Patents

Literature

52results about How to "Small scale of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of replacing lime with limestone for slagging and producing steel in oxygen top blown converter

The present invention belongs to the field of steel production, and relates to a method of replacing lime with limestone for slagging and producing steel in an oxygen top blown converter. The invention is characterized in that the limestone is directly added during slagging in the steel production process. The added batch number is increased and the amount of each batch of material is reduced. Namely the lime is added by 1-3 times for slagging formerly, and when the limestone is added for slagging, the limestone is added by 4-8 times. The adding amount of each time, calculated according to the CaO therein, is 1 / 2-1 / 3 of lime added formerly and is for preventing the condensing and incrusting at the metal surface in the furnace in the early period of converting. The adding amount of limestone, calculated according to CaO therein, accounts for 30%-100% of adding amount of lime in the batch. The method of the invention has the main advantages of elimination of lime calcining procedure or reduction of production scale, reduction of cost required for operating the calcining device and reducing the discharged pollution, prevention of heat waste caused by cooling the lime after calcining, low sulfur content in the lime generated in the oxygen top blown converter, and benefit for restraining resulfurization of melted iron in the steel production process.

Owner:UNIV OF SCI & TECH BEIJING

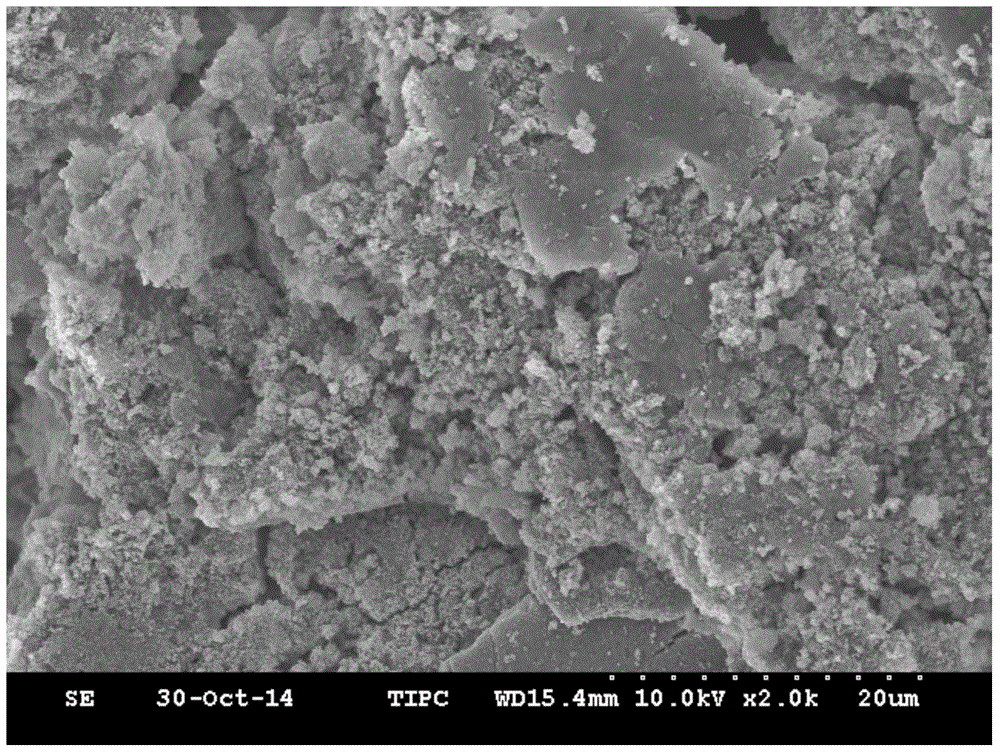

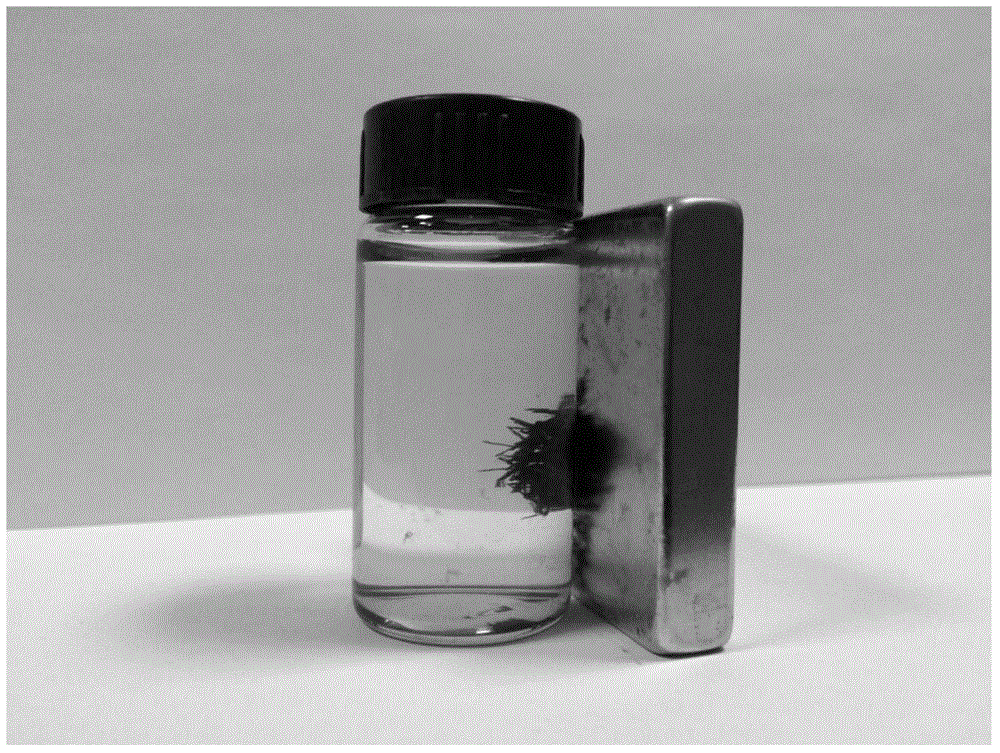

Cellulose base/Fe3O4 composite adsorption material used for removing arsenic in water and preparation method thereof

ActiveCN102476043AImprove adsorption capacityWide working pH rangeOther chemical processesWater/sewage treatment by sorptionAlkaline waterNational standard

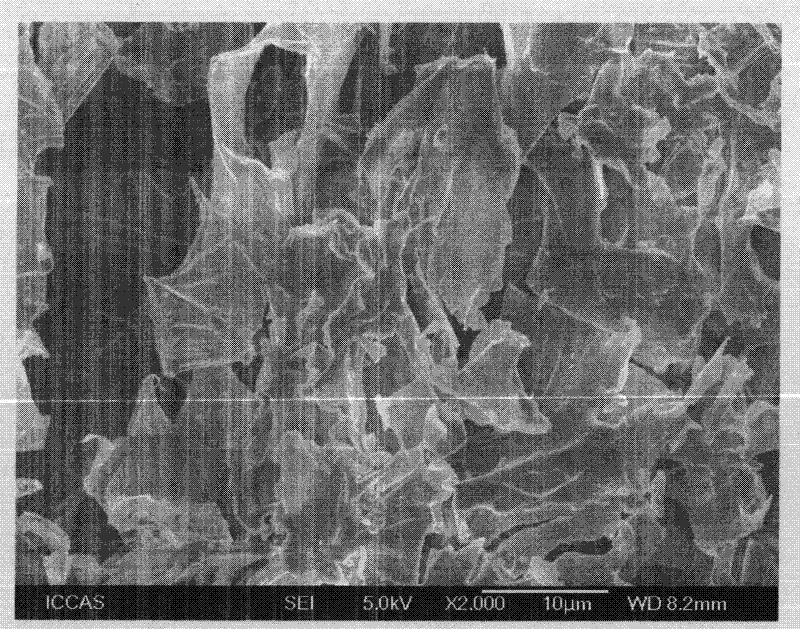

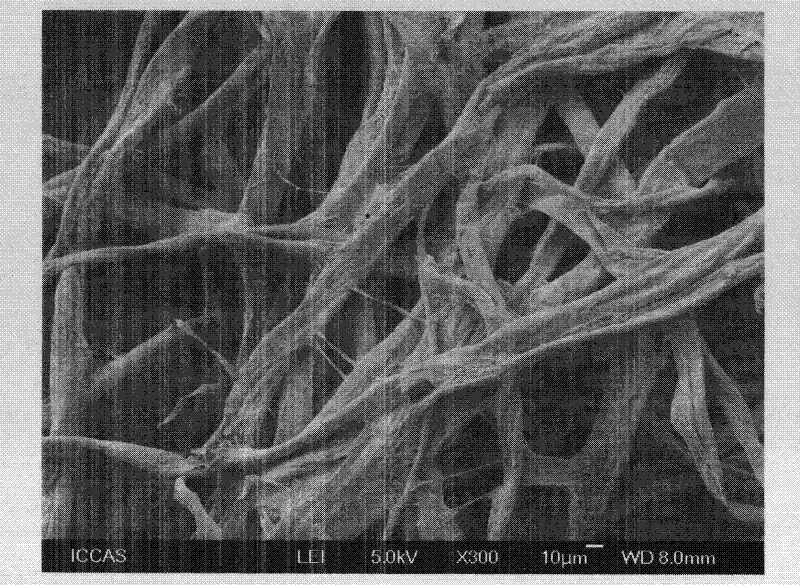

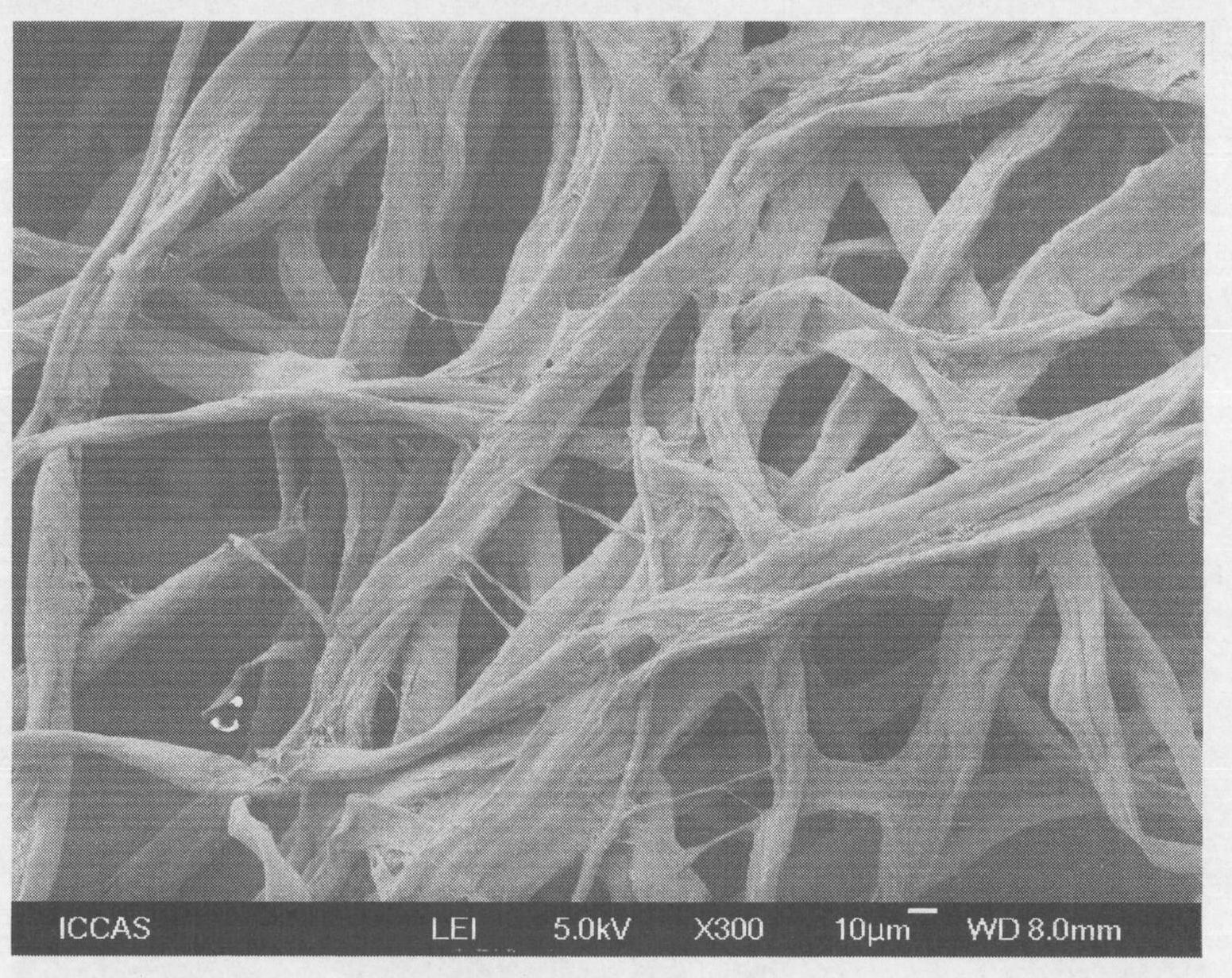

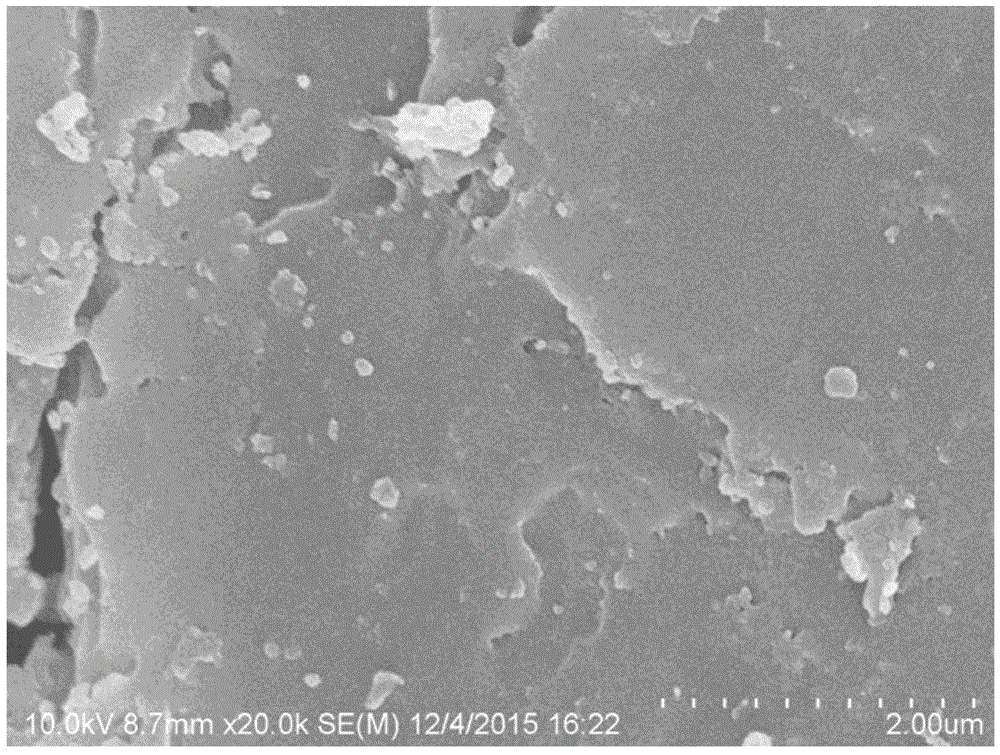

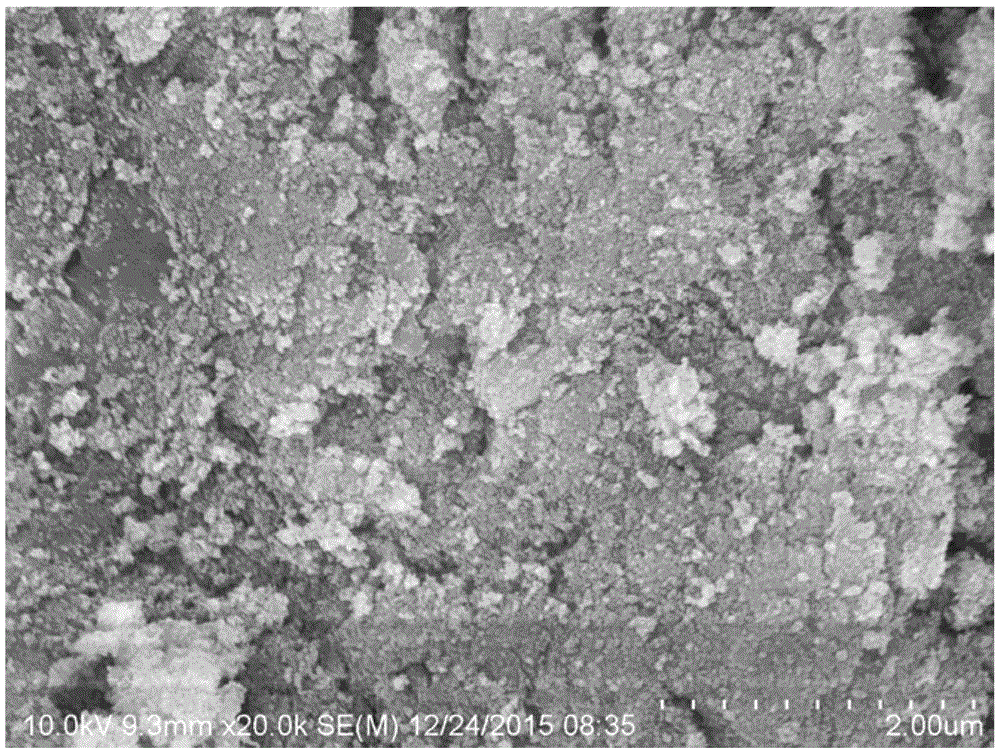

The invention relates to a cellulose base / Fe3O4 composite adsorption material used for removing arsenic in water and a preparation method thereof. According to the invention, with fibers or powder of natural cellulose or fibers of a cellulose derivative as a cellulose matrix material for the composite adsorption material, in an alkaline water system provided by ammoniacal liquor, Fe3O4 particles are loaded on the surface of the cellulose matrix material through in-situ co-precipitation, and the loaded Fe3O4 particles enable the obtained cellulose base / Fe3O4 composite adsorption material to have magnetism and to be easily removed from water, and allow harmful ions like arsenate ions and arsenite ions in water to be absorbed. Compared to arsenic removal materials in the prior art, the invention has the following characteristics: a natural biomass is used as an adsorption carrier, and the natural biomass is cheap and highly efficient, enables the content of arsenic in water to be substantially lower than a national standard and is easy to remove and convenient to use.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

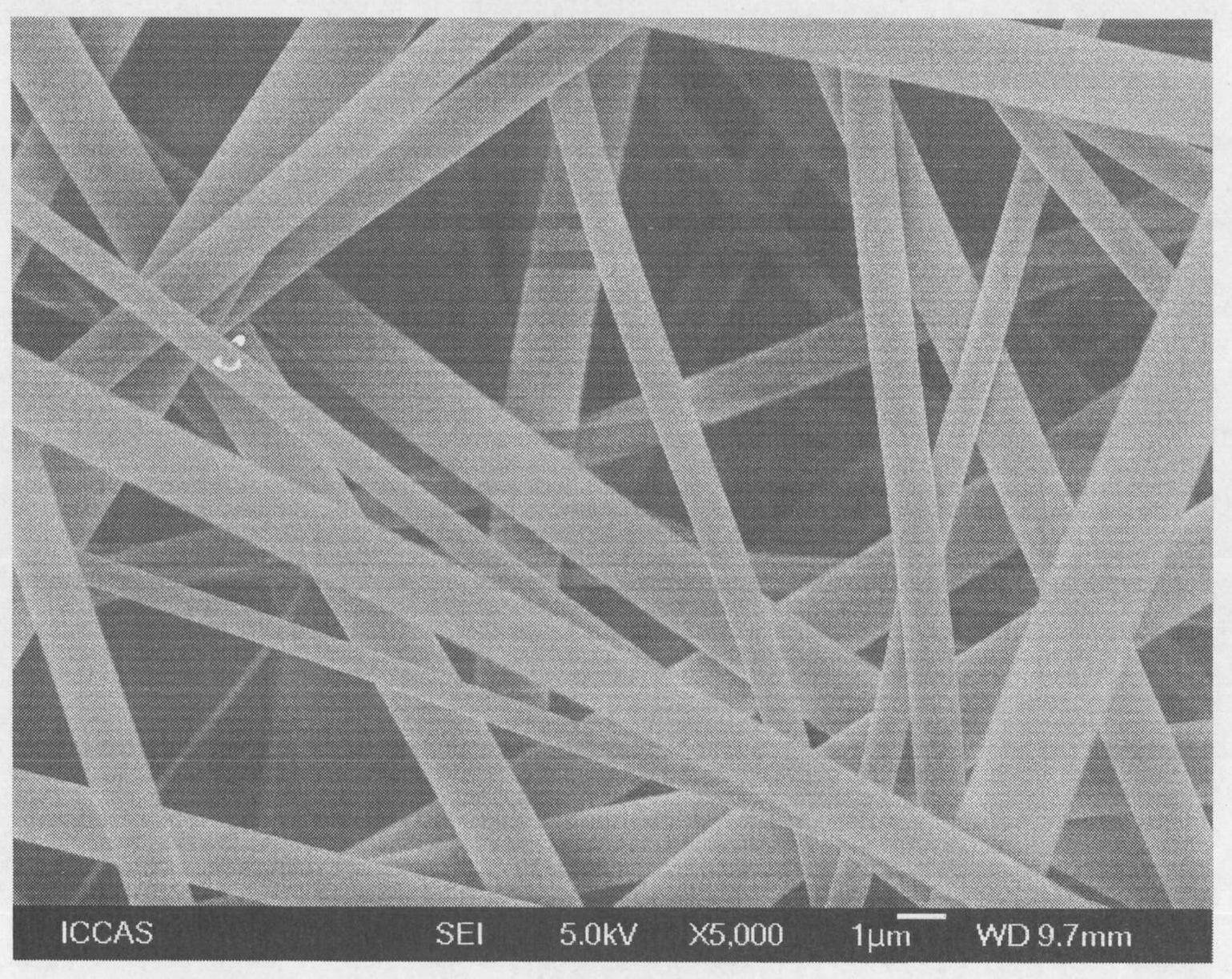

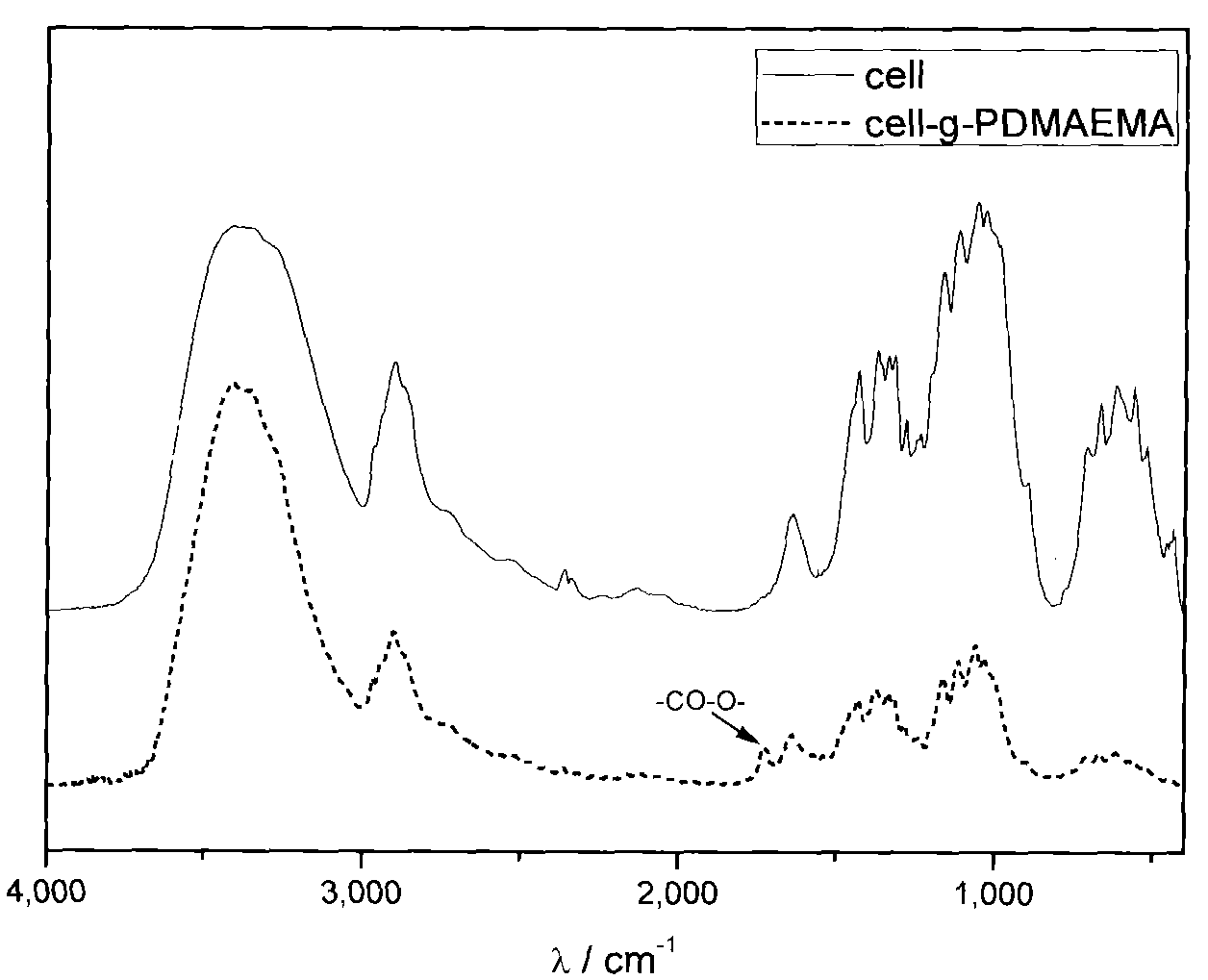

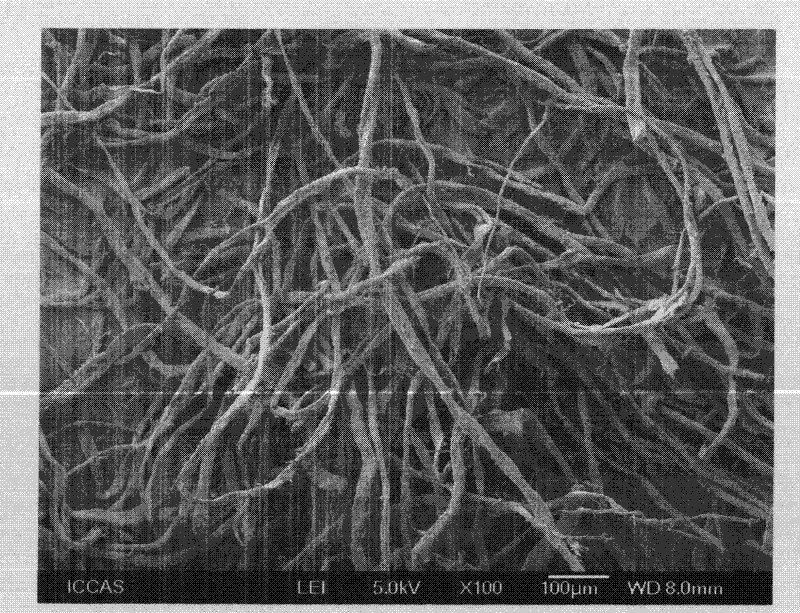

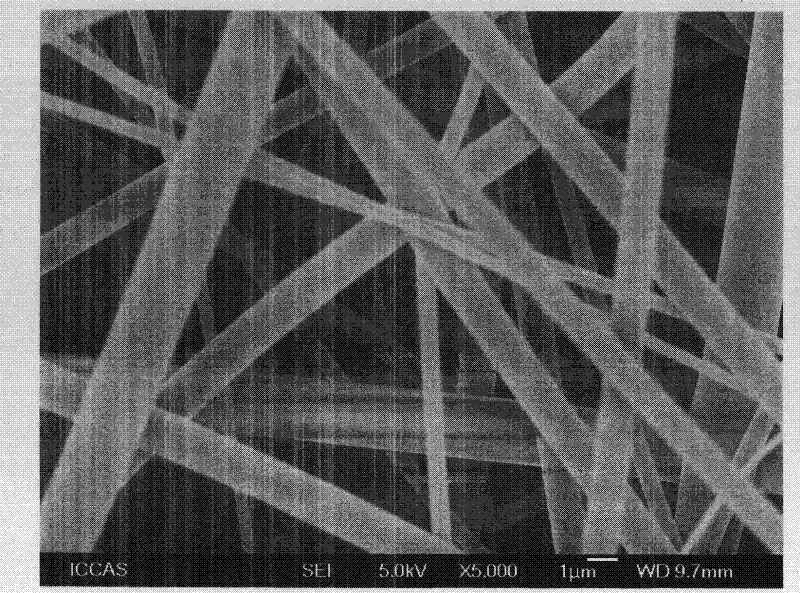

Cellulose base adsorption material used for removing arsenic ions and fluoric ions in water and preparation method thereof

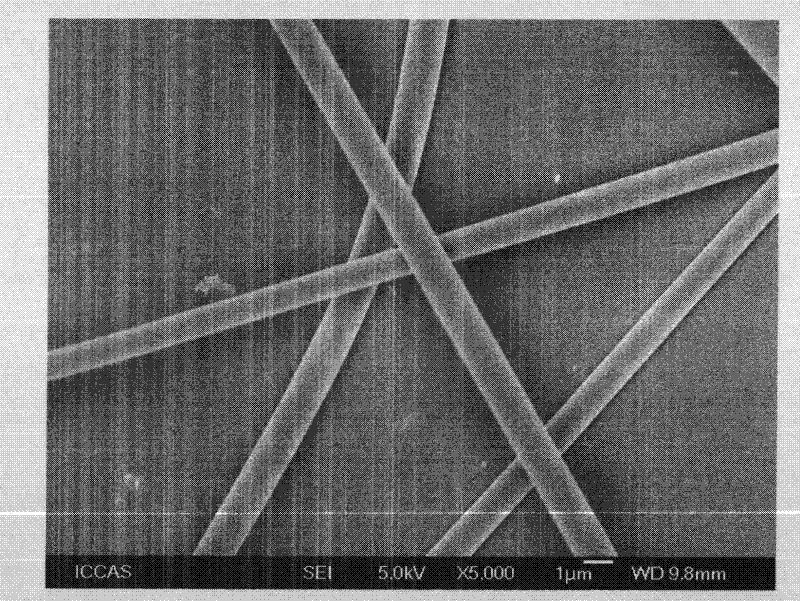

InactiveCN102139202AHigh adsorption capacityWide working pH rangeOther chemical processesWater/sewage treatment by sorptionIonElectrostatic attraction

The invention relates to a cellulose base adsorption material used for removing arsenic ions and fluoric ions in water and a preparation method thereof. In the invention, natural cellulose or fibers of cellulose derivatives with the diameter of 10nm-100mu m is taken as matrix material for the absorption material; polyolefin containing an amino group is grafted on the surface of the cellulose matrix material, thus the surface of the cellulose matrix material contains the amino group; and electrostatic attraction can be realized between the contained amino group and arsenate anions, arsenite anions and fluoric ions in water, thus the harmful ions, namely the arsenate anions, arsenite anions and fluoric ions in water can be removed. Compared with the arsenic and fluorine removing material in the prior art, the material provided by the invention has the advantages that the natural cellulose or cellulose derivative is taken as an absorption carrier, the fluoric ions, arsenate anions and arsenite anions in water can be simultaneously absorbed, and the contents of the arsenic and fluorine in water can be far less than the national standards.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

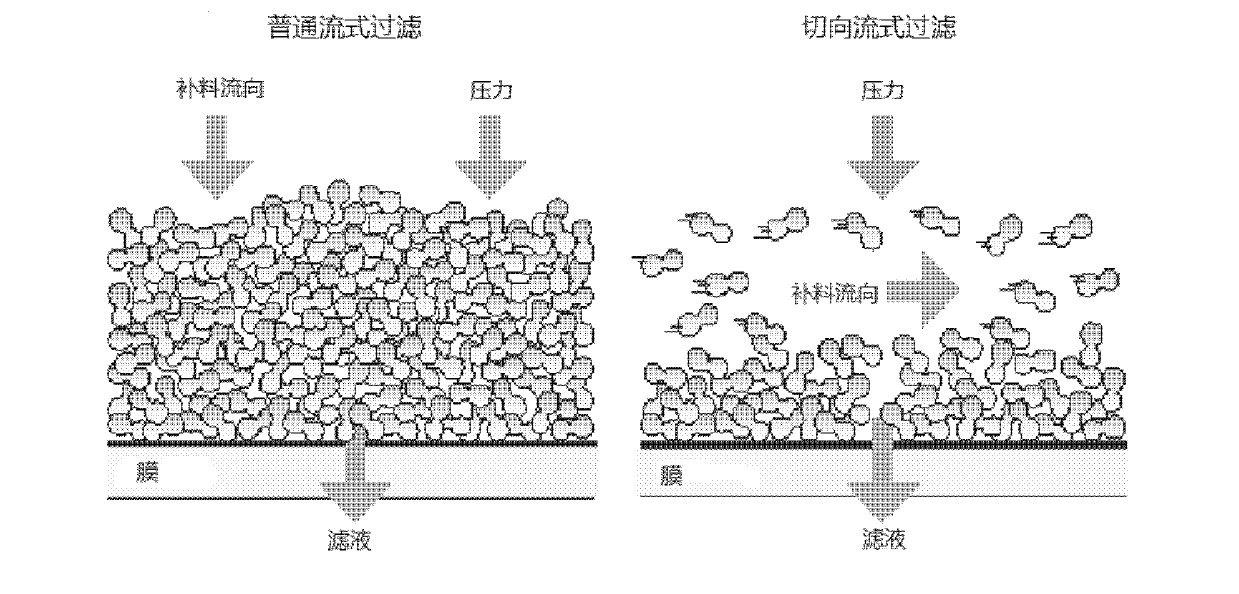

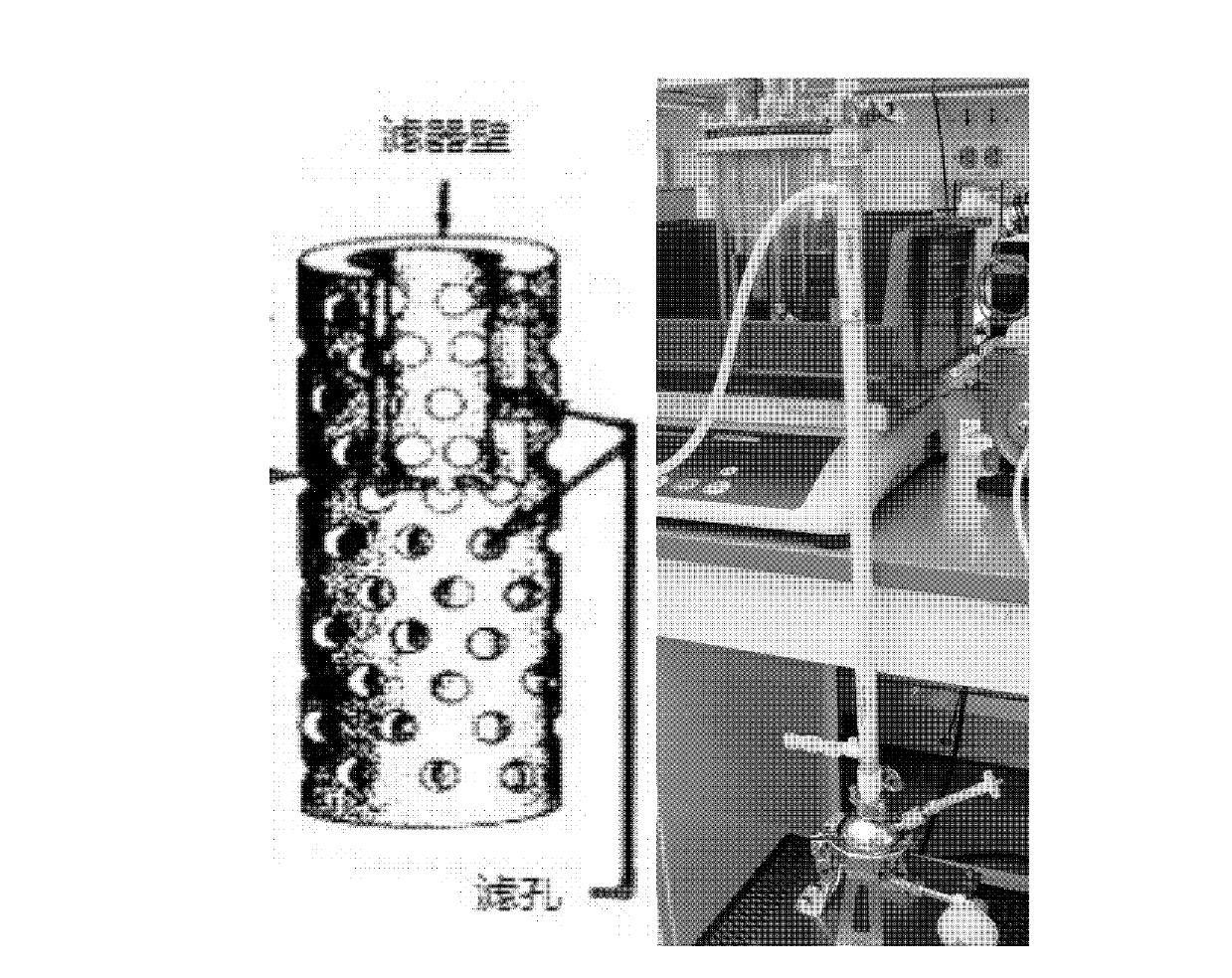

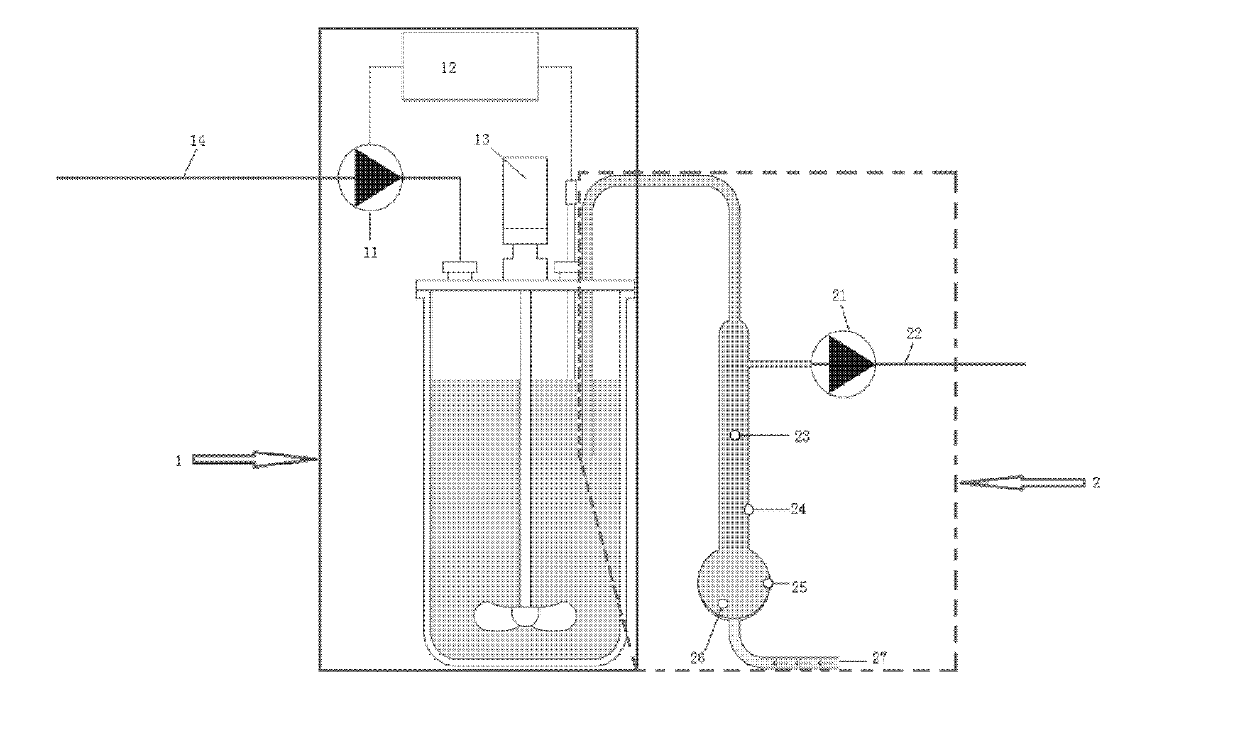

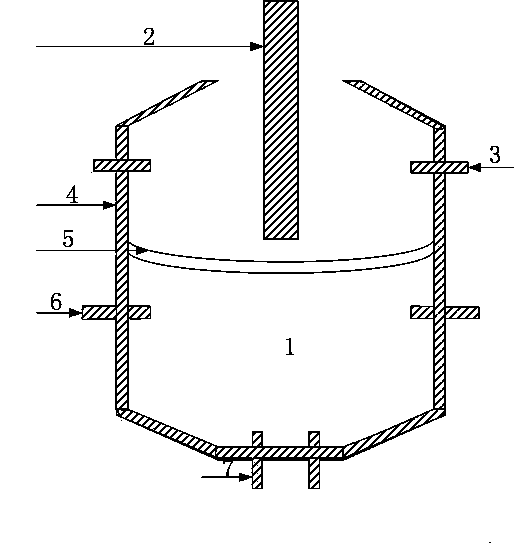

High-yield reactor for protein production, and production method and application thereof

InactiveCN103305417AReduce abnormal structural changesHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureFiber

The invention discloses a high-yield reactor, and a production method and an application thereof. The high-yield reactor comprises a bioreactor and an ATF perfusion apparatus connected with the bioreactor. The protein production method using the high-yield reactor comprises the following steps: 1, connecting the ATF perfusion apparatus with the bioreactor, and completing an offline disinfection or online disinfection program; 2, inoculating seed cells to the bioreactor to a work volume according to the density, and sampling and detecting the number and biochemical indexes of the cells each 24h; 3, starting the ATF apparatus program for perfusion culture when the density of living cells increases to a certain density; and 4, collecting a culture solution in the bioreactor or filtered through hollow fibers in the ATF perfusion apparatus, and purifying to obtain required protein products. The high-yield reactor has the advantages of great shortening of the technological exploitation time of monoclonal antibody or fusion protein expression, production cost reduction, benefiting for the project registering and reporting and the project period shortening, and acceleration of the accomplishment application speeds of the biopharmacy industry.

Owner:WUXI BIOLOGICS CO LTD

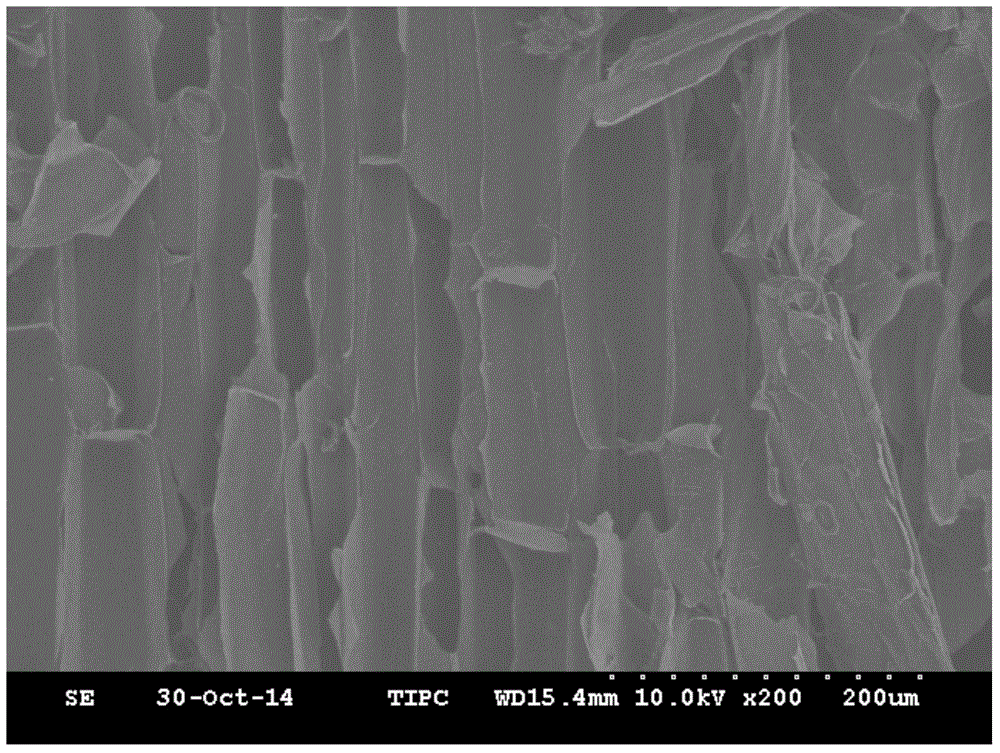

Cellulose base adsorbing material for removing cations of heavy metal in water and preparation method of cellulose base adsorbing material

ActiveCN102476044AImprove adsorption capacityWide working pH rangeOther chemical processesWater/sewage treatment by sorptionPolyolefinNatural fiber

The invention relates to a cellulose base adsorbing material for removing cations of heavy metal in water and a preparation method of the cellulose base adsorbing material. Natural cellulose or cellulose derivative fiber with the diameter of 10nm-100mum is adopted as a matrix material of an adsorbing material; polyolefin containing a carboxyl group is grafted on the surface of the matrix material of the cellulose, so that the surface of the matrix material of the cellulose is provided with the carboxyl group; and electrostatic attraction occurs on the carboxyl group and the cation of the heavy metal, so that Cd<2+>, Cr2<+>, Cu<2+>, Hg<2+>, Ni<2+>, Pb<2+> and / or Zn<2+> and other harmful cations in water are removed. Compared with adsorbing materials for the cations of the heavy metal in the prior art, the cellulose base adsorbing material adopts the natural cellulose or the cellulose derivative as an adsorption carrier, so that the cost performance is higher, and the content of the cations of the heavy metal in the water is greatly lower than that of state-specified standard.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Production method of poly ammonium phosphate

A process for preparing ammonium polyphosphate includes such steps as proportionally mixing polyphosphoric acid with the condensating agent chosen from urea, ammonium dicarbonate, melamine, bicynoamine, ammonium sulfate and their mixture, and reacting at 100-500 deg.C under 0.01-0.35 MPa for 5-210 min.

Owner:YUNNAN CHEM RES INST

Puffing expression method for producing oil with low oil-containing oil-bearing material

InactiveCN101245284AImprove product qualityAvoid excessive denaturationFatty-oils/fats productionPress cakeImpurity

The invention relates to a method for extracting oil by swelling and pressing low oil content oil seeds and is characterized by comprising the following steps: 1) clearing: impurities are removed from the oil seeds; 2) quality-adjusting: the temperatures and water contents are adjusted for the oil seeds; 3) the oil seeds are pressed and swelled; 4) enzyme killing and drying are carried out for the pressed and swelled oil seeds; 5) most of the oil is pressed from the dried oil seeds; the oil seeds can be crushed and then the quality adjusting can be done after the clearing of the step 1); after the step 2) of quality-adjusting, the bloom rolling can be done to the oil seeds and then the pressing and swelling can be done. The method adds the procedures of pressing and swelling before the traditional one time pressing and obtains pure physical pressed oil with high quality and pressed cakes which can be directly used for feed processing, which increases the processing amount of a press and reduces the power consumption and wearing. The method is mainly used for producing small-scale pressed oil and pressed cakes with good qualities and raw materials of low oil content oil seeds such as soybeans and rice bran.

Owner:中机康元粮油装备(北京)有限公司

Method for manufacturing soft-magnetic alloy powder

The production method of soft magnetic alloy powder includes the following steps: smelting soft magnetic mother alloy, making molten metal be quickly coagulated into crystalline sheet alloy, breaking the sheet alloy to obtain alloy powder, and making the alloy powder undergo the processes of activation, annealing treatment and passivation treatment. Said soft magnetic alloy powder is low in oxygen content, stable in property and good in magnetic powder core performance.

Owner:CENT IRON & STEEL RES INST

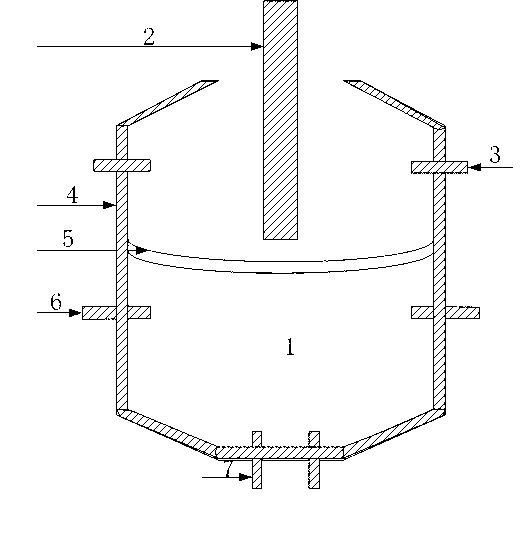

Method for slagging steelmaking by side blowing of powder particle limestone in top-bottom combined blown converter

InactiveCN102796841ATake away decreaseIncrease profitManufacturing convertersSteelmakingMelting tank

The invention belongs to the technical field of metallurgy, and particularly relates to a method for slagging steelmaking by side blowing of powder particle limestone in a top-bottom combined blown converter. The method of the invention comprises the following steps: arranging at least one side blowing spray gun at one side of a converter trunnion center line, wherein the installation site of the side blowing spray gun is located between a molten pool liquid level and a level 500 mm below the liquid level, an angle between the installation range of the side blowing spray gun and the installation site tangent plane is 10 degrees-75 degrees, the side blowing direction of the spray gun is that the included angle between the side blowing spray gun center line and a horizontal line is 10 degrees-60 degrees, the spray gun faces the bottom of the molten pool, the insertion depth of the side blowing spray gun is 0.1-0.6 times larger than the radius of the molten pool; blowing powder particle limestone with carrier gas through a center pipe of the spray gun by using the side blowing spray gun, blowing protective gas around the circular seam. The method of the invention directly sprays powder particle limestone into the molten pool through the side blowing spray gun; the limestone rapidly decomposes and rapidly participates in slagging reactions; limestone taken away by converter furnace gas is reduced; dust is minimized; and the utilization rate of limestone is improved.

Owner:NORTHEASTERN UNIV

Non-shrinkage cement-based roofing material

The invention relates to a non-shrinkage cement-based roofing material, belonging to the technical field of building materials. The roofing material is formed by mixing cement, activated and inert mineral admixtures, plaster, expanding agents, glass fibers and organic synthesis fibers, chemical admixtures, sand and the like based on a certain proportion. At the construction field, right amount of water is added and stirred evenly, and is constructed by hand spreading or spraying. Regarding constructed roofing, the thickness of the waterproof layer is 35-50mm and the area of the separate bin is 50-300m. The non-shrinkage roofing material has high strength, good volume stability and excellent waterproof property, can be used for thin layer construction and is convenient, fast and flexible in construction. The roofing material is low in cost, convenient in production and changeable in production scale, and is applicable to the requirements of construction of villages and small towns. In addition, the roofing material utilizes a substantial proportion of industrial residues, thus not only reducing cost but also conducing to environment protection.

Owner:TSINGHUA UNIV

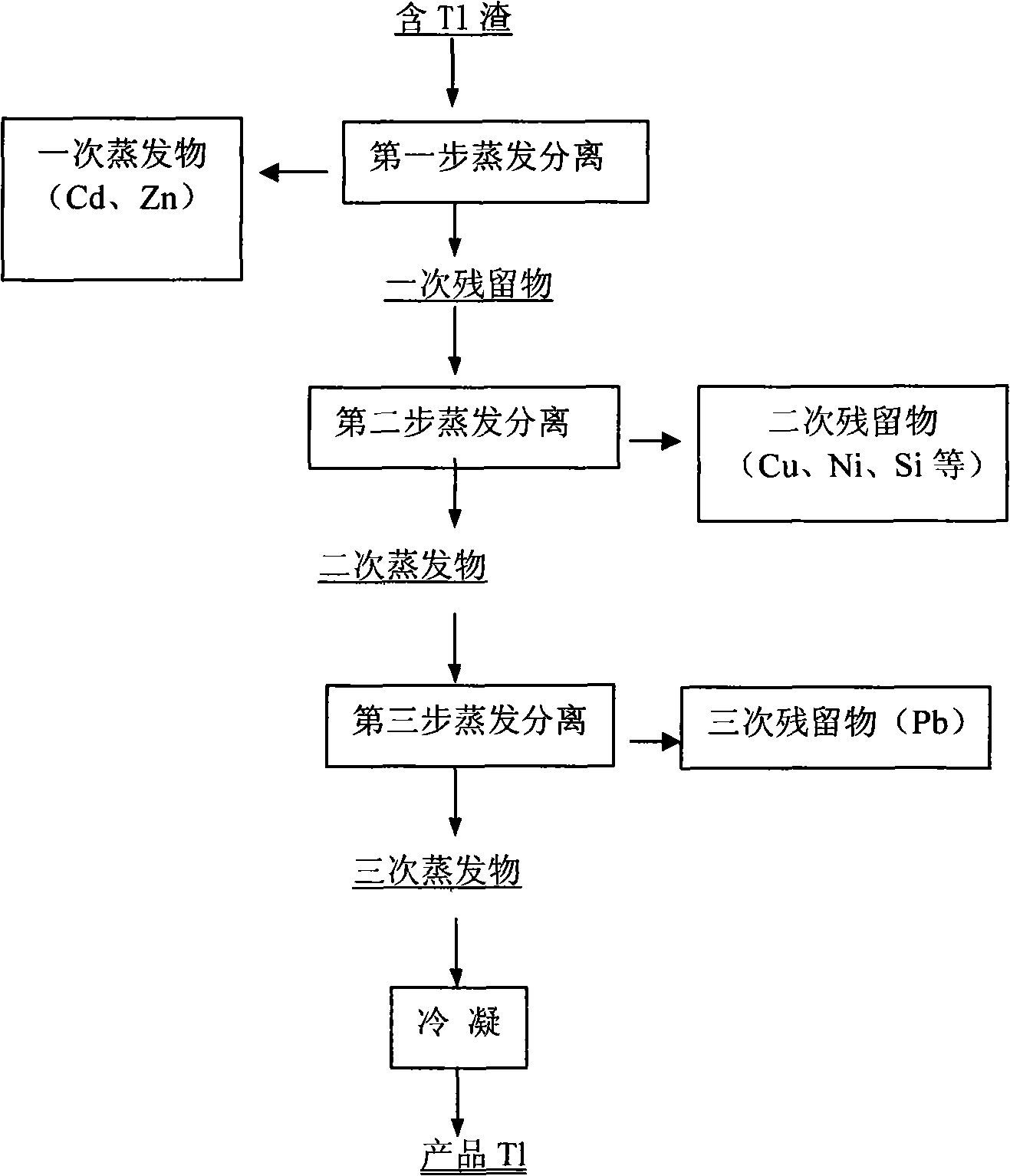

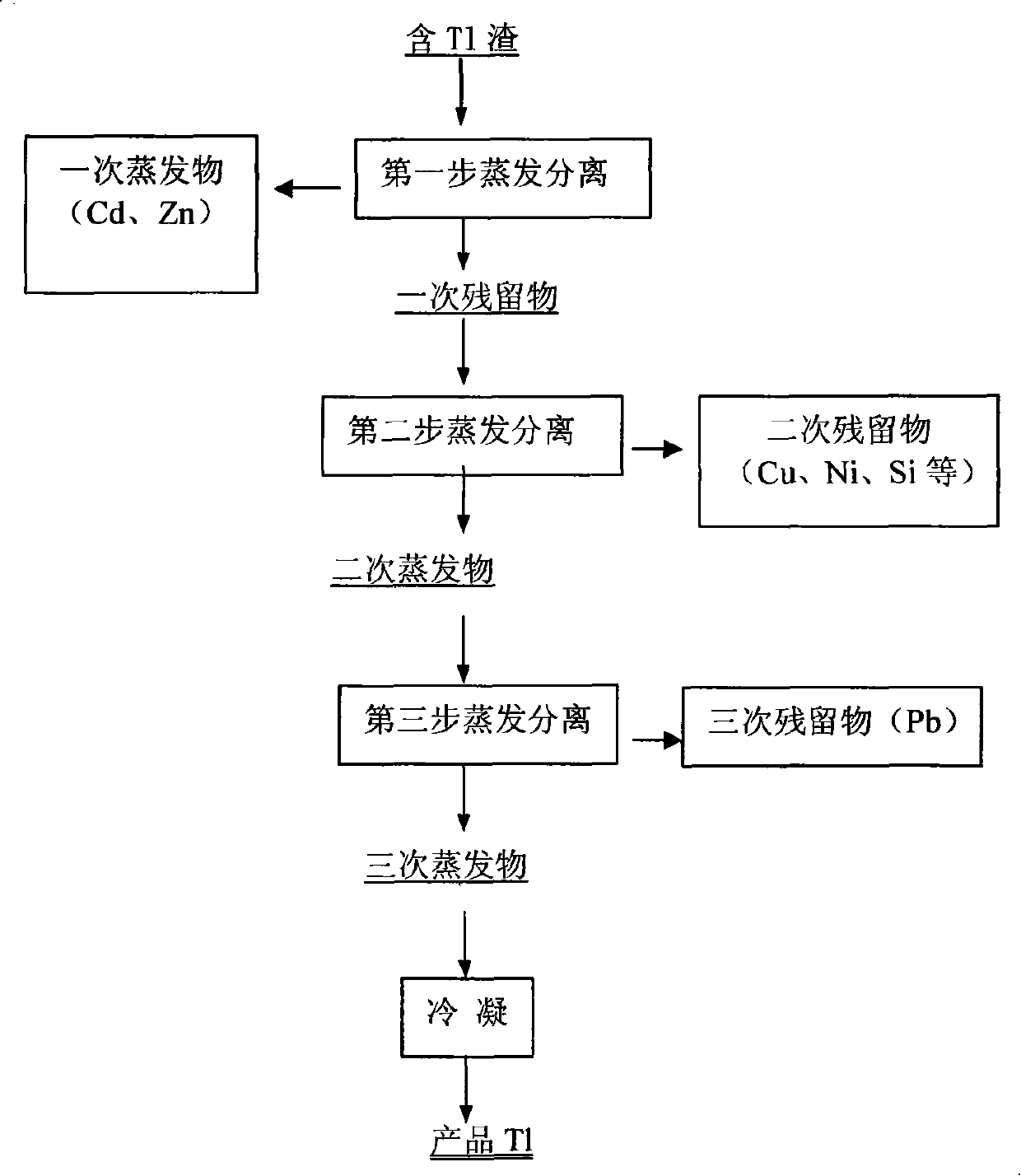

Method for extracting thallium from thallium containing slag

The invention relates to a method for extracting metallic thallium from thallium-containing slag, and belongs to the vacuum metallurgy technology field. The thallium-containing slag is adopted to extract the metallic thallium in a vacuum firing furnace based on three-step distillation; the vacuum degree is control between 8 to 40Pa, and the time is 30 to 60 minutes; three-step distillation temperatures respectively range from 450 to 600 DEG C, from 900 to 1100 DEG C, and from 700 to 850 DEG C; the purity quotient of the thallium which is extracted in the vacuum firing furnace can reach more than 99.9 percent; the coefficient of recovery of the thallium can reach more than 90 percent.

Owner:KUNMING UNIV OF SCI & TECH

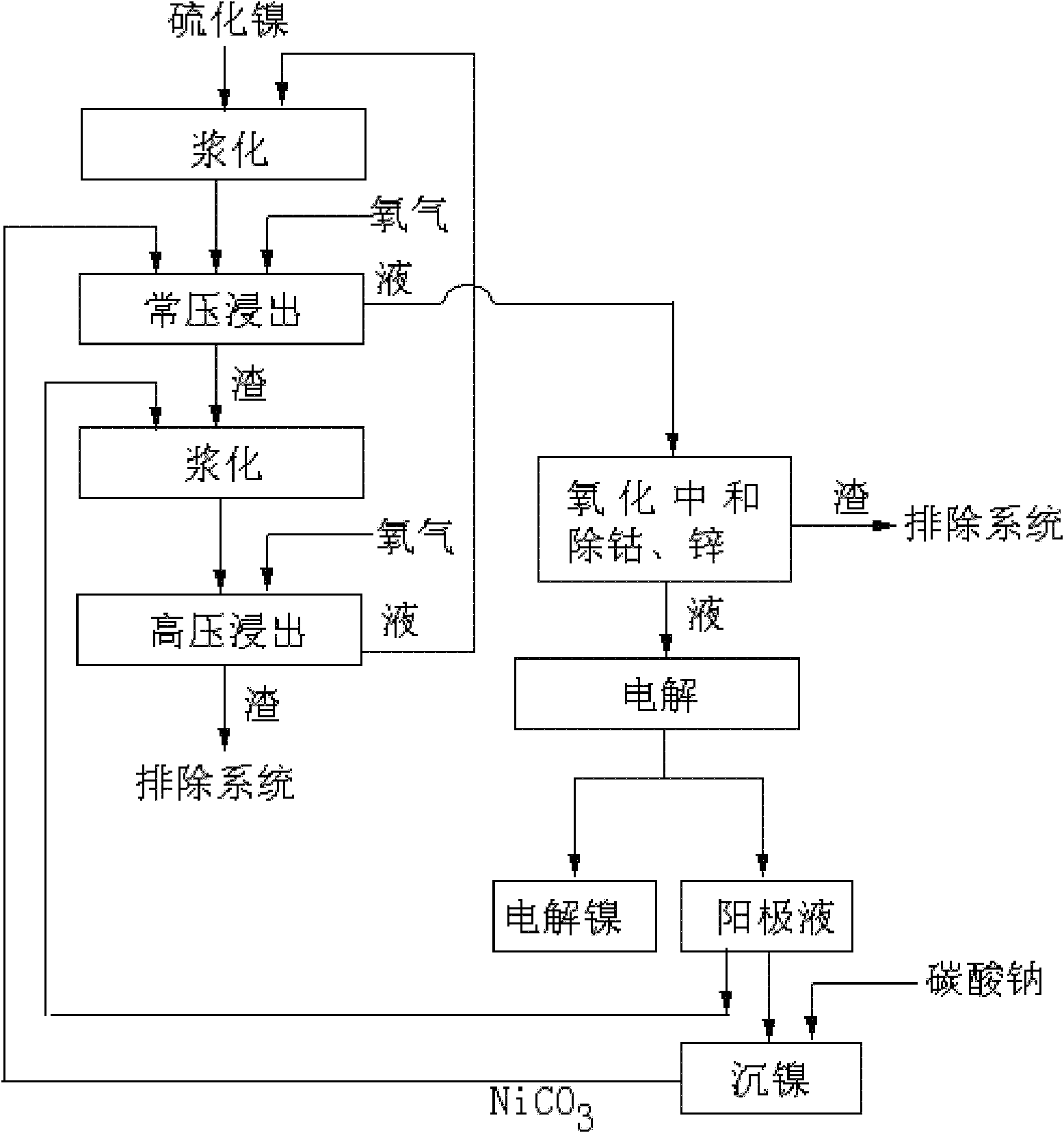

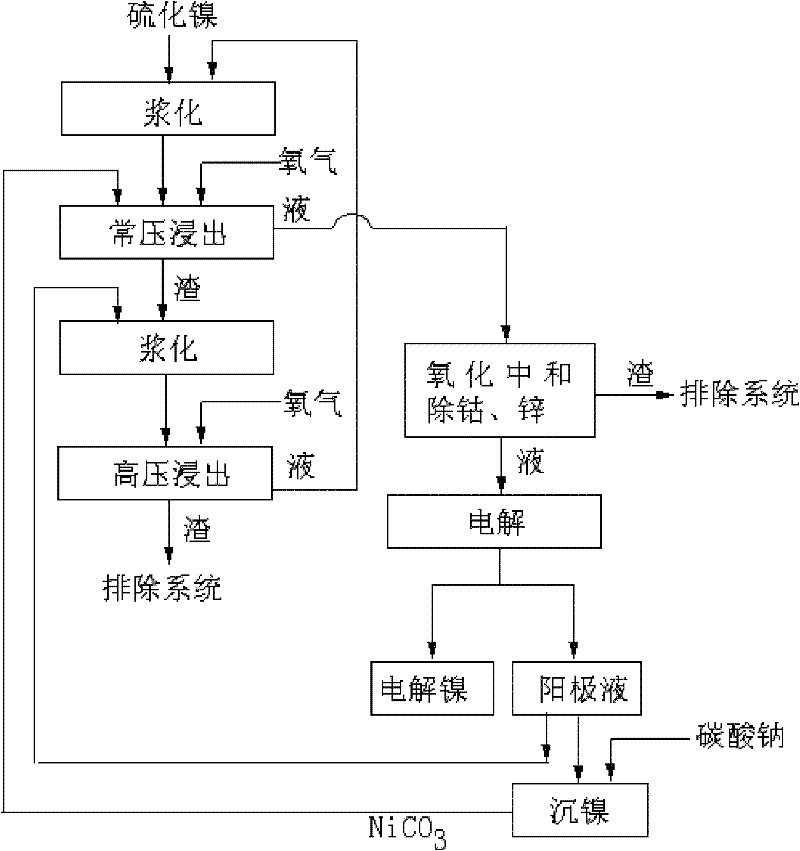

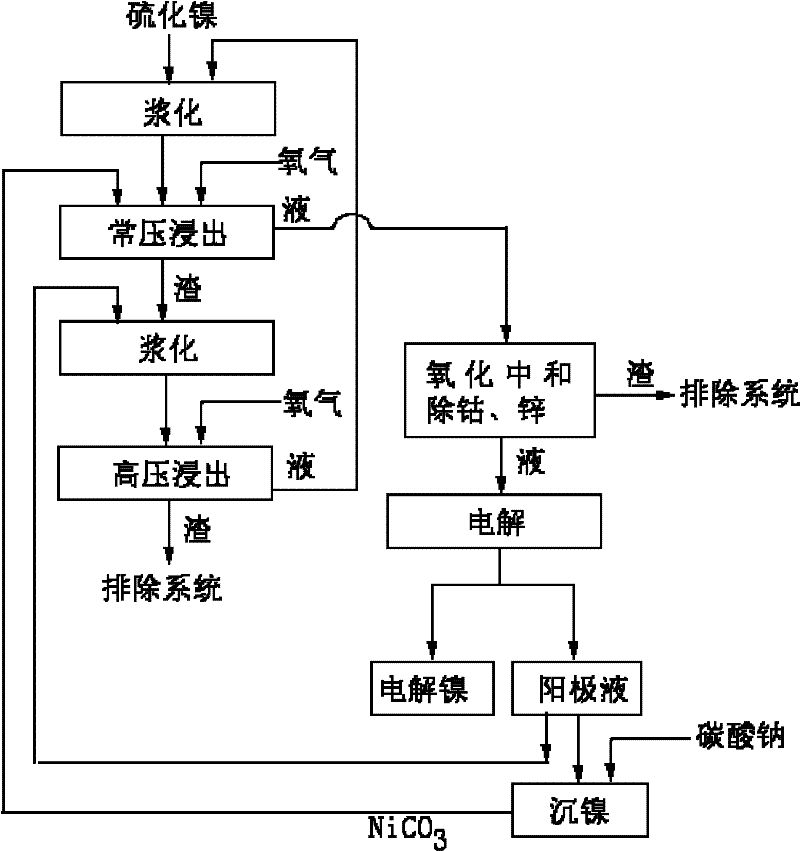

Method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen

InactiveCN101899568AImprove leaching rateWide range of resource utilizationPhotography auxillary processesProcess efficiency improvementPregnant leach solutionNickel sulfide

The invention discloses a method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen, comprising the following steps: mixing and pulpifying chemically precipitated nickel sulfide and high pressure leachate based on the mass ratio of (8-10):1, performing one-stage atmospheric pressure leaching on the pulpified material, removing impurities from one-stage leachate and electrolyzing, producing electrolytic nickel and anolyte, mixing one-stage leached residue with anolyte for secondary pulpifying, further leaching by two-stage high pressure, and returning the obtained leached filtrate to one-stage pulpifying for utilization. The process technique has widely utilized resources, simple technical route, small investment, low energy consumption, no environment pollution, high leaching rate of nickel and cobalt, simple and convenient operation and low production cost, and provides an effective and economical way for producing electrolytic nickel in nickel sulfide concentrates.

Owner:SHAANXI HUAZE NICKEL & COBALT METAL

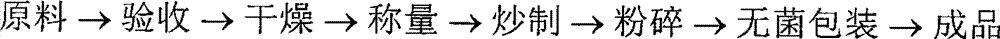

Natural seasoning and preparation method thereof

The invention discloses natural seasoning and a preparation method of the natural seasoning, and belongs to the technical field of seasoning processing. The seasoning comprises natural spice and Chinese herbal medicines such as pepper, anise, fructus amomi, myristica fragrans, cinnamon, galangal, syzygium aromaticum, amomum tsao-ko, fennel, rhizoma zingiberis, rhizoma kaempferiae, white pepper, radix angelicae, pericarpium citri reticulatae and elecampane. The natural seasoning is prepared through food high and new technologies of microwave drying, aseptic packaging and the like. The seasoning is reasonable in compatibility and can be used for cooking, cold mixing and food industrial production. The seasoning is aromatic and palatable and has the effects of invigorating stomach and improving digestion, maintaining beauty and keeping young, regulating the blood sugar level, reducing blood fat, cooling down to dissipate the dampness and building the body.

Owner:郝涤非

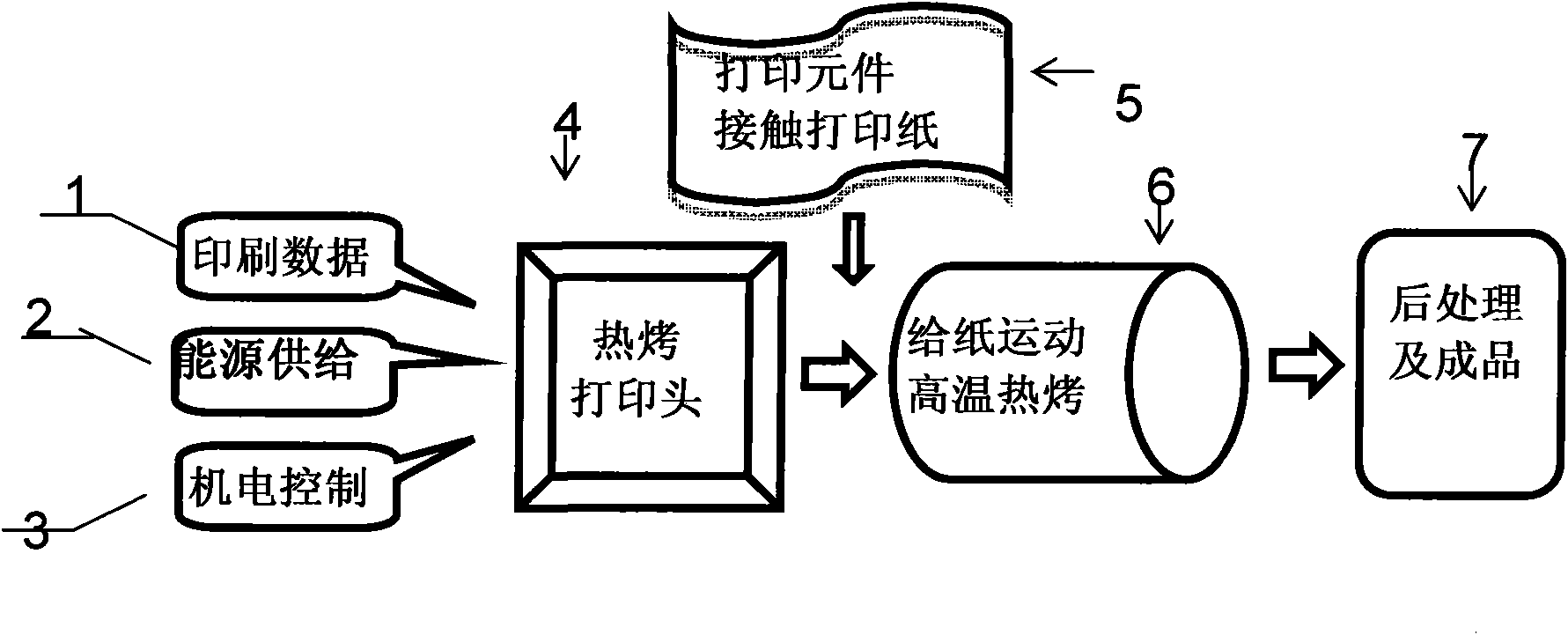

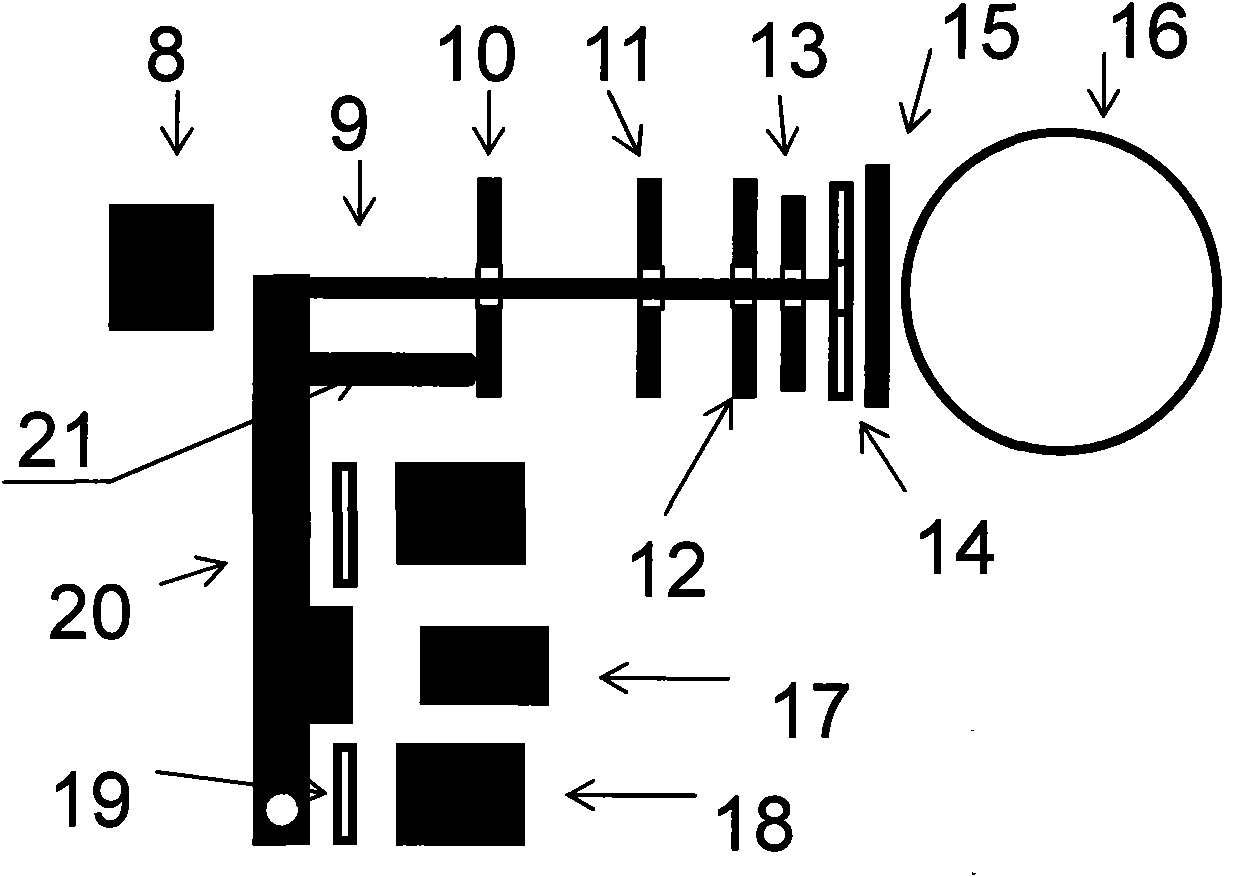

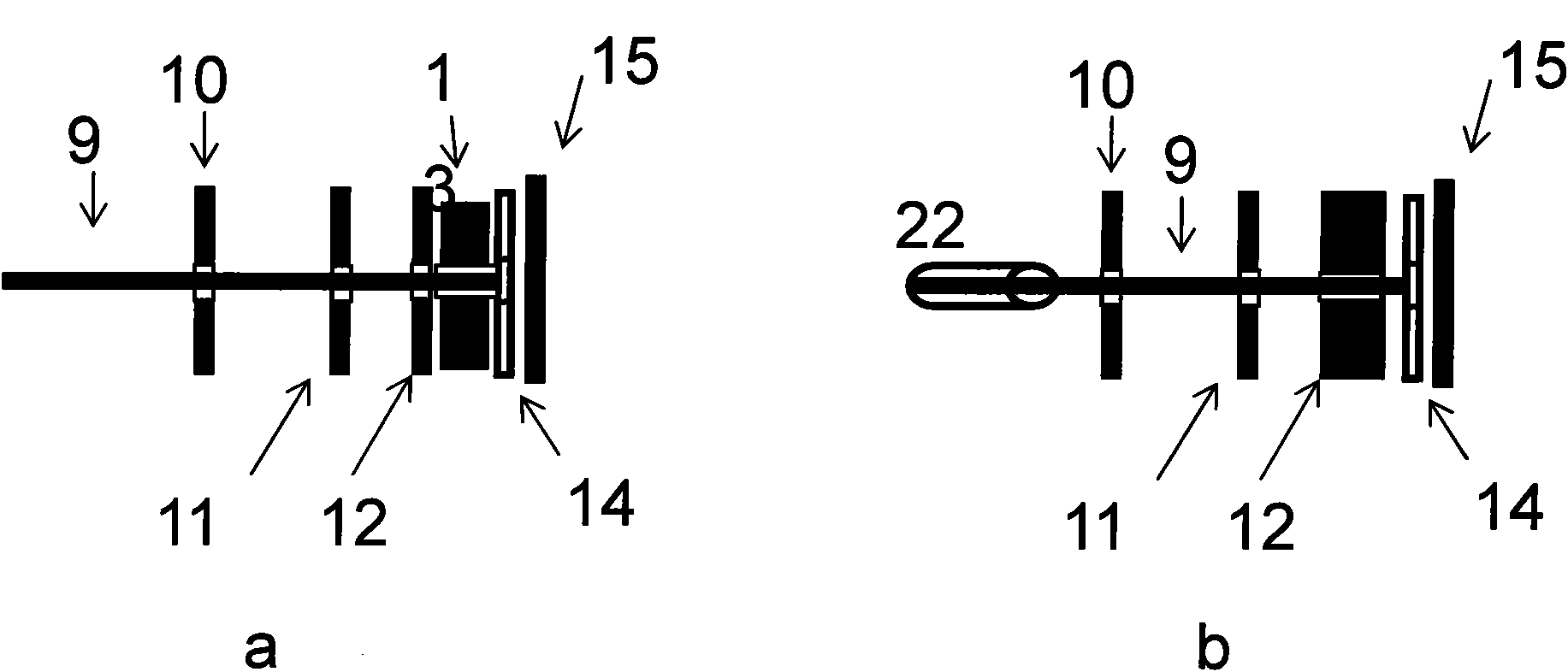

Inkless ecological hot baking printing method and printing head device

InactiveCN102310657AEliminate pollutionSmall scale of productionDecorative surface effectsPrintingSocial benefitsSurface layer

The invention discloses an inkless ecological hot baking printing method and a printing head device. Ordinary printing paper is used, a printing head and the paper adopts either a direct contact mode or a non-direct contact mode. The inkless ecological hot baking printing method and the printing head device are characterized in that a heating element is arranged on the printing head, the color ofthe surface layer of the printing paper is changed through the heat energy of the printing head, so characters or patterns are formed. During the direct contact, the temperature of the printing head is set into 100 to 1000 DEG C, the stop time of the printing head is 0.1 to 100 ms, during the non-direct contact, the temperature of the printing head is set into 200 to 1000 DEG C, and the stop timeof the printing head is 0.1 to 100 ms. Ink powder or ink or paint is not needed, the printing effect can be reached through hot baking by only adopting the single ordinary printing paper, and good low-carbon energy-saving effects and social benefits are realized.

Owner:SOUTHEAST UNIV

Biomass-based adsorption material for removing heavy metal ions in water as well as preparation method and application thereof

InactiveCN107175080AImprove adsorption capacityEasy to removeOther chemical processesWater contaminantsInorganic particleSorbent

The invention discloses a biomass-based adsorption material for removing heavy metal ions in water as well as a preparation method and application thereof. The biomass-based adsorption material comprises a base material and inorganic particles, wherein the specific surface area of the biomass-based material is 1m<2> / g-100m<2> / g; the inorganic particles comprise iron-containing inorganic magnetic particles and magnesium-containing inorganic particles; the loading amount of the inorganic particles is 10-70wt% of the total amount of the adsorbent material. The iron-containing inorganic magnetic particles and the magnesium-containing inorganic particles are loaded on the biomass surface through an in-situ co-precipitation method. The compound adsorbent material is capable of removing the heavy metal ions such as Cu<2+>, Cr2O7<2->, Pb<2+> and the like in the water and can be easily removed from the water. Compared with the heavy metal ion adsorbent material in the prior art, a natural and cheap biomass material can be used as an adsorption carrier; the biomass material is green, environmentally friendly and efficient, is capable of enabling the content of the heavy metals in the water to be far lower than the national standard, is easily removed under the action of external magnetic field, and is convenient and extensive in application.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

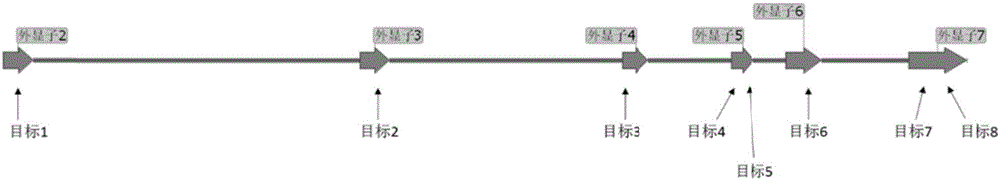

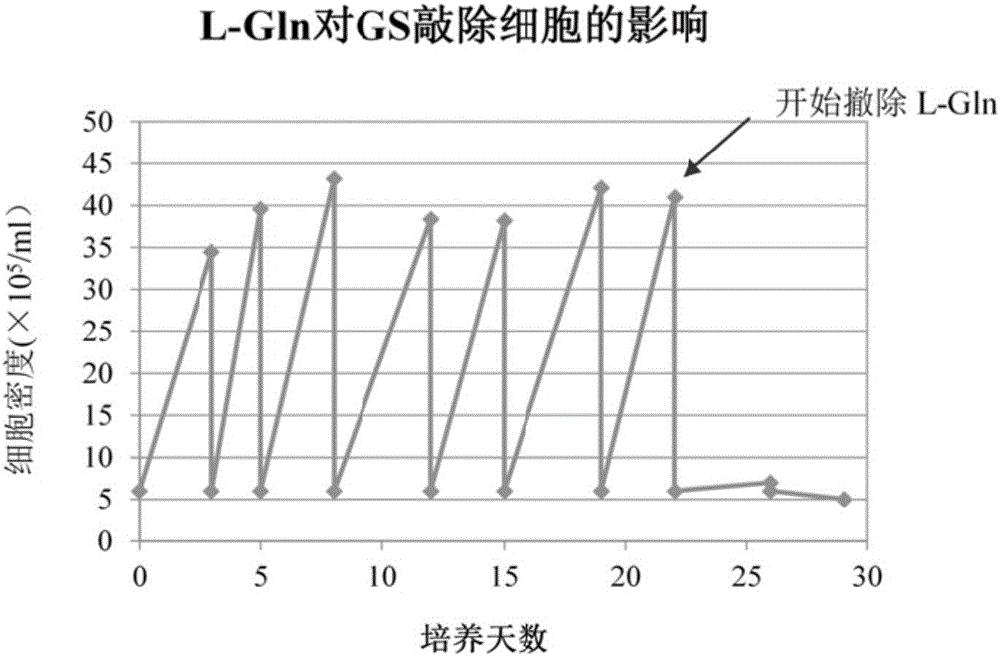

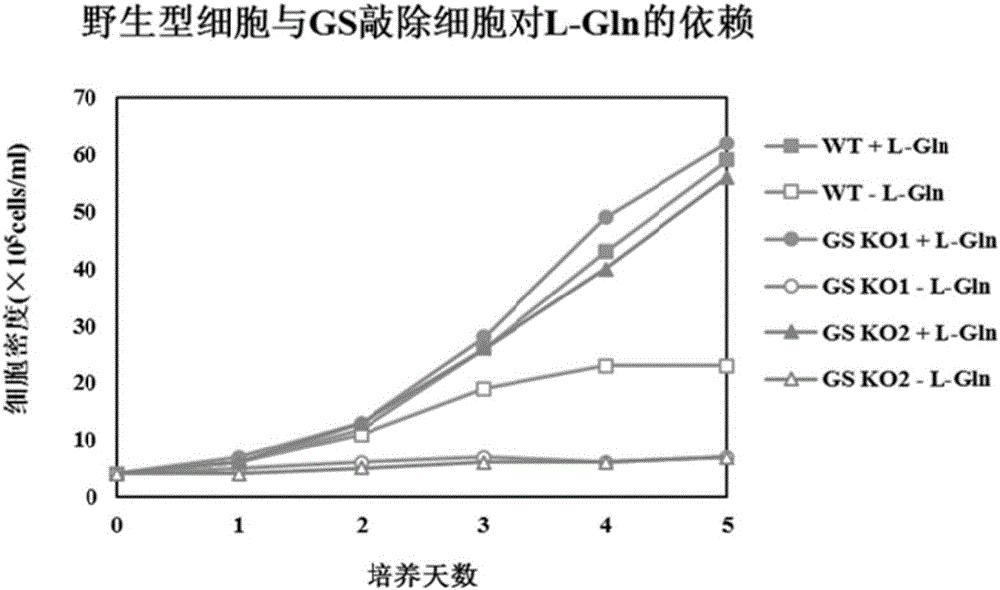

GS (glutamine synthetase) gene specific identification crRNA and application thereof

ActiveCN105950622AMixed knockouts are easily achievedImprove efficiencyNucleic acid vectorFermentationProtein targetWild type

The invention belongs to the field of cell and gene engineering, genetic modification and therapeutic recombinant protein industrial production, and particularly relates to GS (glutamine synthetase) gene specific identification crRNA and application thereof. DNA (deoxyribonucleic acid) sequences identified by the GS gene specific identification crRNA are selectively DNA sequences shown as one of sequences SEQ ID NO.1-SEQ ID NO.8. The GS gene specific identification crRNA and the application have the advantages that GS genes of diversified cells can be specifically identified by the GS gene specific identification crRNA, the GS gene specific identification crRNA is wide in applicability, and integral procedures can be implemented easily and efficiently; the target protein expression quantities of cells without the GS genes can be greatly increased on the basis of imported exogenous carriers as compared with wild host cells, and accordingly required-to-be-inputted labor, material resources and financial resources for screening protein expression cell strains can be reduced; the GS genes are knocked out, and accordingly the industrial production cost can be reduced; the cells without the GS are used as host target gene expression cells, other chemical substances can be omitted in procedures for producing the cells, and accordingly the production safety can be improved.

Owner:苏州晟济药业有限公司

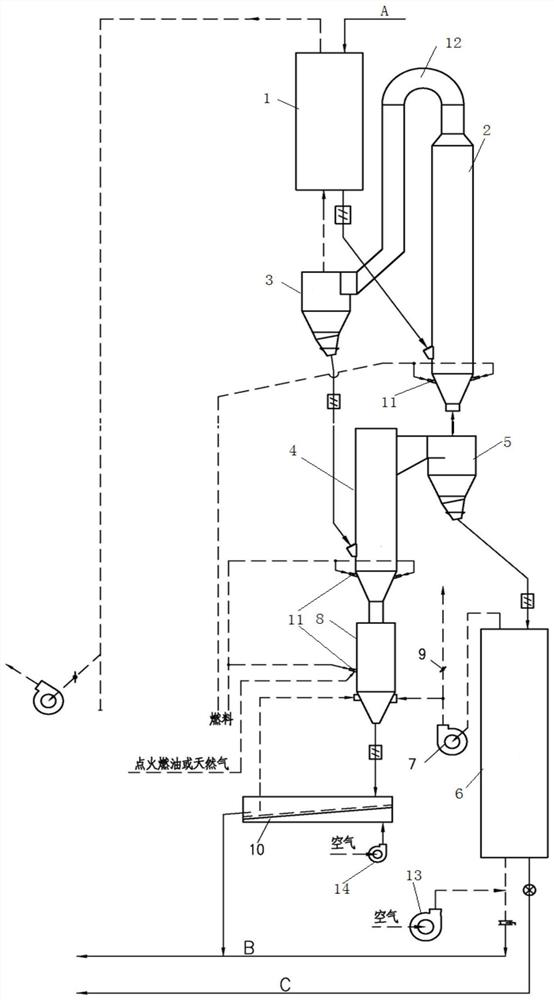

Black talcum powder-shaped suspension calcining and whitening device and process

PendingCN111847466AUniform and controllable temperature distributionImprove heat exchange efficiencyMagnesium silicatesChemical industryMetallurgyPowder talcum

The invention discloses a black talcum powder-shaped suspension calcining and whitening device and a process. A powdery calcined black talc product with the whiteness being greater than 90% is obtained. The process comprises the following steps: firstly, taking black talcum as a raw material, beneficiating, crushing and grinding to obtain black talcum powder; preheating the black talcum powder byadopting a multi-stage series suspension preheater, feeding the preheated black talcum powder into a suspension calcining furnace system for calcining, and combusting and releasing organic matters inthe black talcum powder; and finally, discharging the calcined talcum powder from the suspension calcining furnace system to enter a multi-stage series suspension cooler to be cooled. The device is composed of the multi-stage series suspension preheater, a first-stage cyclone separator, a first-stage suspension calcining furnace, a second-stage cyclone separator, a second-stage suspension calcining furnace, an auxiliary combustion ignition chamber, the multi-stage series suspension cooler, a fluidization cooler and the like, and the whole process of preheating and calcining black talcum powderand cooling finished product calcined talcum powder is completed in a suspension state. The process is advanced, green and energy-saving; the automation degree is high, and intelligence can be achieved; and the single-line production scale can be greatly improved.

Owner:HEFEI CEMENT RES DESIGN INST

Method for extracting thallium from thallium containing slag

The invention relates to a method for extracting metallic thallium from thallium-containing slag, and belongs to the vacuum metallurgy technology field. The thallium-containing slag is adopted to extract the metallic thallium in a vacuum firing furnace based on three-step distillation; the vacuum degree is control between 8 to 40Pa, and the time is 30 to 60 minutes; three-step distillation temperatures respectively range from 450 to 600 DEG C, from 900 to 1100 DEG C, and from 700 to 850 DEG C; the purity quotient of the thallium which is extracted in the vacuum firing furnace can reach more than 99.9 percent; the coefficient of recovery of the thallium can reach more than 90 percent.

Owner:KUNMING UNIV OF SCI & TECH

Production method of poly ammonium phosphate

A process for preparing ammonium polyphosphate includes such steps as proportionally mixing polyphosphoric acid with the condensating agent chosen from urea, ammonium dicarbonate, melamine, bicynoamine, ammonium sulfate and their mixture, and reacting at 100-500 deg.C under 0.01-0.35 MPa for 5-210 min.

Owner:YUNNAN CHEM RES INST

Mushroom planting waste culture medium produced organic fertilizer and preparation method thereof

InactiveCN109574723AImprove structural performanceLow costCalcareous fertilisersBio-organic fraction processingCalcium hydroxideContinuous fermentation

The invention discloses a mushroom planting waste culture medium produced organic fertilizer. A preparation method of the mushroom planting waste culture medium produced organic fertilizer comprises the steps sequentially including, debagging, drying and then crushing mushroom planting waste culture mediums; adding in an appropriate amount of ammonium hydrogen carbonate or powder calcium hydroxideor a mixture of the ammonium hydrogen carbonate and the powder calcium hydroxide, and regulating the pH to 5.5-8.5; proportionally and uniformly mixing the crushed mushroom planting waste culture medium and straw decomposing agent to obtain a mixed material; stacking the mixed material into bars for decomposition, covering the stacked mixed material with plastic films, increasing the stacked mixed material to 60-70 DEG C for continuous fermentation for 7-15 days; uniformly mixing bentonite into the fermented materials, and then performing pelletizing to obtain fertilizer pellets; drying the fertilizer pellets into a drying cylinder to obtain dried fertilizer pellets; cooling the dried fertilizer pellets inside a cooling cylinder to obtain cooled fertilizer pellets; performing grain size screening on the cooled fertilizer pellets to obtain the finished organic fertilizer.

Owner:郧西县金穗肥业中心

A biomass-based adsorption material used for removing harmful anions from water and a preparing method thereof

InactiveCN105642241ALow costEasy to operateOther chemical processesAlkali metal oxides/hydroxidesChemistryBiomass

A biomass-based adsorption material used for removing harmful anions from water and a preparing method thereof are disclosed. The surface of the biomass-based adsorption material is loaded with iron-containing inorganic magnetic particles and / or aluminum-containing inorganic particles. The main raw material of the biomass-based adsorption material is agriculture waste. The harmful anions include F<->, AsO<2><-> and AsO<4><3->. Compared with materials adsorbing the harmful anions at present, the biomass-based adsorption material adopts the biomass agriculture waste as an adsorption substrate, and is simple in process, convenient in operation and suitable for treating water polluted by a plurality of harmful anions. A production scale can be large or small, thus facilitating popularization in remote rural areas and individual users, and allowing the biomass-based adsorption material to be suitable for large-scale water treatment.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Process for stage-by-stage biological dump leaching desulfurization of high-sulfur-content coal mine

ActiveCN106833797AEffective oxidationEfficient degradationSolid fuelsPregnant leach solutionDump leaching

The invention provides a process for stage-by-stage biological dump leaching desulfurization of a high-sulfur-content coal mine. By stage-by-stage biological dump leaching removal of inorganic sulfur and organic sulfur, the process comprises the following steps: dump making, acid balancing, inorganic sulfur removal, neutralization of leachate and organic sulfur removal. The method can fulfill the aim of effectively removing sulfur from the high-sulfur-content coal mine. Compared with conventional physical and chemical methods, the method has the advantages of mild condition, low cost, zero discharge of harmful gas and the like, and has a wide application prospect in the field of coal mine desulfurization.

Owner:有研资源环境技术研究院(北京)有限公司

Method for slagging steelmaking by side blowing of powder particle limestone in top-bottom combined blown converter

InactiveCN102796841BTake away decreaseIncrease profitManufacturing convertersSteelmakingMelting tank

The invention belongs to the technical field of metallurgy, and particularly relates to a method for slagging steelmaking by side blowing of powder particle limestone in a top-bottom combined blown converter. The method of the invention comprises the following steps: arranging at least one side blowing spray gun at one side of a converter trunnion center line, wherein the installation site of the side blowing spray gun is located between a molten pool liquid level and a level 500 mm below the liquid level, an angle between the installation range of the side blowing spray gun and the installation site tangent plane is 10 degrees-75 degrees, the side blowing direction of the spray gun is that the included angle between the side blowing spray gun center line and a horizontal line is 10 degrees-60 degrees, the spray gun faces the bottom of the molten pool, the insertion depth of the side blowing spray gun is 0.1-0.6 times larger than the radius of the molten pool; blowing powder particle limestone with carrier gas through a center pipe of the spray gun by using the side blowing spray gun, blowing protective gas around the circular seam. The method of the invention directly sprays powder particle limestone into the molten pool through the side blowing spray gun; the limestone rapidly decomposes and rapidly participates in slagging reactions; limestone taken away by converter furnace gas is reduced; dust is minimized; and the utilization rate of limestone is improved.

Owner:NORTHEASTERN UNIV LIAONING

Method for stabilizing liquid photosynthetic bacterium living bacterium preparation

InactiveCN109022283AGood storage stabilityHigh viscosityMicroorganism preservationMicrobiologyOrganic media

The invention discloses a method for stabilizing a liquid photosynthetic bacterium living bacterium preparation. A nontoxic, harmless and residual-free polymeric organic medium difficultly utilized byphotosynthetic bacteria is added into a photosynthetic bacterium suspension to prepare the photosynthetic bacterium liquid living bacterium preparation, and the concentration of the polymeric organicmedium is 3.0 to 6.0 g / L. The preparation can be stored in a 4-30 DEG C dark environment for at least 12 months, the appearance color of the liquid preparation has no obvious change, the preparationhas uniform properties, has no obvious liquid preparation bacterium sedimentation stratification phenomenon, and still has high biological activity, and the ability to remove nitrite nitrogen is maintained at 80% or above. The stored living bacterium preparation is miscible with water, and can be easily dispersed in water without obvious bacterial agglomerates. The preparation method of the preparation is disclosed in details, and a new use of xanthan gum and other media in the production of photosynthetic bacterium products is also developed. The method has the advantages of simplicity in operation, low cost, and easiness in large-scale operation.

Owner:HUAQIAO UNIVERSITY

Method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen

InactiveCN101899568BImprove leaching rateWide range of resource utilizationPhotography auxillary processesProcess efficiency improvementPregnant leach solutionNickel sulfide

The invention discloses a method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen, comprising the following steps: mixing and pulpifying chemically precipitated nickel sulfide and high pressure leachate based on the mass ratio of (8-10):1, performing one-stage atmospheric pressure leaching on the pulpified material, removing impurities from one-stage leachate and electrolyzing, producing electrolytic nickel and anolyte, mixing one-stage leached residue with anolyte for secondary pulpifying, further leaching by two-stage high pressure, and returning the obtained leached filtrate to one-stage pulpifying for utilization. The process technique has widely utilized resources, simple technical route, small investment, low energy consumption, no environment pollution, high leaching rate of nickel and cobalt, simple and convenient operation and low production cost, and provides an effective and economical way for producing electrolytic nickel in nickel sulfide concentrates.

Owner:SHAANXI HUAZE NICKEL & COBALT METAL

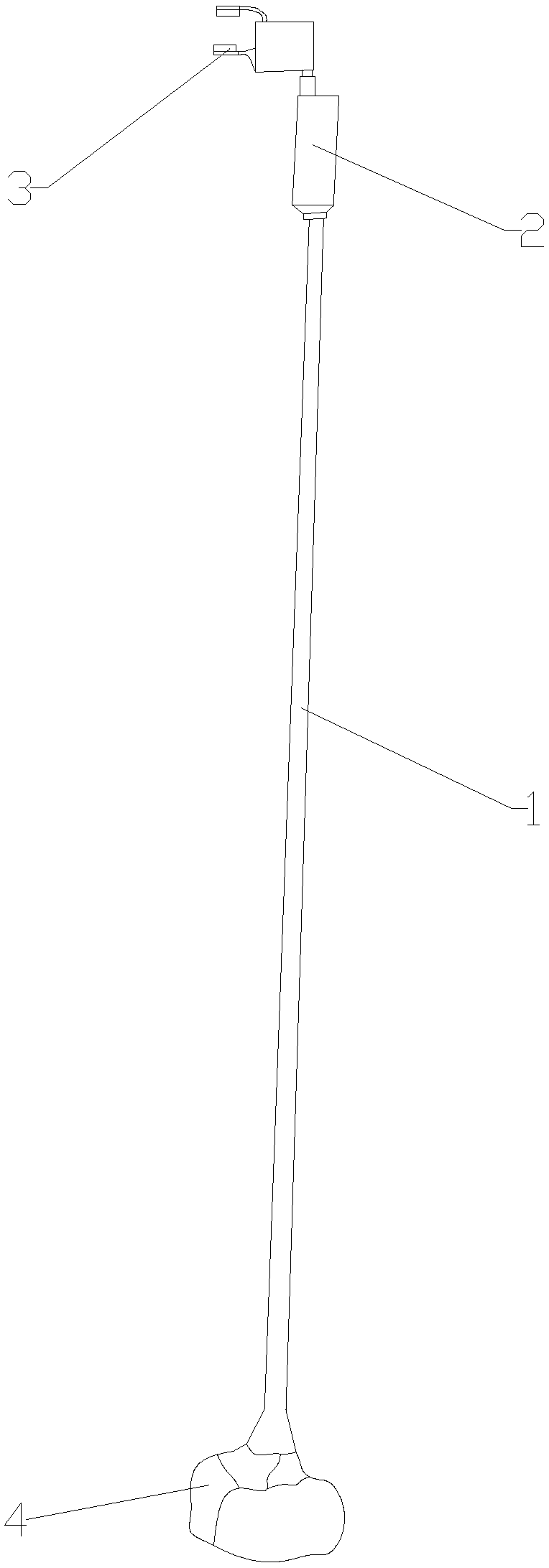

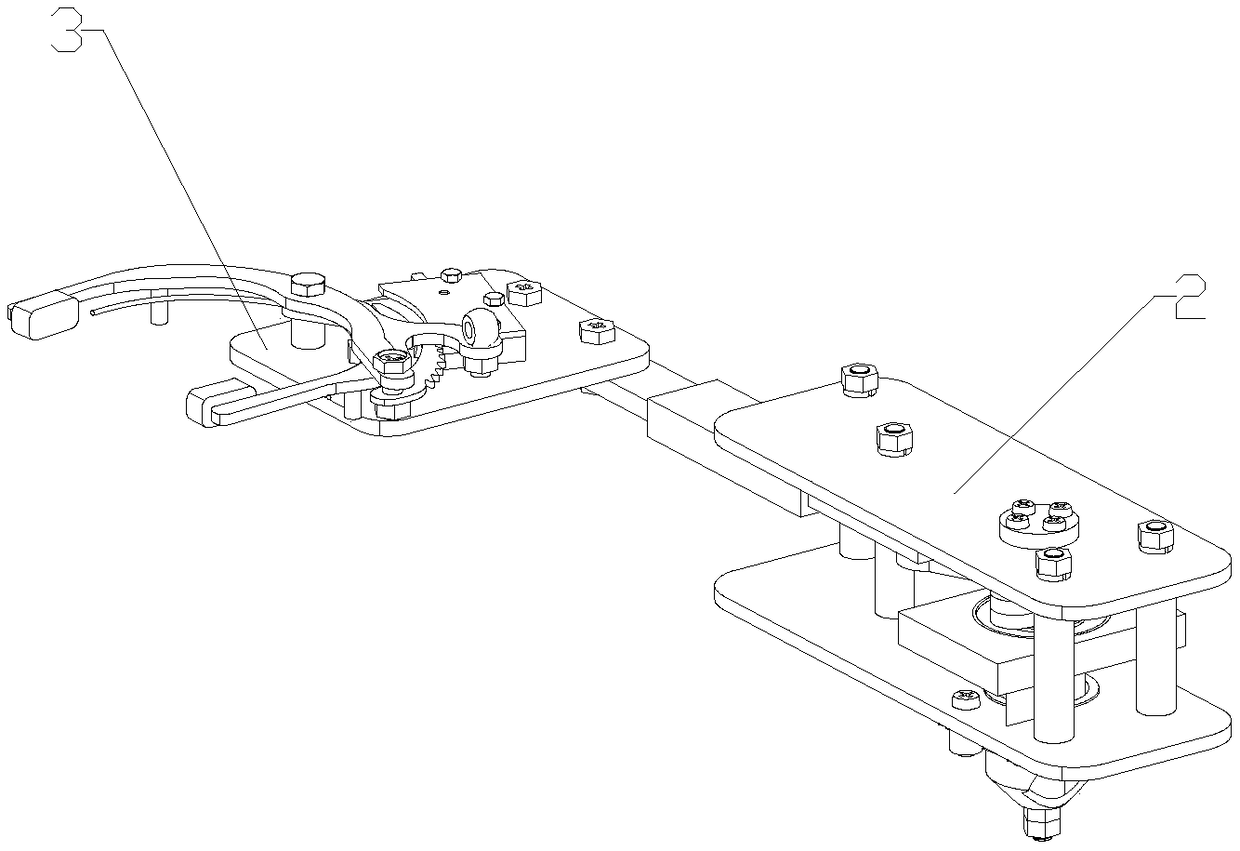

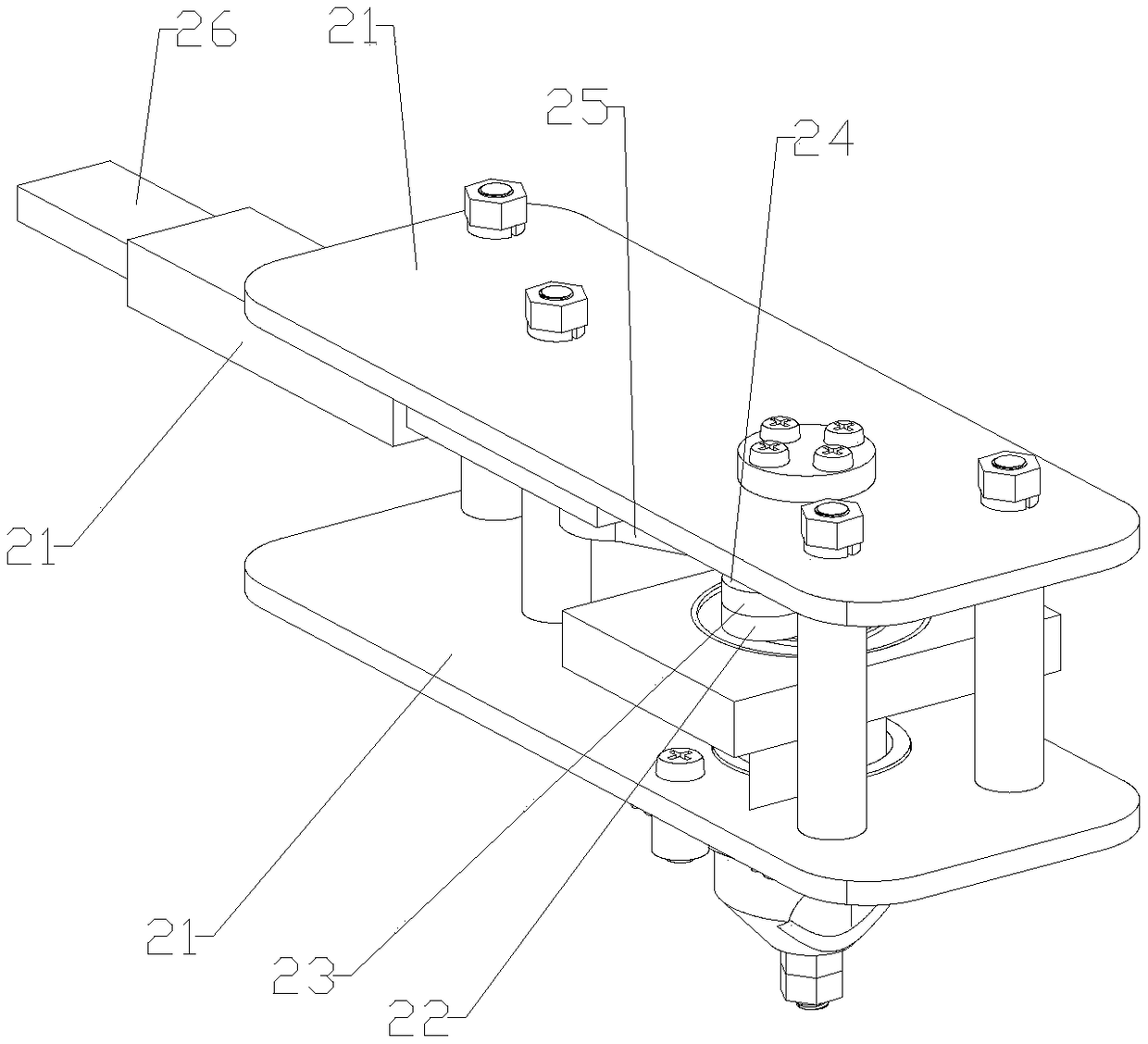

Inertial picker

The invention discloses an inertial picker including an operating rod, a transmission device mounted on the operating rod, a gripper which is mounted on an upper end of the operating rod and can graspand loosen a branch and a first driving component. The transmission device comprises a bracket, a driving crank, a bracket connecting rod, a driven crank, a connecting rod and a sliding block. The bracket is fixedly mounted on the operating rod, two ends of the driving crank are hinged to the bracket and the bracket connecting rod, the other end of the bracket connecting rod is hinged to the driven crank, and the other end of the driven crank is hinged to the bracket. Two ends of the connecting rod are hinged to the driven crank and the sliding block, the sliding block is slidingly installedon the bracket, the gripper is fixedly installed on the sliding block, and the first driving component can drive the driving crank to rotate around a hinge shaft of the bracket and the driving crank.The inertial picker provided by the invention is suitable for fruit picking of orchards with small scale, diverse planting modes and dispersed cultivation.

Owner:余传佩

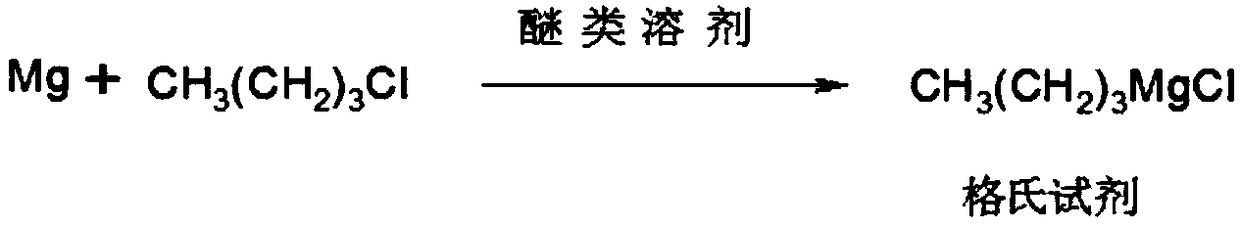

Tetrabutyl tin preparation method

The invention discloses a tetrabutyl tin preparation method. The preparation method comprises the following steps: adding magnesium powder and an ether solvent into a reactor with a stirring and refluxing device, starting to stir and heat till refluxing; then adding a small quantity of chlorobutane and a YF-017 catalyst, slowly adding a mixed solution of chlorobutane and anhydrous tin tetrachloride dropwise, conducting a refluxing reaction to the end after finishing adding; cooling to the normal temperature, adding hydrochloric acid while stirring, then allowing standing still for layering; releasing an aqueous phase on the lower layer, distilling an organic phase at the normal pressure, changing to perform reduced pressure distillation after the solvent is completely distilled, and collecting a fraction of 148-150 DEG C under the condition of the vacuum degree of minus 650 Pa, to obtain tetrabutyl tin. A small quantity of catalyst is added into a one-step reaction device, the Grignardreaction is started immediately, the heat produced in the Grignard reaction in the first step is rapidly absorbed by the alkylation reaction in the second step. Therefore, the phenomenon of materialspraying of the reaction is avoided, and safety in the industrial production is guaranteed.

Owner:SHANGHAI NO 4 REAGENT & H V CHEM

Low energy consumption clean paper pulp extracting method and papermaking process thereof

InactiveCN101694075BAchieve recyclingGood flexibilityPretreatment with alkaline reacting compoundsPulp de-wateringFiberChemical solution

The invention relates to a low energy consumption clean paper pulp extracting method and a papermaking process thereof, solving the problems that fibrous raw materials need to be boiled at high temperature and pressure in the pulp preparing and papermaking processes and chemical solutions produce a large quantity of black or red liquid in the pulp preparing and papermaking processes to cause great waste to resources and great pollution to the environment in the prior art. The invention adopts the following technical scheme: the low energy consumption clean paper pulp extracting method is realized by removing impurities from biomass raw materials rich of fiber, crushing, softening and soaking, separating organic matters, grinding and pulping, wherein a softening and soaking solution contains the following components in percent by weight: 10-20 sodium oxide, 3-5 sodium carbonate, 0.5-2.5 penetrating agent T, 0.5 magnesium oxide and 0.05-0.15 chelating agent EDTA. The papermaking processmatched with the method comprises the following steps: getting materials ready, rubbing to devillicate, soaking to react, separating liquid medicine, spirally squeezing pulp, refining with high consistency, removing slag, coarsely screening and making paper. The pulp preparing process has simple course, no high requirements on environment and equipment condition, easily popularized technology, norequirement on the scale of production, low costs for building production lines and purchasing equipment and less running expense.

Owner:林宣禧

Preparation process of cotton woven fabric with strong antibacterial effect

PendingCN112941908AGood antibacterial effectSmall scale of productionBiochemical fibre treatmentWoven fabricsPolymer scienceCotton fibre

The invention discloses a preparation process of a cotton woven fabric with a strong antibacterial effect. Three parts of raw materials, namely a blending weaving raw material, an antibacterial agent and a functional auxiliary agent are used, wherein the blending weaving raw material comprises corn fibers, cotton fibers, polyamide fibers, cashmere fibers, chemical fibers, linen fibers, triacetate fibers, mint fibers, chitosan fibers and polylactic acid fibers; the antibacterial agent comprises a honeysuckle chlorogenic acid solution, a nano-silver antibacterial solution, a zinc oxide solution, an ammonium dihydrogen phosphate solution and a lithium carbonate solution; and the functional auxiliary agent comprises a dispersing agent and a modifier. According to the present invention, the prepared cotton woven fabric has the characteristics of strong antibacterial activity, health and sanitation during the use process, small production scale, low production cost, and improved product performance.

Owner:恒天(江苏)化纤家纺科技有限公司

Exclusive bacteria and technology for removing organic sulfur in high sulfur coal mine through exclusive bacteria

ActiveCN106544288AIncrease utilizationComprehensive recovery rate is highBacteriaSolid fuelsLaboratory cultureChemistry

The invention discloses exclusive bacteria and a technology for removing organic sulfur in high sulfur coal mine through the exclusive bacteria. The exclusive bacteria have a class name of Bacillus subtilis Retech Organosulfur-I, are preserved in the China general microbiological culture collection center in the microbiology institute with the address of No. 3, Beichen West Road, Chaoyang District, Beijing, China on the collection date of May 28, 2015, and has a preservation number of CGMCC No. 10933. The bacillus can degrade the organic sulfur in the coal mine under acidic and aerobic conditions, and through combination of the bacillus and the high efficiency desulfurization mixed strain Retech TS-I, inorganic sulfur is removed and effective total sulfur removal of high sulfur coal mine is realized. Compared with the conventional physical and chemical methods, the technology has the advantages of mild conditions, low cost and no harmful gas emission, and has a wide application prospect in the field of coal mine desulfurization.

Owner:有研资源环境技术研究院(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com