Oil making method, edible oil and application thereof

A frying and oiling technology, which is applied in food science, fat oil/fat production, fat oil/fat refining, etc., can solve problems such as food safety hazards and products that fail to meet quality requirements, so as to avoid pollution and make the oil rosy in color , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

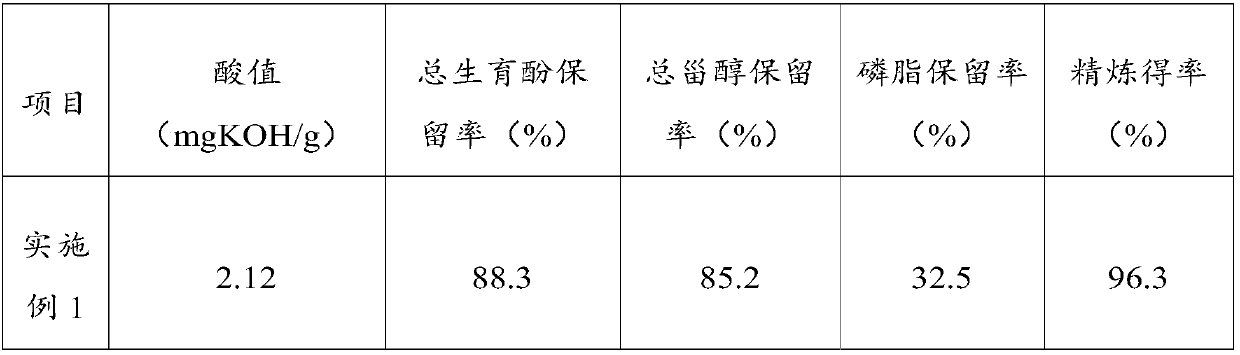

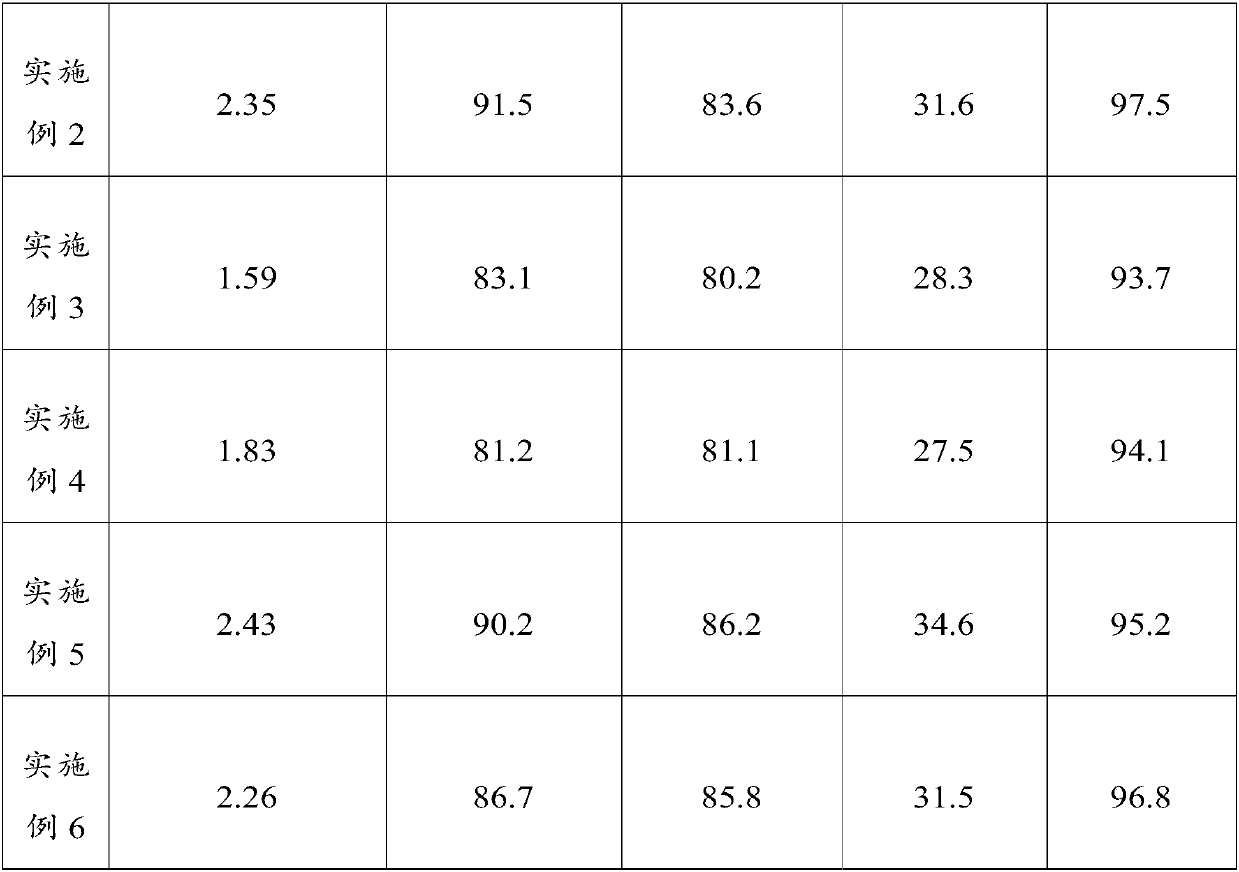

Examples

Embodiment 1

[0045] A method for producing oil, comprising:

[0046] Sodium chloride, rice flour and water were mixed in a mass ratio of 0.5:1:20, and after standing for 40 minutes, the solid and liquid were separated to obtain the soaking liquid. Soak the rapeseed soaking solution for 1.5 hours, wash and drain, and fry at 150°C for 90 minutes. Pass the fried rapeseed through 3 windmills, spread out and cool down to 105°C, grind it into a powder of -40~+60°C, and steam it with water steam until the water content of the powder is 12%. The steamed powder is cooled to 75°C, wrapped into cakes, and pressed at 65°C to obtain crude oil.

[0047] Put the crude oil under the protection of ≥90v / v% nitrogen for 15h to remove the sediment at the bottom; place it for 12h under the protection of ≥90v / v% nitrogen to remove the bottom sediment to obtain an oil.

[0048] Mix silica gel with a particle size of -60 ~ +100 mesh, sodium calcium montmorillonite with a particle size of -80 ~ +120 mesh and alk...

Embodiment 2

[0050] A method for producing oil, comprising:

[0051] Sodium chloride, rice flour and water were mixed in a mass ratio of 0.5:0.5:20, and after standing for 30 minutes, the solid and liquid were separated to obtain the soaking liquid. Soak the sesame soaking liquid for 1 hour, wash and drain, and fry at 140°C for 80 minutes. The roasted sesame is ground into -40~+60 powder, steamed with water steam until the water content of the powder is 15%. The steamed powder is cooled to 80°C, wrapped into cakes, and pressed at 70°C to obtain crude oil.

[0052] Put the crude oil under the protection of ≥90v / v% nitrogen for 15h to remove the sediment at the bottom; place it for 12h under the protection of ≥90v / v% nitrogen to remove the bottom sediment to obtain an oil.

[0053] Mix silica gel with a particle size of -60 ~ +100 mesh, sodium calcium montmorillonite with a particle size of -80 ~ +120 mesh and alkaline microcrystalline cellulose with a particle size of -150 ~ +200 mesh acc...

Embodiment 3

[0055] A method for producing oil, comprising:

[0056] Sodium chloride, rice flour, and water were mixed at a mass ratio of 0.8:1:20, left to stand for 45 minutes, and solid-liquid separated to obtain soaking liquid. Soak the peanut soaking solution for 2 hours, wash and drain, and fry at 170°C for 100 minutes. Pass the roasted peanuts through 2 windmills, spread out and cool down to 110°C, grind them into a powder of -40~+60°C, and steam them with water steam until the water content of the powder is 9%. The steamed powder is cooled to 80°C, wrapped into cakes, and pressed at 60°C to obtain crude oil.

[0057] Put the crude oil under the protection of ≥90v / v% nitrogen for 15h to remove the sediment at the bottom; place it for 12h under the protection of ≥90v / v% nitrogen to remove the bottom sediment to obtain an oil.

[0058] Mix silica gel with a particle size of -60 ~ +100 mesh, sodium calcium montmorillonite with a particle size of -80 ~ +120 mesh and alkaline microcryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com