A kind of preparation method of natural high-purity gardenia essential oil crystal

A high-purity technology of gardenia essential oil, which is applied in the direction of essential oil/perfume, fat production, etc., and can solve the problems of dissolving flower residue, not suitable for industrial production, storage of extract or base essential oil, inconvenient transportation, etc. , to achieve the effect of convenient transfer and transportation, long working life and wide adsorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

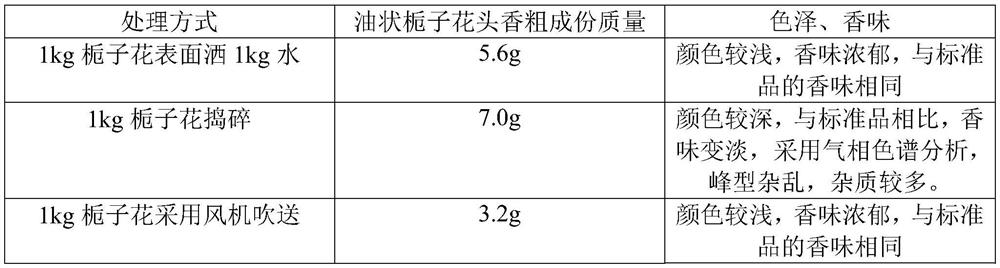

[0023] Step 1. Resin adsorption treatment: Spray 1000g of fresh gardenia flowers picked in the morning with 1000g of water, put them in a flower storage container, and use resin to absorb the volatile substances in gardenia flowers at normal temperature (20-25°C). Component adsorption for 3h;

[0024] Step 2, the resin after step (1) adsorption is placed in the extractor of 0.5L, CO 2 After the gas is purified by the purifier, it is compressed by the compressor and enters the extractor, so that the pressure in the extractor is kept at 20MPa, the desorption valve is opened, and the air pressure in the desorber is maintained at 5MPa, the temperature in the extractor and desorber 30°C and 35°C, respectively. CO 2 Fully contact with the resin in the extractor, dissolve the adsorbed gardenia fragrance components and analyze it in the resolver to obtain 5.6g oily gardenia head fragrance components;

[0025] Step 3. Use 30mL of ethanol and 60mL of n-hexane to crystallize the 5g of...

Embodiment 2

[0027] Step 1, resin adsorption treatment: spray 1800g of water on 1500g of fresh gardenias picked in the morning, put them in a flower storage container, and use resin to absorb the volatile substances in gardenia flowers at normal temperature (20-25°C). Component adsorption for 4h;

[0028] Step 2, the resin in step 1 is placed in the extractor of 1L, CO 2 After the gas is purified by the purifier, it is compressed by the compressor and enters the extractor, so that the pressure in the extractor is kept at 25MPa, the desorption valve is opened, and the air pressure in the desorber is maintained at 6MPa, the temperature in the extractor and desorber 28°C and 30°C, respectively. CO 2 Fully contact with the resin in the extractor, dissolve the adsorbed gardenia fragrance components and resolve it in the resolver to obtain 8g gardenia head fragrance crude components;

[0029] Step 3. Recrystallize 5 g of Gardenia jasminoides crude components obtained in step 2 with 20 mL of e...

Embodiment 3

[0031] Step 1. Resin adsorption treatment: Spray 2000g of fresh gardenia flowers picked in the morning with 2000g of water, put them in the flower storage container, and use macroporous resin to remove the gardenia flowers from gardenia flowers at normal temperature (20-25°C). Adsorption of volatile components for 3h;

[0032] Step 2, the macroporous resin in step 1 is placed in the extractor of 0.5L, CO 2 After the gas is purified by the purifier, it is compressed by the compressor and enters the extractor, so that the pressure in the extractor is kept at 20MPa, the desorption valve is opened, and the air pressure in the desorber is maintained at 5MPa, the temperature in the extractor and desorber 28°C and 35°C, respectively. CO 2 Fully contact with the resin in the extractor, dissolve the adsorbed gardenia fragrance components and resolve it in the resolver to obtain 8g gardenia head fragrance crude components;

[0033]Step 3. Recrystallize the 8 g of gardenia head fragra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com