Natural seasoning and preparation method thereof

A seasoning and pure natural technology, which is applied in the preparation of seasonings from Chinese herbal medicines, natural seasonings and their preparation, and natural spices. It can solve the problems of difficulty in quality control, difficulty in gathering raw materials, and many ingredients, so as to ensure food safety and production. The steps are simple and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

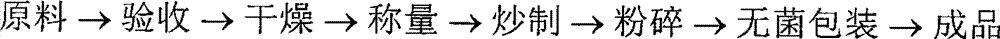

Image

Examples

Embodiment 1

[0038] The raw material formula is: 10 parts of pepper, 10 parts of anise, 3 parts of amomum, 2 parts of nutmeg, 3 parts of cinnamon, 3 parts of galangal, 2 parts of clove, 2 parts of grass fruit, 3 parts of cumin, and 2 parts of dried ginger , 1 part of Kaempfer, 2 parts of self-pepper, 1 part of Angelica dahurica, 1 part of tangerine peel, and 0.5 part of woody fragrance.

[0039] (1) Raw material pretreatment. The raw materials are checked and accepted, and then put into the microwave drying and sterilizing machine to dry for later use. Then, weigh according to the formula.

[0040] (2) Fried. Put various raw materials such as tsaoko, prickly ash, star anise, etc. into the frying machine for frying, and then cool down after frying for later use.

[0041] (3) Smash. Various raw materials in the formula are mixed and pulverized to 50 mesh with a pulverizer.

[0042] (4) Packaging. The cleanliness of the workshop reaches 10,000 grade, and the finished product is packaged...

Embodiment 2

[0044] The raw material formula is: 9 parts of pepper, 9 parts of anise, 3 parts of amomum, 2 parts of nutmeg, 3 parts of cinnamon, 3 parts of galangal, 2 parts of clove, 2 parts of grass fruit, 3 parts of cumin, and 2 parts of dried ginger , 1 part of Kaempfer, 2 parts of white pepper, 1 part of Angelica dahurica, 2 parts of tangerine peel, 0.5 part of woody fragrance.

[0045] (1) Raw material pretreatment. The raw materials are checked and accepted, and then put into the microwave drying and sterilizing machine to dry for later use. Then, weigh according to the formula.

[0046] (2) Fried. Put various raw materials such as tsaoko, prickly ash, star anise, etc. into the frying machine for frying, and then cool down after frying for later use.

[0047] (3) Smash. Various raw materials in the formula are mixed and pulverized to 80 mesh with a pulverizer.

[0048] (4) Packaging. The cleanliness of the workshop reaches 10,000 grade, and the finished product is packaged und...

Embodiment 3

[0050] The raw material formula is: 8 parts of pepper, 7 parts of anise, 3 parts of amomum, 2 parts of nutmeg, 3 parts of cinnamon, 3 parts of galangal, 2 parts of clove, 2 parts of grass fruit, 3 parts of cumin, and 3 parts of dried ginger , 1 part of Kaempfer, 2 parts of white pepper, 1 part of Angelica dahurica, 2 parts of tangerine peel, 0.5 part of woody fragrance.

[0051] (1) Raw material pretreatment. The raw materials are checked and accepted, and then put into the microwave drying and sterilizing machine to dry for later use. Then, weigh according to the formula.

[0052] (2) Fried. Put various raw materials such as tsaoko, prickly ash, star anise, etc. into the frying machine for frying, and then cool down after frying for later use.

[0053] (3) Smash. Various raw materials in the formula are mixed and pulverized to 90 mesh with a pulverizer.

[0054] (4) Packaging. The cleanliness of the workshop reaches 10,000 grade, and the finished product is packaged und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com