A biomass-based adsorption material used for removing harmful anions from water and a preparing method thereof

A technology for adsorbing materials and biomass, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal compounds, etc. It can solve the problems of complex preparation process and high cost, and achieve simple process, simple operation and wide adsorption range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

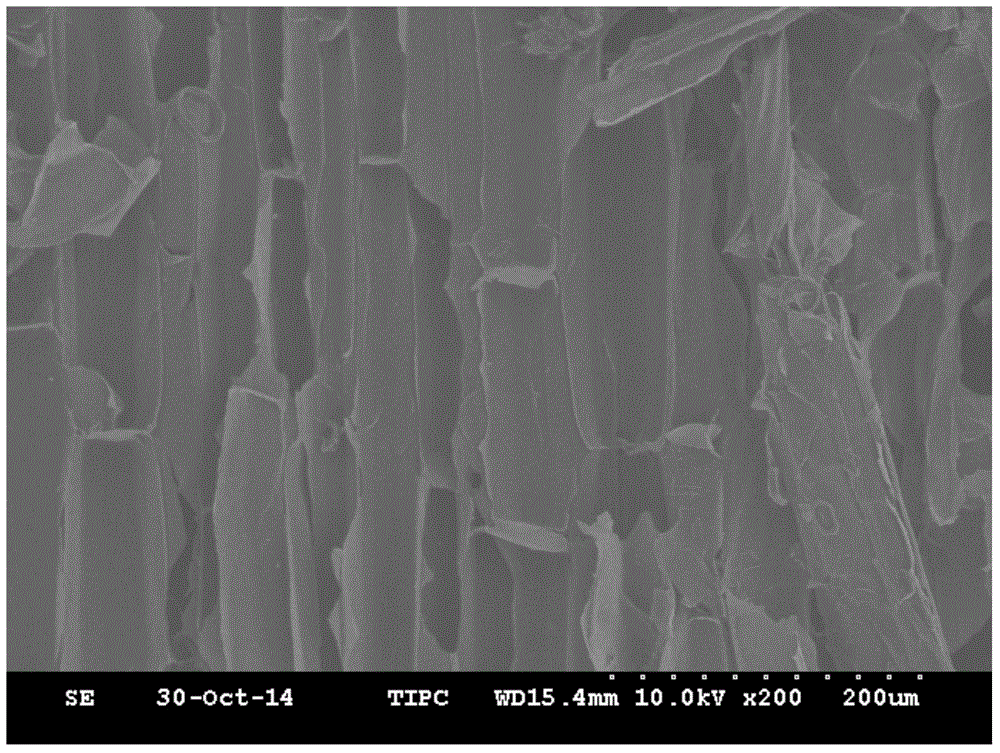

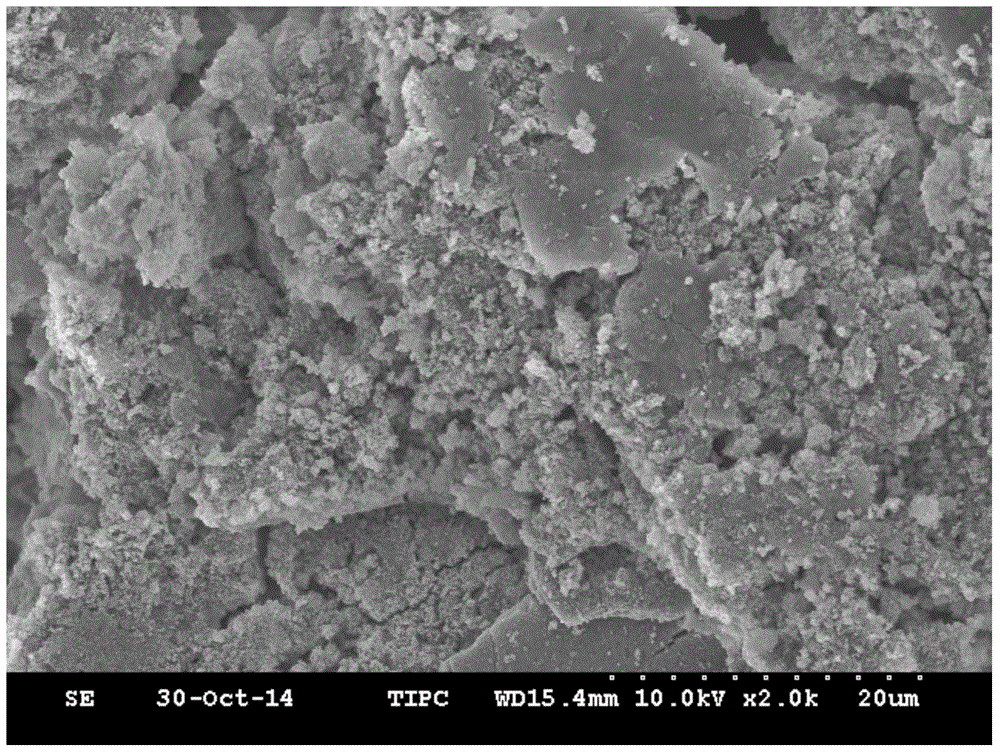

[0036] Biomass material powder obtained by crushing wheat straw prepared from wheat straw as raw material (scanning electron microscope photos of the figure 1 shown), the preparation of biomass material / Fe 3 o 4 (sample 1), and carry out the test of adsorption performance to sample 1.

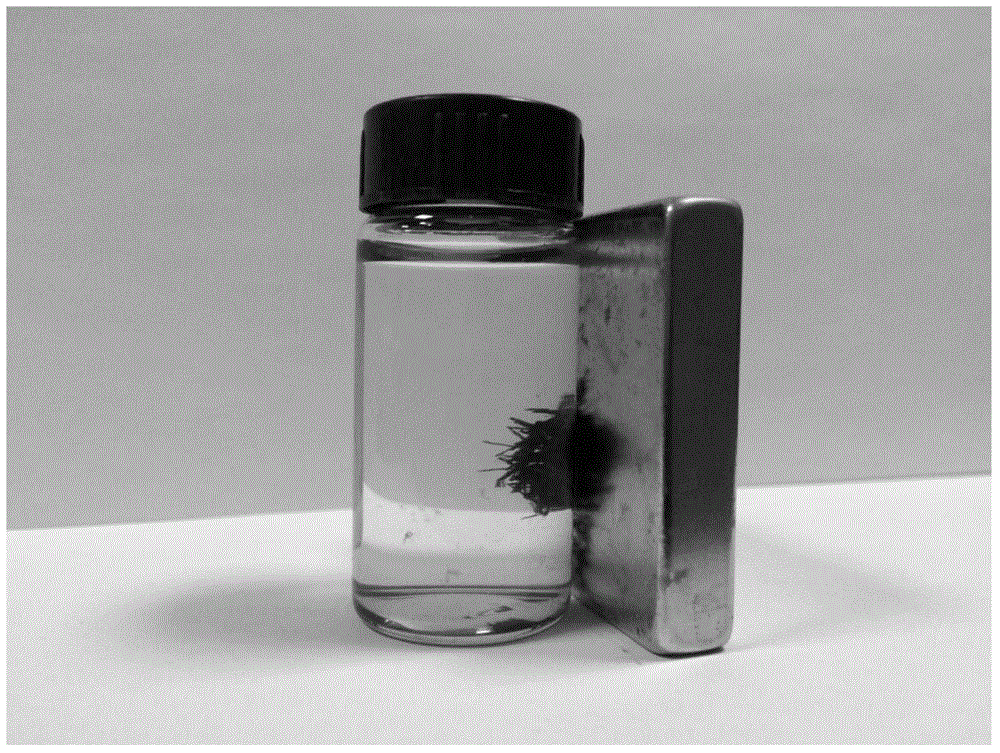

[0037] In a 100mL flask, add 50mL ultrapure water, 4.5gFeCl 3 ·6H 2 O, 2.3g FeSO 4 ·7H2 O, 0.5 g of biomass material powder obtained by mechanical crushing, fully stirred and dispersed, passed nitrogen gas for 3 minutes, began to add ammonia water dropwise, added 10 mL of ammonia water, and continued nitrogen gas flow for 2 minutes. After the system was closed, it was placed in an oil bath at 70°C for 4 hours to react. After the reaction was terminated, the reaction product was repeatedly washed with water, magnetically separated, and dried to obtain a biomass-based adsorption material sample 1 for removing harmful anions in water.

[0038] Take 0.05g of sample 1, put in 100mLAsO 4 3- In...

Embodiment 2

[0042] Wheat straw was used as raw material to prepare biomass material powder obtained by crushing wheat straw, and biomass material / iron-aluminum (hydr) oxide (sample 2) was prepared, and the adsorption performance of sample 2 was tested.

[0043] In a 100mL flask, add 50mL ultrapure water, 4.5gFeCl 3 ·6H 2 O, 2.3g FeSO 4 ·7H 2 O, 9.4gAl(NO 3 ) 3 9H 2 O, 0.5 g of biomass material powder obtained by mechanical crushing, fully stirred and dispersed, passed nitrogen gas for 3 minutes, began to add ammonia water dropwise, added 20 mL of ammonia water, and continued nitrogen gas flow for 2 minutes. After the system was closed, it was placed in an oil bath at 70°C for 4 hours to react. After the reaction was terminated, the reaction product was repeatedly washed with water, magnetically separated, and dried to obtain a biomass-based adsorption material sample 2 for removing harmful anions in water.

[0044] Take 0.1g of sample 2 and place in 100mLF - solution, stirred for 4...

Embodiment 3

[0046] Wheat straw was used as a raw material to prepare biomass material powder obtained by crushing wheat straw, to prepare biomass material / iron-aluminum (hydr) oxide (sample 3), and to test the adsorption performance of sample 3.

[0047] In a 100mL flask, add 50mL ultrapure water, 2.3g FeCl 3 ·6H 2 O, 1.2g FeSO 4 ·7H 2 O, 4.7gAl(NO 3 ) 3 9H 2 O, 0.5 g of biomass material powder obtained by mechanical crushing, fully stirred and dispersed, passed nitrogen gas for 3 minutes, began to add ammonia water dropwise, added 10 mL of ammonia water, and continued nitrogen gas flow for 2 minutes. After the system was closed, it was placed in an oil bath at 70°C for 4 hours to react. After the reaction was terminated, the reaction product was repeatedly washed with water, separated, and dried to obtain a biomass-based adsorption material sample 3 for removing harmful anions in water.

[0048] Take 0.1g of sample 3 and place in 100mLF - solution, stirred for 4 hours, and measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com