Cellulose base adsorbing material for removing cations of heavy metal in water and preparation method of cellulose base adsorbing material

An adsorption material, cellulose-based technology, which is applied in the field of cellulose fiber surface functionalization to prepare water treatment adsorption materials, can solve the problems of heavy metals that cannot be degraded, not easily metabolized, and physiological disorders, and achieves convenient operation, high adsorption efficiency, and high adsorption. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The cellulose (cellulose) obtained after the pulverization of the paper plate prepared by using rice straw as a raw material is used to prepare cellulose-g-PMAA (sample 1), and to test the adsorption performance of sample 1

[0036]In a 100ml one-mouth bottle, add 40ml ultrapure water, 1.3g (NH 4 ) 2 Ce(NO 3 ) 6 Dissolve fully with 1mL of nitric acid with a mass concentration of 65%-68%, then add 0.5g of cellulose fiber with a diameter of 1μm-100μm processed by a pulverizer, fully stir and disperse, bubble nitrogen for 30 minutes, and add 2mL monomer MAA, continue to sparge with nitrogen for 10 min. After sealing, place it in an oil bath at 70°C for 1 hour and pass Ce in an acidic water system 4+ Initiate free radical polymerization, graft polymerize MAA at the -OH place of cellulose to obtain carboxyl-containing MAA monomers on the surface of cellulose, and control the grafted PMAA containing carboxyl groups to be the total weight of the sample 1 About 16wt%. Air...

Embodiment 2

[0039] Using sawdust as raw material to prepare cellulose (cellulose) obtained after pulverizing the cardboard to prepare cellulose-g-PMAA (sample 2), and to test the adsorption performance of sample 2

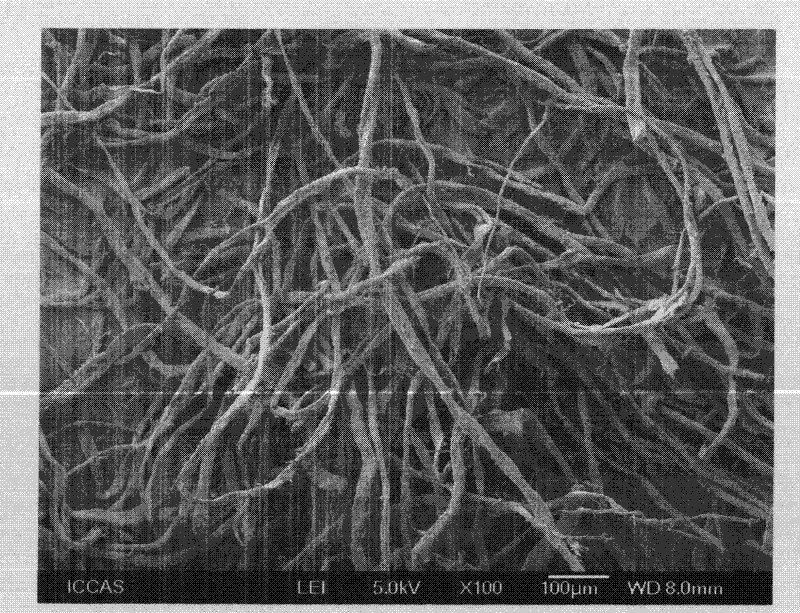

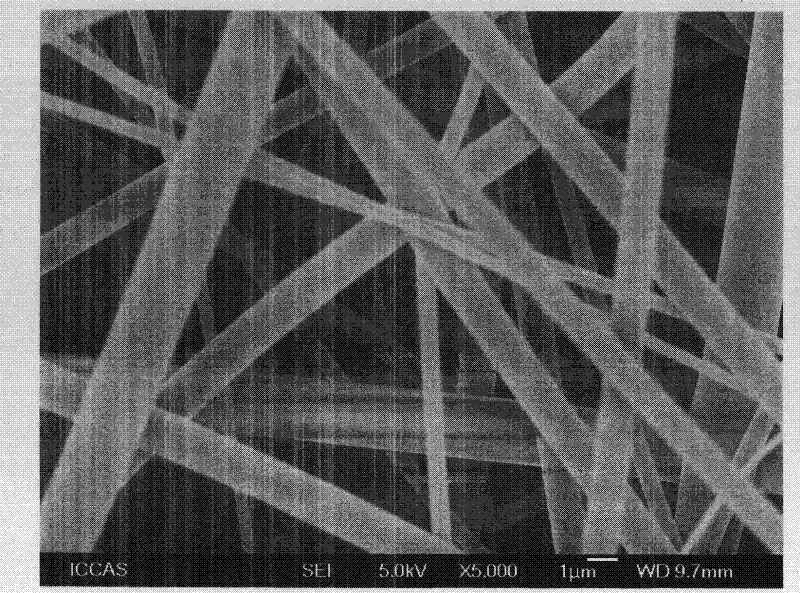

[0040] In a 100ml one-mouth bottle, add 40ml ultrapure water, 0.25g (NH 4 ) 2 Ce(NO 3 ) 6 And 4.8mL mass concentration is the nitric acid of 65%-68%, fully dissolves, then add the cellulose fiber (the SEM photo of cellulose fiber see figure 1 ), fully stirred to disperse, nitrogen bubbled for 30 minutes, added 3mL monomer MAA, and continued nitrogen flow for 10 minutes. After sealing, place it in a water bath at 40°C for 4 hours and pass Ce in an acidic water system 4+ Initiate free radical polymerization, graft polymerize MAA at the -OH place of cellulose to obtain carboxyl-containing MAA monomer on the surface of cellulose, and control the grafted PMAA containing carboxyl group to be the total weight of sample 2 About 50wt% of it. Air was introduced to terminate the re...

Embodiment 3

[0043] Using sawdust as raw material to prepare cellulose-g-PAA (sample 3) from the cellulose (cellulose) obtained after the pulverization of the paper plate prepared by the raw material, and to test the adsorption performance of sample 3

[0044] In a 100ml one-mouth bottle, add 40ml ultrapure water, 2.3g (NH 4 ) 2 Ce(NO 3 ) 6 and 0.5mL of nitric acid with a mass concentration of 65%-68%, fully dissolved, then add 0.5g of cellulose fiber with a diameter of 1μm-100μm processed by a pulverizer, fully stir and disperse, nitrogen bubble for 30 minutes, add 4.5mL Monomer AA, continue to pass nitrogen for 10 minutes. After sealing, place it in a water bath at 40°C for 24 hours to react, and pass Ce in an acidic water system 4+ Initiate free radical polymerization, graft AA at the -OH of the cellulose to obtain a carboxyl-containing AA monomer on the surface of the cellulose, and control the grafted carboxyl-containing PAA to the total weight of the sample 3 About 11wt%. Air w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com