Patents

Literature

40results about How to "Wide range of adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel adsorbing and treating agent for mycotoxins in feed and application thereof

InactiveCN101849609AWide range of adsorptionImprove adsorption capacityAnimal feeding stuffSurface finishMycotoxin

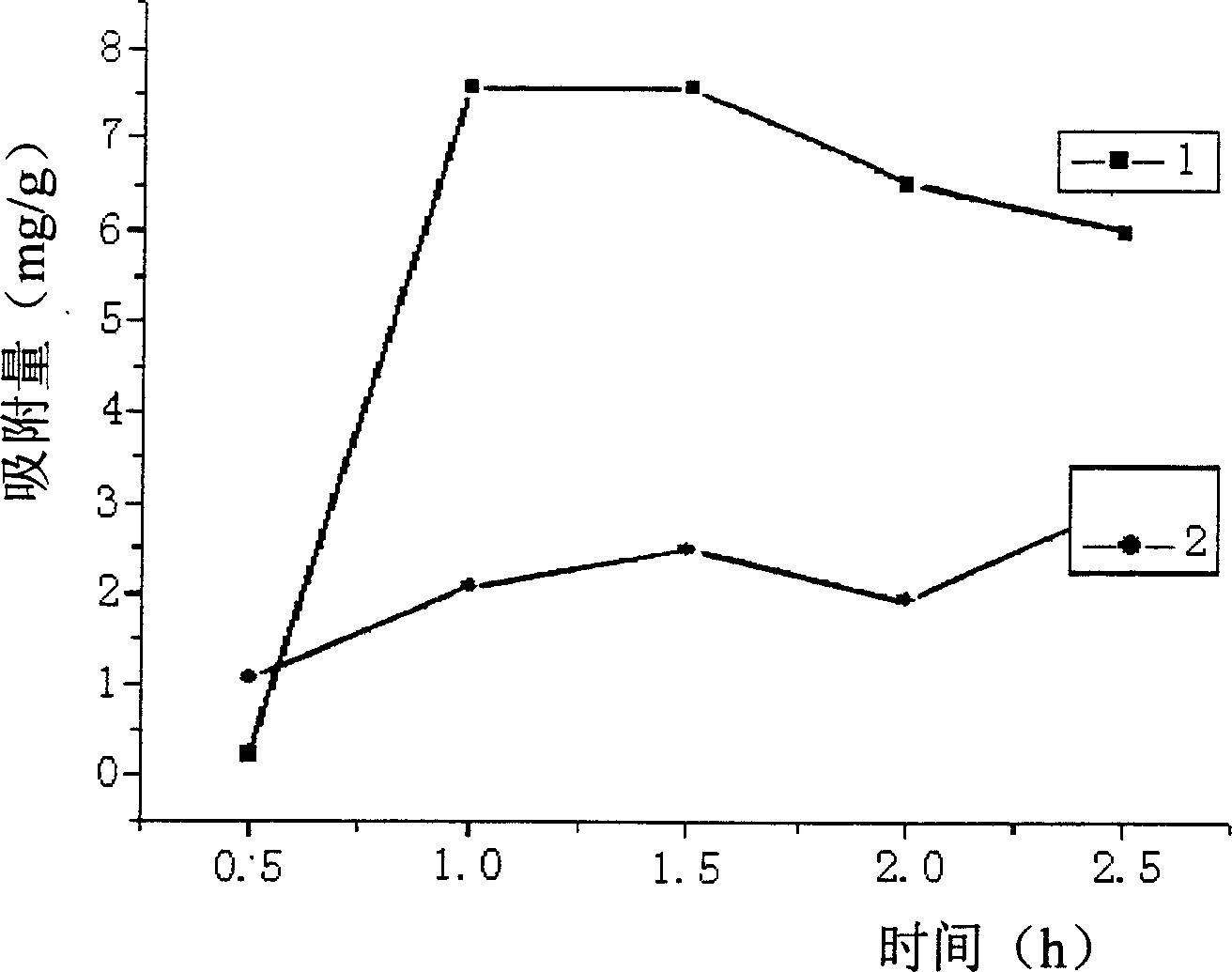

The invention discloses a novel adsorbing and treating agent for mycotoxins in a feed, and application thereof. The invention is characterized in that: the adsorbing and treating agent comprises the following components: 20 to 80 percent of hydrated aluminosilicate subjected to surface finish and intercalation, 10 to 70 percent of beta-glucan, and 0.5 to 15 percent of licorice extract; and the adsorbing and treating agent accounting for 0.05 to 0.5 percent of the weight of the feed is added into the feed. The adsorbing and treating agent has the advantages of wide adsorption range, so the adsorbing and treating agent can adsorb various mycotoxins steadily; the adsorbing and treating agent has good flowability, so the adsorbing and treating agent is suitable for feed production; and the adsorbing and treating agent has no toxic or side effect and low cost, so the adsorbing and treating agent is suitable for promotion.

Owner:南京奥迈科技有限公司 +1

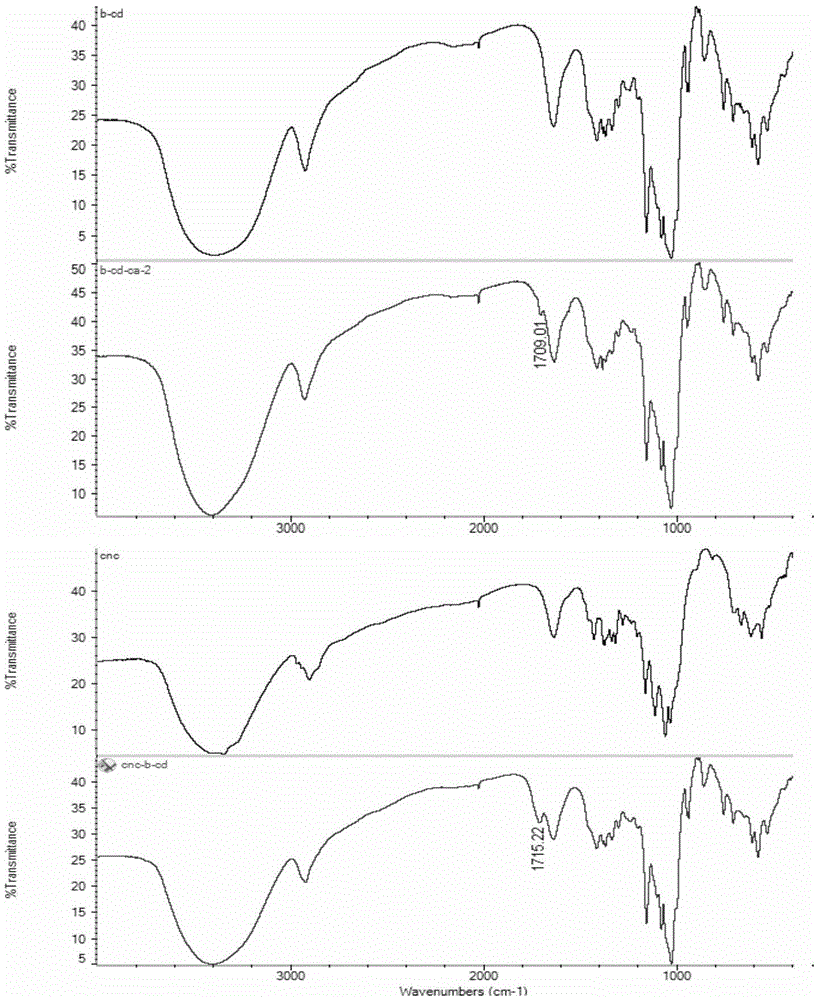

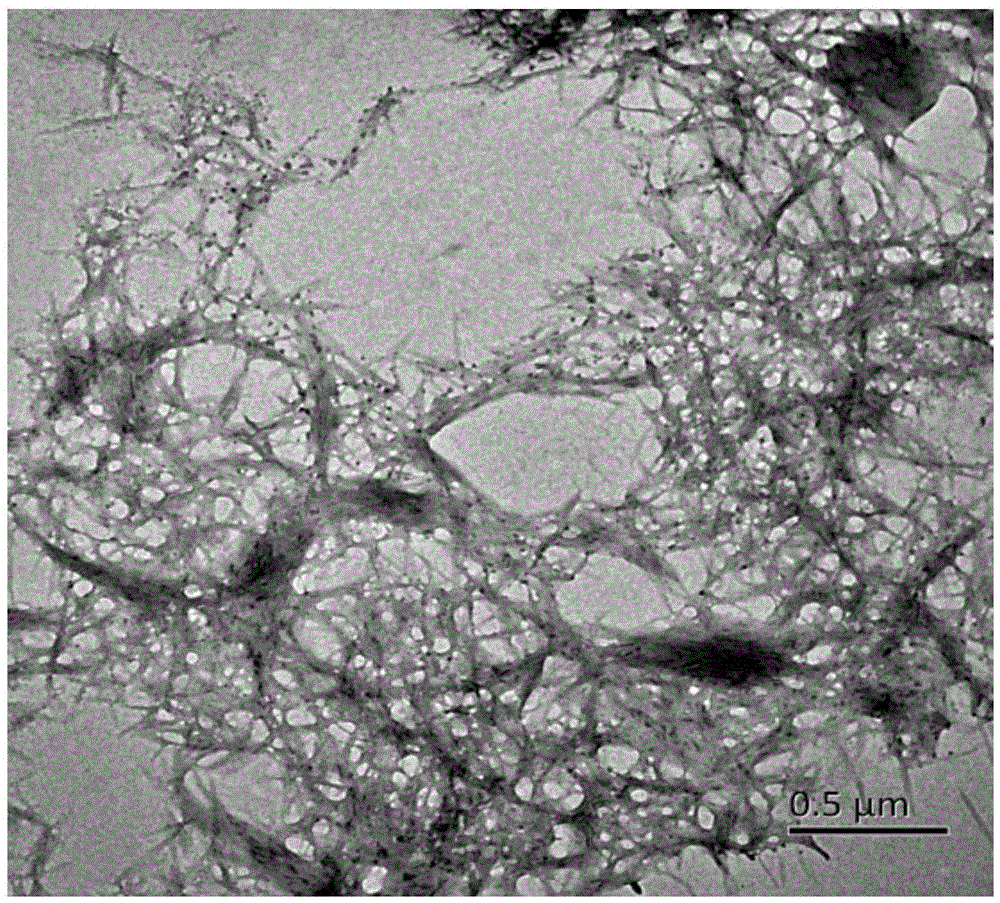

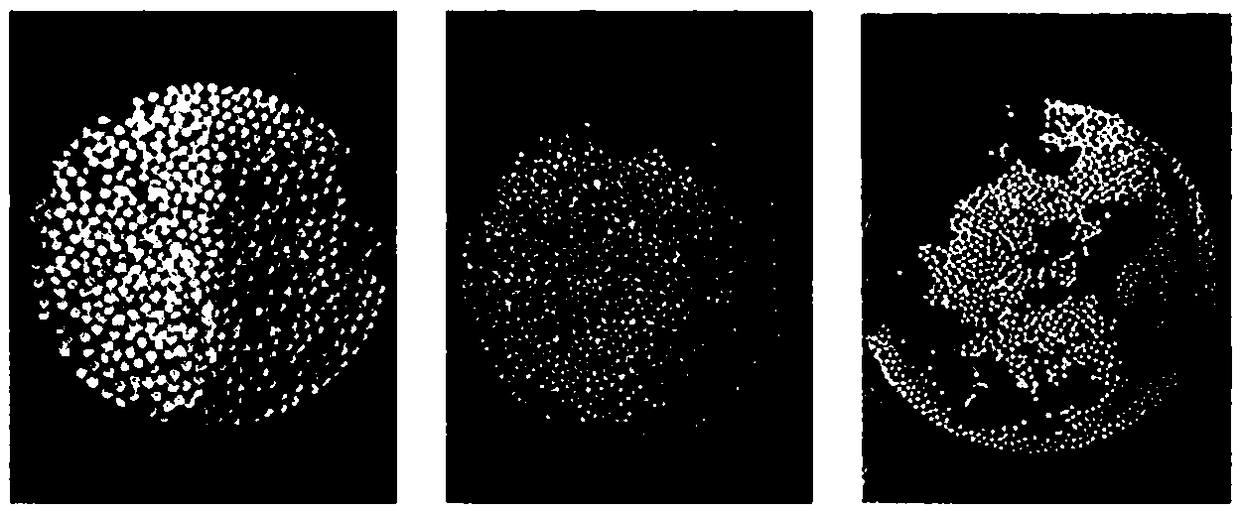

Preparation method of composite cyclodextrin hydrogel

ActiveCN105622962AWide range of adsorptionImprove adsorption capacitySodium Hypophosphite MonohydrateGraft reaction

The invention discloses a preparation method of composite cyclodextrin hydrogel. The preparation method comprises the following steps that 1, sodium hypophosphite is used as a catalyst, and beta-cyclodextrin and citric acid are subjected to a grafting reaction; 2, a grafting product of the beta-cyclodextrin and the citric acid is grafted to nano-microcrystalline cellulose by using the sodium hypophosphite as the catalyst; 3, ppo segment and chain of triblock copolymer pluronic enters a cavity of the product in the step (2) through ultrasonic treatment; 4, alpha-cyclodextrin is added, and standing is performed for hydrogel forming. The prepared hydrogel has the unique structure and good biocompatibility, the gelation time is short, the gelation strength is higher than that of common gel, and hydrogel can be formed at room temperature; the application prospect is wide in the aspects of functional materials, biological medicine carrying and the like.

Owner:JIANGNAN UNIV

Heavy metal adsorbent and preparation method and application thereof

ActiveCN108620032AIncrease costLow costOther chemical processesWater contaminantsSorbentService condition

The invention discloses a heavy metal adsorbent and a preparation method and application thereof. The heavy metal adsorbent is prepared by modifying raw materials including attapulgite clay and microcrystalline cellulose, wherein the mass ratio of attapulgite clay to microcrystalline cellulose is (1-4) : 1, and attapulgite refers to aqueous magnesium-rich aluminosilicate mineral having the laminated chain structure. The heavy metal adsorbent is applied to preparation of adsorbent products for overcoming heavy metal pollution. Since attapulgite and microcrystalline cellulose are taken as the raw materials, cellulose is dissolved by an alkali / urea system, and attapulgite and calcium carbonate are added to prepare a porous attapulgite and cellulose composite adsorbent; the the modifying process needs mild condition without pollution, is easy to control and has high yield. Besides, the attapulgite and cellulose composite adsorbent is low in cost, environmental friendly, high in adsorptioncapacity, wide in service condition, and can be applied industrialized production.

Owner:YUNNAN SHENGQING ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method and application of polyvinylamine functional magnetic carbon-based nano adsorbing agent

InactiveCN109821511AAvoid partial agglomerationLarge specific surface areaOther chemical processesWater contaminantsPhenol adsorptionDesorption

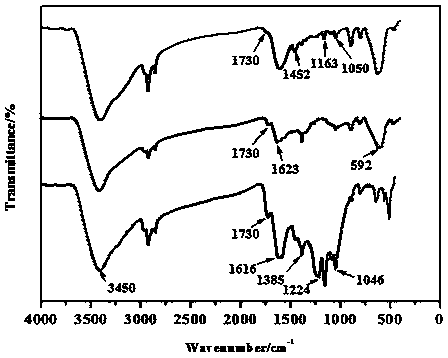

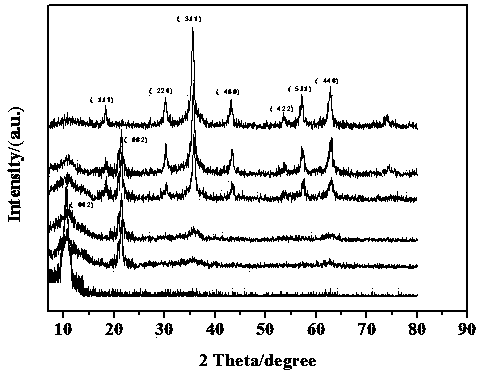

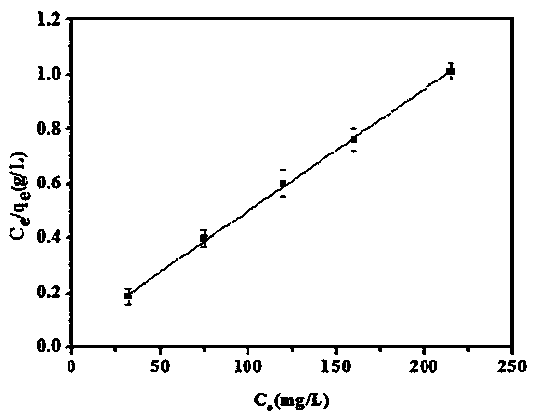

The invention discloses a preparation method and application of a polyvinylamine functional magnetic carbon-based nano adsorbing agent. The preparation method is specifically characterized in that a chemical coprecipitation method is used to deposit magnetic particles to the surface of graphene oxide-carbon nanotubes, and amidation is used to modify high-cation polyvinylamine (PVAm) to the magnetic (graphene oxide-carbon nanotubes) hybrid body. The prepared adsorbing agent has the advantages that the adsorbing agent has large specific surface area and rich adsorption sites, has a large numberof amino functional groups and can effectively combine with phenol through a hydrophobic effect, pi-pi keys, electrostatic attraction and hydrogen bonding so as to effectively remove phenol in wastewater, and the maximum phenol adsorption quantity, calculated through a Langmuir model, of the adsorbing agent is 224.21mg / g; the adsorbing agent can be reused through simple enrichment desorption, andindustrial wastewater treatment cost is lowered.

Owner:UNIV OF JINAN

Formaldehyde adsorption material

InactiveCN106582573AHigh removal rateImprove wear resistanceGas treatmentOther chemical processesPhosphateSodium nitrate

The invention relates to the field of adsorption materials, in particular to a formaldehyde adsorption material. The formaldehyde adsorption material is prepared from, by weight, 100 parts of activated carbon, 10-30 parts of calcium carbonate, 20-60 parts of ethanol, 5-25 parts of medical stones, 20-40 parts of sepiolite, 15-35 parts of glycine, 1-20 parts of perlite, 1-5 parts of sodium nitrate, 6-10 parts of ammonium bicarbonate, 2-6 parts of titanium dioxide, 3-7 parts of methylcellulose, 13-17 parts of ferric phosphate, 5-25 parts of magnesium chloride and 12-18 parts of talcum powder. According to the formaldehyde adsorption material, the formaldehyde removal rate reaches up to 98% to 99.8%; the formaldehyde adsorption material is high in wear resistance, long in service life, capable of being reused, green, environmentally friendly, high in adsorption and wide in adsorption range; after the formaldehyde adsorption material is taken to be put into a closed space with the formaldehyde content ranging from 400 micrograms per cubic meter to 500 micrograms per cubic meter for 40 h to 48 h, the formaldehyde concentration ranges from 1 microgram per cubic meter to 8 micrograms per cubic meter; the formaldehyde adsorption material is simple in preparation method, low in cost, high in operability and capable of being widely produced and continuously replacing existing materials.

Owner:SUZHOU LVDIAN INFORMATION TECH CO LTD

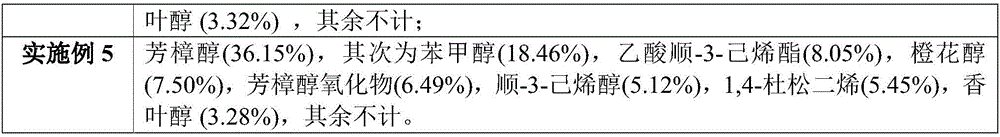

Preparation method of jasmine flower essential oil crystal

The invention discloses a preparation method of a jasmine flower essential oil crystal. The preparation method comprises the following steps: (1) pretreatment: treating fresh picked jasmine flowers by using a bioenzyme solution; (2) adsorption treatment: adsorbing the pretreated jasmine flowers by using resin at normal temperature; (3) elution treatment: eluting with an eluent after resin adsorption saturation, drying, removing water and performing reduced-pressure distillation to obtain jasmine flower essential oil, wherein the eluent is at least one of petroleum ether, normal hexane, ethanol and ethyl acetate; and (4) crystallization treatment: adding an organic solvent into the jasmine flower essential oil, standing and crystallizing at 3 to 5 DEG C and filtering to obtain the jasmine flower essential oil crystal, wherein the organic solvent is at least one of petroleum ether, normal hexane, ethyl acetate and ethanol. The essential oil crystal provided by the crystallization method is pure in color and convenient to transfer and transport; and recrystallization is conducted at low temperature, so that the yield is increased, impurities are reduced, the effectively components of the essential oil are improved, the quality is high, and the essential oil is not liable to deterioration.

Owner:YUNNAN LORRAINE AROMATIC PROD CO LTD

Volatile organic compound adsorbent for industrial waste gas treatment

InactiveCN107398259AFast absorptionEmission reductionGas treatmentOther chemical processesSorbentPotassium carbonate

The invention discloses a volatile organic compound adsorbent for industrial waste gas treatment. The volatile organic compound adsorbent contains the following components: sol titanium dioxide, a phenolic resin, potassium carbonate, ethanol amine, diethanol amine, triethanolamine, primary amino monomers, vanadium pentoxide, sodium hydrogen sulfite, activated carbon, an activated carbon modifier and a halogenated benzyl monomer. Due to adding of carbon dioxide adsorbent to a photocatalyst, carbon dioxide decomposed from volatile organic compounds after photocatalytic oxidation can be rapidly absorbed, and thus the emission amount of carbon dioxide is reduced.

Owner:德阳护球环保科技有限公司

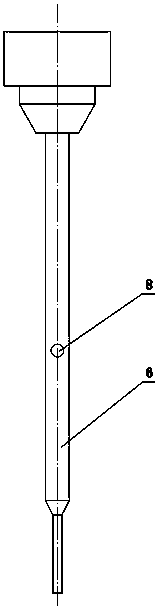

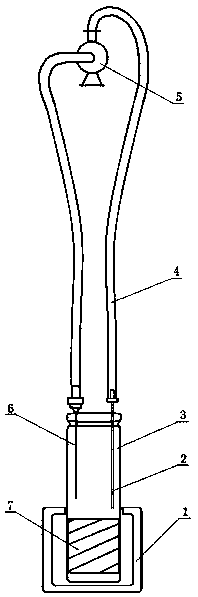

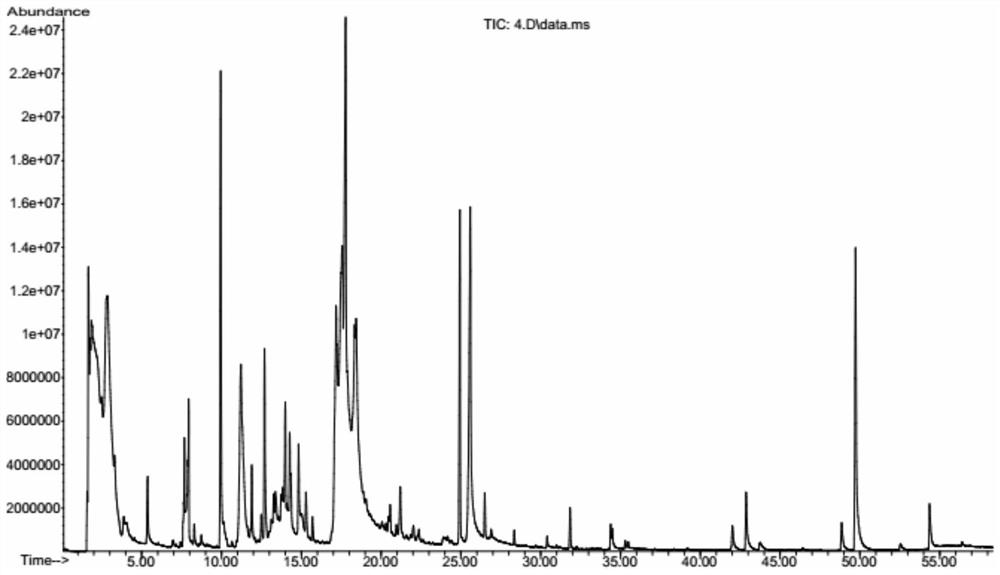

Method for analyzing electronic cigarette tar component through combination of dynamic pin capture and gas chromatography and mass spectrometry

InactiveCN107703246AGood repeatabilityHigh enrichment efficiencyComponent separationInjection portDesorption

The invention discloses a method for analyzing an electronic cigarette tar component through combination of dynamic pin capture and gas chromatography and mass spectrometry. The method comprises inserting a dynamic capture pin connected with a circular purging apparatus into a head-space bottle, starting the circular purging apparatus, performing heating at 50 DEG C for 30 min, inserting the dynamic capture pin into a GC-MS injection port to perform desorption, and then performing GC-MS qualitative analysis. According to the method, a non-equilibrium continuous adsorption process is adopted, the sample enrichment efficiency can be greatly improved, and volatile components in a sample are extracted from the sample. The dynamic capture pin is used for capture, adsorption and sampling, and after desorption, the sample enters a detector for analysis. The method is suitable for sampling and analyzing a trace amount of an organic target component. The method allows the trace-amount componentto be enriched, and is high in sensitivity, wide in adsorption range, good in reproducibility and easy to operate. After adsorption, the trace-amount component can be sealed and stored. A by-productproduced in an adsorption process is less. The method is accurate in qualitative and quantitative analysis, simple to operate, and relatively long in life.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

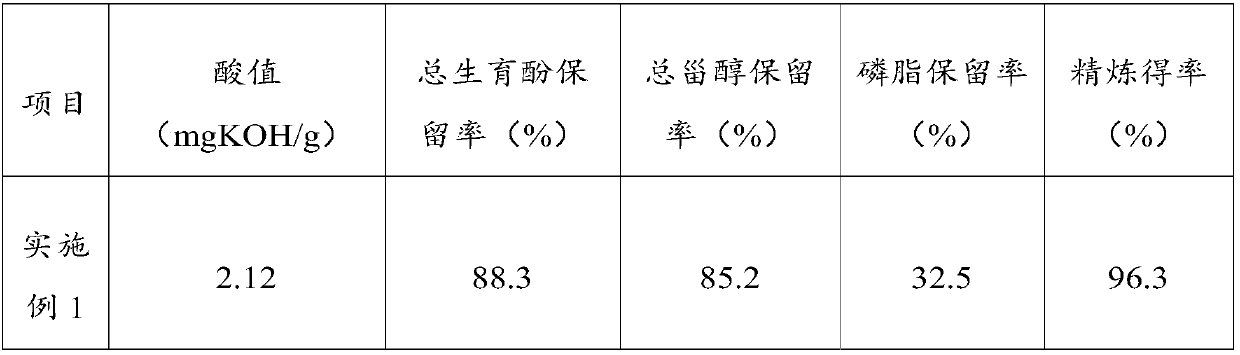

Oil making method, edible oil and application thereof

InactiveCN107619713AAvoid destructionFull of nutritionFatty-oils/fats refiningFatty-oils/fats productionOil and greaseSorbent

The invention discloses an oil making method, edible oil and application thereof and belongs to the technical field of food processing. The oil making method comprises the following steps: soaking anoil squeezing raw material with water for 1-2 hours, and frying for 80-100 minutes at 140-170 DEG C; grinding the fried oil squeezing raw material, steaming, caking, and squeezing so as to obtain crude oil; settling the crude oil so as to obtain an oil liquid; adsorbing the oil liquid with an adsorbent at 30-50 DEG C while the liquor ratio is (0.5-1):50, wherein the adsorbent comprises silica gel,sodium calcium based montmorillonite and alkali microcrystalline cellulose in a mass ratio of 1:(1-2):(1-2). By adopting the oil making method, excessive components in oil can be effectively removed,the refining loss can be reduced, nutrient components and good flavor of the oil can be maintained, the oil making method is applicable to popularization, and industrialization can be achieved. The edible oil made by using the oil making method is high in security, complete in nutrient component and good in flavor. The edible oil is applied to food processing, and foods made with the edible oil are high in security and good in flavor.

Owner:湖北香满宇生物科技有限公司

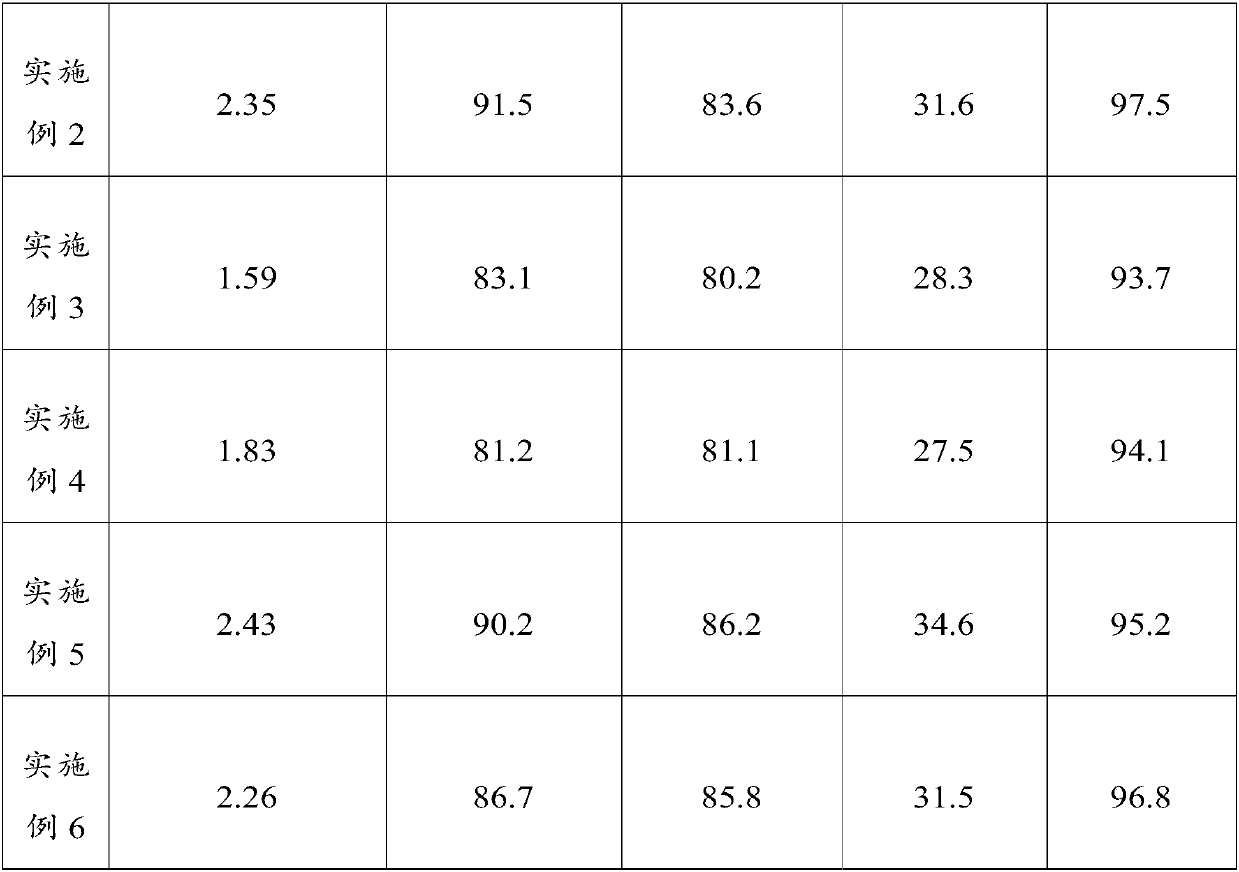

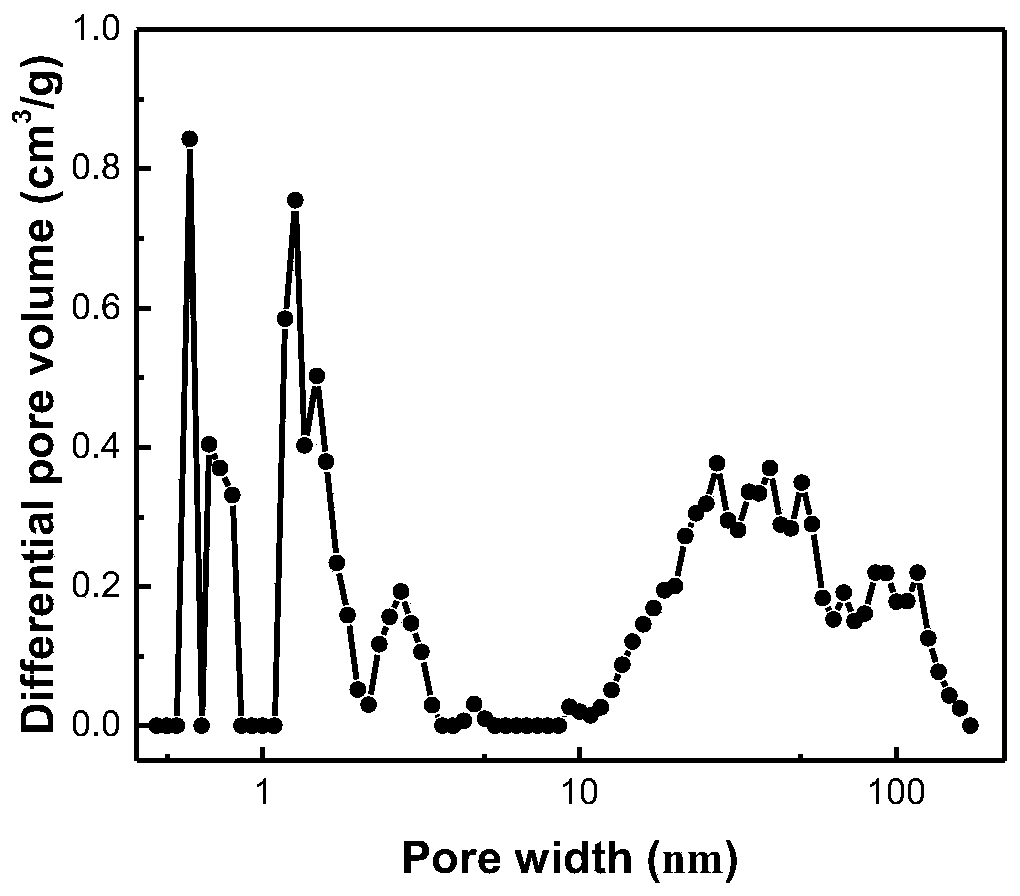

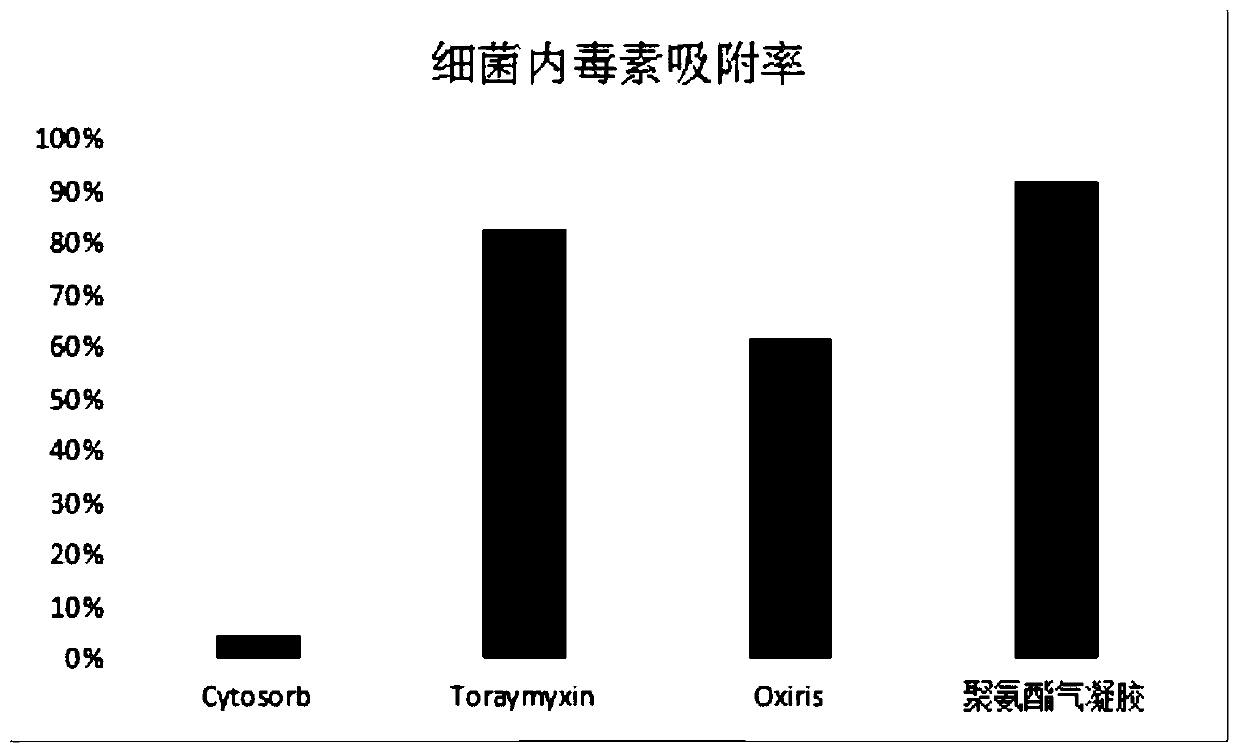

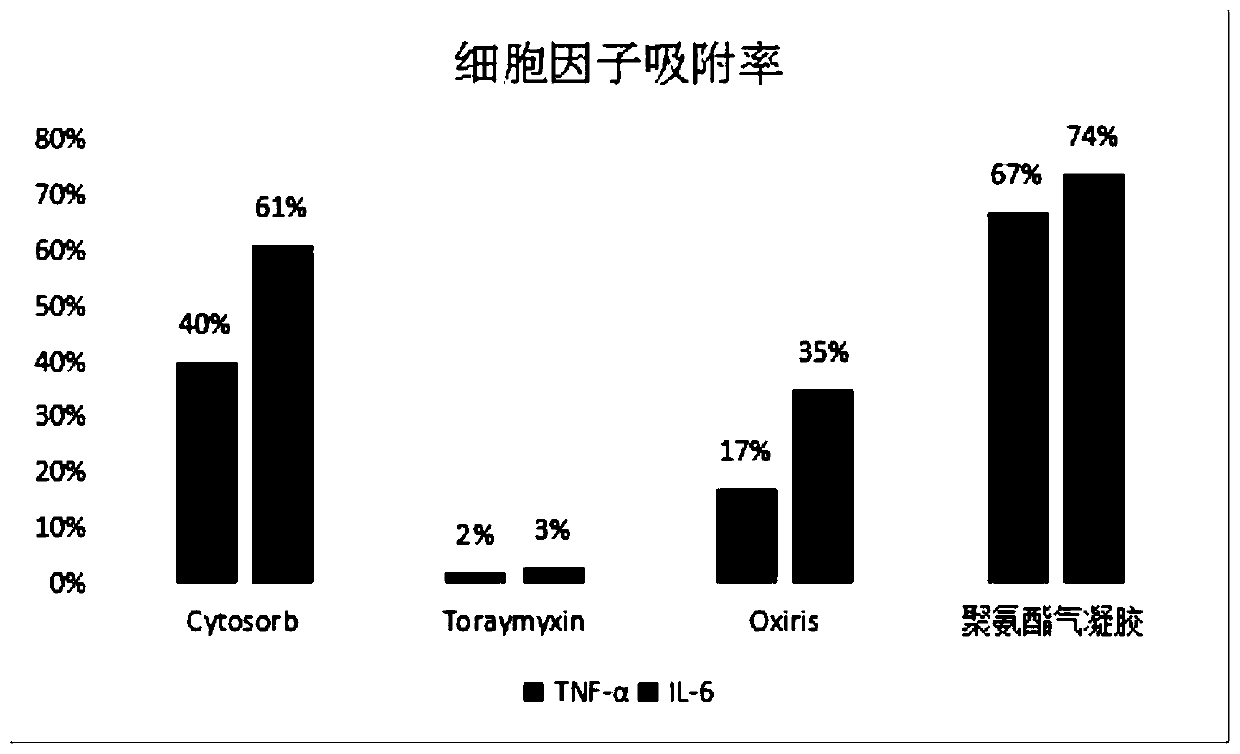

Blood purification adsorbent and preparation method thereof and hemoperfutor

PendingCN111097390AImprove mechanical propertiesControllable distributionOther chemical processesAlkali metal oxides/hydroxidesInterleukin 6Polythylene glycol

The invention discloses a blood purification adsorbent. The blood purification adsorbent is porous polyurethane aerogel. The invention also discloses a preparation method of the blood purification adsorbent, and the blood purification adsorbent is prepared by taking MDI trimer and polyethylene glycol / polypropylene glycol as raw materials through adoption of a sol-gel method and supercritical carbon dioxide drying. The invention also discloses a hemoperfutor. The porous polyurethane aerogel is used as an adsorbent in the hemoperfutor. The blood purification adsorbent provided by the invention adopts a porous polyurethane aerogel material, and has the advantages of excellent mechanical properties, controllable pore size and distribution, the high specific surface area, the large adsorption capacity and the like; and the adsorbent is wide in adsorption range, can adsorb bacterial endotoxin, tumor necrosis factors, interleukin 6 and other cytokines in blood plasma at the same time, and canbe used for treating endotoxemia, sepsis, cytokine storm and other diseases caused by severe infection.

Owner:苏州仝康医疗科技有限公司

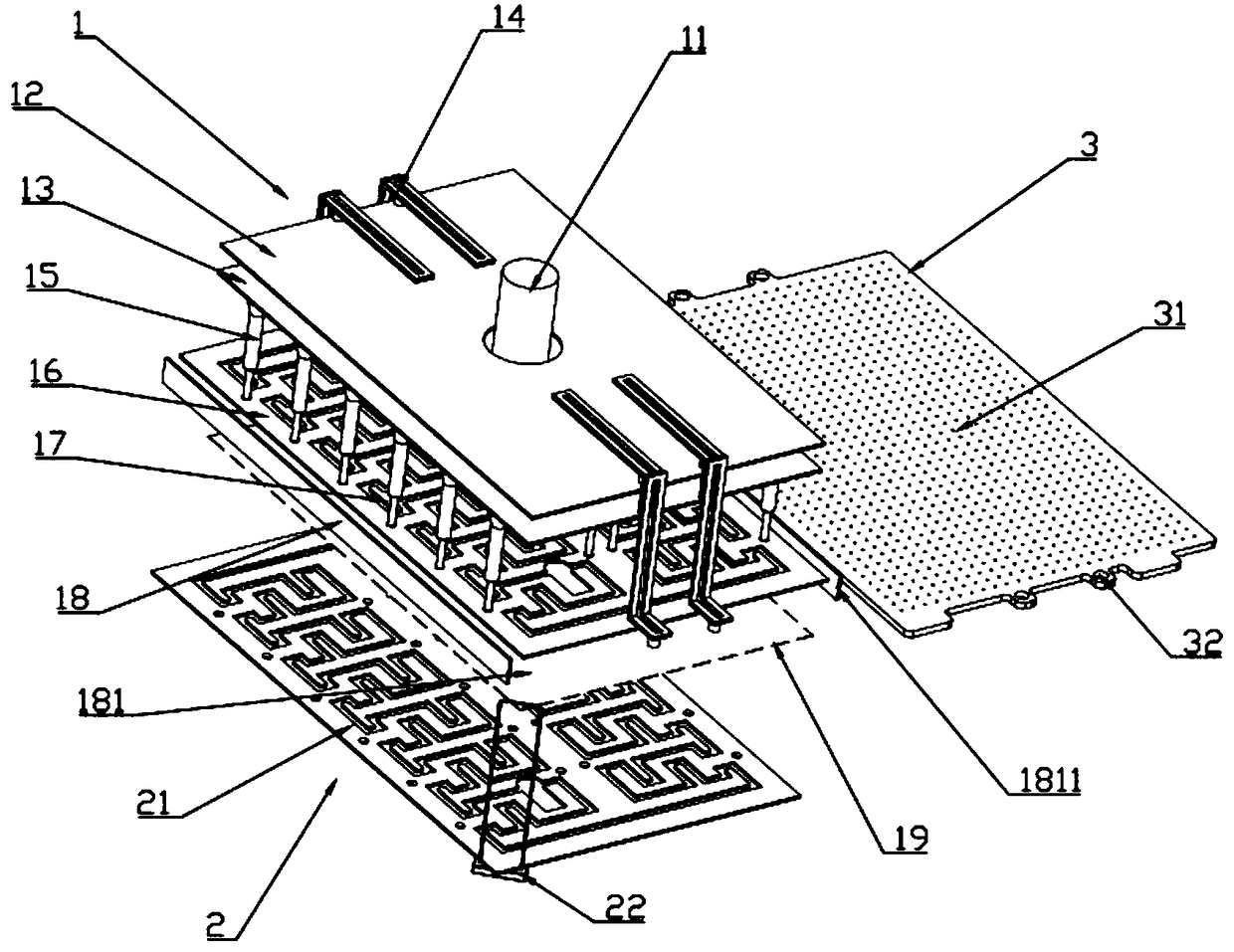

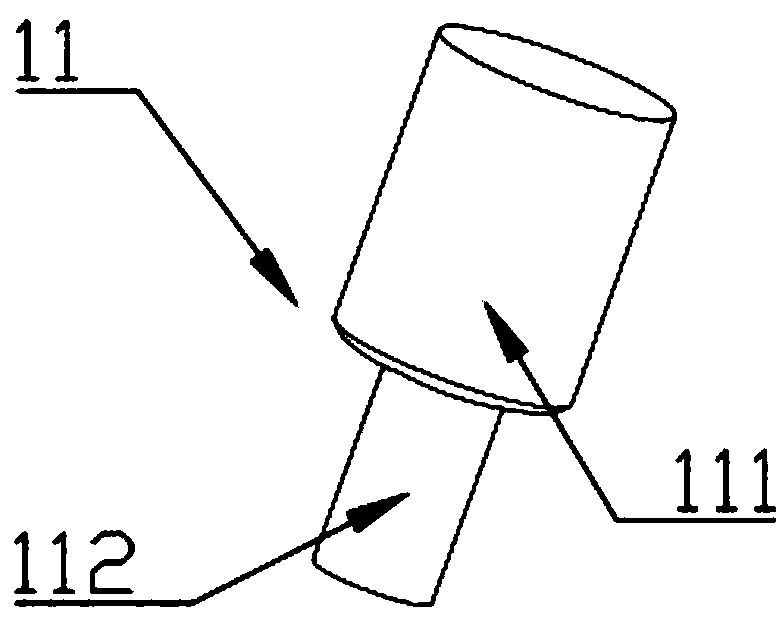

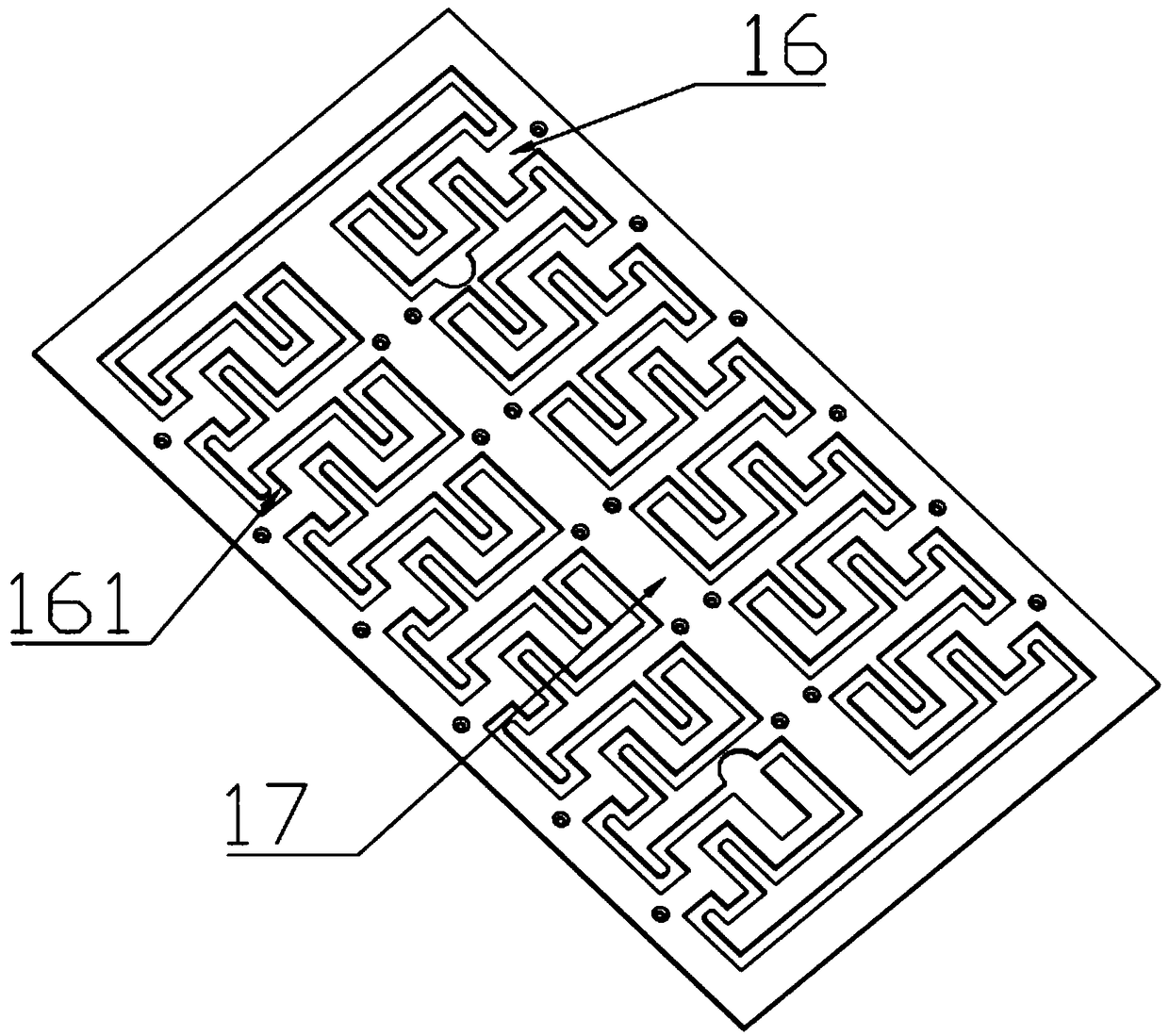

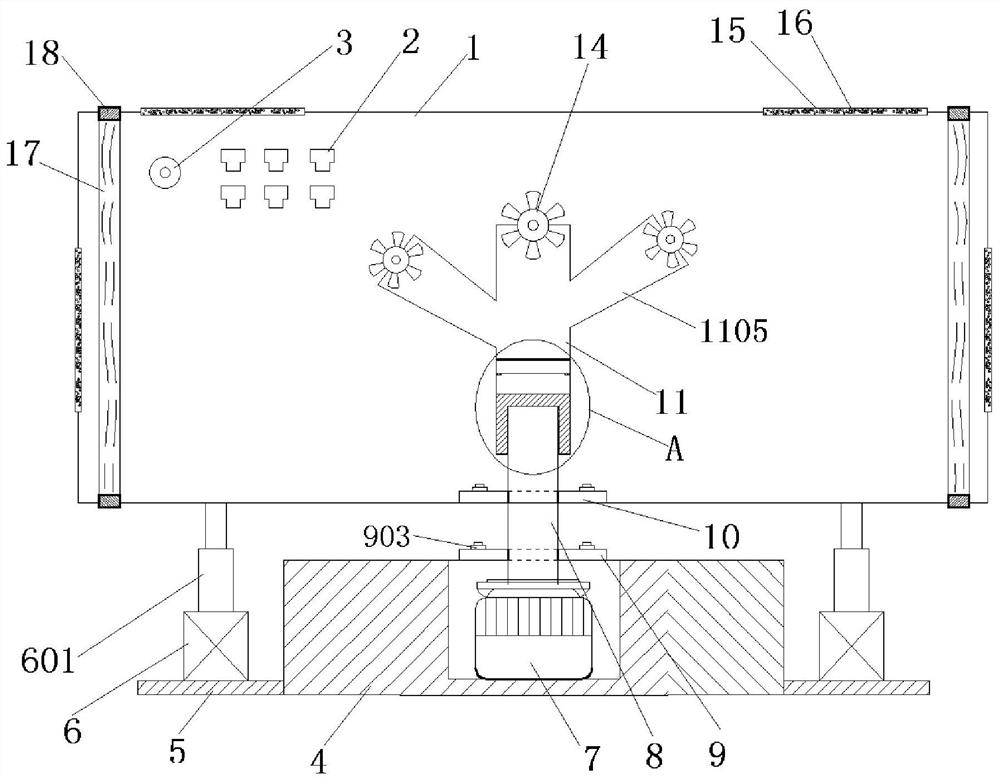

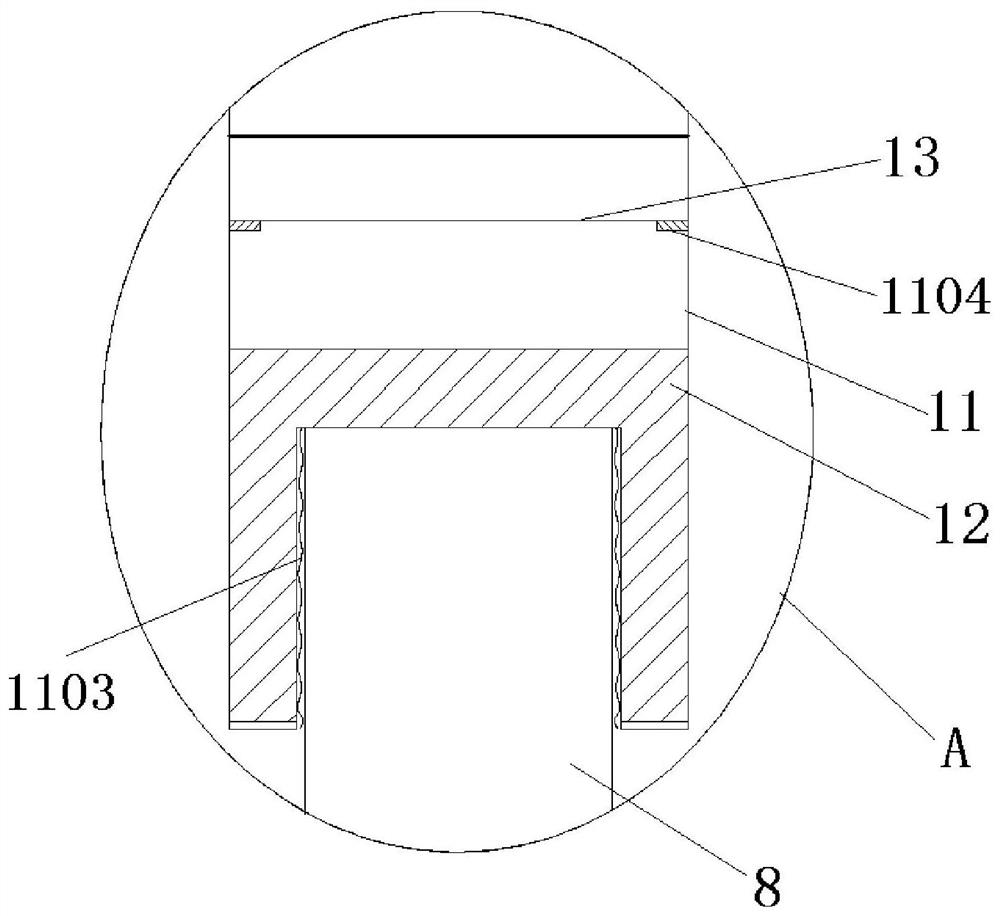

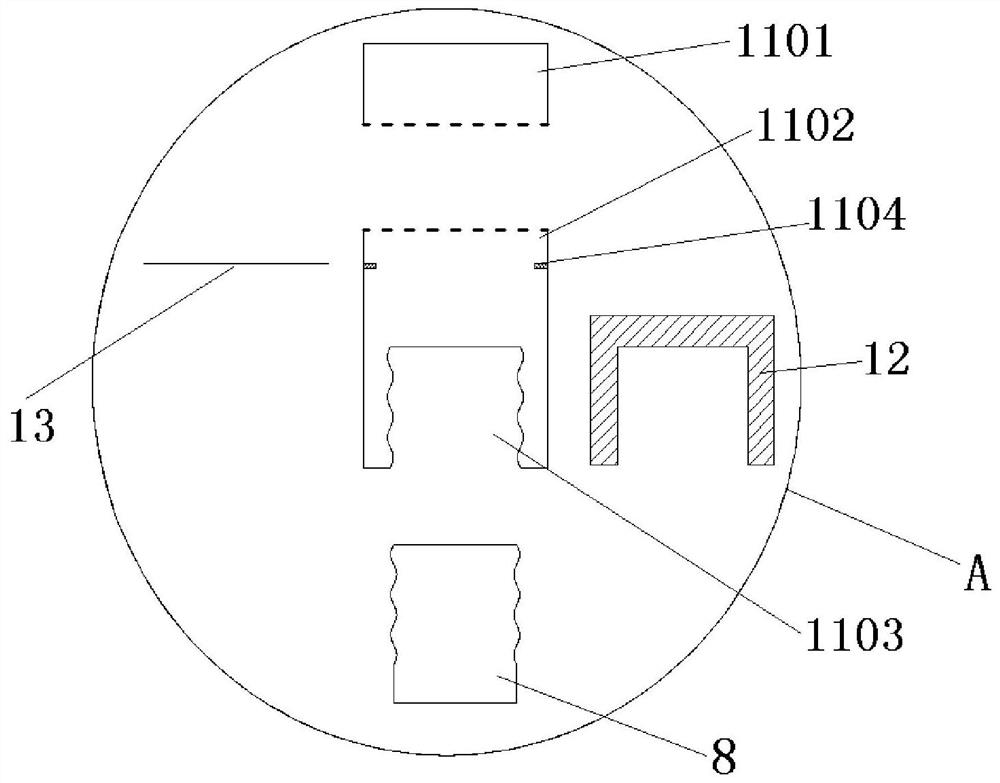

Intelligent FPC board adsorbing and releasing device

PendingCN108275458ASimple structureMovement coordinationConveyorsControl devices for conveyorsEngineeringManipulator

The invention relates to an intelligent FPC board adsorbing and releasing device comprising a material storage mechanism, a receiving mechanism and a moving mechanism moving a FPC board to the receiving mechanism from the material storage mechanism. A mechanical arm comprises a fixed shell and a moving column. The moving column is movably arranged on the fixed shell. A fixed plate is fixed to thefixed shell. A holding plate is fixed to one end of the moving column. The holding plate is provided with buffering columns. An adsorption plate and a release plate are fixed to the lower ends of thebuffering columns. Multiple limiting mechanisms are located at the two ends of the adsorption plate. The lower surface of the adsorption plate is provided with adsorption pieces which are adhesive materials. The intelligent FPC board adsorbing and releasing device is simple in structure, harmonious in overall operation action, small in power, convenient to assemble and maintain, free of noise andcapable of conveying FPC boards of different sizes.

Owner:深圳市升宇智能科技有限公司

Micropore large-surface material used for adsorbing volatile organic pollutants

InactiveCN106750499AStable structureSimple methodOther chemical processesAlkali metal oxides/hydroxidesSolventAdsorption effect

The invention discloses a micropore large-surface material used for adsorbing volatile organic pollutants. The micropore large-surface material is prepared from the following raw materials in a formula: 15 to 30 parts of polyhydroxyl polyurethane, 20 to 35 parts of polyacrylamide, 1 to 3 parts of a catalyst, 3 to 7 parts of an initiator, 15 to 30 parts of a foaming agent, 1 to 3 parts of a curing agent, 2 to 4 parts of a preservative, 3 to 5 parts of a penetrating agent, 20 to 30 parts of a solvent and 11 to 15 parts of nano active carbon; selection and preparation methods of the material are provided according to the formula. The method is simple and convenient, technological conditions are moderate, and the production cost is low; the structure of the material is stable and is not damaged by high temperature; the micropore large-surface material has good temperature resisting performance and good corrosion resistance; the adsorption property of resin and active carbon is sufficiently utilized, so that the adsorption effect is greatly improved and the adsorption range is wide.

Owner:俞潮军

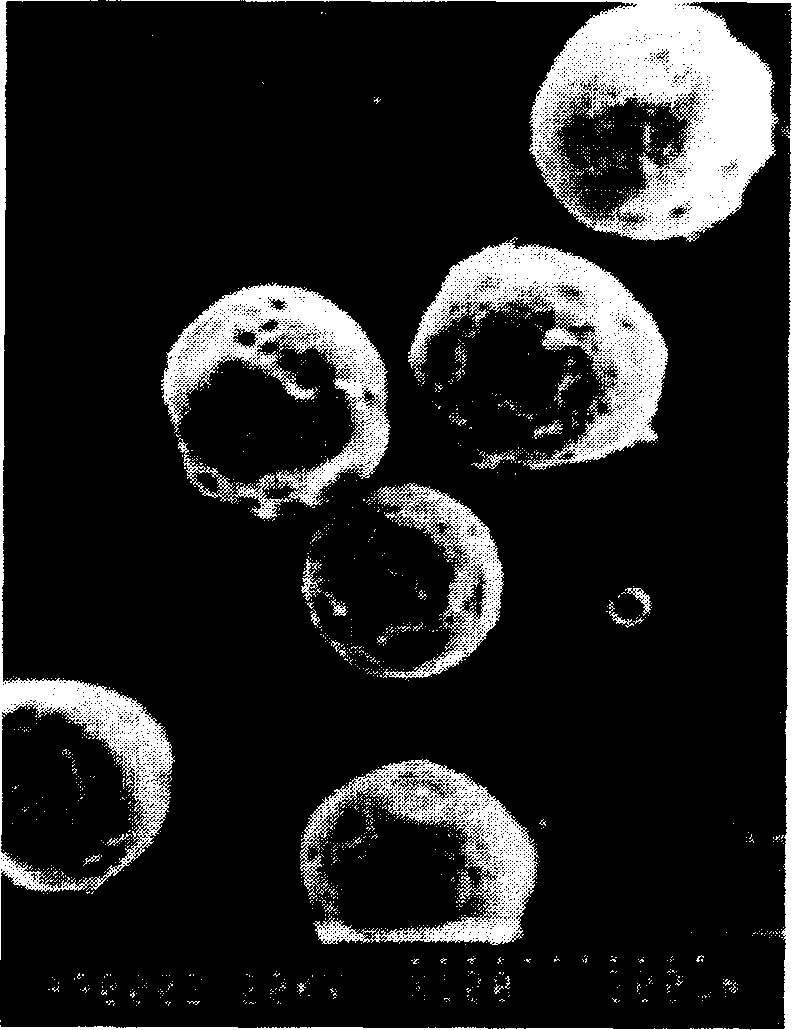

Macromolecular chromoprotein adsorbing medium and its application

InactiveCN1739850AImprove adsorption capacityWide range of adsorptionOther chemical processesPolymer scienceMicrosphere

The present invention relates to the preparation of adsorbent, and is especially porous chitosan-amino acid copolymer ball as the macromolecular chromoprotein adsorbing medium. The present invention has the advantages including opening one way of introducing ¿CCOOH into chitosan microballoon, and synthesizing one kind of porous copolymer ball with high adsorption capacity on macromolecular chromoprotein.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Adjustable dustproof and moistureproof industrial Ethernet switch

ActiveCN112752168AEasy to cleanEasy to replaceClimate change adaptationSelection arrangementsIndustrial EthernetRotational axis

The utility model discloses an adjustable dustproof and moistureproof industrial Ethernet switch, and belongs to the technical field of communication equipment industrial switches. A counterweight base is arranged below the switch shell, a rotating motor is fixedly arranged in an open slot of the counterweight base, and the rotating motor is in upward output connection with a rotating shaft rod, penetrates through the switch shell, extends into the switch shell, is detachably connected with a blast adsorption assembly and can control the blast adsorption assembly to rotate in a linkage manner; hydraulic power cylinder bodies are arranged on the left and right sides of the counterweight base, and the upper part of an output hydraulic telescopic rod is fixedly connected with a switch shell, so that the switch shell can be controlled to lift up and down in a linkage manner; the blast adsorption assembly comprises a blast electric fan and a hollow pipe body; the top wall surface and / or the side wall surface of the switch shell are / is connected with a silica gel water absorption assembly in a sealed and embedded manner; the left and right ends of the switch housing are hermetically provided with cooling heat absorption assemblies penetrating the upper and lower wall surfaces. Dehumidification, dust removal, heat absorption and heat dissipation can be comprehensively and efficiently carried out in the switch shell, and the application effect is good.

Owner:INFORMATION & COMM COMPANY OF STATE GRID HEILONGJIANG ELECTRIC POWER COMPANY +2

Platinum-absorbing modified carbon fiber containing organic chelating group as well as preparation method and application of platinum-absorbing modified carbon fiber

ActiveCN114505053AIncrease the saturated adsorption capacityAvoid cloggingOther chemical processesProcess efficiency improvementFiberCarbon fibers

The invention discloses a platinum-absorbing modified carbon fiber containing an organic chelating group and a preparation method and application of the platinum-absorbing modified carbon fiber, the platinum-absorbing modified carbon fiber comprises a carbon fiber and the organic chelating group bonded to the carbon fiber, and the organic chelating group is a platinum-absorbing organic chelating group. The platinum-absorbing organic chelating group is mainly obtained by condensation reaction of an active group and an amino-containing organic matter, and the active group at least comprises carboxyl. The preparation method comprises the following steps: carrying out oxidation reaction on the carbon fiber and hydrogen peroxide, and carrying out organic condensation reaction on the oxidized carbon fiber and an amino-containing organic matter in an organic solvent. The platinum adsorption modified carbon fiber can be used for adsorbing platinum ions in an acidic aqueous solution containing platinum ions, can efficiently adsorb platinum ions with high, medium and low concentrations in a complex acidic environment, and is high in adsorption selectivity, high in saturation adsorption capacity and wide in pH application range.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

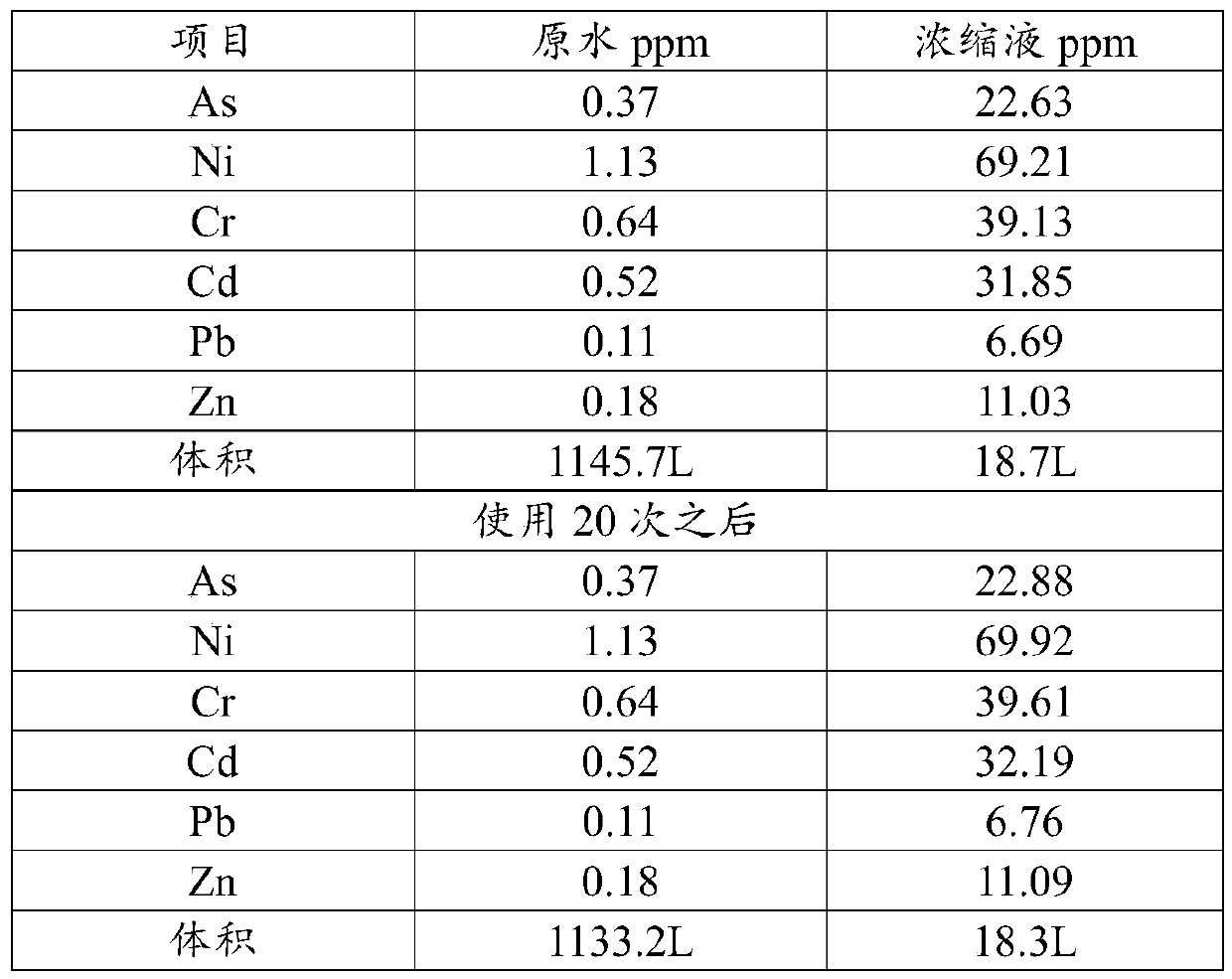

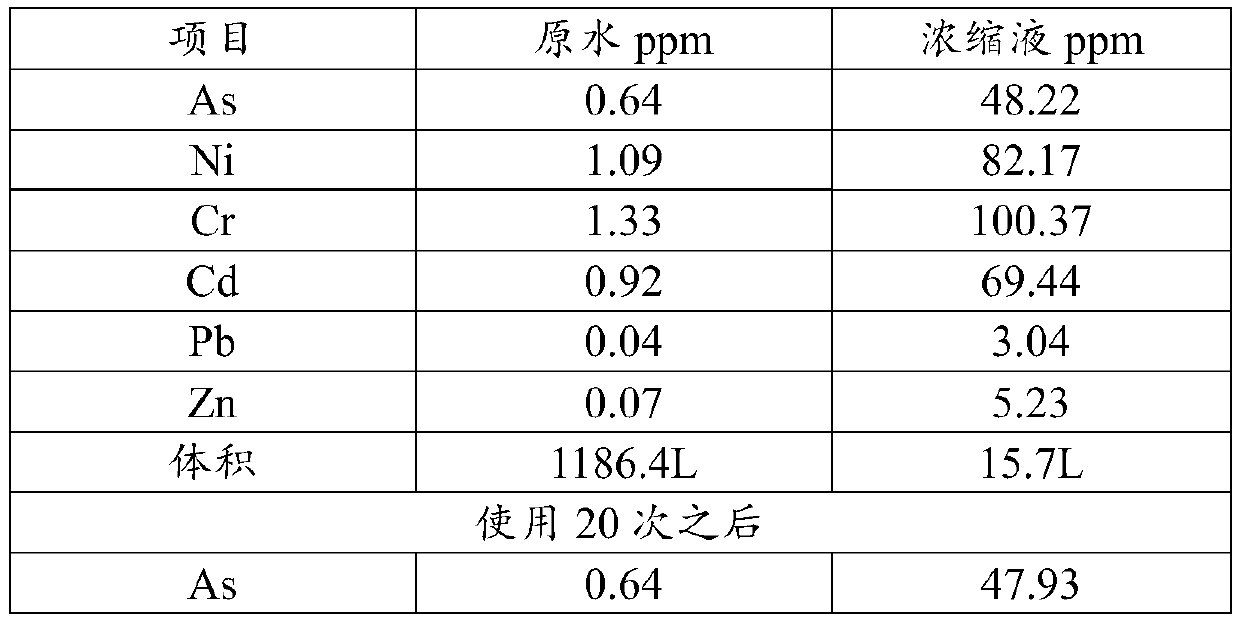

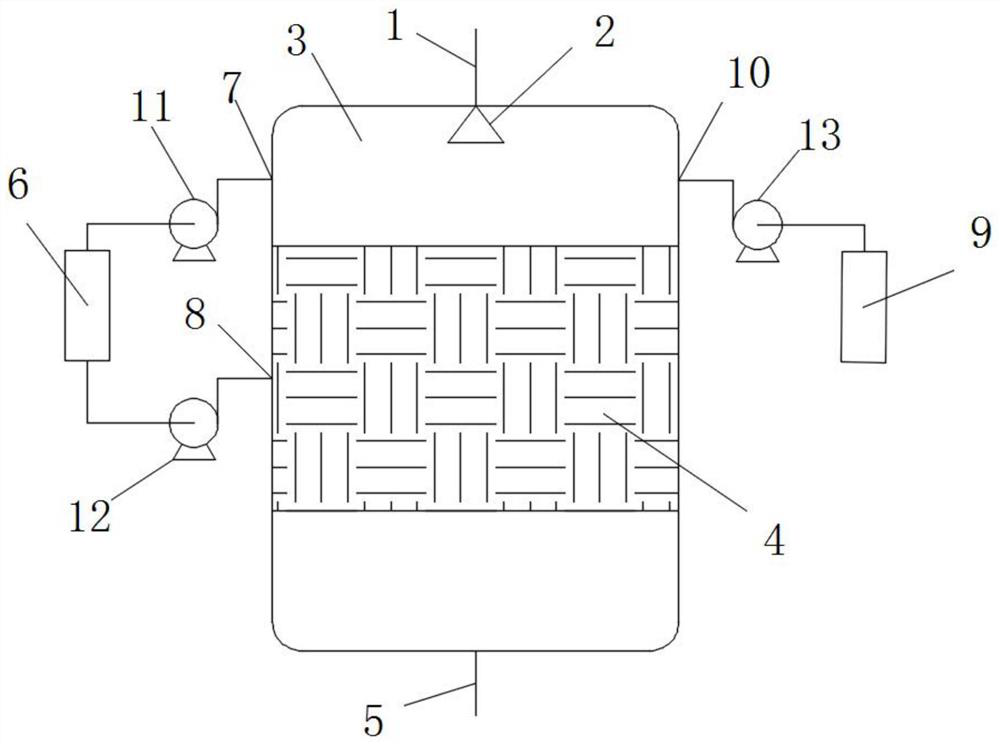

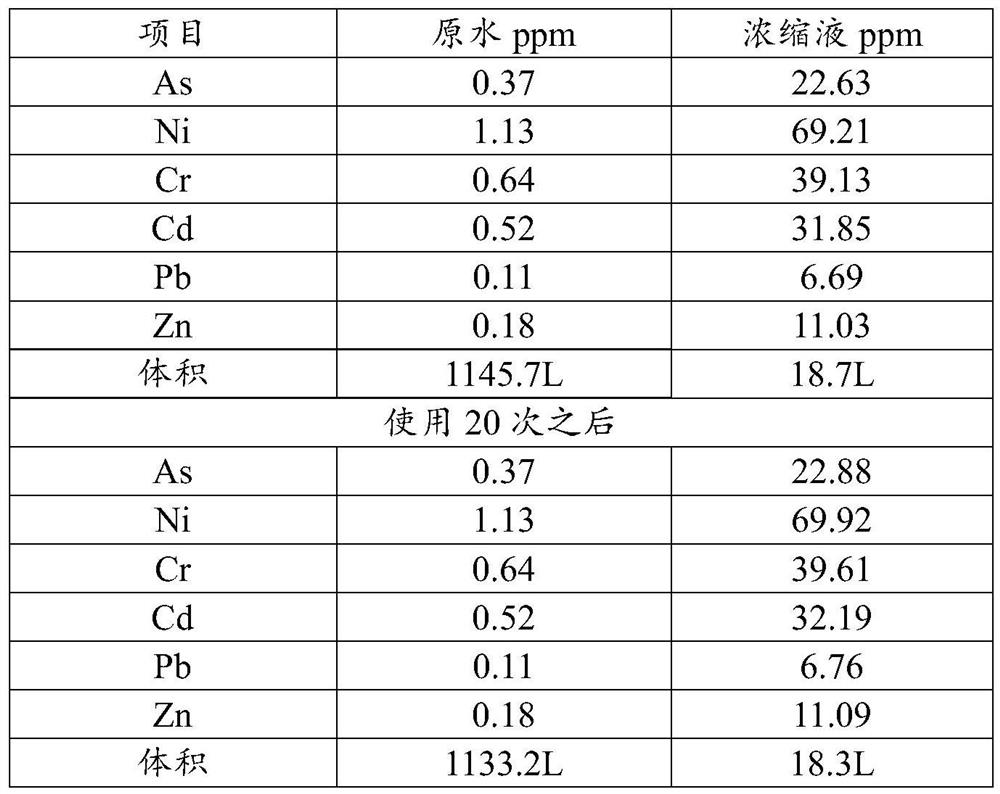

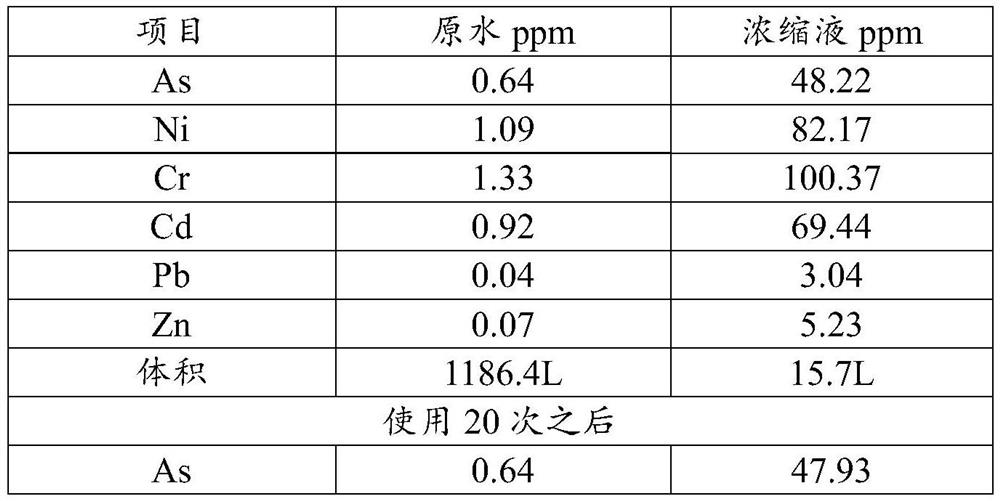

Process for enriching heavy metals in desulfurization wastewater based on high-stability adsorbent

ActiveCN110935422AStable chemical propertiesAffect the reuse effectOther chemical processesWater contaminantsAir atmosphereSorbent

The invention discloses a process for enriching heavy metals in desulfurization wastewater based on a high-stability adsorbent. A high-stability ceramic adsorbent is adopted to prepare a leaching andeluting process for heavy metal separation; the preparation method of the high-stability ceramic adsorbent comprises the following steps: uniformly mixing and compressing aluminum oxide, magnesium carbonate, titanium dioxide, iron oxide and a carbon material; calcining in an air atmosphere; washing ta calcined material with diluted hydrochloric acid; soaking in a sodium hydroxide solution; addingsodium carbonate and sodium citrate into the soaked material for hydrothermal reaction; and reacting to obtain the high-stability ceramic adsorbent. According to the process, heavy metal ions in the desulfurization wastewater are separated and then enriched; because the dissolved heavy metal ions are more widely used than the combined heavy metal ions, the process provided by the invention provides a reasonable recycling way for the separated heavy metal ions, thereby not only meeting the current environmental protection requirement, but also meeting the green process route of current resourcerecycling.

Owner:HUANENG SHANDONG POWER GENERATION CO LTD +1

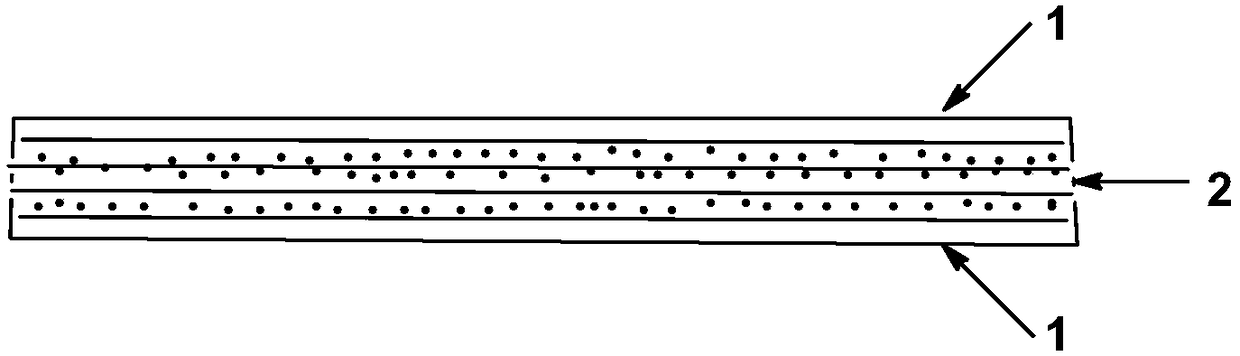

Anti-poison mask with metal organic framework adsorption material

InactiveCN108939335AHigh adsorption selectivityFast purificationBreathing filtersFire rescueIonSelf-assembly

The invention relates to an anti-poison mask with a metal organic framework adsorption material. The anti-poison mask with the metal organic framework adsorption material mainly solves the problems that in the prior art, the adsorption capacity is poor, and the adsorption range is narrow. By the adoption of the anti-poison mask with the metal organic framework adsorption material, a filtering material of the anti-poison mask comprises non-woven fabric and metal organic framework material layers, and the metal organic framework material layers are arranged between the two layers of non-woven fabric. The metal organic framework material layers are one or more non-woven fabric layers with a certain metal organic framework material loading capacity. The metal organic framework material is a three-dimensional framework crystal material which is formed by self-assembly of metal ions and organic ligands containing oxygen and nitrogen. By means of the technical scheme characterized in that -NH2 and -OH functional groups are added to an organic ligand framework to form the MOFs preferential adsorption material in a composite mode, the problems are preferably solved, and the anti-poison maskcan be used in anti-poison tools.

Owner:CHINA PETROLEUM & CHEM CORP +1

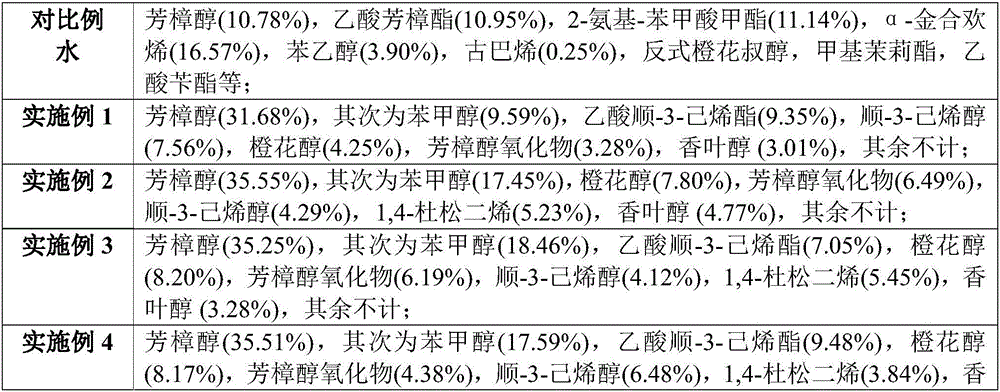

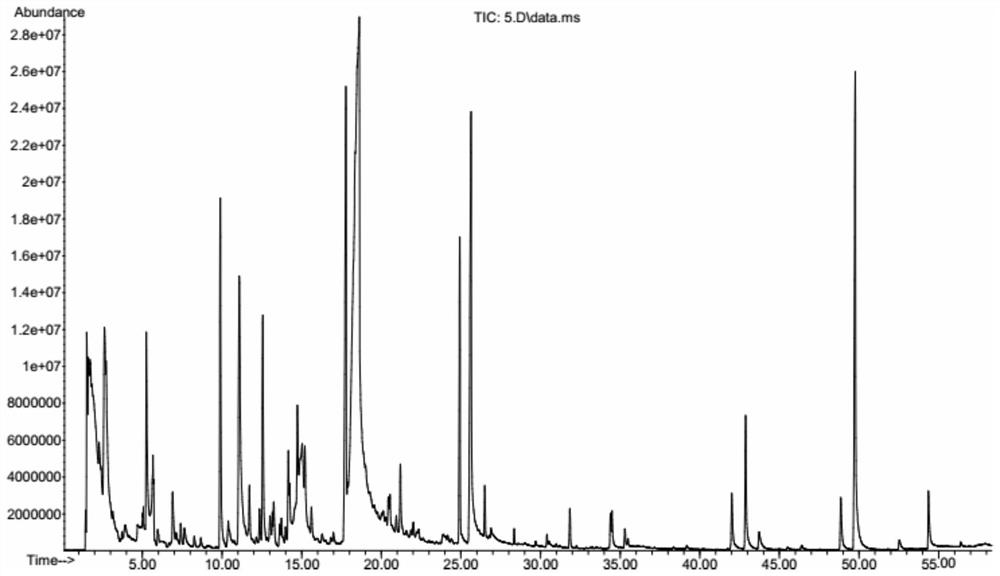

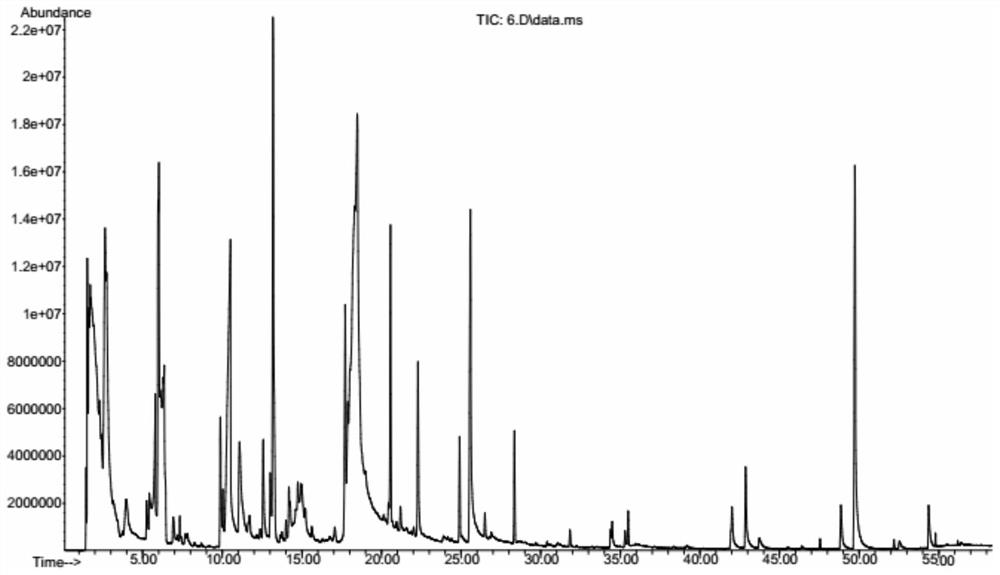

A needle trapping-gas chromatography-mass spectrometry method for the analysis of rose aroma components

ActiveCN110412183BHigh enrichment efficiencyHigh sensitivityComponent separationGas liquid chromatographicPhysical chemistry

The invention discloses a method for analyzing aroma components of roses using needle capture-gas chromatography-mass spectrometry. Needle trapping is an advanced solvent-free sample pretreatment technology. After placing fresh hot field roses in a headspace bottle, turn on the heating device for heating, insert the capture needle into the headspace bottle for adsorption, and then Pull out the trapping needle from the headspace bottle, and then insert it into the gas chromatography-mass spectrometry inlet for desorption, and perform qualitative analysis by gas chromatography-mass spectrometry after desorption. The invention adopts a continuous adsorption process, which can greatly improve the enrichment efficiency of the sample, overflow the volatile components in the sample from the sample, use the capture needle to capture the adsorption sample, and enter the detector for analysis after desorption, which is suitable for trace organic targets Component sampling analysis. It can enrich trace components, with high sensitivity, wide adsorption range, good reproducibility and easy operation. It can be sealed and stored after adsorption, with few by-products in the adsorption process, accurate qualitative and quantitative results, simple operation and long service life.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

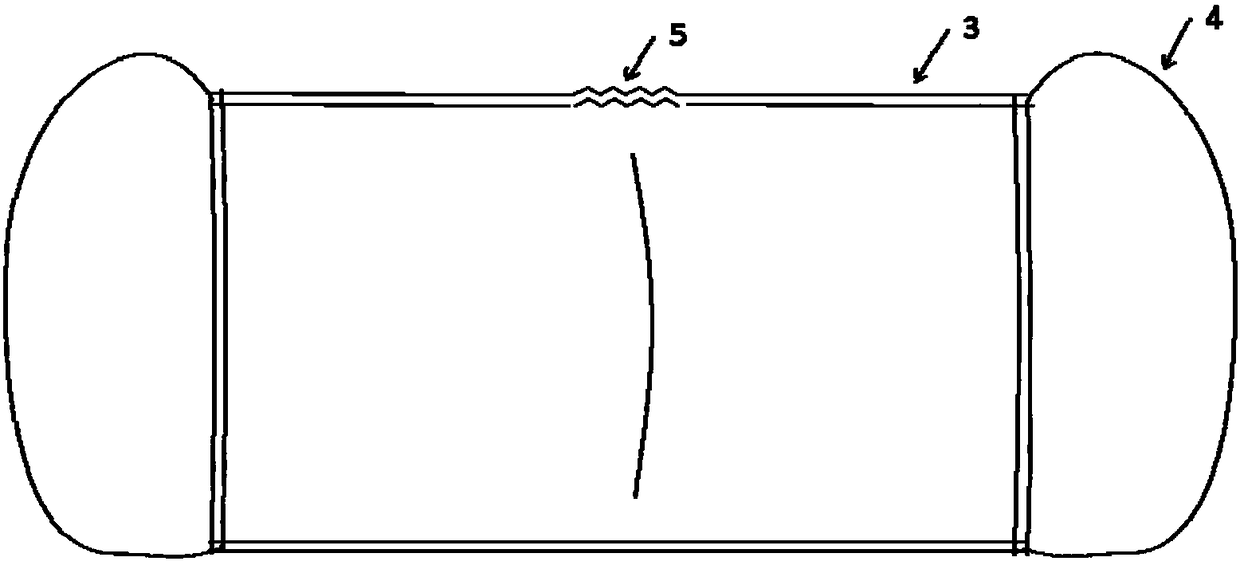

Preparation method of activated carbon fiber compounded molecular sieve adsorption concentration runner

PendingCN114247261ALarge adsorption capacityWide adaptability to adsorptionGas treatmentDispersed particle separationMolecular sieveActivated carbon

The invention discloses a preparation method of an activated carbon fiber compounded molecular sieve adsorption concentration runner. The method comprises the following steps: A, performing surface treatment on activated carbon fibers; b, carrying out pre-doping treatment on the treated activated carbon fiber and the treated fiber matrix, and carrying out corrugated forming; c, the corrugated composite paper and the flat fiber paper are subjected to stacking or winding forming through an adhesive, the stacking or winding mode is that one layer of composite paper and one layer of flat paper are stacked, and a honeycomb body module is obtained in the step; d, preparing an activated carbon fiber / molecular sieve composite adsorption material by a sol-gel method; and E, preparing to obtain the activated carbon fiber / molecular sieve composite adsorption concentration runner module. The activated carbon fiber / molecular sieve composite adsorption concentration rotating wheel module has the advantages of large adsorption capacity and strong adsorption capacity, in addition, the adsorption adaptability is wide, the adsorption capacity is large, the adsorption range is wide, and the problem that the adsorption concentration rotating wheel is poor in treatment effect on some waste gas components is solved.

Owner:ZHENJIANG EAST CHINA ELECTRIC POWER EQUIP FACTORY CO LTD

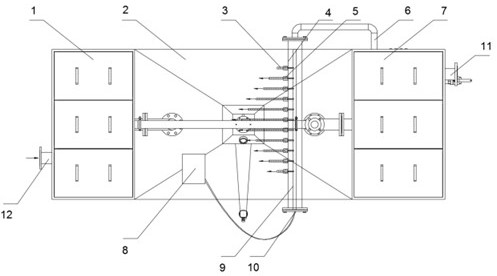

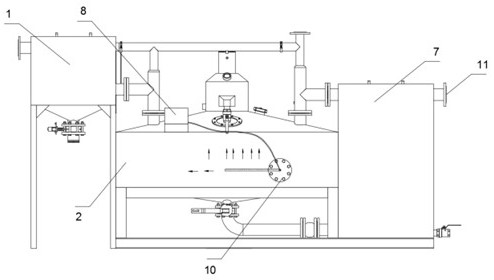

Convective bonded steam drum generator

ActiveCN109761310BProcessing speedWide range of adsorptionFatty/oily/floating substances removal devicesWaste water treatment from food industryAir pumpWater flow

The invention relates to a steam drum generating device, in particular to a convective bonded steam drum generating device, comprising an oil-water separation bin, the upper end of the oil-water separation bin is equipped with a generator fixing tube, and an air guide tube is installed inside the generator fixing tube, on the air guide tube It is connected with microbubble guide tubes distributed in an array, an air stone is installed at the connection between the microbubble guide tube and the airway tube, and the two ends of the fixed tube of the generating device are respectively equipped with a pressurized water flow inlet tube and an air pump. In the present invention, the air stone crushes the air to generate micro-bubbles, and mixes the bubbles with water according to the laminar flow effect of the water flow, so that the micro-bubbles collide with the slick oil to perform a wider range of adsorption, and the treatment speed of oily wastewater is fast. It further solves the problem that the air bubbles are concentrated and occupy a small area of the separation chamber, while the wastewater passing through the oil-water separation chamber occupies the entire separation chamber, so the bubbles have little effect on the entire accelerated separation and cannot fully affect the wastewater.

Owner:SHANGHAI RENMIN ENTERPRISE GRP WATER PUMP

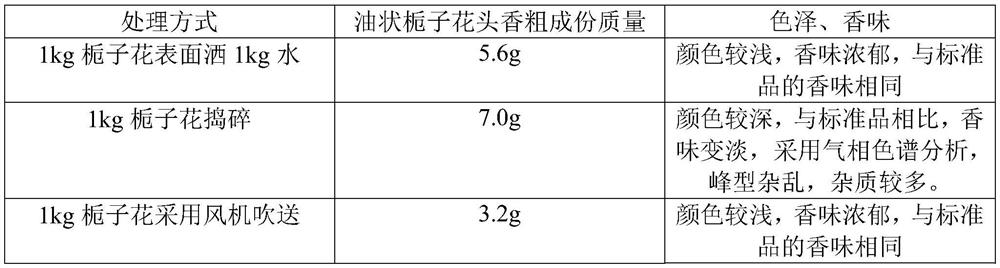

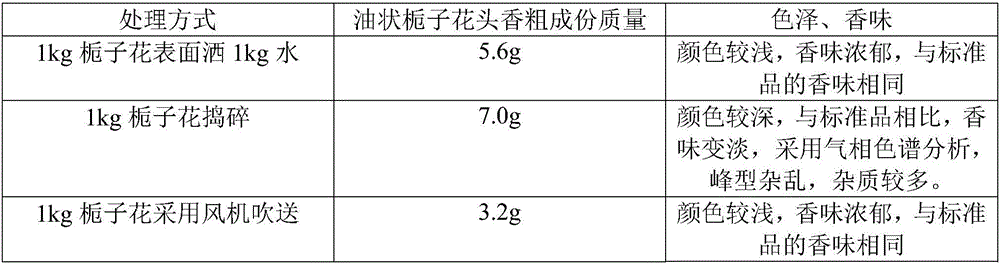

A kind of preparation method of natural high-purity gardenia essential oil crystal

ActiveCN106701320BEasy to handleWide range of adsorptionEssential-oils/perfumesOrganic solventPhysical chemistry

The invention discloses a preparation method of a natural high-purity cape jasmine flower essential oil crystal. The preparation method comprises the following steps: firstly, spraying water on fresh picked cape jasmine flowers and then putting into a fresh flower container for later use; secondly, adsorbing volatile components in the fresh cape jasmine flowers by adopting resin at room temperature; thirdly, putting resin adsorbed with cape jasmine flower head volatile in the first step into extraction equipment, and carrying out CO2 supercritical extraction to obtain an oily cape jasmine flower head volatile coarse component; fourthly, dissolving the oily cape jasmine flower head volatile coarse component by adopting the organic solvent, allowing standing still and crystallizing at low temperature, and filtering to obtain the cape jasmine flower essential oil crystal. The essential oil crystal provided by the invention is good in color and is convenient for taking out and transporting; the natural high-purity cape jasmine flower essential oil crystal is recrystallized under the low-temperature condition, so that the yield is increased, and impurities are reduced.

Owner:昆明悦馨生物科技有限公司

Preparation method of wear-resisting formaldehyde adsorption material

InactiveCN106582544AHigh removal rateImprove wear resistanceGas treatmentOther chemical processesSodium BentoniteOperability

The invention discloses a preparation method of a wear-resisting formaldehyde adsorption material. The preparation method comprises the following steps: (1) weighing hydroxypropyl ammonium hydrogen carbonate, ethylene glycol, leucine, bentonite, ground quartz, aluminum oxide, ammonium hydrogen carbonate, menthol and tetrahydrofuran and adding into a reaction kettle provided with a stirrer and a thermograph; raising the temperature to 40 DEG C-60 DEG C and stirring for 30min-50min; adding de-ionized water and continually stirring for 30min-50min; (2) weighing diatomite, rock wool, magnesium oxide and Portland cement and drying at a constant temperature of 90 DEG C-110 DEG C, and mixing a mixture with a product which is uniformly stirred in the step (2); and (3) putting the product mixed in the step (2) into a vacuum drying box and drying at 30 DEG C-40 DEG C for one night to obtain the wear-resisting formaldehyde absorption material. The formaldehyde removing rate of the product is up to 97.8%-99.5%; the product has the advantages of high wearing resistance, long service life, capability of being repeatedly utilized, and environmental protection, wide adsorption speed and wide adsorption range; after the product is put into a sealed space with the formaldehyde content of 400microg / m<3>-500microg / m<3> for 24h-48h, the concentration of formaldehyde is 2 microg / m<3>-8 microg / m<3>; and the preparation method is simple, the cost is low, the operability is high and the wear-resisting formaldehyde adsorption material can be widely produced and continuously replace an existing material.

Owner:SUZHOU LVDIAN INFORMATION TECH CO LTD

Waste gas purification adsorbing agent

InactiveCN109289776AImprove the adsorption effectWide range of adsorptionGas treatmentOther chemical processesActivated carbonChemistry

A waste gas purification adsorbing agent comprises, by weight, 20-30 parts of activated carbon fibers, 8-10 parts of diatom ooze, 6-12 parts of metal oxide, 3-5 parts of silicon sol and 8-10 parts ofcalcium carbonate granules. The waste gas purification adsorbing agent has the advantages that the adsorbing agent can simultaneously adsorb sulfur dioxide, nitride and organic gas in waste gas and wide in adsorption range and more convenient to use, separate treatment of different components in the waste gas is avoided, the treatment efficiency of the waste gas is improved, and the treatment costof the waste gas is reduced.

Owner:ANHUI WANSHANHONG ENVIRONMENTAL PROTECTION TECH CO LTD

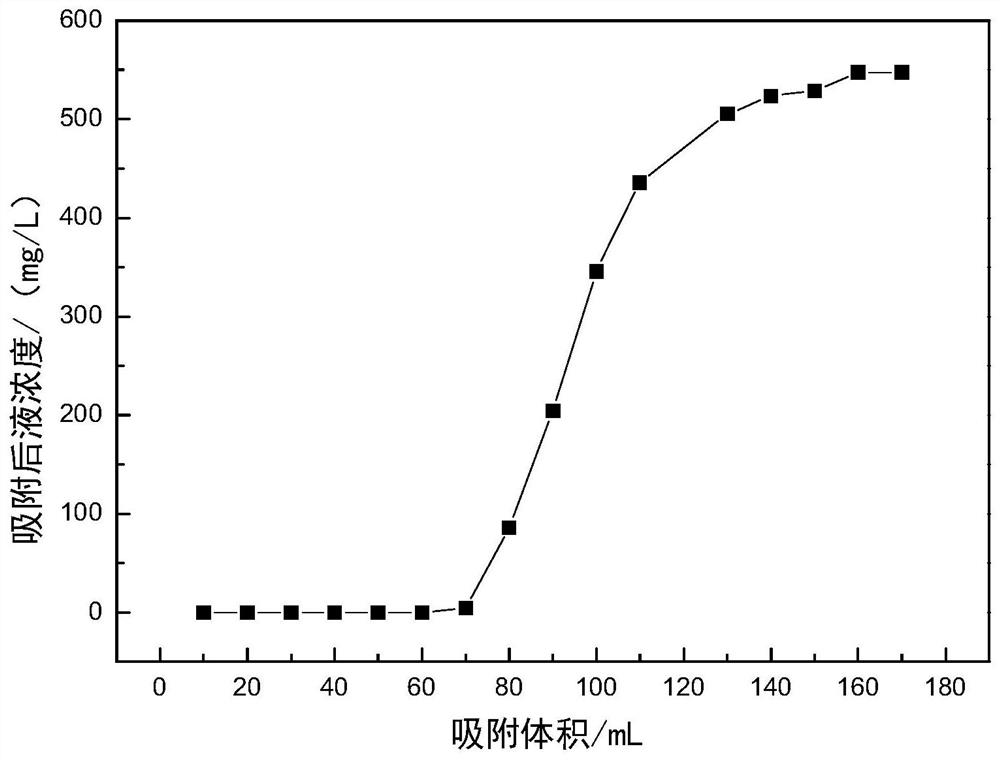

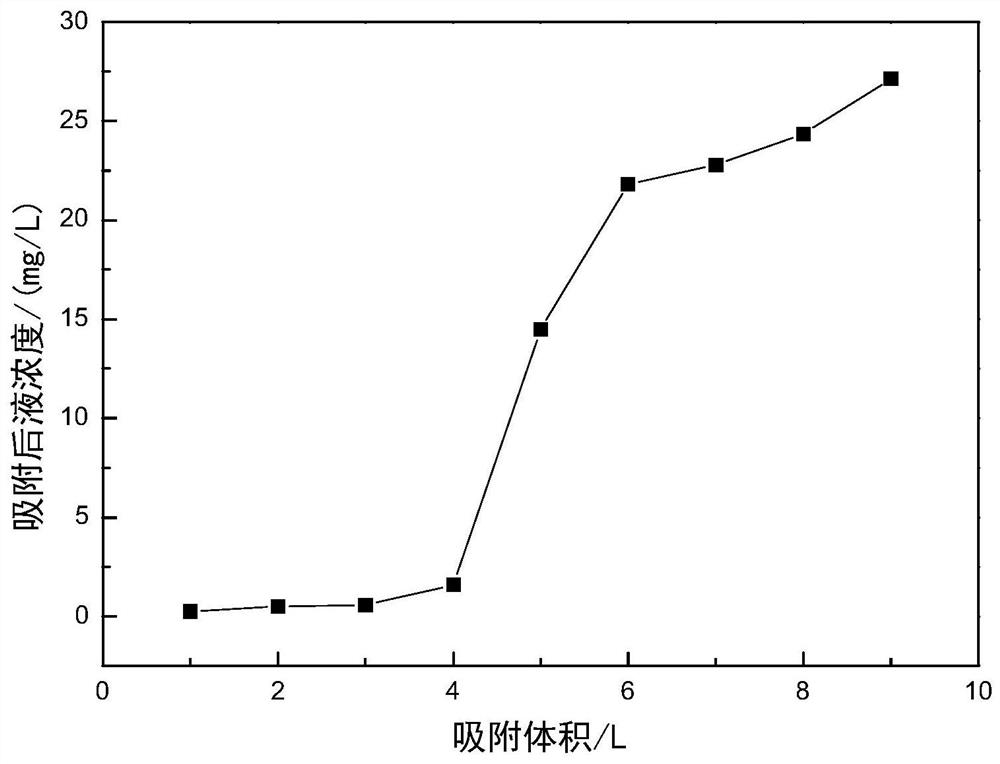

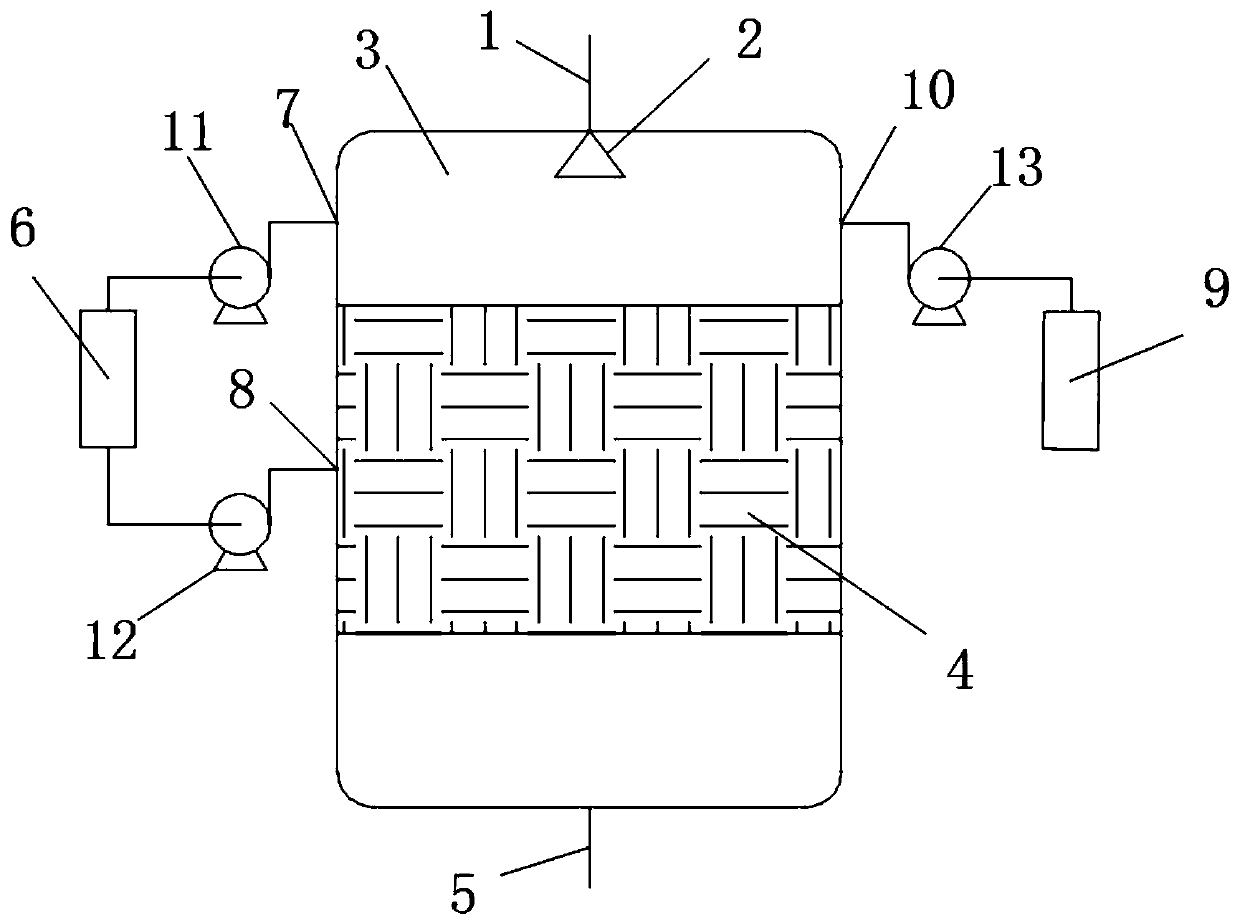

Extraction and purification process of total flavonoids from rose

The invention provides a process for extracting and purifying total flavone from rose flower. The total flavone provided by the invention is obtained by extracting dry petals of plant rose flower by using a solvent, and purifying by using macroporous resin, polyamide and C18; the total flavone uses flavonoid compounds as main components. The invention provides a simple, convenient and easily-implemented method for determining the content of the total flavone in the rose flower, and optimizes the process for extracting and purifying the total flavone from the rose flower; the content of the final total flavone from the rose flower is obviously increased, so that the process is wide in application prospect.

Owner:CHENGDU PUSH BIOLOGICAL TECH

Enrichment process of heavy metals in desulfurization wastewater based on high stability adsorbent

ActiveCN110935422BStable chemical propertiesAffect the reuse effectOther chemical processesWater contaminantsAir atmosphereSorbent

The invention discloses a process for enriching heavy metals in desulfurization wastewater based on a high-stability adsorbent. A high-stability ceramic adsorbent is used to configure a leaching and elution process for heavy metal separation. The preparation method of the high-stability ceramic adsorbent is as follows: Alumina, magnesium carbonate, titanium dioxide, iron oxide and carbon materials are mixed uniformly and then compacted, and then calcined in an air atmosphere. The calcined materials are washed with dilute hydrochloric acid, and then soaked in sodium hydroxide solution. The latter material is added with sodium carbonate and sodium citrate for hydrothermal reaction, and high-stability ceramic adsorbent is obtained after the reaction. This process separates heavy metal ions in desulfurization wastewater for enrichment. The uses of heavy metal ions are more extensive. Therefore, the process of the present invention provides a reasonable reuse route for the separated heavy metal ions, which not only meets the current environmental protection requirements, but also meets the current green process route of resource reuse.

Owner:HUANENG SHANDONG POWER GENERATION CO LTD +1

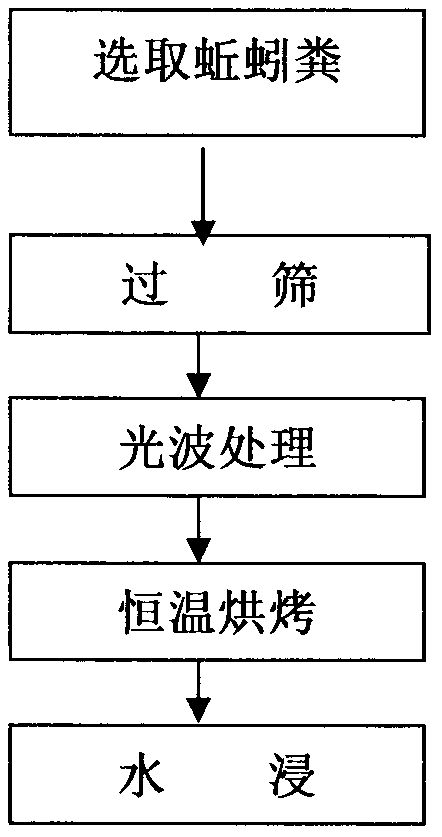

Air freshener and preparation method thereof

InactiveCN106039371AReduce purification costsImprove purification effectDeodrantsAir cleaningOrganic fertilizer

The invention relates to an air freshener and a preparation method thereof. The air freshener is prepared by the following steps: mixing earthworm cast with water, wherein earthworm cast is Daping No.2 earthworm cast containing earthworm eggs; sieving the earthworm cast; processing the earthworm cast by virtue of a convection oven; and roasting the earthworm cast at constant temperature in a timed mode. The air freshener disclosed by the invention can overcome the shortcomings of a single purification mode, high using cost, risk of secondary pollution and the like in the past. The air freshener disclosed by the invention is simple in program, high in adsorption efficiency, convenient to use and low in preparation cost, and the freshener, which can serve as organic fertilizer after being used, is capable of avoiding the risk of secondary pollution, strong in adsorption capacity, broad in adsorption scope, high in air purification speed and efficient; with the application of the air freshener disclosed by the invention, current air purification cost can be reduced by 60% and purification efficacy can be improved by 40%; and the air freshener is suitable for air purification in various occasions.

Owner:YANGZHOU UNIV

Wear resistant formaldehyde adsorption material

InactiveCN106732406AHigh removal rateImprove wear resistanceGas treatmentOther chemical processesSodium BentoniteWear resistant

The invention discloses a wear resistant formaldehyde adsorption material. The wear resistant formaldehyde adsorption material contains the raw materials in parts by weight: 100 parts of diatomite, 12-18 parts of hydroxypropyl ammonium bicarbonate, 20-60 parts of ethylene glycol, 5-25 parts of rock wool, 1-5 parts of magnesium oxide, 30-50 parts of Portland cement, 1-20 parts of leucine, 6-10 parts of bentonite, 4-8 parts of a quartz powder, 3-7 parts of aluminum oxide, 2-6 parts of ammonium bicarbonate, 13-17 parts of menthol, 15-35 parts of tetrahydrofuran and 20-40 parts of deionized water. The wear resistant formaldehyde adsorption material disclosed by the invention has the advantages that the formaldehyde removal rate reaches up to 97.8-99.5%; the wear resistance is strong; the service life is long; the wear resistant formaldehyde adsorption material can be repeatedly used and is green and environment-friendly; the adsorption speed of the wear resistant formaldehyde adsorption material is high; the adsorption range of the wear resistant formaldehyde adsorption material is wide; after the wear resistant formaldehyde adsorption material is put in a sealed space with formaldehyde content of 400-500 ug / m3 for 24-48 hours, the formaldehyde concentration of the sealed space is 2-8 ug / m3.

Owner:SUZHOU LVDIAN INFORMATION TECH CO LTD

Preparation method of natural high-purity cape jasmine flower essential oil crystal

ActiveCN106701320AImprove processing powerWide range of adsorptionEssential-oils/perfumesSupercritical fluid extractionChemistry

The invention discloses a preparation method of a natural high-purity cape jasmine flower essential oil crystal. The preparation method comprises the following steps: firstly, spraying water on fresh picked cape jasmine flowers and then putting into a fresh flower container for later use; secondly, adsorbing volatile components in the fresh cape jasmine flowers by adopting resin at room temperature; thirdly, putting resin adsorbed with cape jasmine flower head volatile in the first step into extraction equipment, and carrying out CO2 supercritical extraction to obtain an oily cape jasmine flower head volatile coarse component; fourthly, dissolving the oily cape jasmine flower head volatile coarse component by adopting the organic solvent, allowing standing still and crystallizing at low temperature, and filtering to obtain the cape jasmine flower essential oil crystal. The essential oil crystal provided by the invention is good in color and is convenient for taking out and transporting; the natural high-purity cape jasmine flower essential oil crystal is recrystallized under the low-temperature condition, so that the yield is increased, and impurities are reduced.

Owner:昆明悦馨生物科技有限公司

A modified molecular sieve for purifying olefins and a method for using it to remove oxygen-containing impurities in olefins

ActiveCN108126664BWide range of adsorptionEnhanced interactionOther chemical processesCombustible gas purificationOrganic synthesisKetone

The invention provides a modified molecular sieve for purifying olefins and a method for removing oxygen-containing impurities in olefins by using the modified molecular sieve. The modified molecular sieve is modified by metal-organic compounds, and the method includes: the olefin stream containing oxygen-containing impurities such as water, ether, aldehyde, ketone, alcohol, etc. passes through the molecular sieve bed layer modified by metal-organic compounds to obtain high-purity olefin stream. After the molecular sieve bed is saturated, the molecular sieve bed can be regenerated by purging with inert gas under high temperature conditions. The olefins purified by the method of the present invention, especially the isobutene, reach a high-purity standard and can be used in polymerization-level reactions and organic synthesis reactions.

Owner:WANHUA CHEM GRP CO LTD

Novel composite sludge activated carbon adsorbent

InactiveCN104888737AHigh carbon contentImprove adsorption capacityOther chemical processesSorbentPolyvinyl alcohol

The invention discloses a novel composite sludge activated carbon adsorbent which is characterized by being prepared from the following raw materials, by weight, 100-150 parts of sludge, 13-17 parts of corn straw, 15-24 parts of peanut shell, 10-15 parts of manganese ore powder, 30-50 parts of zinc chloride, 13-16 parts of magnesium silicate, 5-8 parts of silicon dioxide, 3-5 parts of polyvinyl alcohol, 3-5 parts of polyacrylamide, 6-9 parts of teflon powder, 5-7 parts of attapulgite powder, 7-9 parts of calcium sulphide and a proper amount of distilled water. with addition of the teflon powder, attapulgite powder and calcium sulphide, acidic and alkali resistance, bactericidal activity and adsorption capacity of the sludge activated carbon are greatly enhanced, and wear rate during the preparation process is reduced. The source of materials is wide, and cost is low. The preparation process is simple; production efficiency is high; and no secondary pollution is caused. The adsorbent is environmentally friendly, has a wide range of adsorption and is worthy of popularization.

Owner:BENGBU PIONEER FILTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com