Intelligent FPC board adsorbing and releasing device

An intelligent, bottom-plate technology, used in conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of power consumption, high use cost, and loud noise of adsorption devices, and achieve coordinated operation, convenient release, and low power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

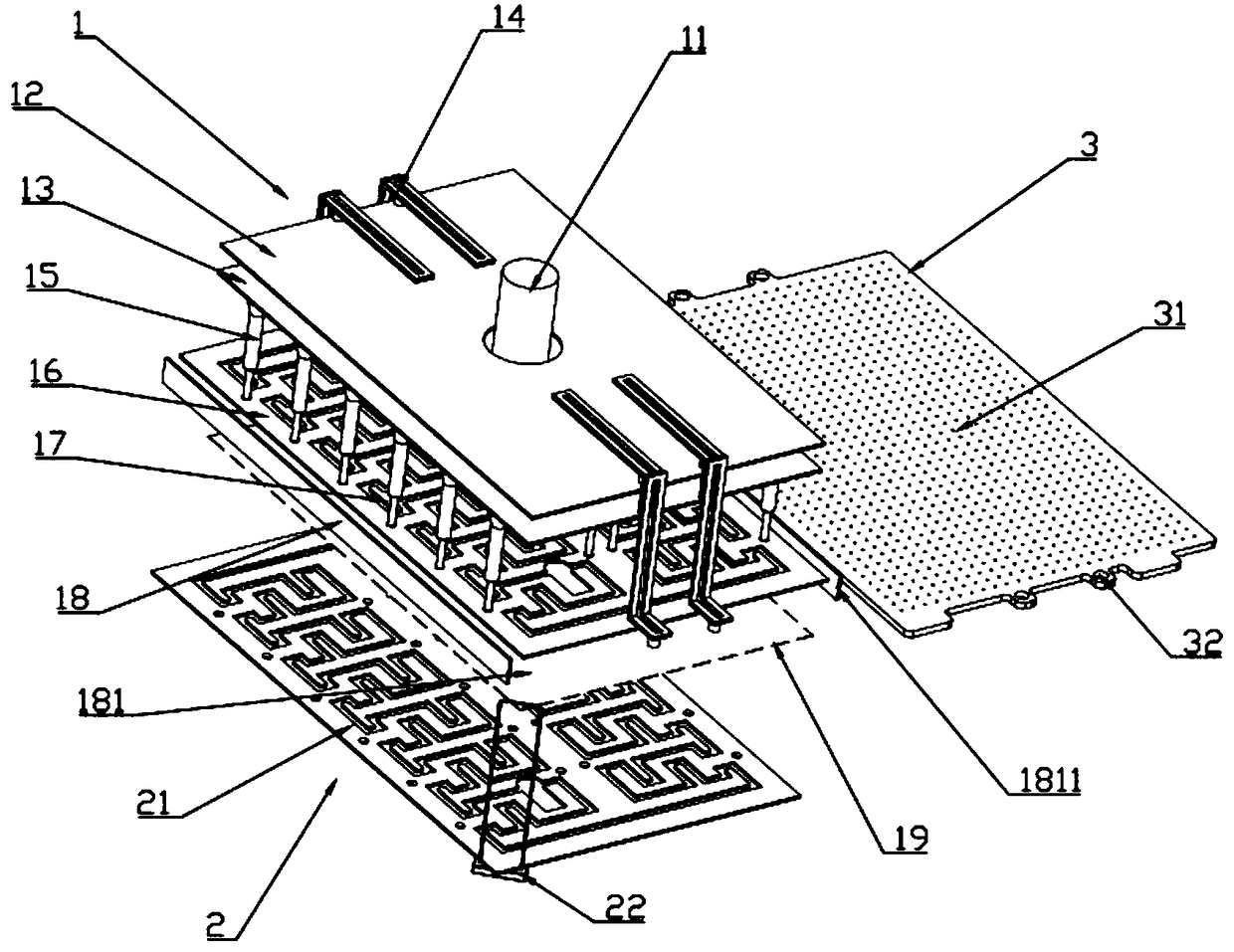

[0029] as attached figure 1 As shown, an FPC board intelligent pick-and-place device includes a storage mechanism 2, a receiving mechanism 3, and a moving mechanism 1 for moving the FPC circuit board from the storage mechanism 2 to the receiving mechanism 3.

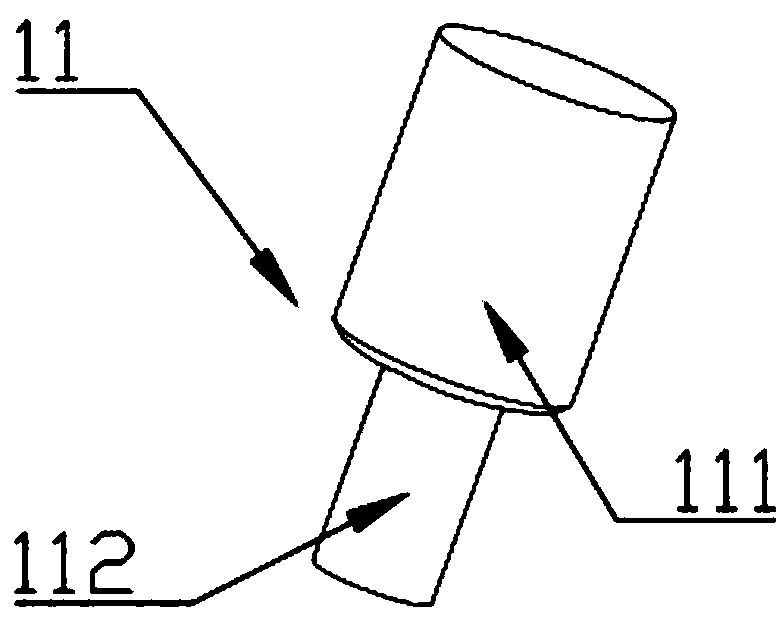

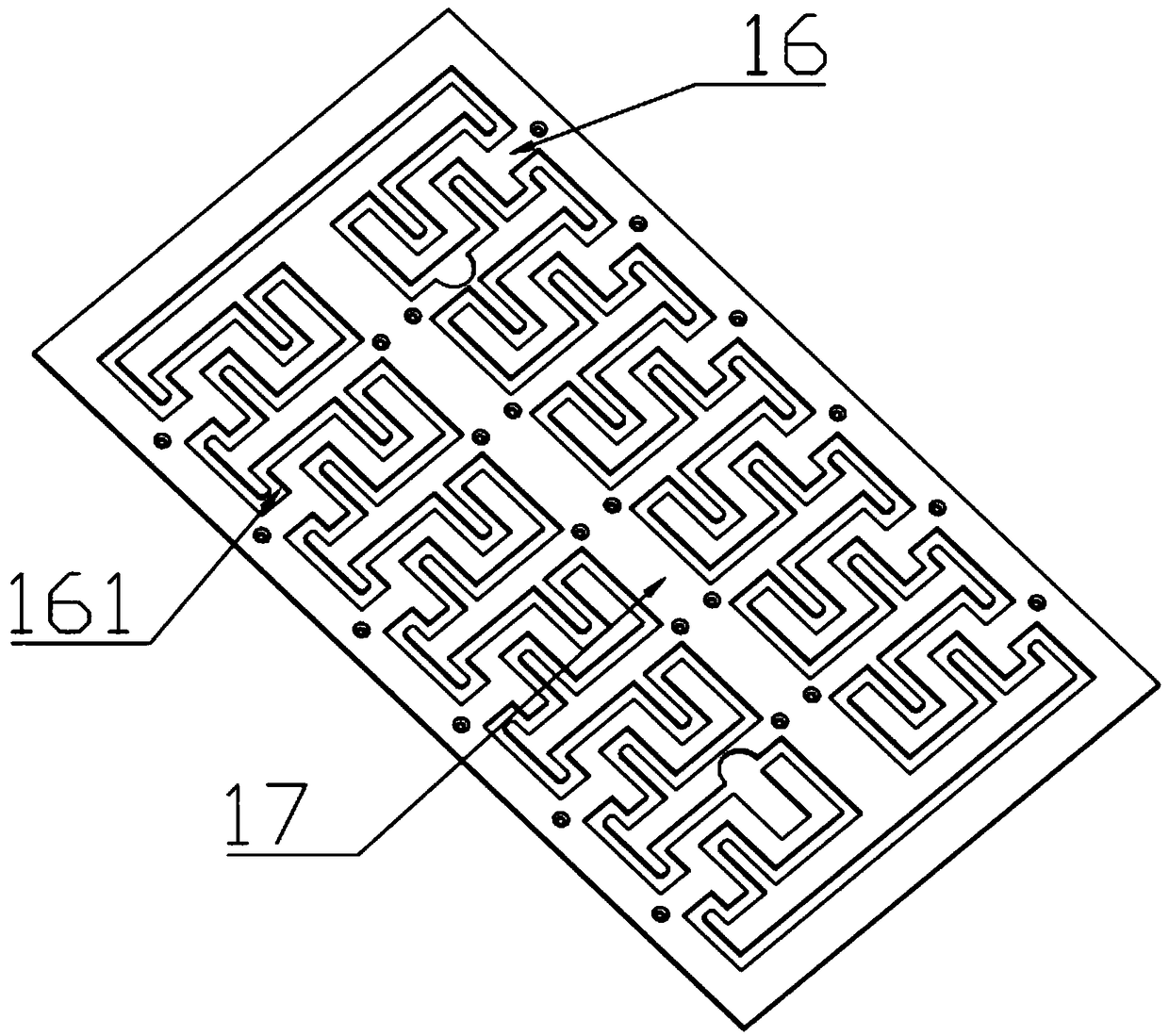

[0030] Please combine the attached figure 1 , 2As shown in and 3, the moving mechanism 1 includes a manipulator 11, a fixed plate 12, a placement plate 13, an adsorption plate 16, a release plate 17 and a plurality of limiting mechanisms 14 that limit the downward movement of the adsorption plate 16, and the manipulator 11 includes a fixed shell 111 and the moving column 112, the moving column 112 is movably arranged on the fixed shell 111, the fixed plate 12 is fixed on the fixed shell 111, the placing plate 13 is fixed with one end of the moving column 112, the placing plate 13 has a plurality of buffer columns 15, The adsorption plate 16 and the release plate 17 are fixed on the lower ends of different buffer column...

Embodiment 2

[0037] Different from Embodiment 1, in this embodiment, the adsorbent is double-sided adhesive, which has strong cohesive force, good waterproof effect, and the double-sided adhesive is easy to cut. Covered on the adsorption plate 16, the double-sided adhesive tape is easy to replace.

Embodiment 3

[0039] The difference from Example 1 is that in this example, the adsorbent is adhesive glue, which has strong cohesive force, good waterproof effect, easy extrusion, no glue leakage, fast surface drying speed, and convenient operation .

[0040] When the FPC board intelligent suction and release device starts, the moving mechanism 1 moves to the top of the bottom plate 21 of the storage mechanism 2 at the preset position, the manipulator 11 presses down, the adsorption piece absorbs the FPC circuit board, and the laser sensing device 18 senses the FPC circuit board. After being located in the laser resonant cavity 181, the moving mechanism 1 moves upwards. When the FPC circuit board moves to position A19, the retaining ring 22 moves the FPC circuit board to prevent the adsorption piece from absorbing multiple FPC circuit boards, and then the moving mechanism 1 moves To the top of the receiving mechanism 3 and press down, the second buffer pad 145 is in contact with the receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com