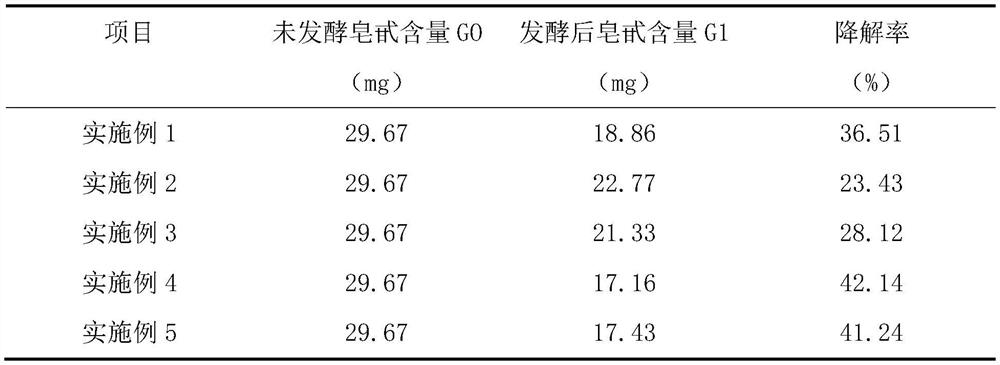

Fermentation improvement method of feed peony seed meal and fermentation product and application thereof

PendingCN113604508APromote the development and utilization of resourcesEasy to develop resourcesAnimal feeding stuffMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a fermentation improvement method of feed peony seed meal and a fermentation product and application thereof. The fermentation improvement method mainly comprises the following steps: crushing treatment, strain activation and fermentation treatment, i.e., the process of degrading saponin by microbial fermentation of peony seed meal is completed. In addition, the invention further provides a preparation method of an enzyme capable of degrading the saponin in the peony seed meal. The method can rapidly extract the saponin, utilize microorganisms to degrade the saponin in the peony seed meal, find out the enzyme for degrading the saponin in the peony seed meal, fully process and utilize the peony seed meal and lay a foundation for increasing the proportion of the peony seed meal added into a laying hen feed in the future, is convenient for development and utilization of peony seed meal resources, reduces waste of the peony seed meal resources and environmental pollution, is beneficial to promotion of stable development of the oil peony industry, and is simple and low in cost.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Image forming apparatus

ActiveCN103809408ANo reduction in productivityEasy to reprintElectrographic process apparatusInput/output processes for data processingComputer hardwareImage formation

To restrain generation of waste sheets and a decrease in production efficiency as much as possible in sample sheet discharge, provided is an image forming apparatus including an image forming unit for forming an image on a sheet, an image read unit for reading the output image on the sheet on which the image has been formed, an operation / display unit for providing operation and display, and a control unit for controlling the image forming apparatus, where the control unit can display a screen image of the output image read by the image read unit on the operation / display unit for check by a user, thereby saving of waste sheets and minimizing a decrease in the production efficiency, and efficiently checking the output image.

Owner:KONICA MINOLTA INC

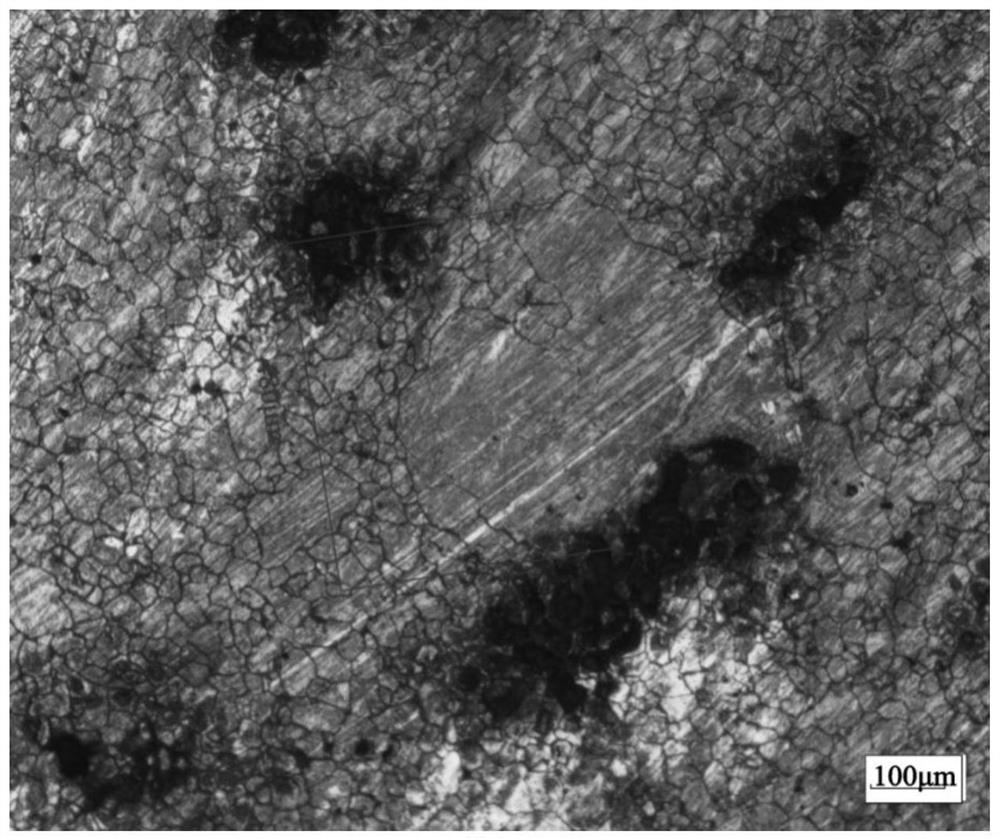

Rolling process capable of eliminating 20MnCr5 steel as-rolled mixed crystal structure

InactiveCN112893489APromote recrystallizationGrain refinementTemperature control deviceWork heating devicesHardnessMechanical property

The invention provides a rolling process capable of eliminating the 20MnCr5 steel as-rolled mixed crystal structure. The rolling process comprises the following steps: 1, selecting a billet of 20MnCr5 steel; 2, heating the steel billet; 3, performing rough rolling on the steel billet; 4, performing intermediate rolling on the steel billet; 5, performing finish rolling on the steel billet; and 6, cooling the steel to obtain a 20MnCr5 steel finished product finally. According to the method, after the temperature at which the 20MnCr5 steel starts dynamic recrystallization is accurately checked, the appropriate rolling starting temperature is determined, and rolling is started in the temperature interval higher than 1050 DEG C, so that distortion energy in the steel is accumulated, the recrystallization tendency is increased, and finally the effects of refining grains and eliminating mixed crystals are achieved. The uniformity, the grain size, the hardness and the mechanical property of the obtained 20MnCr5 steel as-rolled structure are greatly improved, and the production efficiency cannot be reduced due to process changes.

Owner:XINING SPECIAL STEEL +1

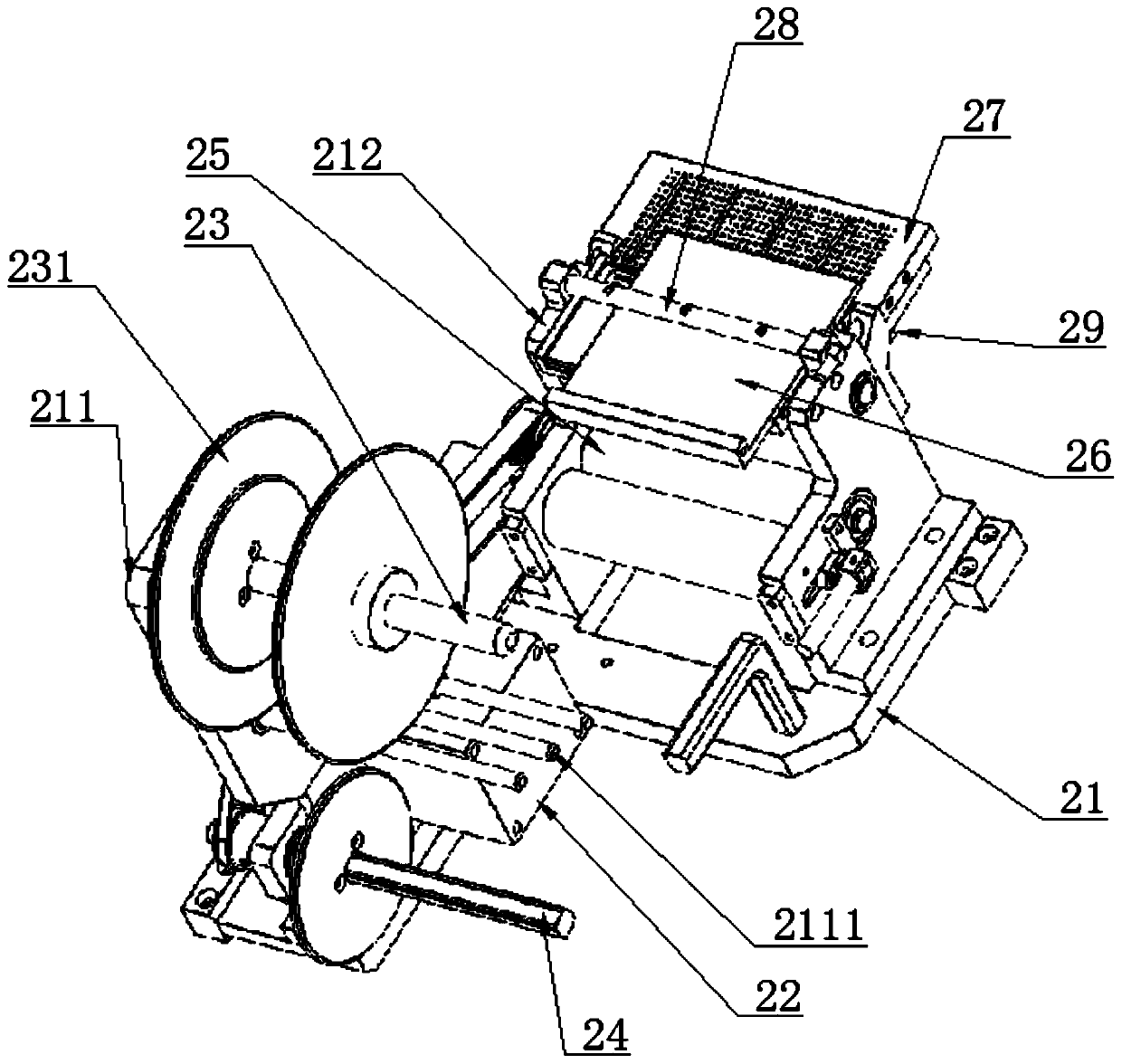

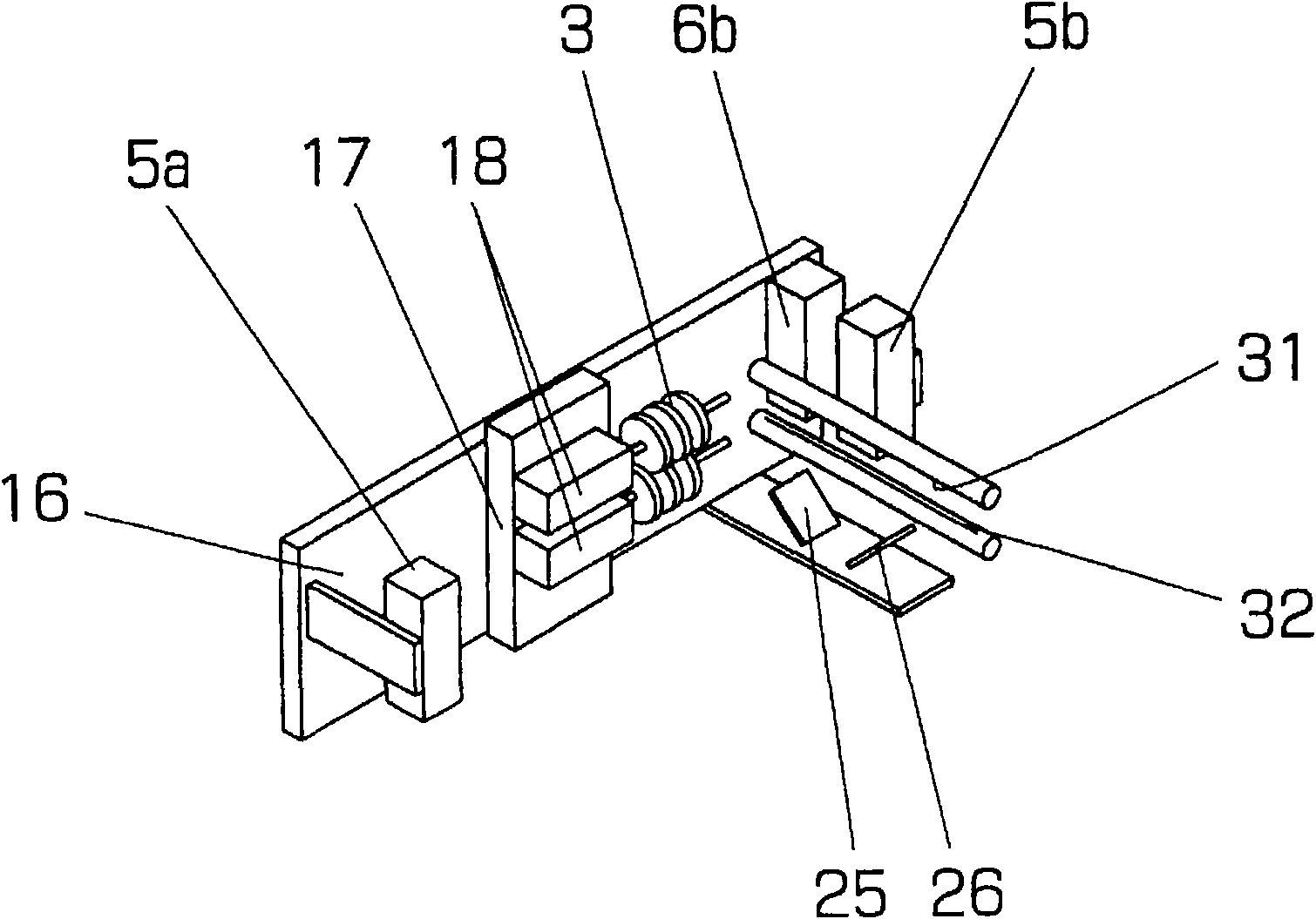

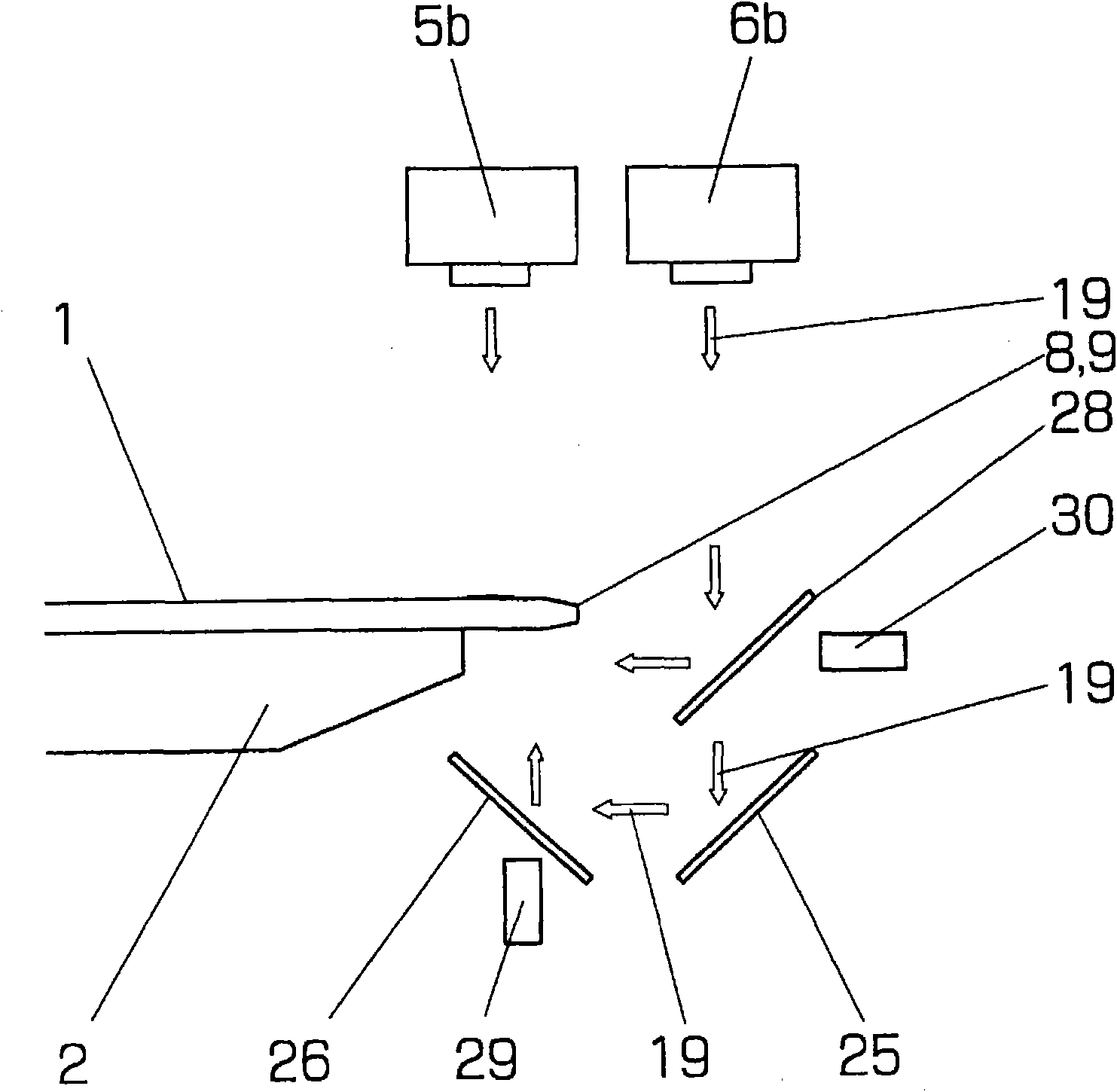

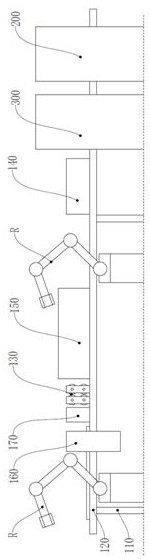

Chamfering device of hard fragile plate

InactiveCN102145471ALittle or no loss of productivityNo reduction in productivityEdge grinding machinesGrinding feed controlDisplay deviceEngineering

The invention provides a chamfering device of a hard fragile plate, which is used for processing a glass base plate used for a display panel and edges of other hard fragile plates. The chamfering device can measure the processing dimensions of all processed workpieces completely without or hardly increasing production beats, thereby being capable of realizing higher processing accuracy without reducing the processing accuracy. In the chamfering device comprises upstream side upper video cameras, a downstream side upper video camera and a downstream side lower camera, wherein the upstream side upper video cameras for observing the upper surfaces of the two side edge parts of workpieces are configured at both sides of the width direction of a work table, which are opposite to the upstream side of the feed direction of a tool; the downstream side upper video camera for observing the upper surfaces of the two side edge parts of the workpieces is arranged at the downstream side of the feed direction of the work table of the tool; and the downstream side lower camera for observing the lower surfaces of the two side edge parts of the workpieces is arranged at the downstream side. By means of the chamfering device, chamfering processing is carried out when the work table is in feed motion, and the chamfering dimension is measured by utilizing the downstream side cameras after the chamfering processing is carried out.

Owner:NAKAMURATOME SEIMITSU IND

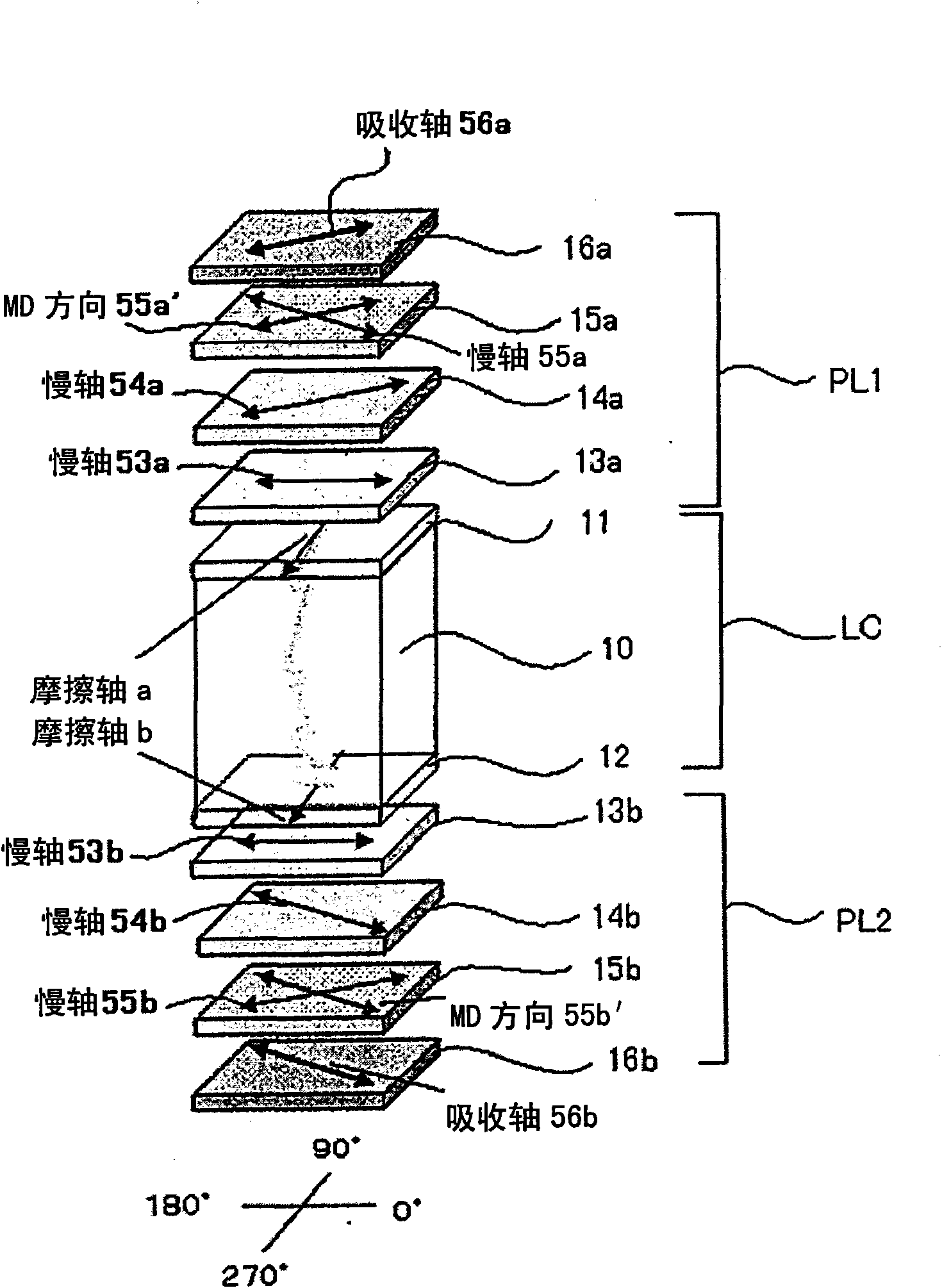

Liquid-crystal display device

InactiveCN101784946ASimple compositionImprove transmittancePolarising elementsNon-linear opticsOptical propertyEngineering

A liquid-crystal display device comprising a liquid-crystal cell and at least three optically-anisotropic layers disposed on each side of the liquid crystal cell, wherein they are combined so that the deltand value of the liquid-crystal cell and the optical characteristics of the optically-anisotropic layers can satisfy predetermined relationships, is disclosed.

Owner:FUJIFILM CORP

Vacuum arc film forming device and film forming method

ActiveCN107709605BImprove corrosion resistanceInhibitionElectric discharge tubesVacuum evaporation coatingDc currentElectron flow

A vacuum arc film forming apparatus for forming a ta-C film on a substrate by arc discharge includes: a holding unit that holds a target portion; an anode portion into which electrons discharged from the target portion flow; and a power source that operates at A current that generates plasma through arc discharge is supplied between the target portion and the anode portion; wherein, during the arc discharge, the current supplied by the power supply is superimposed on a DC current with a pulse frequency not higher than 140 Hz The current of the pulse current.

Owner:CANON ANELVA CORP

Washing machine

ActiveCN102191650BNo reduction in productivityCheap manufacturingOther washing machinesWashing machine with receptaclesFiberEngineering

The present invention provides a washing machine which comprises the following components: a wave wheel (6) which is provided at an inside part of the bottom of an internal tank (4) for mixing clothes; an upper frame (48) which is provided at the upper part of a housing (4); an air supply part (65) which is provided with an air injection port (20) that supplies air into the internal tank (4); anda static atomization generation unit (53) which is provided in the upper frame (48) and is provided with a static atomization generation device (55) that generates electrified particle water through static atomization. The static atomization generation unit (53) discharges the electrified particle water from the upper part into the internal tank (4) by means of the air injection port (20) in a sterilization deodorization step, thereby deeply and reliably penetrating into the inner part of the fiber of the clothes by the electrified particle water which is discharged into the internal tank (4)from the upper part for sterilization and deodorization.

Owner:PANASONIC CORP

Production method of decorative plate

PendingCN113580283AImprove the decorative effectNo reduction in productivityOther plywood/veneer working apparatusSpecial ornamental structuresSolid woodAdhesive glue

The invention discloses a production method of a decorative plate. The production method comprises the following steps that S1, cleaning is conducted, specifically, a multi-layer plate is put into a flat pasting machine, the multi-layer plate is cleaned through a dust removal device of the flat pasting machine, the surface of the multi-layer plate is rolled and brushed through a brush roller, and meanwhile the plate face is flushed and blown through negative pressure dust removal and blast airflow; S2, gluing is conducted, specifically, the multi-layer plate is subjected to the cleaning process and conveyed to a gluing roller through a conveying device, and glue is smeared on the surface of the multi-layer plate through the gluing roller; S3, drying is conducted, specifically, the multi-layer plate with the glued surface is conveyed into a dryer, and the drying time is set according to the quality of the glue and the plate till moisture of the glue is fully evaporated; and S4, plate covering is conducted, specifically, after moisture of glue on the multi-layer plate is removed, the multi-layer plate is conveyed to a plate covering station, the glued face of the multi-layer plate is covered with a solid wood plate, rolling is conducted, and a pine plate and the multi-layer solid wood plate are fully pasted. According to the scheme, the produced novel composite decorative plate can be modeled by pine wood and shaped by multi-layer solid wood, is attractive and practical, and has better nail-holding power and decorative effect.

Owner:佛山市骏品装饰材料有限公司

Ink-jet recording device and recording method

InactiveCN1305679CQuality improvementNo reduction in productivityInking apparatusOther printing apparatusEngineeringPosition control

An inkjet recording device and inkjet recording method capable of forming a high quality image with a simple structure. A transport belt position detection component detects a position of an end portion of a transport belt and outputs the detected position to a system control section. A recording medium position detection component detects a position of an end portion of a recording medium and outputs the detected position to the system control section. A position control component is capable of moving on the basis of instructions from the system control section for movement across a transport direction.

Owner:FUJIFILM CORP

Method of replacing lime with limestone for slagging and producing steel in oxygen top blown converter

The present invention belongs to the field of steel production, and relates to a method of replacing lime with limestone for slagging and producing steel in an oxygen top blown converter. The invention is characterized in that the limestone is directly added during slagging in the steel production process. The added batch number is increased and the amount of each batch of material is reduced. Namely the lime is added by 1-3 times for slagging formerly, and when the limestone is added for slagging, the limestone is added by 4-8 times. The adding amount of each time, calculated according to the CaO therein, is 1 / 2-1 / 3 of lime added formerly and is for preventing the condensing and incrusting at the metal surface in the furnace in the early period of converting. The adding amount of limestone, calculated according to CaO therein, accounts for 30%-100% of adding amount of lime in the batch. The method of the invention has the main advantages of elimination of lime calcining procedure or reduction of production scale, reduction of cost required for operating the calcining device and reducing the discharged pollution, prevention of heat waste caused by cooling the lime after calcining,low sulfur content in the lime generated in the oxygen top blown converter, and benefit for restraining resulfurization of melted iron in the steel production process.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com