Heavy metal adsorbent and preparation method and application thereof

A heavy metal and adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as biological hazards, and achieve the effect of easy to obtain raw materials, easy to control, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

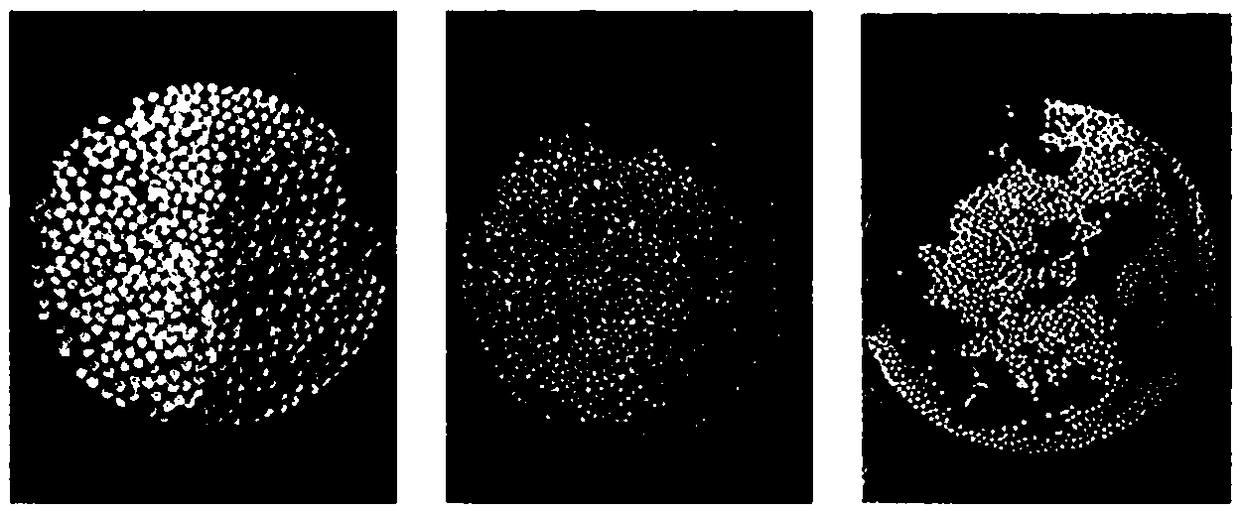

Image

Examples

preparation example Construction

[0031] The preparation method of heavy metal adsorbent of the present invention comprises the following steps:

[0032] A. Pulverize the attapulgite clay of the formula ratio through a 200-mesh sieve, then carry out acid activation treatment, wash to neutrality and dry and grind to obtain material a for subsequent use;

[0033] B. Make a mixed solution with NaOH, urea, and water according to the mass ratio of (5~7):(3~5):(80~100) to obtain material b, and add cellulose in the formula ratio to material b , placed at 0-5°C for 10-18 hours, then thawed and stirred to obtain cellulose solution c;

[0034] C. Add material a to cellulose solution c, stir at a temperature of 10~30°C for 3~5h to obtain a mixed solution d, and then add CaCO with a weight percentage of 1~10% in the mixed solution d 3 , sonicated for 30-60 minutes to obtain material e;

[0035] D. Add the HCl solution or ethanol solution with a pH value of 1 to 5 dropwise into the material e, and stir while adding to o...

Embodiment 1

[0045] Set up the test device and prepare the adsorbent according to the following steps:

[0046] 1) Take 4g of 200-mesh attapulgite clay for acid activation treatment, wash until neutral, dry and grind for later use;

[0047]2) Make a mixed solution with the mass ratio of NaOH, urea, and water as 6:4:90, then add 4% cellulose by mass, freeze in the refrigerator overnight, and stir while thawing to obtain a cellulose solution; Add 1.3g spare attapulgite clay to the plain solution, stir at room temperature for 5 hours; add 5% CaCO to the mixed solution 3 Ultrasound for 30min;

[0048] 3) Prepare HCl solutions or ethanol solutions with pHs of 1, 3, and 5 respectively, and add the mixture dropwise with a constant pressure funnel while stirring to obtain a spherical attapulgite cellulose composite adsorbent, soak the composite adsorbent in water and acetone Wash until neutral, freeze-dry for later use;

[0049] 4) Load iron and manganese oxides with the prepared spherical adso...

Embodiment 2

[0052] Set up the test device and prepare the adsorbent according to the following steps:

[0053] 1) Take 4g of 200-mesh attapulgite clay for acid activation treatment, wash until neutral, dry and grind for later use;

[0054] 2) Make a mixed solution with the mass ratio of NaOH, urea, and water as 6:4:90, then add 4% cellulose by mass, freeze in the refrigerator overnight, and stir while thawing to obtain a cellulose solution; Add 2g of spare attapulgite clay to the plain solution, and stir at room temperature for 5 hours; add 10% CaCO to the mixed solution 3 Ultrasound for 30min;

[0055] 3) Prepare HCl solutions or ethanol solutions with pHs of 1, 3, and 5 respectively, and add the mixture dropwise with a constant pressure funnel while stirring to obtain a spherical attapulgite cellulose composite adsorbent, soak the composite adsorbent in water and acetone Wash until neutral, freeze-dry for later use;

[0056] 4) Load iron and manganese oxides with the prepared spheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com