Preparation method of jasmine flower essential oil crystal

A technology of jasmine essential oil and jasmine, which is applied in the direction of essential oil/perfume, fat production, etc., can solve the problems of high equipment manufacturing requirements, large equipment investment, high product cost, etc., and achieve quantitative fragrance distribution, low operating cost and long working life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

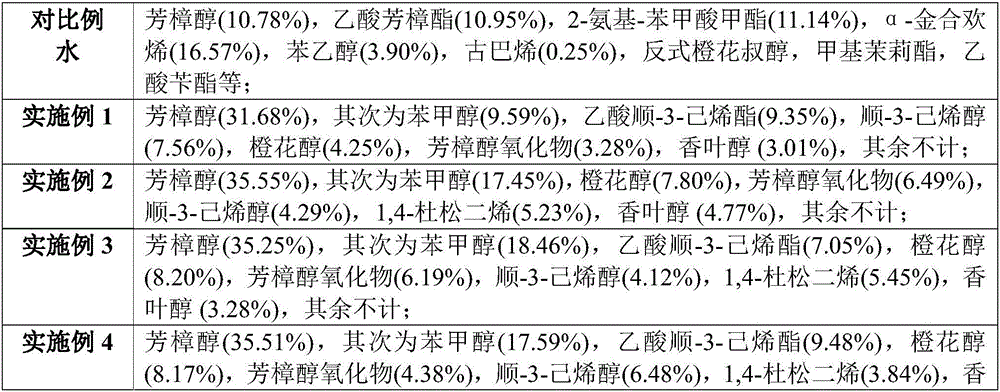

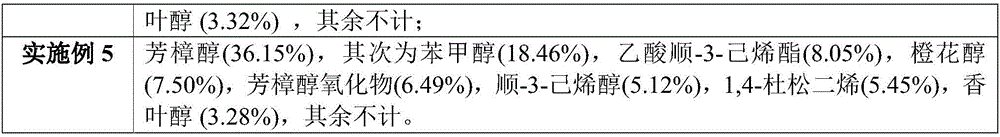

Examples

Embodiment 1

[0032] 1, pretreatment: freshly picked jasmine 250g is put into reactor (reactor is placed in 50 ℃ of water baths), then the β-glucosidase (1.5%) solution that the buffer solution of pH5.0 extracts is sprayed on above the flower;

[0033] 2. At a temperature of 25°C, use a new type of resin to absorb the volatile components in the above-mentioned pretreated fresh flowers for 4 hours;

[0034] 3. After absorbing and saturating the above-mentioned new resin, then elute with 2500mL petroleum ether solvent, and distill under reduced pressure;

[0035] 4. Crystallization: After distillation, 2.2g of crude essential oil is obtained, then add 60mL of n-hexane and 20mL of ethanol, cool to room temperature, and then stand at 1-3°C for crystallization, and filter to obtain 1.7g of jasmine essential oil crystals after 12 hours. The filtrate can be recovered Continue to take advantage. The purity of jasmine essential oil analyzed by gas chromatography is about 99%, its fragrance is simi...

Embodiment 2

[0037] 1. Pretreatment: 150g of freshly picked jasmine is put into a reactor (the reactor is placed in a 50°C water bath), and then the naringinase (1%) solution extracted with a buffer solution of pH5.0 is sprayed on the flower. above;

[0038] 2. At a temperature of 20°C, use a new type of resin to absorb the volatile components in the above pretreated fresh flowers for 3 hours;

[0039] 3. After absorbing and saturating the above-mentioned new resin, then elute with 1500mL petroleum ether solvent, and distill under reduced pressure;

[0040]4. After the distillation, 1.6g of crude essential oil was obtained, then 60mL of ethyl acetate and 20mL of ethanol were added, and then left to crystallize at 3-5°C. After 12 hours, it was filtered to obtain 1.2g of jasmine essential oil crystals, and the filtrate could be recycled for further use. The purity of jasmine essential oil analyzed by gas chromatography is about 99%, its fragrance is similar to that of jasmine head essential...

Embodiment 3

[0042] 1. Pretreatment: 200g of freshly picked jasmine is put into a reactor (the reactor is placed in a 50°C water bath), and then the naringinase (2%) solution extracted with a buffer solution of pH 4.5 is sprayed on the flower. above;

[0043] 2. At a temperature of 23°C, use a new type of resin to absorb the volatile components in the above pretreated fresh flowers for 4 hours;

[0044] 3. After absorbing and saturating the above-mentioned new resin, it is then eluted with 2000mL of n-hexane solvent and distilled under reduced pressure;

[0045] 4. Obtain 2.1g of crude essential oil after distillation, then add 60mL of petroleum ether and 30mL of ethanol, cool to room temperature, then stand at 3-5°C for crystallization, and filter to obtain 1.8g of jasmine essential oil crystals after 12 hours, the filtrate can be recovered and reused . The purity of jasmine essential oil analyzed by gas chromatography is about 99%, its fragrance is similar to that of jasmine head essen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com