Patents

Literature

236results about How to "Prevent self-aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

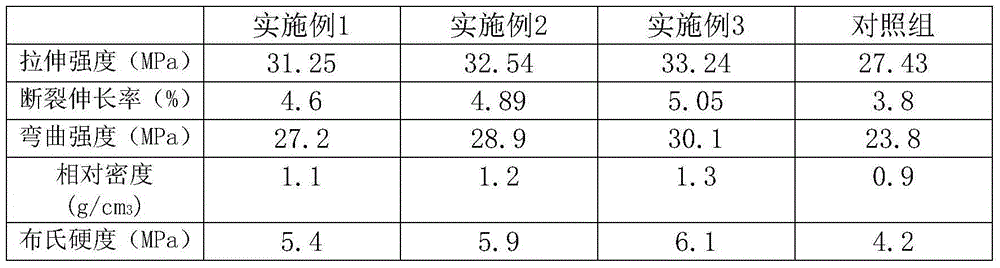

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

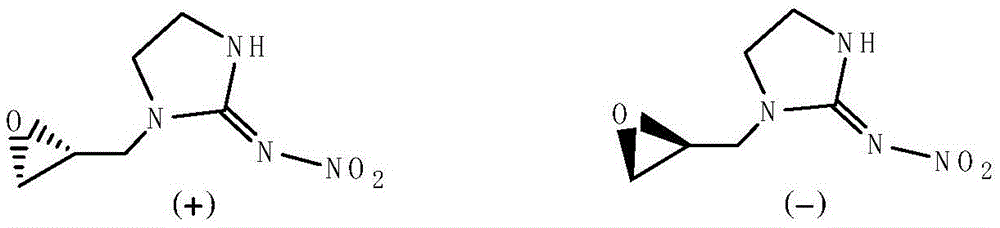

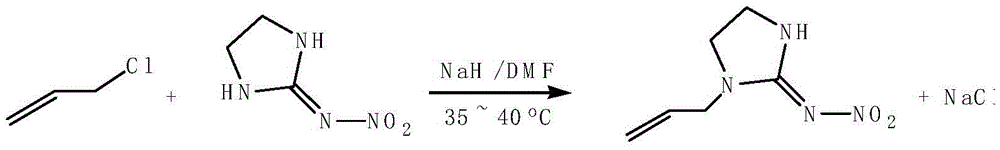

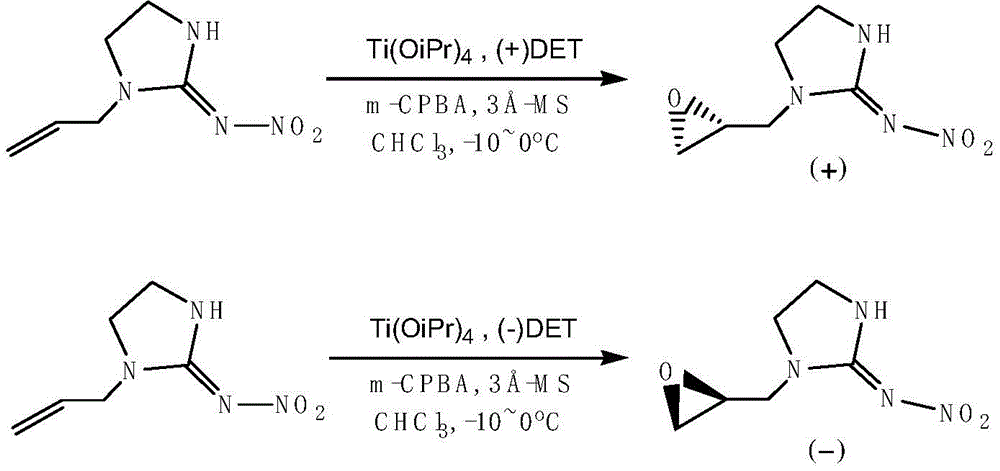

Preparation method for cycloxylidin enantiomer with photoactivity

InactiveCN105481839APrevent self-aggregationMild thermal conditionsOrganic chemistry methodsHydrogenResonance

The invention discloses a preparation method for a cycloxylidin enantiomer with photoactivity, which belongs to the technical field of asymmetric catalytic synthesis of medicines with optical activity. The method comprises a first step of synthesizing 1-allyl-N-2-nitroiminoimidazolidine and a second step of synthesizing the 1-(1,2-glycidyl)-N-2-nitroiminoimidazolidine enantiomer. The method employs sodium hydride to effectively completely remove hydrogen with weak acidity in a resonance structure of N-nitroiminoimidazolidine and convert the hydrogen into a sodium salt, wherein organic by-products are not produced; through asymmetric epoxidation, levorgyrate or dextrorotary enantiomer products with high yield can be obtained; and the method prepares high-purity enantiomer products, substantially improves insecticidal activity of the products and reduces environmental pollution.

Owner:安徽千和新材料科技发展有限公司

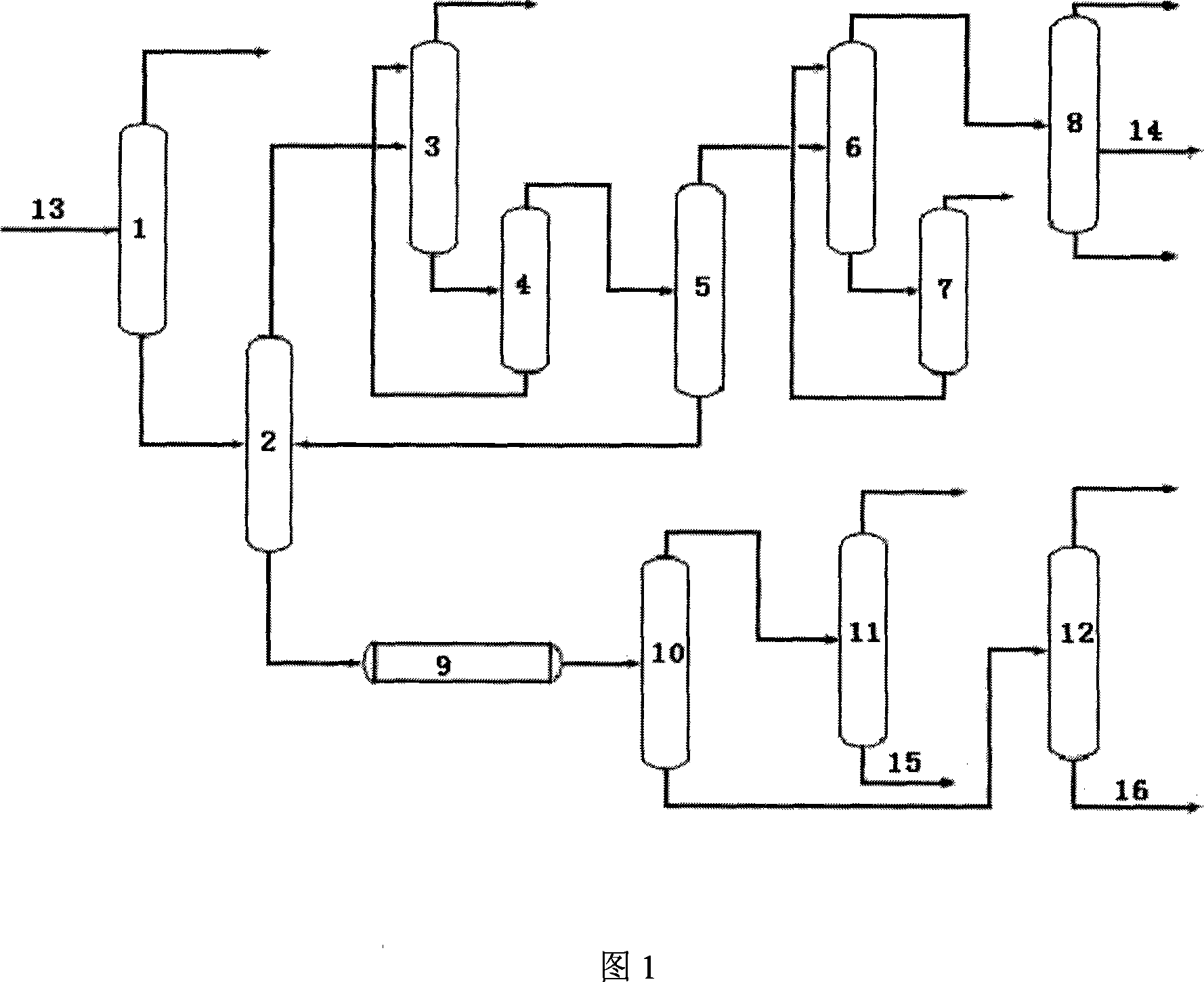

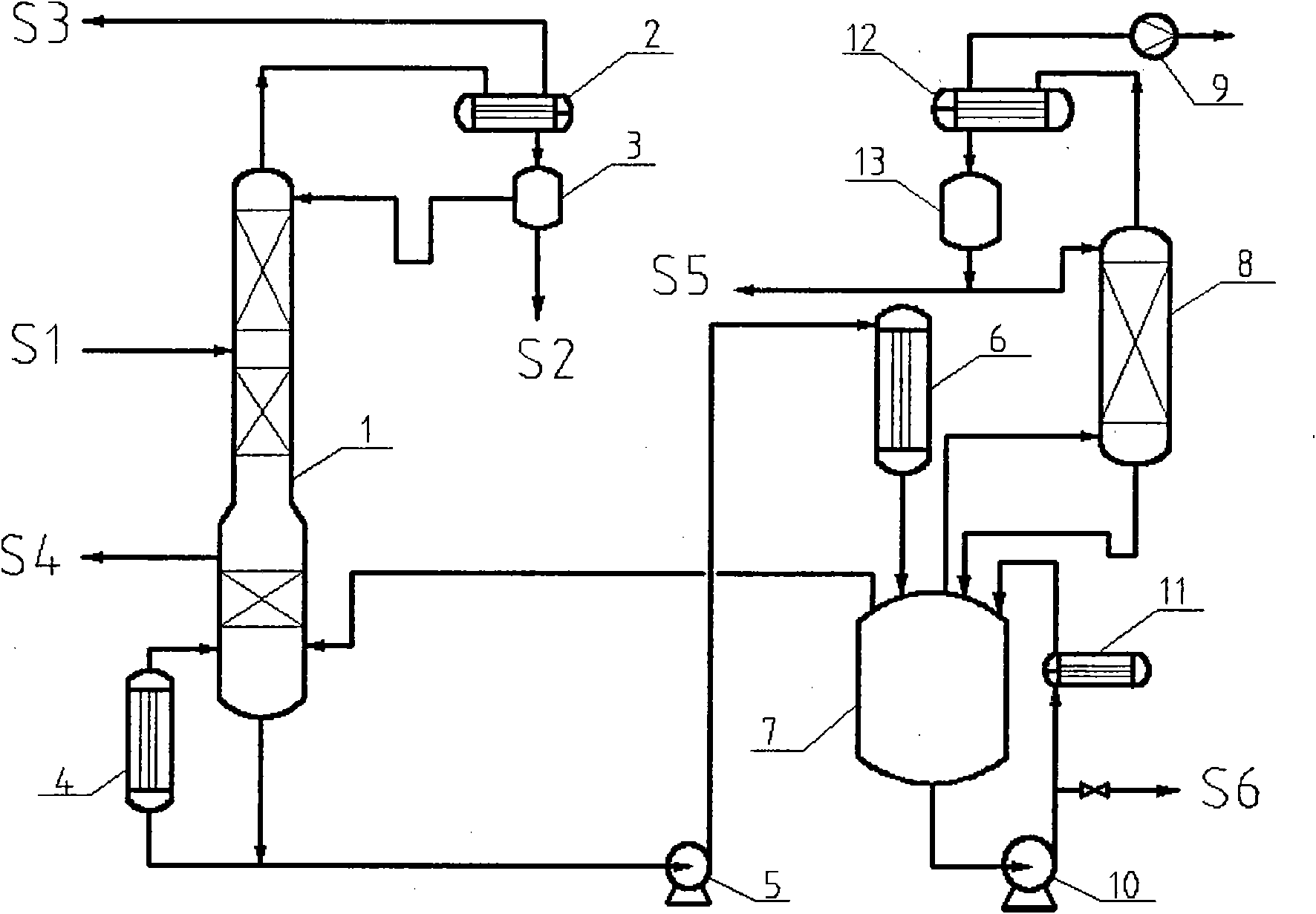

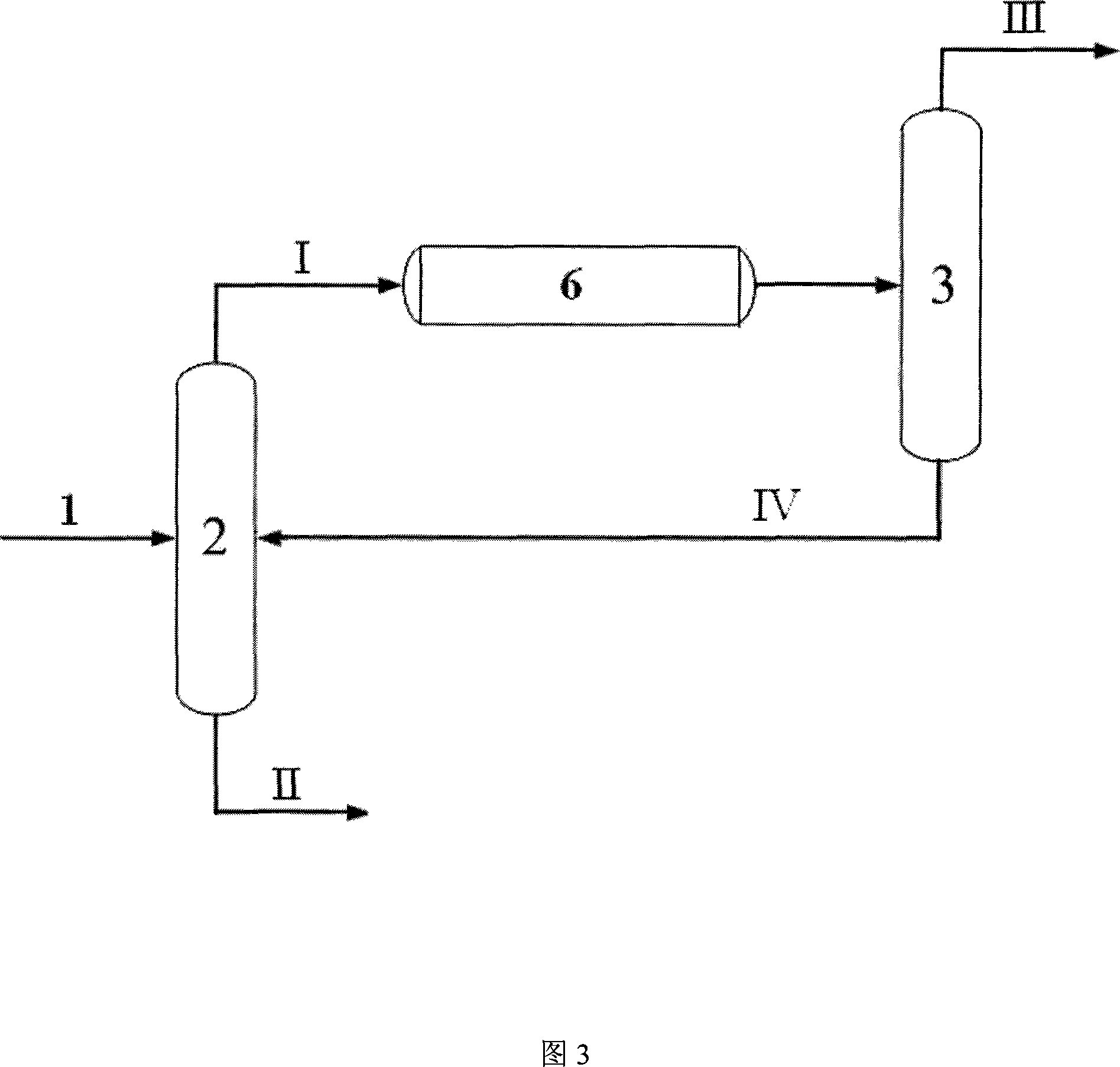

Separation method of diene hydrocarbon in five fractions of petroleum cracked carbon

ActiveCN101108782AImprove conversion rateReduced temperature control requirementsDistillation purification/separationHydrocarbonsPetroleumIsoprene

The invention relates to a separation method of the diolefin in the petroleum cracking C5 fraction, which mainly solves the problems that the cracking C5 fraction in the past technology generates the dicyclopentadiene via the thermal dimerization reactor, the isoprene does self-polymerization and does copolymerization with the cyclopentadiene to cause great loss of the isoprene and the cyclopentadiene, at the same time the dicyclopentadiene has low product purity and low utilization value. The invention better solves the problem through the technical proposal that the isoprene in the C5 fraction is separated with the cyclopentadiene and the cyclopentadiene enters the thermal dimerization reactor to generate the dicyclopentadiene and separate with the m-pentadiene, which can be used in the industrial production of the diolefin separation in the cracking C5 fraction.

Owner:CHINA PETROCHEMICAL CORP +1

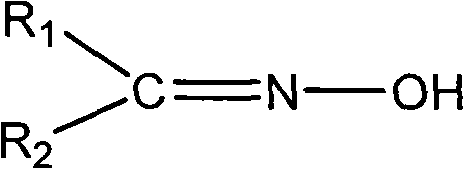

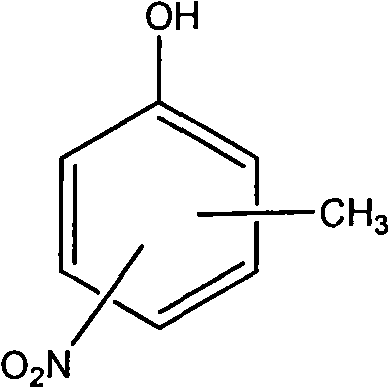

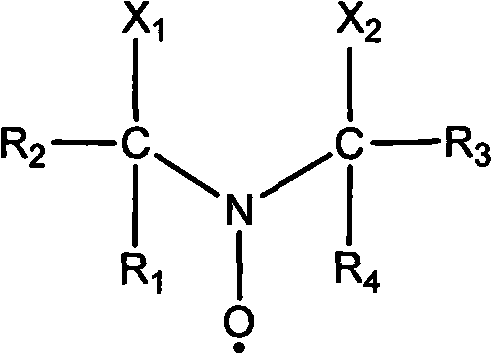

Polymerization inhibitor suitable for vinyl aromatic compound

ActiveCN101857519AHigh inhibition efficiencyLow costDistillation purification/separationHydrocarbonsSolubilityOrganic solvent

The invention discloses a polymerization inhibitor suitable for a vinyl aromatic compound, which can be applied in the processes of production, treatment, transportation and utilization of vinyl aromatic compounds. The compounded polymerization inhibitor is composed of an oxime compound, a nitrophenol compound and a nitroxide free radical compound and skilfully utilizes the respective advantages of a true polymerization inhibitor and a retarder; the synergy of components obviously improves inhibition effect, reduces use amount of highly toxic substances, lowers toxicity, improves solubility in the organic solvent and obtains good economic benefit.

Owner:ZHEJIANG UNIV

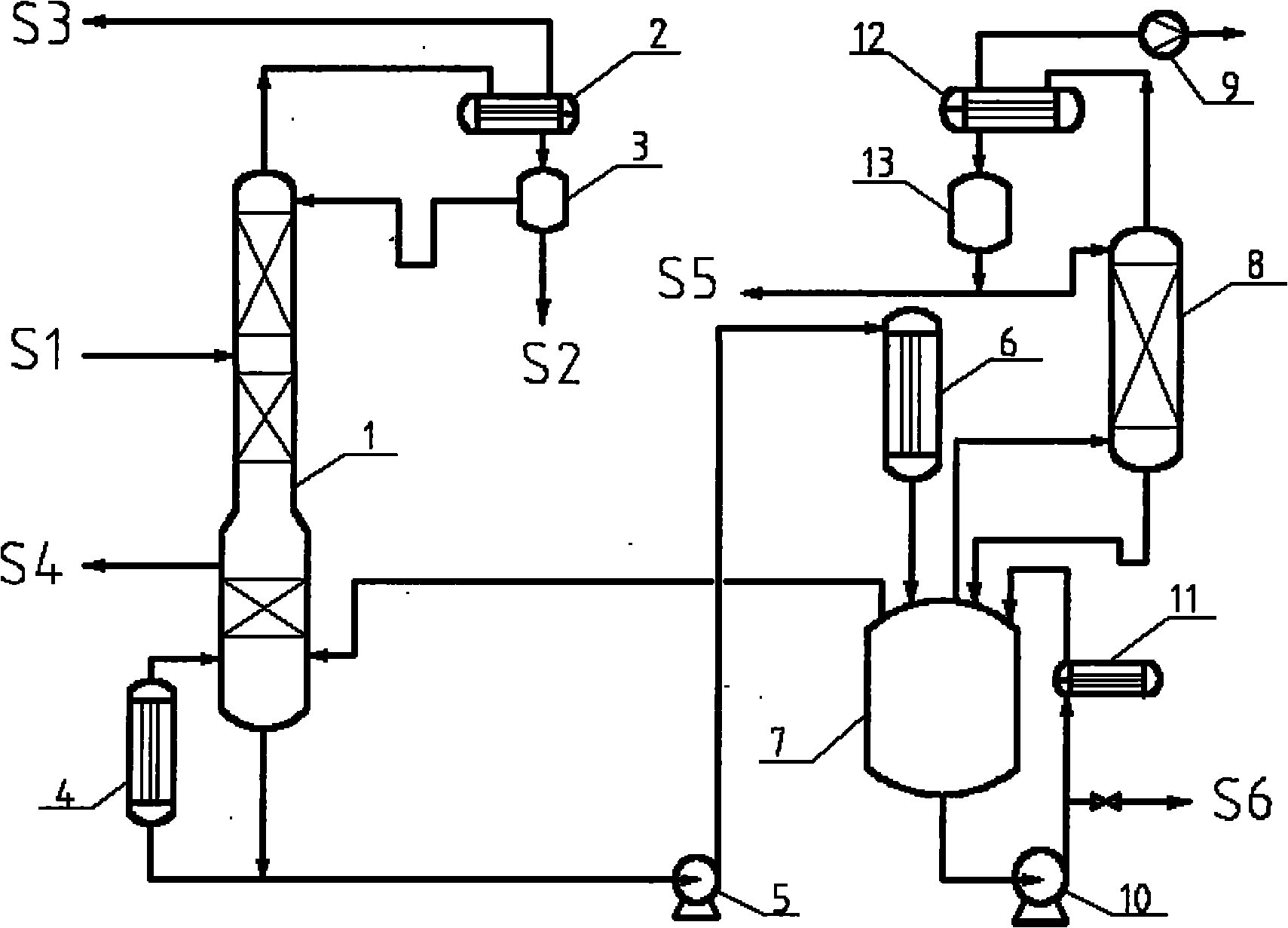

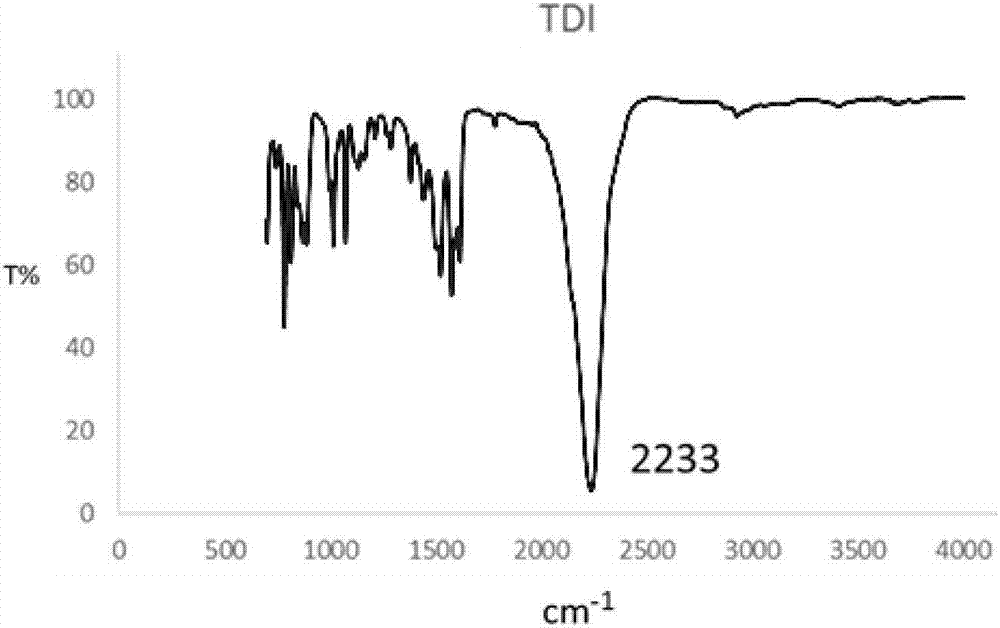

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

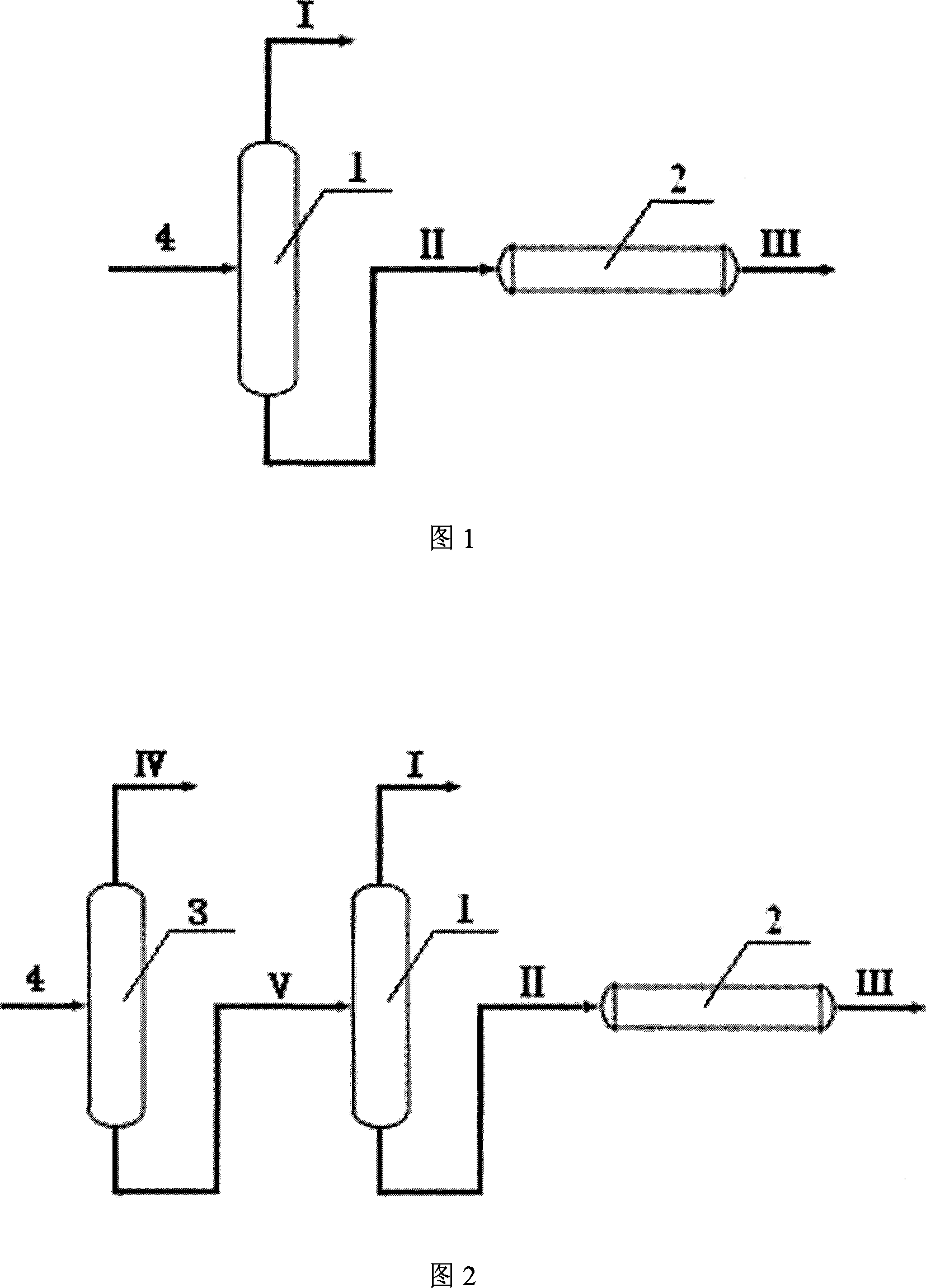

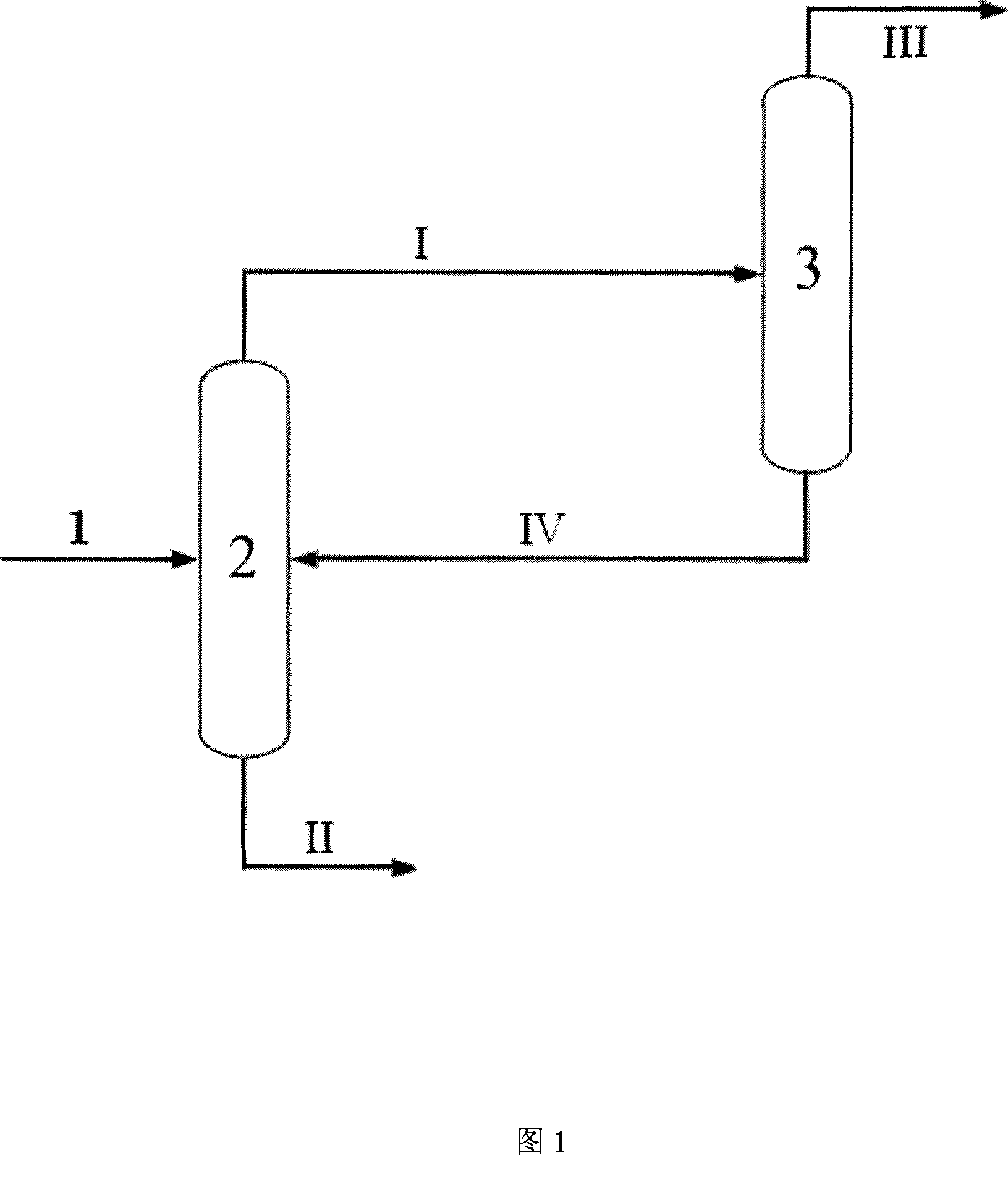

Postheating dimerization method for separating C5 diene

ActiveCN101100412AReduce volumeReduced temperature control requirementsDistillation purification/separationHydrocarbonsEngineeringAlkene

A method for separating C-5-diene-hydrocarbon from after-heating dimerization is carried out by cracking C-5 fraction to enter into middle of isoprene separating tower 1, separating at tower top to obtain material circulation Icontaining isoprene, separating to obtain isoprene, separating by tower to obtain material circulation IIcontaining cyclopentadiene and metapentadiene, entering material circulation IIinto thermal dimmer reactor 2 to generate material circulation III containing bicyclo-pentylene, after-refining and separating to obtain final product. It has less loss and better purity.

Owner:SINOPEC SHANGHAI ENG

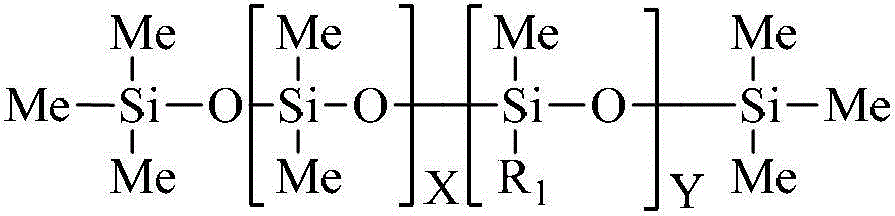

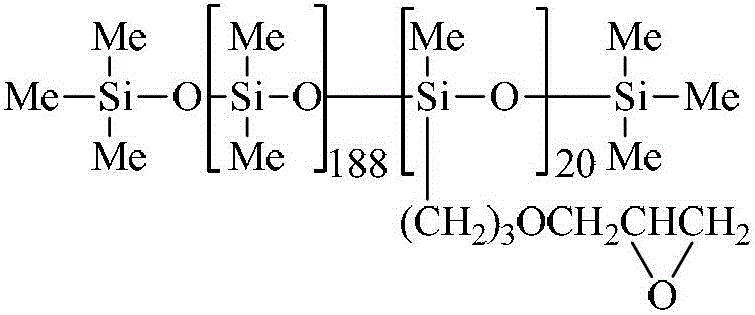

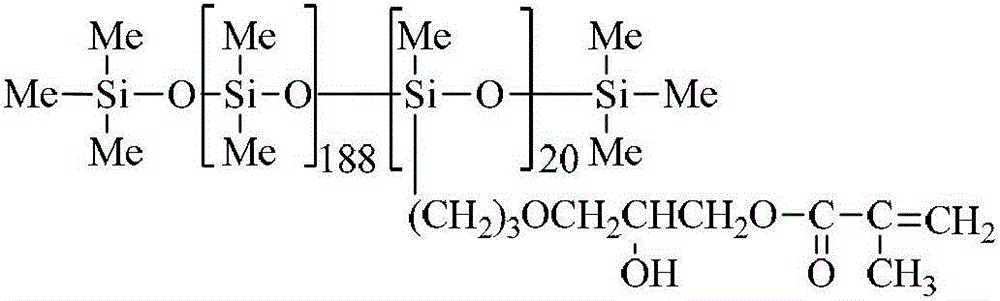

Preparation method for organosilicone acrylate

The invention discloses a preparation method for organosilicone acrylate, and belongs to the preparation field of coating defoamer. The method comprises two steps of preparing an epoxy organosilicone intermediate by reacting low hydrogen-containing silicone oil and an unsaturated epoxy compound; and then preparing organosilicone acrylate by reacting the obtained epoxy organosilicone intermediate and unsaturated carboxylic acid. Compared with a conventional synthetic method for organosilicone acrylate, the method provided by the invention prevents phenomena of self-polymerization and copolymerization of bi-functional monomers, obtains a series of organosilicone acrylate containing different side chain acrylic ester groups by selecting different raw materials and reaction conditions, overcomes the disadvantage that side chain acrylic ester groups are constant, meets the requirements for good defoaming property and good levelling property of the organosilicone acrylate defoamer in an ultraviolet-curable coating system.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

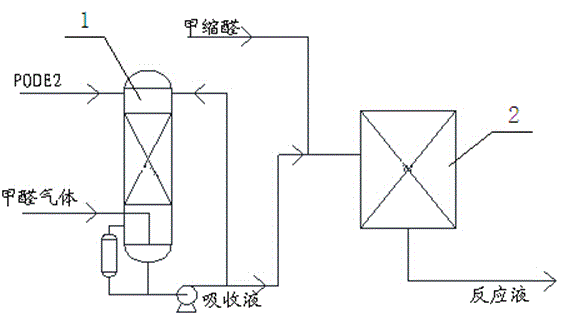

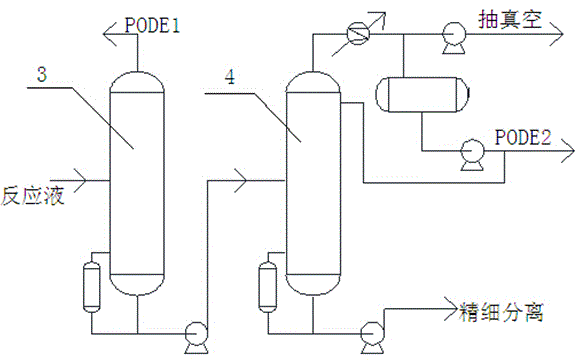

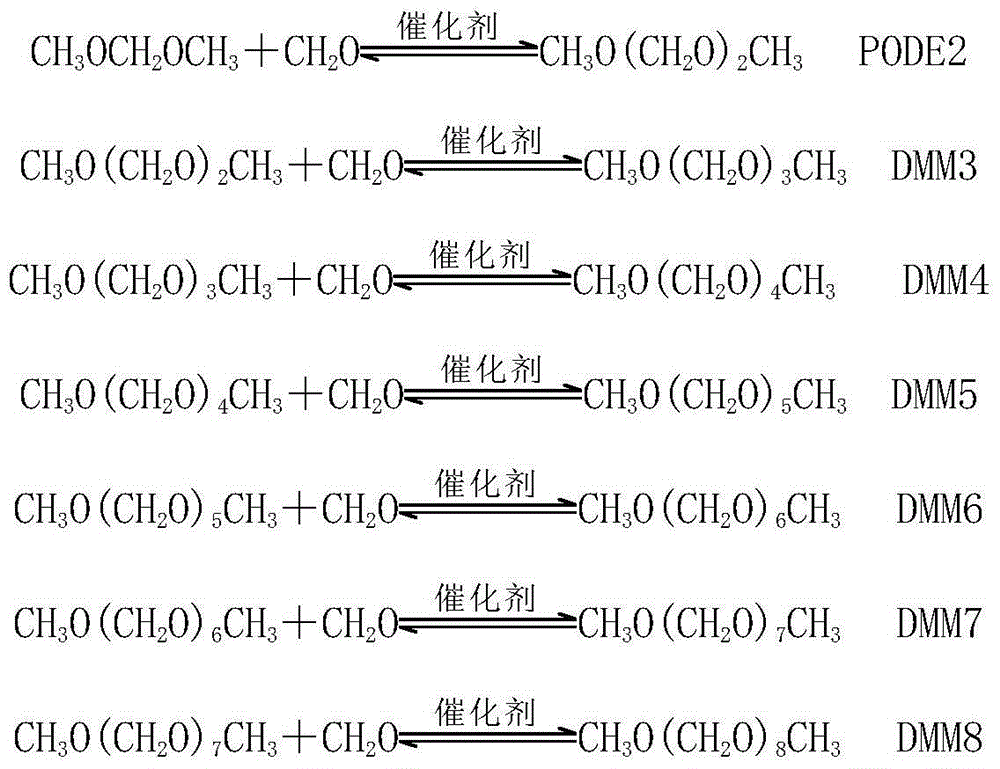

Process unit and method for absorbing formaldehyde in polymethoxy dimethyl ether synthesis

ActiveCN104817440APrevent self-aggregationAvoid reactionOrganic chemistryOrganic compound preparationBoiling pointDimethoxymethane

The invention discloses a process unit and method for absorbing formaldehyde in polymethoxy dimethyl ether synthesis. According to the process, higher-boiling-point intermediate component dimer PODE2 of polymethoxy dimethyl ether is adopted, the formaldehyde dissolved amount is much higher than the methylal dissolved amount, and a PODE2 solution of formaldehyde is obtained, so that the operating pressure and temperature for the subsequent reaction are on the lower level, thereby avoiding the self-polymerization and disproportionation reaction of the formaldehyde, further avoiding the pipeline blockage, lowering the acid content in the polymethoxy dimethyl ether product, and finally enhancing the product yield.

Owner:JIANGSU KAIMAO PETROCHEM TECH

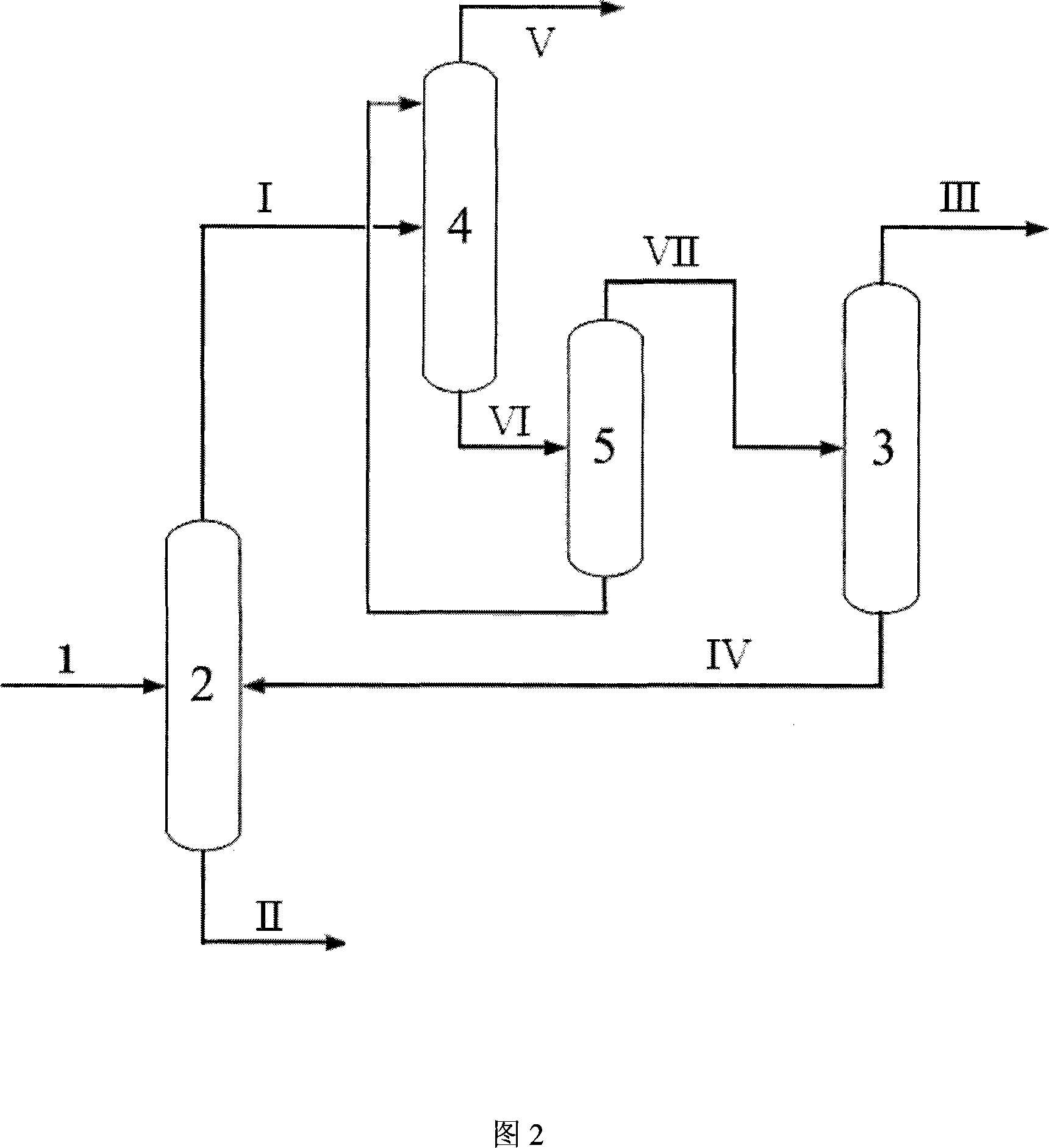

Method for separating isoprene by combined rectification

ActiveCN101104573APrevent self-aggregationAvoid lostDistillation purification/separationComing outBoiling point

The invention relates to a combined isoprene rectification and separation method, mainly aimed at solving the problems in prior art that when to separate and crack the diolefin in c_5 fraction, the raw materials have to enter a thermal dimerization reactor first, resulting in great losses of isoprene and cyclopentadienyl, and that because the boiling points of isoprene and cyclopentadienyl are nearly the same, the cyclopentadienyl affects the purity of the product isoprene and a part of cyclopentadienyl is lost, and particularly the problem that the isoprene knockout tower has high temperature and is energy-consuming. The invention makes the c_5 materials enter the isoprene knockout tower2 from the middle; after separation, material flow I containing isoprene comes out from the top of the tower and the material flow II containing cyclopentadienyl comes out from the bottom of the tower for later processing. Then the material flow I enters the cyclopentadienyl recycling tower from the middle part, after separation the material flow III coming out from the top of the cyclopentadienyl recycling tower enters the follow-up isoprene refining process and the cyclopentadienyl material flow coming out from the bottom of the cyclopentadienyl recycling tower circulates to the middle part of the isoprene knockout tower2. With such technique proposal, the invention solves the problems, thus the invention can be applied to the industrial production of separating the diolefin in c_5 fraction.

Owner:SINOPEC SHANGHAI ENG

Method for preparing ester compound by colophony and glycidyl methacrylate

InactiveCN102659598APrevent self-aggregationLow reaction temperatureOrganic compound preparationCarboxylic acid esters preparationMethacrylatePolymer science

The invention discloses a method for preparing an ester compound by colophony and glycidyl methacrylate. The method comprises the following steps of: dissolving 10 parts by weight of colophony in 10-300 parts by weight of toluene solvent, adding 20-100 parts by weight of glycidyl methacrylate, evenly mixing in a stirring way, adding 0.2-3 parts by weight of catalyst triethylamine and 0.1-1 part by weight of polymerization inhibitor hydroquinone, heating to lead the reaction temperature to keep at 60-100 DEG C, reacting for 5-10h, and after ending the reaction, and distilling by means of pressure reduction under the temperature of 70DEG C and the vacuum degree of 0.1MP to recover solvent toluene, so that the obtained product is the ester compound prepared by colophony and the lycidyl methacrylate. The preparation method has the advantages that the raw material is easy to take, the one-step method is simple in reaction operation, reaction temperature is low, the energy consumption can be saved, the solvent is easy to recover and the like; and the obtained product contains an acryloxy functional group, is high in polymerization activity, and can be co-polymerized with other monomers, so that a ternary phenanthrene ring-containing polymer can be prepared.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of lithium ion battery anode slurry

The invention relates to a preparation method of lithium ion battery anode slurry. The method comprises the following steps: a. weighing anode slurry, an active material, a conductive agent, a thickener, a binder, a solvent and a surfactant in the lithium ion battery anode slurry ratio; b. mixing the thickener with the solvent in the raw materials, adding the conductive agent to the mixed solventafter full stirring, and continuing stirring the mixture uniformly; c, adding the surfactant to the mixture of step b, performing stirring, adding the active material in three batches, and fully stirring the mixture again for 1. 5 h to obtain slurry a with uniform appearance; d, adding the binder to the slurry a, and adjusting the viscosity of the slurry with the solvent in the stirring process toobtain the lithium ion battery anode slurry. With adoption of a step-by-step wet mixing process, the anode slurry is dispersed evenly, the conductive agent SP and the active material form a mutuallydispersed interlocking microstructure, stability is good, settling is not likely to occur, and peel strength of a prepared pole piece is significantly improved compared with that of a pole piece prepared with the traditional process.

Owner:天臣新能源研究南京有限公司

Method for preparing acetylacetone acid molybdenum

InactiveCN101117308AReduce pollutionPrevent self-aggregationGroup 6/16 element organic compoundsPreparation of aldehyde/ketone chelatesCelsius DegreeAntioxidant

The invention discloses a preparation process for molybdenum acetylacetonate. In the prior art, the acetylacetone is easy to be oxidized in the air and polymerized under refluence, so the unreacted molybdenum trioxide and by-products exist in the product, the product is impure and has low yields. In the invention, the molybdenum trioxide is dissolved into the weak-base inorganic alkaline solution, then the antioxidant is added into the solution, the temperature rises to forty to seventy Celsius system, the acetylacetone is dripped into the solution, then the non-oxidizing inorganic acid is added to adjust the solution to the weak acid, then the temperature is preserved until the crystal of molybdenum (II) 2,4-pentanedionate hydrate is precipitated; then the procedure of cooling, filtering, fulling is done to remove the adhesive acetylacetone from the filter cake. The invention is reacted with the molybdenum trioxide under low temperature, thereby the invention avoids the self-polymerization of the acetylacetone, and has less side reactions, high yields as well as high purity.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

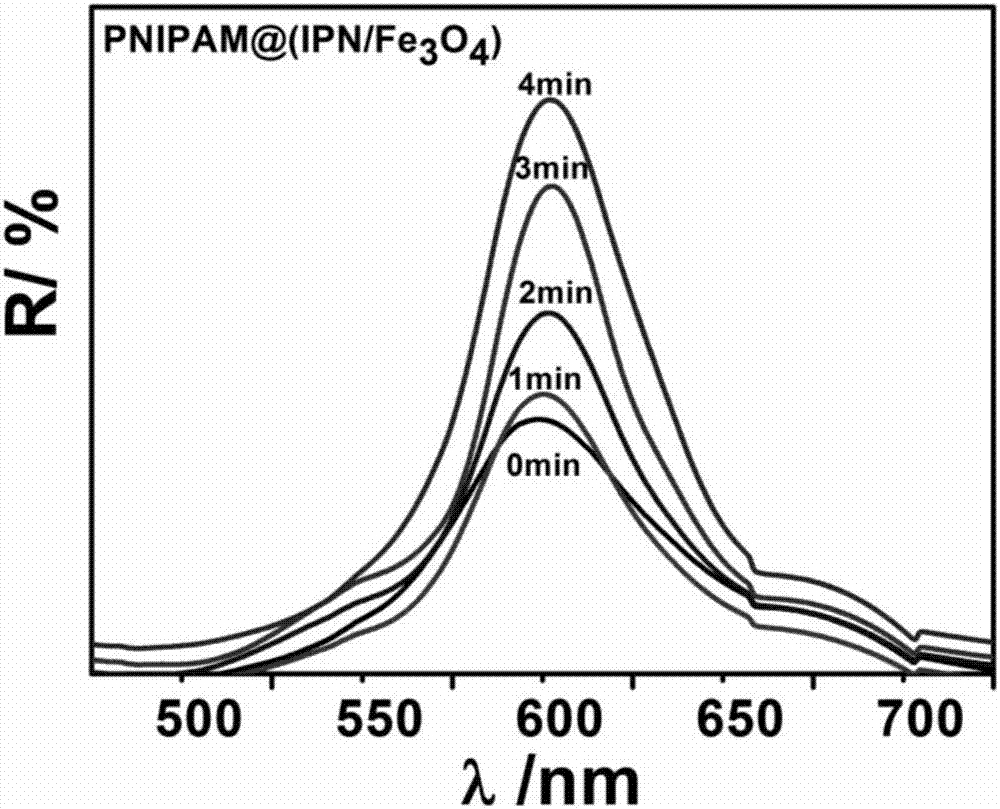

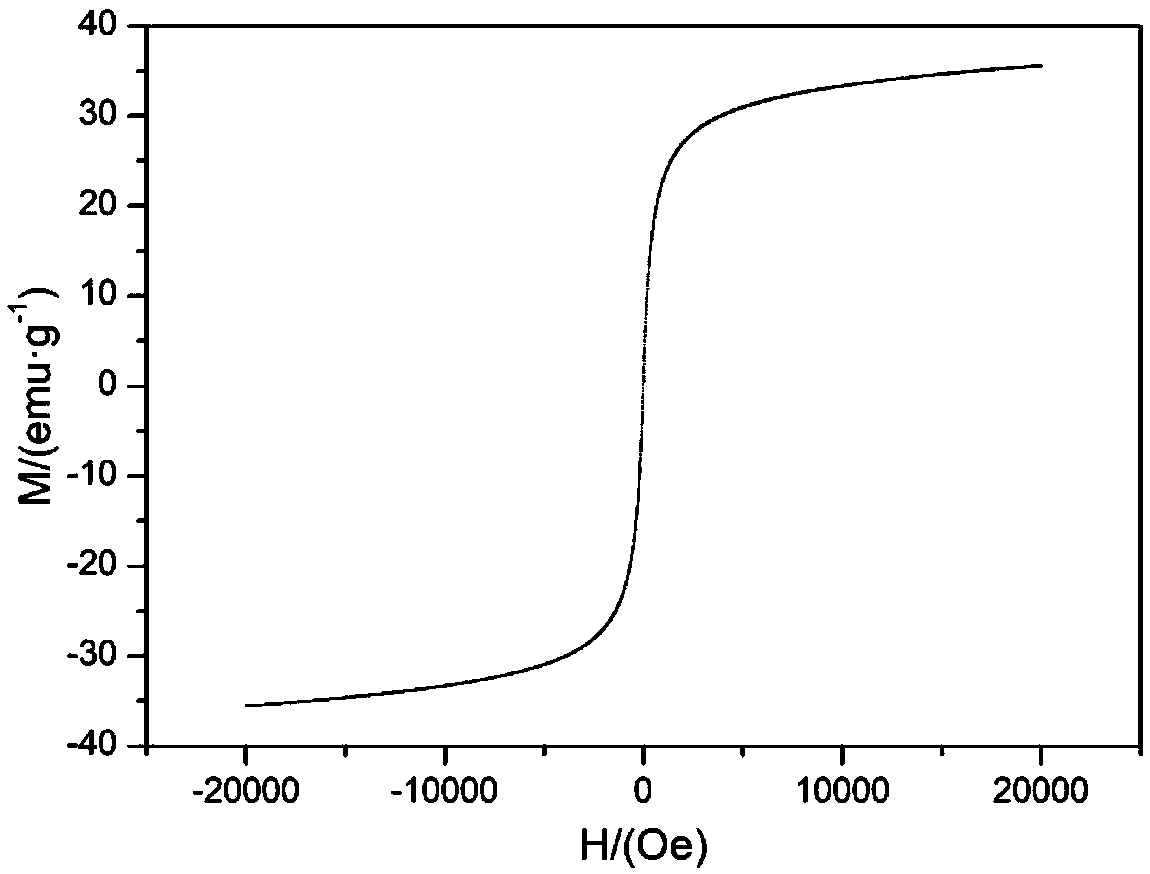

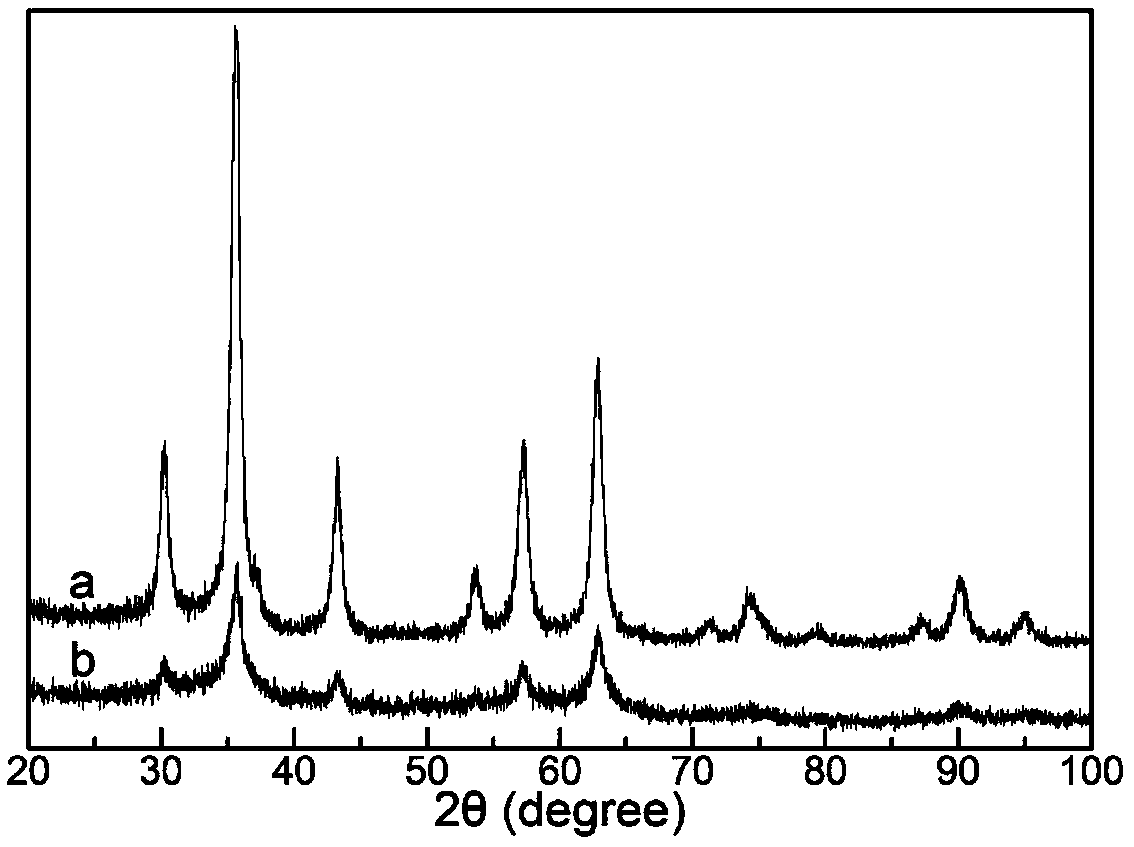

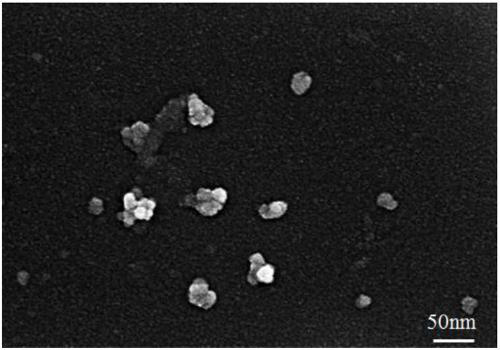

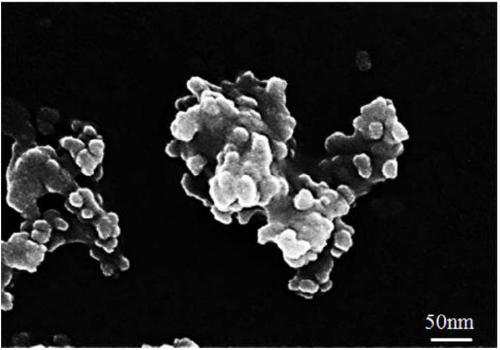

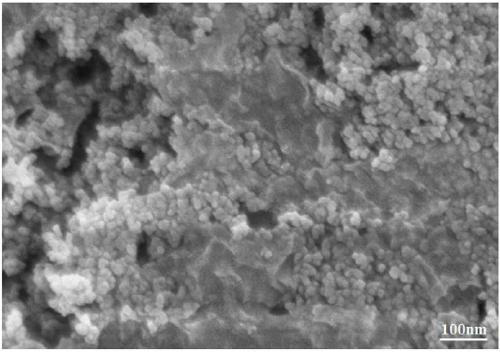

Preparation method of multiple response core-shell structure magnetic nanometer aquagel photonic crystals

ActiveCN107973876ASimple processRaw materials are easy to getEnvironmental resistancePhotonic crystal

The invention relates to a preparation method of multiple response core-shell structure magnetic nanometer aquagel photonic crystals. The method comprises the following steps that NIPAM, crosslinkingagents, emulsifying agents and initiators are mixed for reaction to obtain PNIPAM; dilution is performed by de-ionized water; crosslinking agents, AA, initiators and catalysts are sequentially added for continuous stirring and reaction; PNIPAM / PAA of an IPN structure is obtained; concentration is performed to 1 / 2 of the original mass concentration; reaction is performed with Fe<2+>, NaNO2 and ammonia water to obtain IPN / Fe3O4; NIPAM, crosslinking agents and initiators are added for reaction to obtain PNIPAM@(IPN / Fe3O4); concentration is performed to 2 to 8 weight percent; self assembly is performed to obtain the multiple response core-shell structure magnetic nanometer aquagel photonic crystals. The method has the advantages that the process is simple; the raw materials can be easily obtained; the green and environment-friendly effects are achieved; the prepared product has the core-shell structure and the temperature / pH / magnetic triplex response performance; great application prospects are realized in the fields of optics and biomedicine.

Owner:DONGHUA UNIV

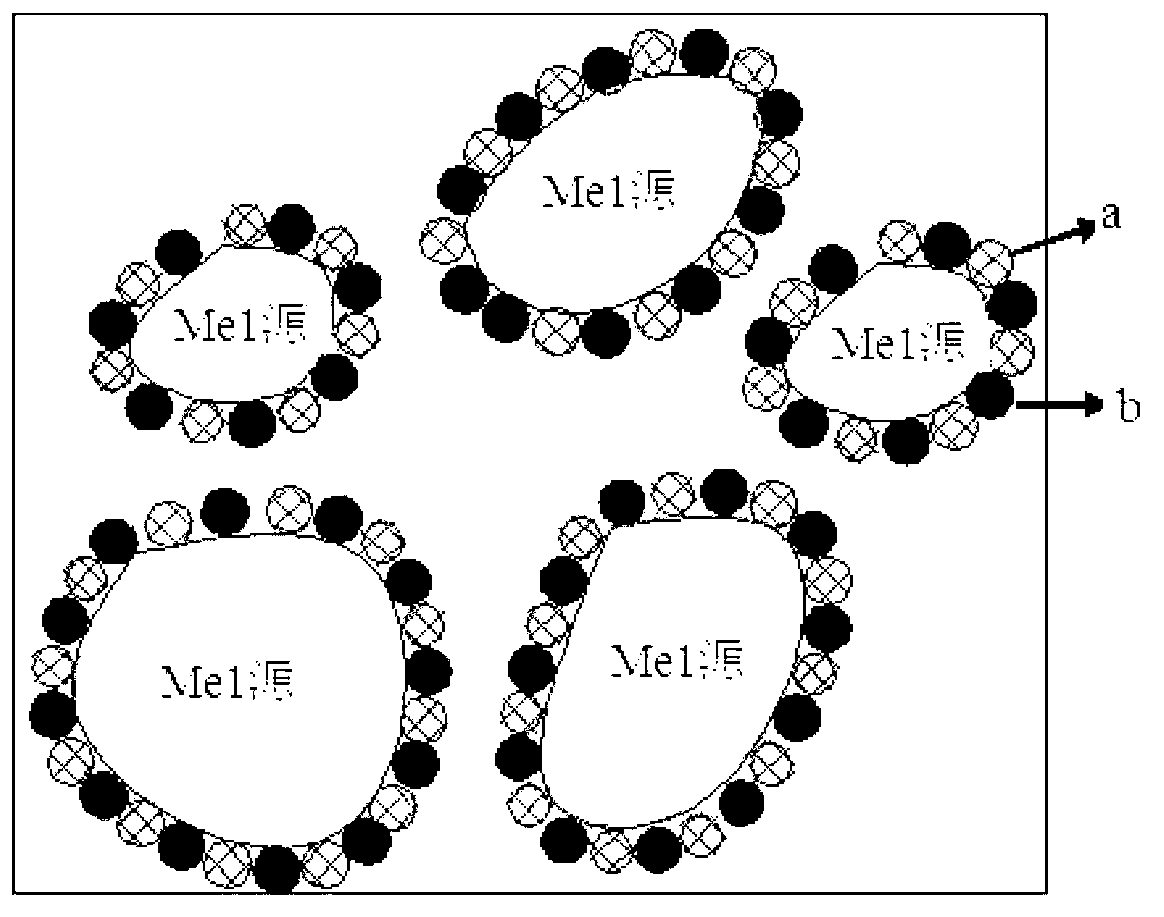

Uniformly dispersed electrode material and preparation method thereof

The invention discloses an electrode material. The chemical composition of the electrode material is LixMe1yMe2a(RO4)z, wherein Me1 is one of or composition of at least two of Mn, Fe, Ni, Co or V, Me2 is one of or composition of at least two of Mg, Mn, Cr, Ni or Al, R refers to P or / and Si, 1< / =x< / =4, 1< / =y< / =3, 1< / =z< / =5, and 0< / =a< / =0.2. The invention further discloses a preparation method of the electrode material. Small particles in solution uniformly wrap surfaces of large particles under the interaction of positive and negative charges of anionic dispersants and cationic dispersants, self-aggregation of the particles is avoided, the wrapping state cannot be destroyed in a precursor forming process, and the obtained electrode material is fine and uniform in crystal particle and good in electrical conductivity and cycle performance and is coated with a thin carbon layer on the surface.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

Method for directly synthesizing polyoxymethylene dimethyl ether by taking dilute formaldehyde and methylal as raw materials

InactiveCN106631720ALess investmentLow costOrganic chemistryOrganic compound preparationMoistureDehydration

The invention discloses a method for directly synthesizing polyoxymethylene dimethyl ether by taking dilute formaldehyde and methylal as raw materials. The method comprises the following steps: directly mixing dilute formaldehyde and methylal, removing the moisture through a membrane separation process, and carrying out a condensation reaction, thereby obtaining the polyoxymethylene dimethyl ether. According to the method disclosed by the invention, the membrane separation dehydration process and the catalytic condensation reaction are efficiently coupled, the polyoxymethylene dimethyl ether is directly synthesized by taking the dilute formaldehyde and methylal as raw materials, and the method achieves the effects of investment conservation and low cost and has high comprehensive benefits in technical economy.

Owner:东方红升江苏新能源有限公司 +1

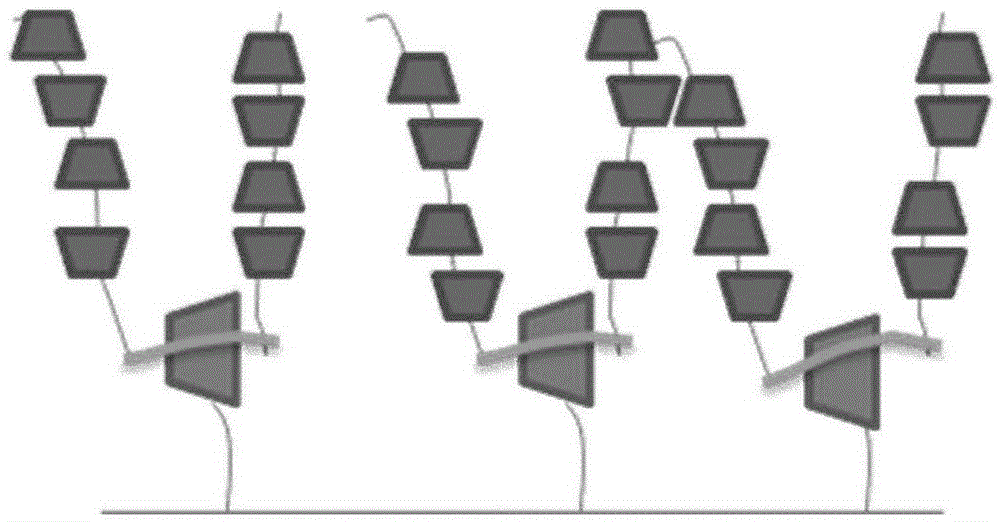

Dentin reactive monomer mixture and preparing method, polycarboxylic oligomer and preparing method, and dental composite resin bonding systems

ActiveCN107028770AFacilitated DiffusionImprove adsorption capacityImpression capsDentistry preparationsWet bondingHydrophilic monomer

The invention provides a dentin reactive monomer mixture and a preparing method, a polycarboxylic oligomer and a preparing method, and dental composite resin bonding systems, wherein the dentin reactive monomer mixture and the polycarboxylic oligomer are used for constructing the dental composite resin bonding systems. The invention further provides a single-component dental composite resin bonding systems and a double-component dental composite resin bonding system. The bonding systems overcome the defect that due to the fact that a large number of hydrophilic monomers are introduced into a traditional wet bonding technique, cured resin can be easily degraded by esterase in saliva as the water absorption rate is increased remarkably.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

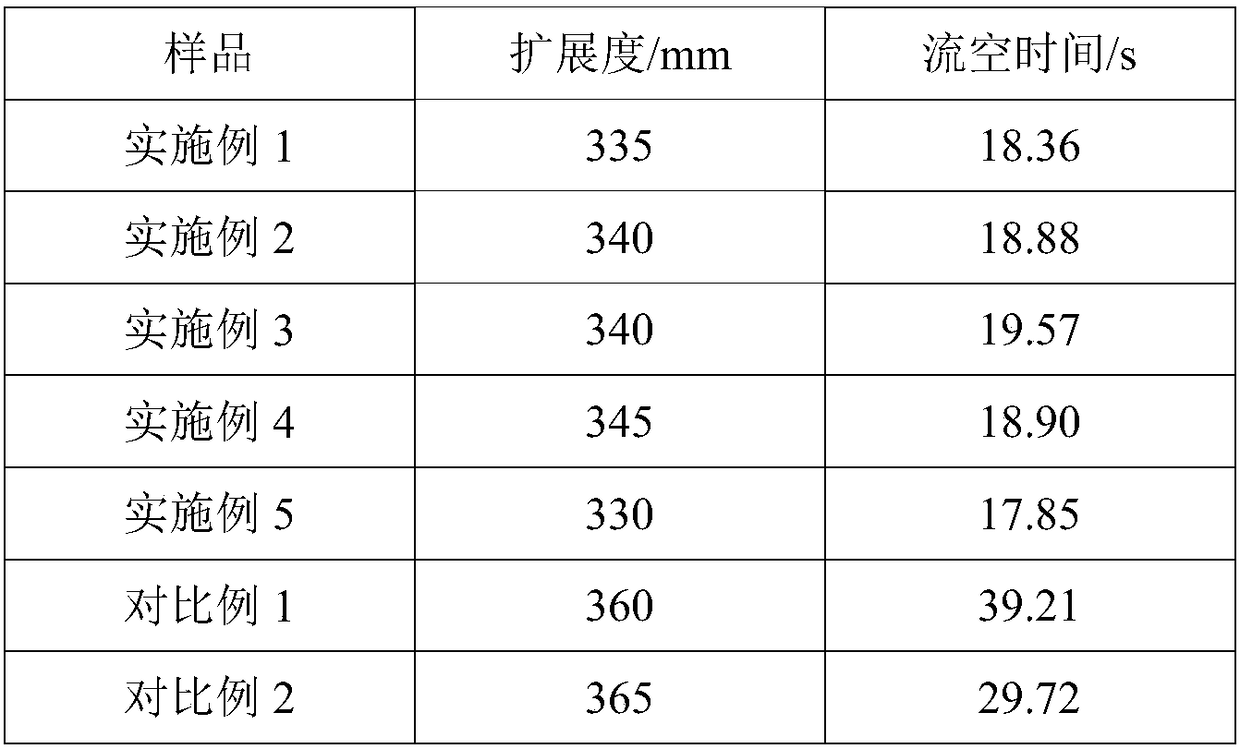

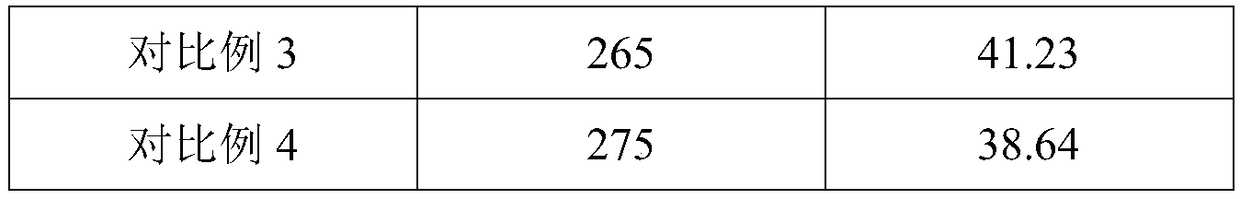

Preparation method of viscosity-reducing type polycarboxylate water reducer

ActiveCN109053974AImprove hydrophilic-lipophilic balanceHas the effect of lubricating and reducing viscosityPhosphateHydrophilic-lipophilic balance

The invention provides a preparation method of a viscosity-reducing type polycarboxylate water reducer. The viscosity-reducing type polycarboxylate water reducer is obtained by free radical polymerization of TPEG monomers, unsaturated dibasic acid monomers or derivative monomers thereof, and viscosity-reducing assistants according to the mole ratio of 1:(3-6):(0.1-0.5) under the action of reducingagents, oxidizing agents and chain transfer agents, wherein the viscosity-reducing assistants are diethanolamide fumarate phosphate. The preparation method has the advantages that the unsaturated dibasic acid monomers or derivative monomers thereof, the diethanolamide fumarate phosphate and the TPEG monomers are subjected to copolymerization, the proportion of polar hydrophilic groups on molecular chains of the TPEG monomers can be increased through two carboxyl groups, introduced into the unsaturated dibasic acid monomers or derivative monomers thereof, and polar groups in the diethanolamidefumarate phosphate, such as ethanol, amide and phosphate groups, the hydrophilic-lipophilic balance of the water reducer is increased, and accordingly, the viscosity reducing effect of the water reducer is improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

5,6-dihydropyrane and preparation method for derivative thereof

InactiveCN101143860ALess corrosivePrevent self-aggregationOrganic chemistryDepolymerizationPresent method

The invention discloses a preparation method of a 5, 6-dihydrogen-pyran and the derivatives of the 5, 6-dihydrogen-pyran. In the present methods, the self-polymerization of conjugate dienes is easily happened in a synthesis reaction, and as a result, the yield rate of products is low. In the invention, under the catalysis of lewis acid, the conjugate dienes and anhydrous formaldehyde synthesize the 5, 6-dihydrogen-pyran and the derivatives by the Diels-Alder reaction; after being depolymerized by paraformaldehyde, trioxymethylene or polyoxymethylene in another reaction kettle, the anhydrous formaldehyde in the form of gas enters into the reaction kettle of synthesis reaction which is carried out under the temperature between 30 DEG C and 100 DEG C. Because the invention separates the depolymerization from the synthesis, the synthesis reaction does not have to be carried out under a high temperature, the self-polymerization of conjugate dienes is avoided, and therefore the yield rate of reaction is increased.

Owner:ZHEJIANG NHU CO LTD

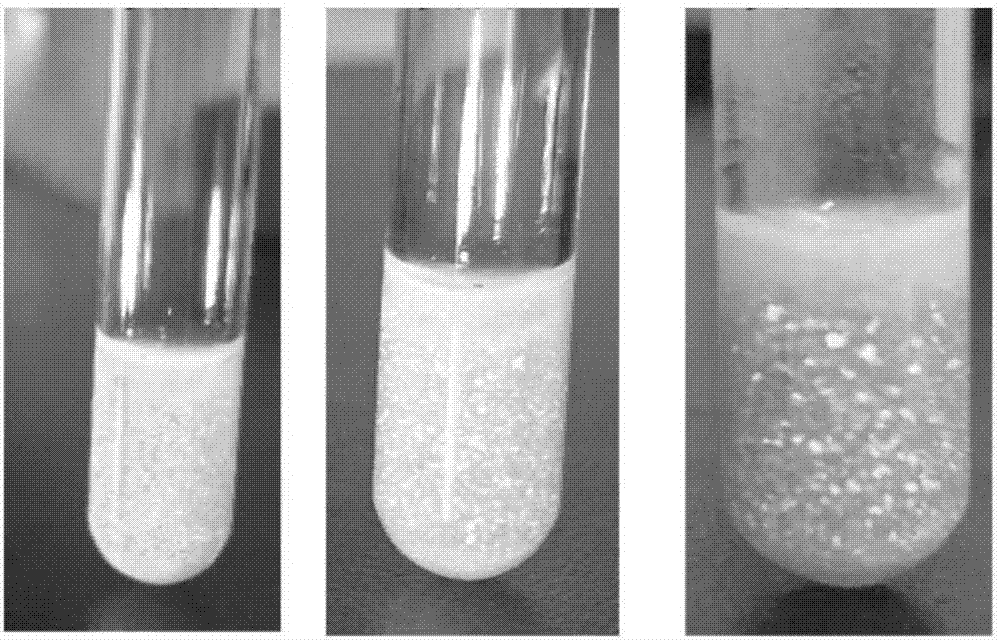

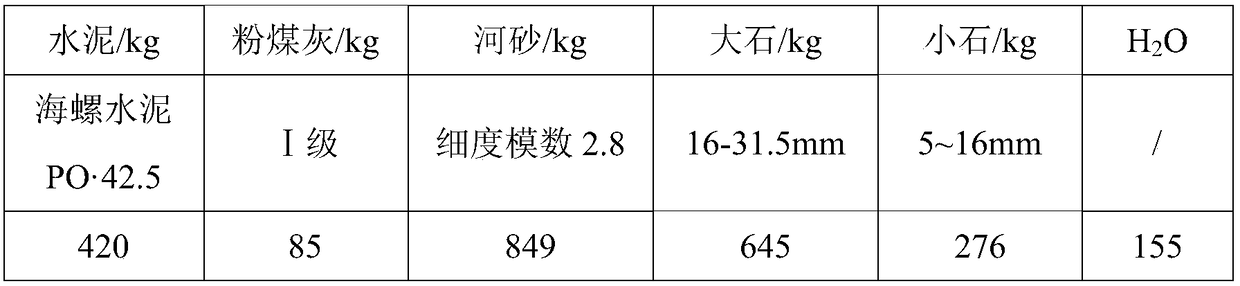

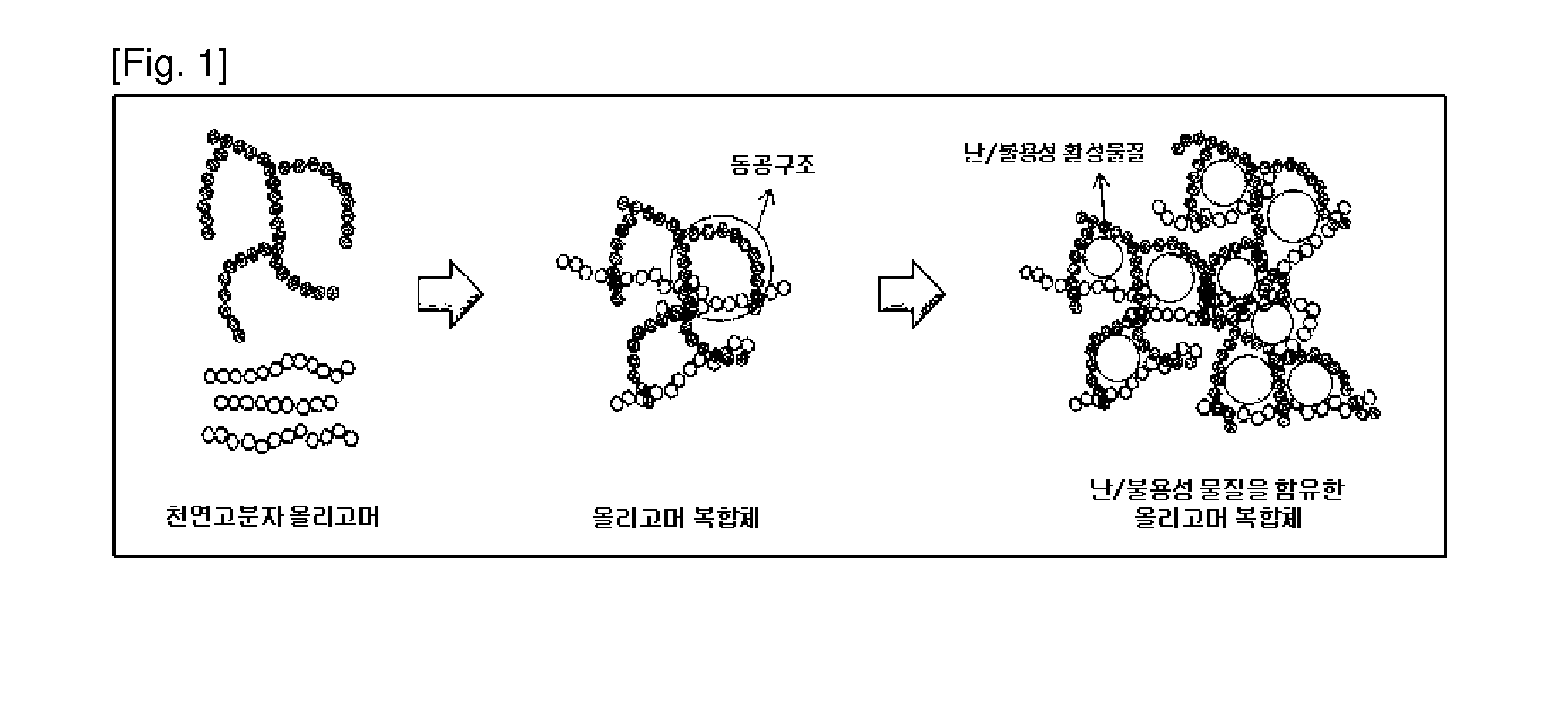

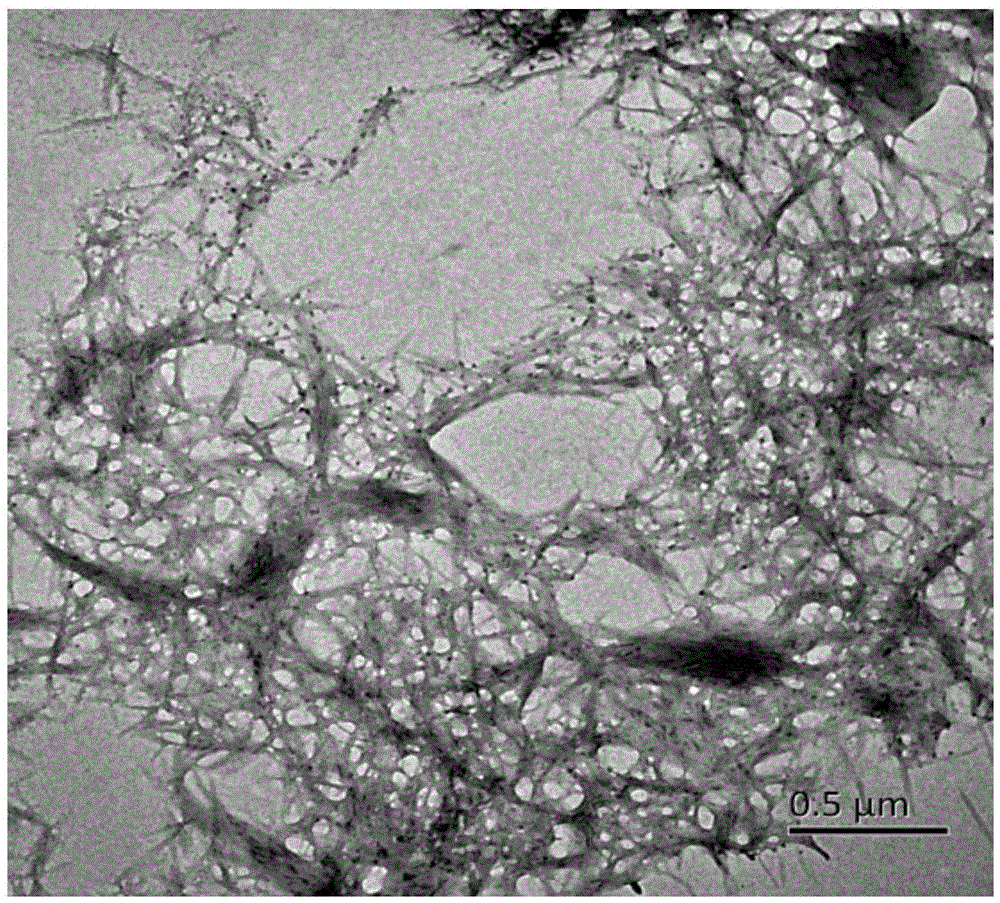

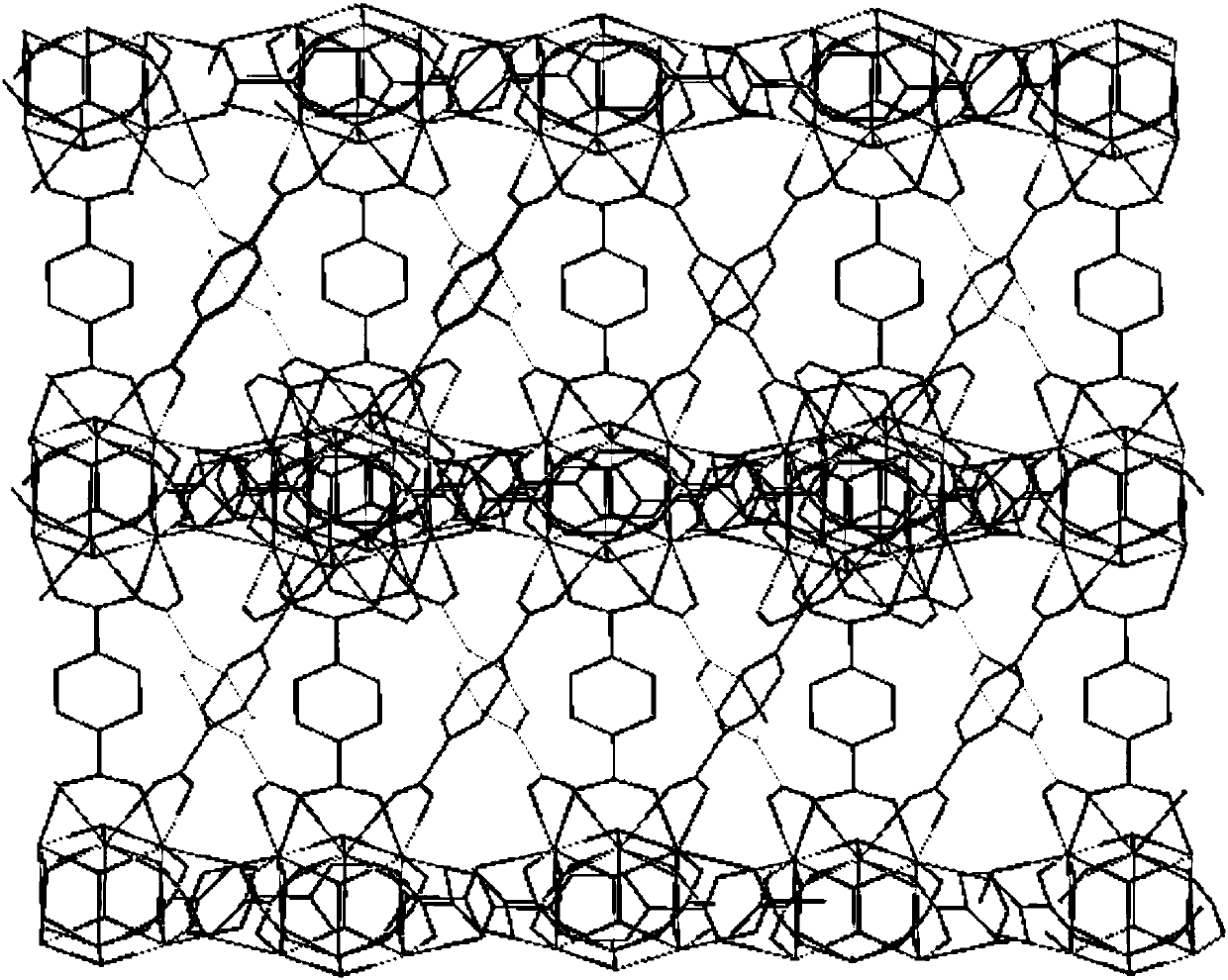

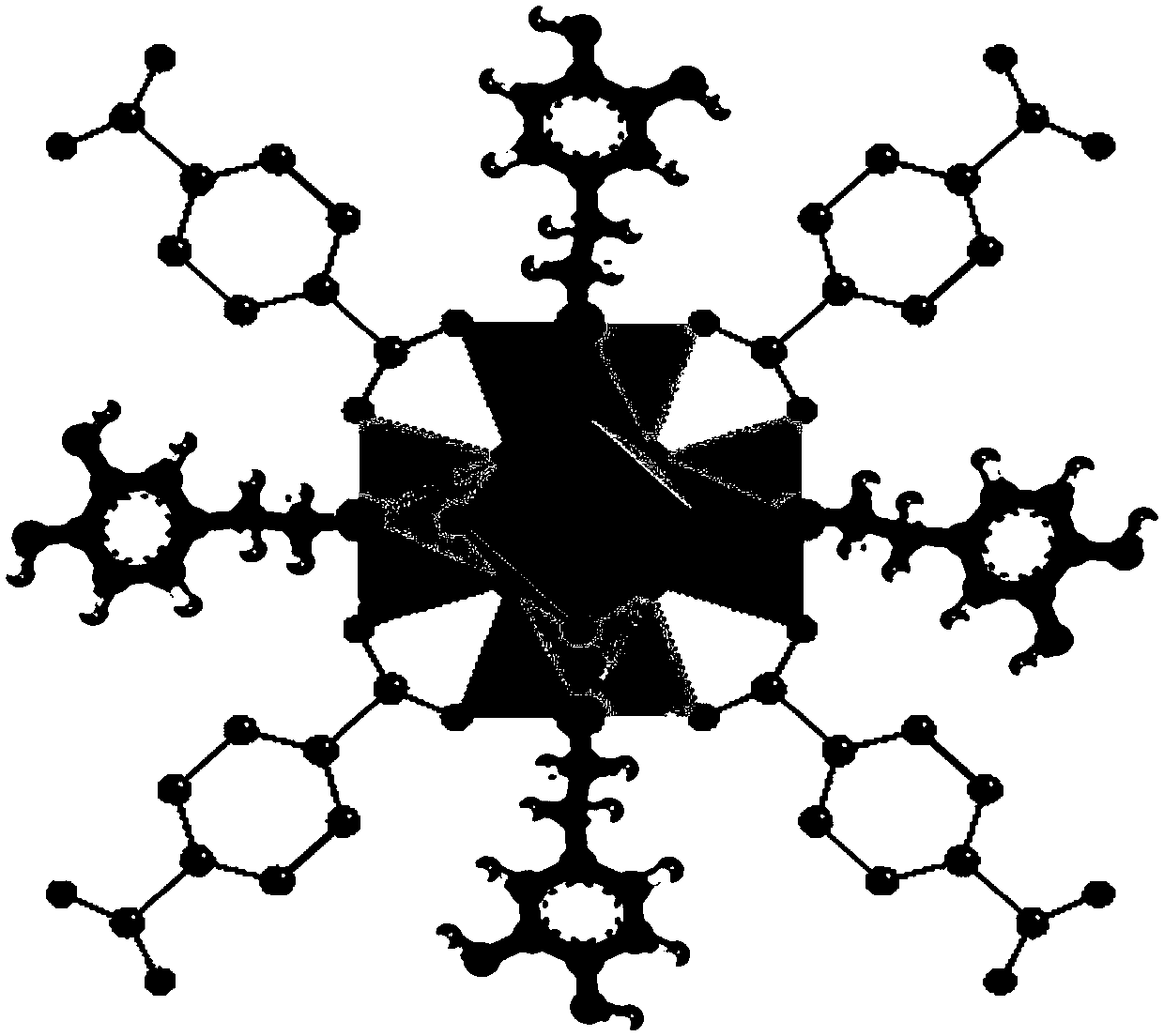

Method of solubilizing poorly soluble/insoluble active material through formation of oligomer composite

ActiveUS20120219604A1High thermodynamic stabilityPoor materialOrganic chemistryCapsule deliverySolubilityCrystallography

Provided is a method of solubilizing a poorly soluble / insoluble active material through formation of an oligomer composite, in which a structure having a hydrophobic cavity structure is formed by using oligomers derived from two types of hydrophilic natural polymers and a poorly soluble / insoluble component is encapsulated in the cavity structure, and thus, self-aggregation of the poorly soluble / insoluble material is prevented and simultaneously, thermodynamic stability increases to effectively solubilize the poorly soluble / insoluble material. According to the constitution of the present invention, the method may include a first operation of preparing an oligomer composite having a cavity structure formed therein by mixing and dissolving oligomers derived from two types of hydrophilic natural polymers in water, and a second operation of adding a poorly soluble / insoluble material to the oligomer composite to encapsulate the poorly soluble / insoluble material in the hydrophobic cavity structure of the oligomer composite.

Owner:BIOGENICS

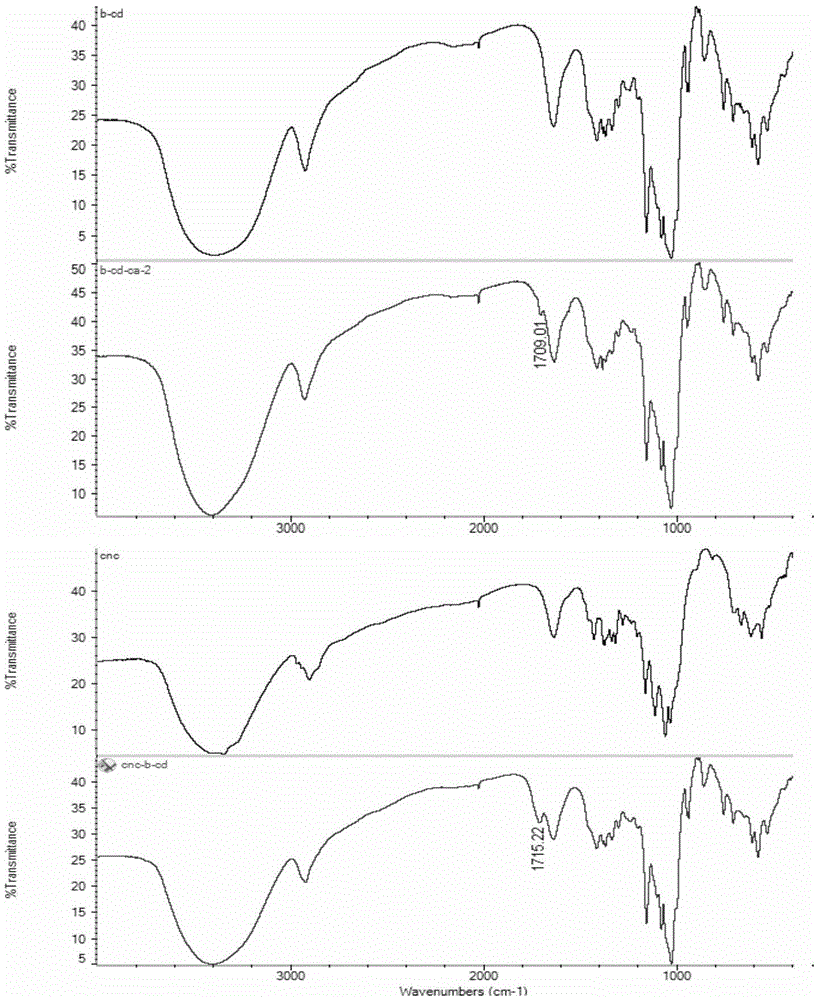

Preparation method of composite cyclodextrin hydrogel

ActiveCN105622962AWide range of adsorptionImprove adsorption capacitySodium Hypophosphite MonohydrateGraft reaction

The invention discloses a preparation method of composite cyclodextrin hydrogel. The preparation method comprises the following steps that 1, sodium hypophosphite is used as a catalyst, and beta-cyclodextrin and citric acid are subjected to a grafting reaction; 2, a grafting product of the beta-cyclodextrin and the citric acid is grafted to nano-microcrystalline cellulose by using the sodium hypophosphite as the catalyst; 3, ppo segment and chain of triblock copolymer pluronic enters a cavity of the product in the step (2) through ultrasonic treatment; 4, alpha-cyclodextrin is added, and standing is performed for hydrogel forming. The prepared hydrogel has the unique structure and good biocompatibility, the gelation time is short, the gelation strength is higher than that of common gel, and hydrogel can be formed at room temperature; the application prospect is wide in the aspects of functional materials, biological medicine carrying and the like.

Owner:JIANGNAN UNIV

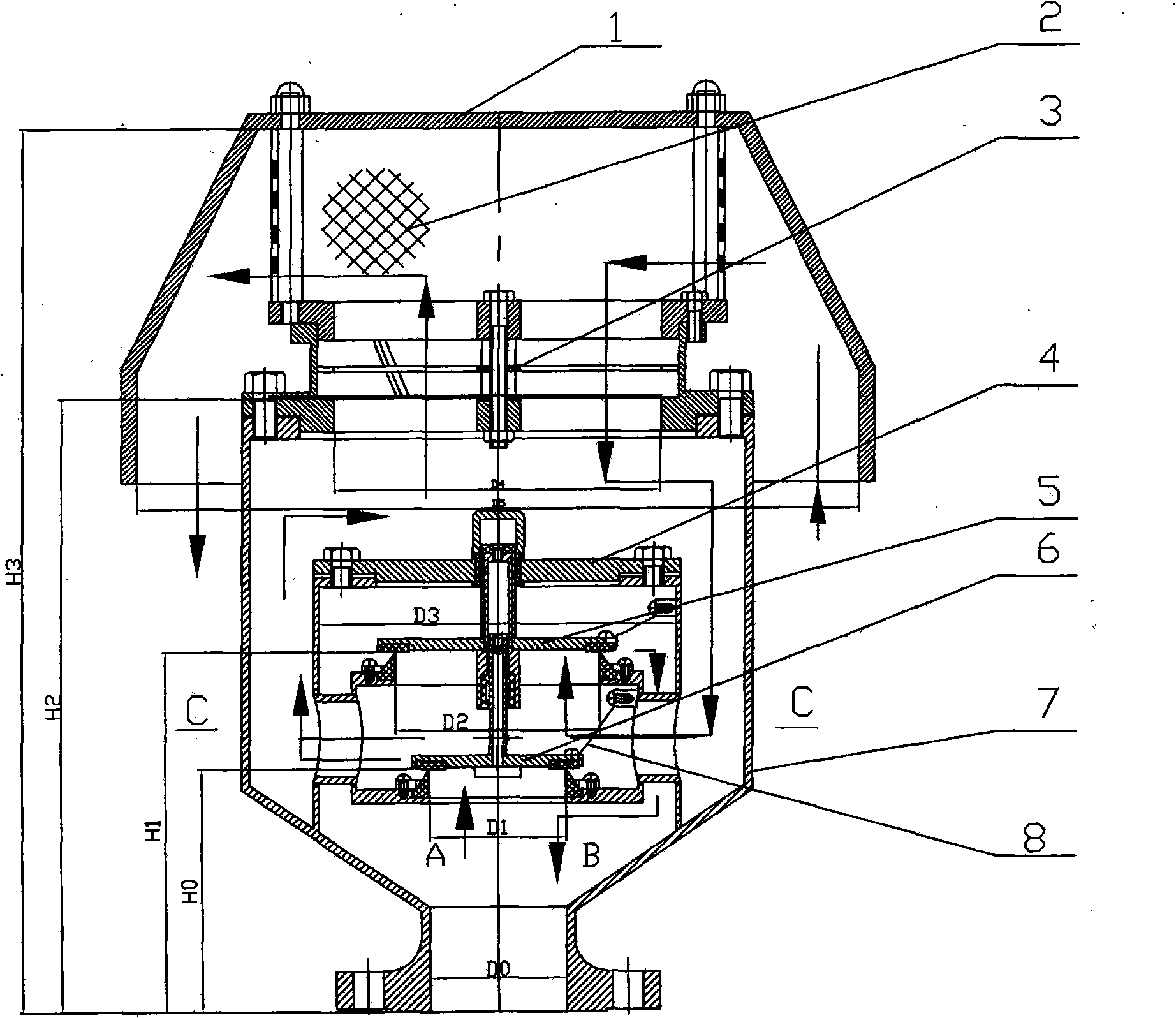

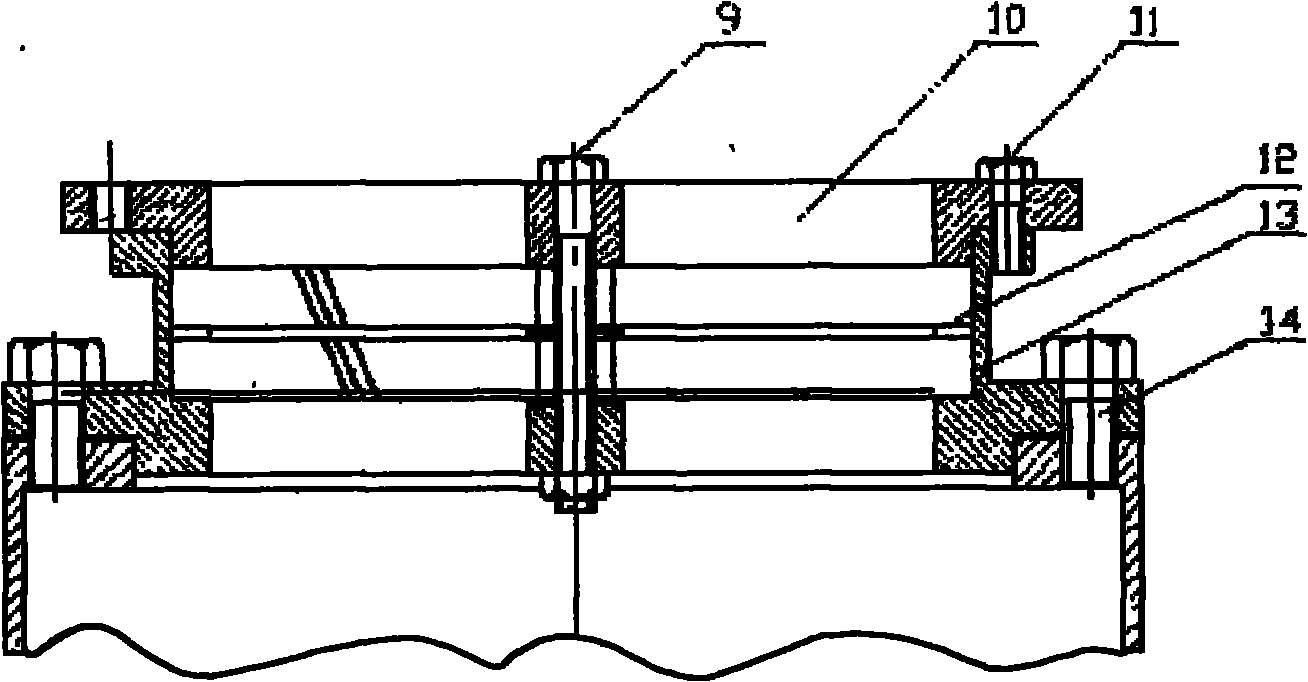

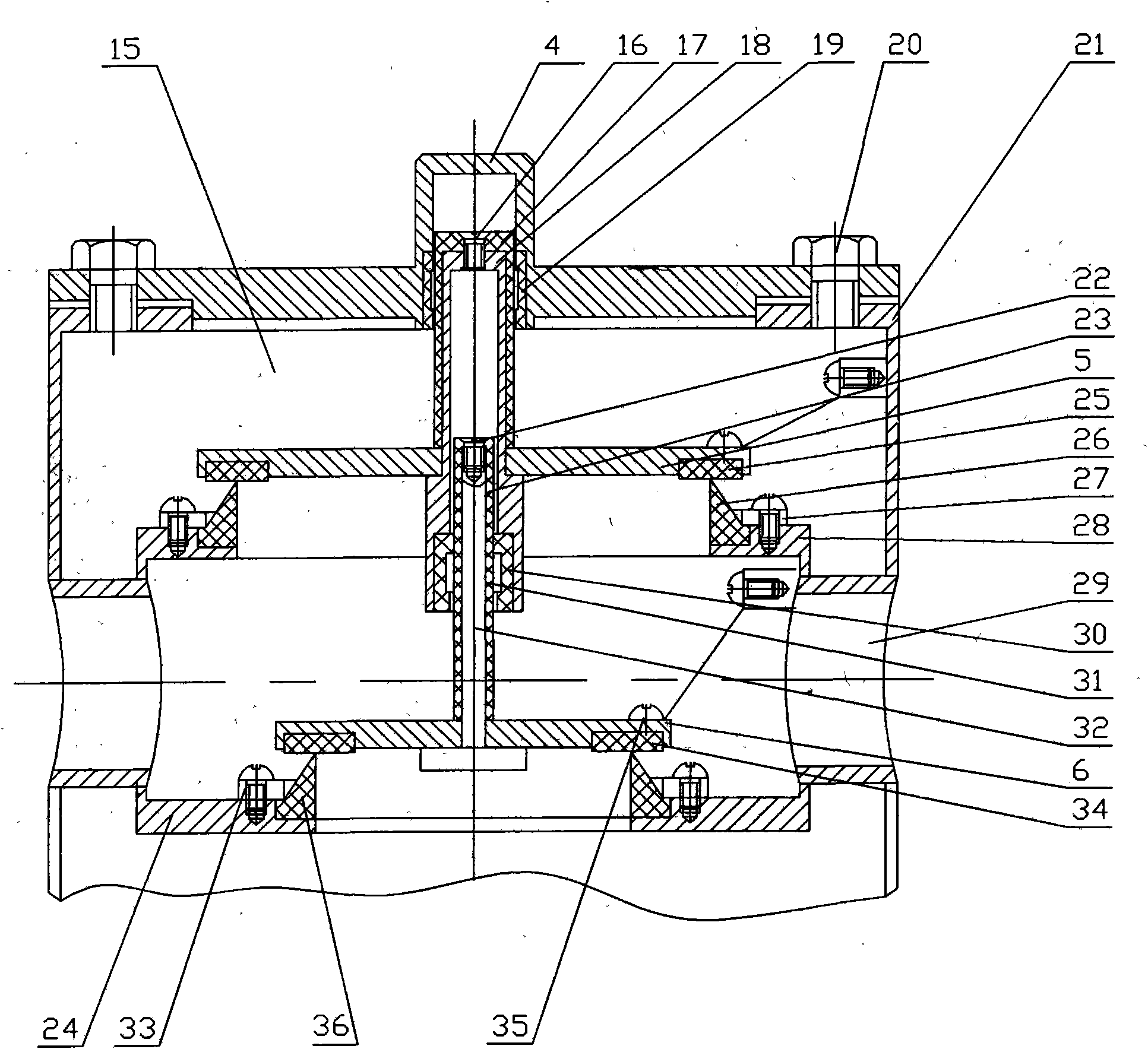

Vertical coaxial anti-explosion fire-retardant breather valve

The invention belongs to fire-retardant ventilation equipment of a petroleum storage tank, which consists of an anti-explosion flame arrester and a breather valve. The flame arrester is positioned at the top and plays a role in preventing explosion first and then preventing fire. The top of a breather valve cavity consisting of a vacuum valve and a pressure valve is provided with a pressure cavity sealing guide sleeve cover. The vertical movement of a vacuum valve disk is restrained by a guide sleeve of the pressure cavity sealing guide sleeve cover, and the vertical movement of a pressure valve disk is restrained by a guide rail of the vacuum valve disk. The fire-retardant ventilation equipment has reasonable design. Particularly, the pressure cavity sealing guide sleeve cover at the breather valve further plays a role in blocking the breather valve and the anti-explosion flame arrester, effectively adds the functions of flame arrest and explosion prevention, and enhances the safety and reliability of the whole equipment. The vertical coaxial symmetrical mounting structure stabilizes the center of the equipment; and the pressure valve disk and the vacuum valve disk are stressed uniformly so as to prolong the service life of the equipment, reduce the maintenance frequency and the production cost, facilitate assembly and disassembly, facilitate the operation and maintenance of a tank top and improve the production efficiency.

Owner:抚顺华海石油机械制造有限公司 +1

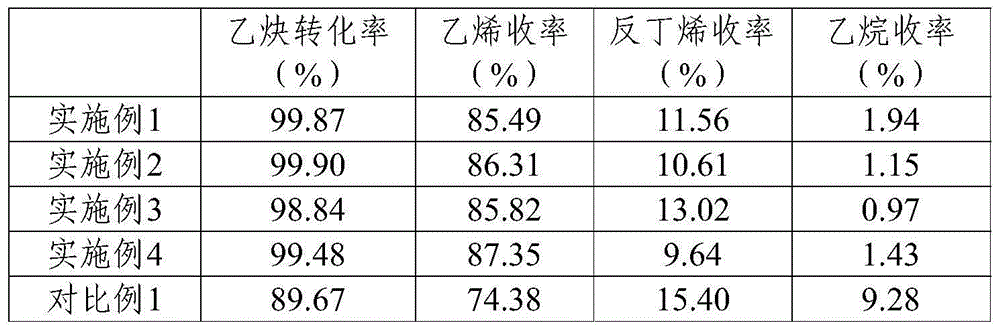

Method for preparing ethylene by heterogeneous reaction

ActiveCN104829406AReduce surface tensionLow yieldHydrocarbon by hydrogenationSlurry reactorGas phase

The invention relates to a method for preparing ethylene by heterogeneous reaction. The method comprises the following steps: (1) providing a hydrogen-containing gas-phase material; (2) absorbing acetylene with a liquid-phase solvent with the surface tension of at most 1mN / m to form a liquid-phase material; (3) providing a heterogeneous reaction system uniformly composed of the liquid-phase material, the gas-phase material and a hydrogenation catalyst, wherein the reaction temperature of the heterogeneous reaction system is 110-185 DEG C, and the reaction pressure is 2.5-7.5 MPa; and (4) introducing the gas-phase material and the liquid-phase material into the heterogeneous reaction system to perform continuous reaction according to the hydrogen / acetylene mole ratio of (3-9):1 at the operation air speed of 30000-90000 mL / (gcat.h), and separating the gas-phase product to obtain the product. The method provided by the invention overcomes the defects of temperature runaway, difficulty in transfer of reaction heat and great bed pressure drop in the fixed bed, and the detects of low reaction pressure, low productivity, lower ethylene selectivity and catalyst deactivation due to high tendency to producing green oil in the slurry reactor in the traditional methods for preparing ethylene by high-purity acetylene hydrogenation.

Owner:BEIJING HUAFU ENG

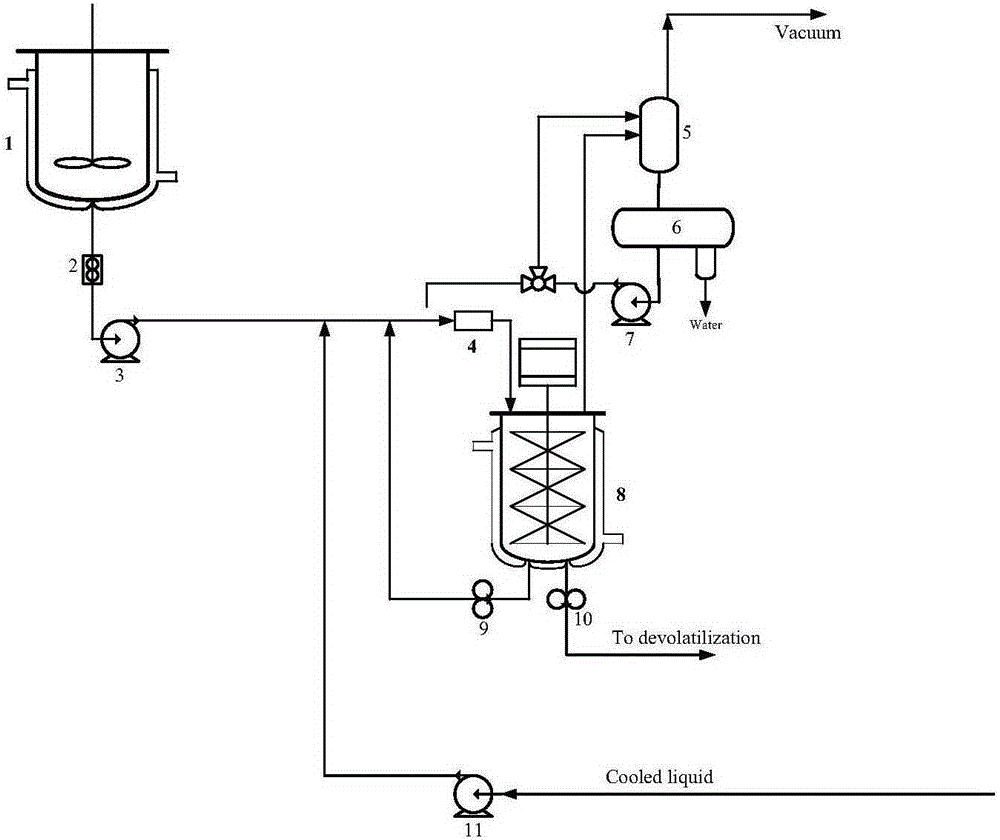

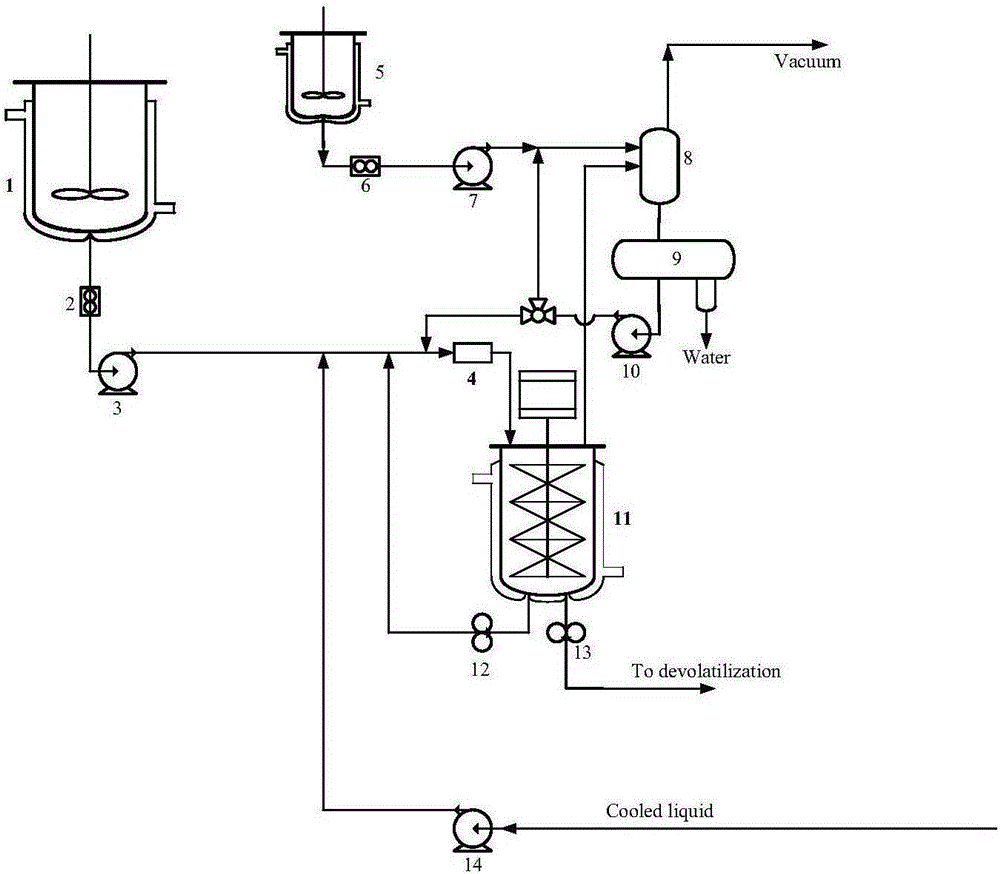

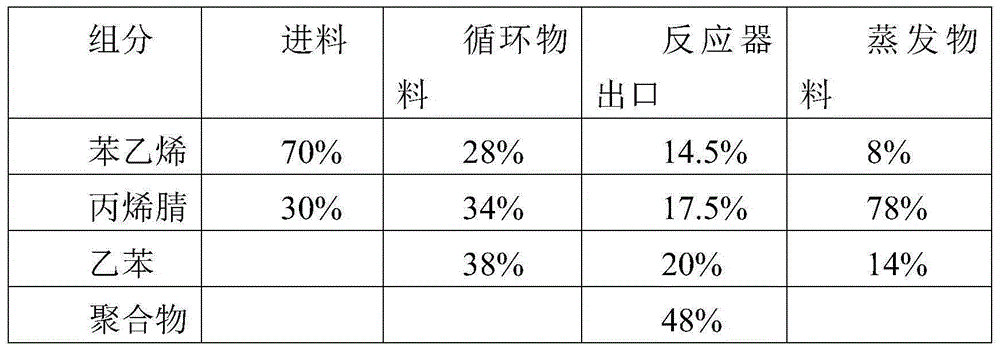

High-nitrile SAN resin and production method thereof

InactiveCN106188374ANarrow molecular weight distributionReduce yellow indexAcrylonitrileMelt flow index

The invention relates to a production method of high-nitrile SAN resin. The method comprises the specific steps of (a) mixing acrylonitrile with part of styrene cinnamene to obtain a mixture A, then mixing the mixture A with a circulating material and a condensation circulating material outside a reactor in a static mixer through a metering pump so as to obtain a mixture B, and then continuously leading the mixture B to the reactor; and enabling the rest of the styrene to be pumped into a steam condenser at the top of a reaction kettle through the metering pump, to be in contact with steaming air flows of the reactor, and to be mixed with condensation steam to become a condensation circulating material, and enabling the condensation circulating material to enter the reactor through a static mixer ; (c) polymerizing a reaction mixture at 140-160 DEG C in the reactor for 1.5-2.5 hours so as to obtain an SAN copolymer; and (d) performing two-stage devolatilization in a devolatilization machine, and performing pelleting in a pelletizer, so as to obtain the high-nitrile SAN resin with narrow distribution. According to the high-nitrile SAN resin produced by the method disclosed by the invention, the percentage by mass of acrylonitrile is greater than or equal to 32%, the melt indexes of products are smaller than 6g / 10min(230 DEG C, 2.16Kg), and the yellow index of the products is smaller than 12.

Owner:PETROCHINA CO LTD

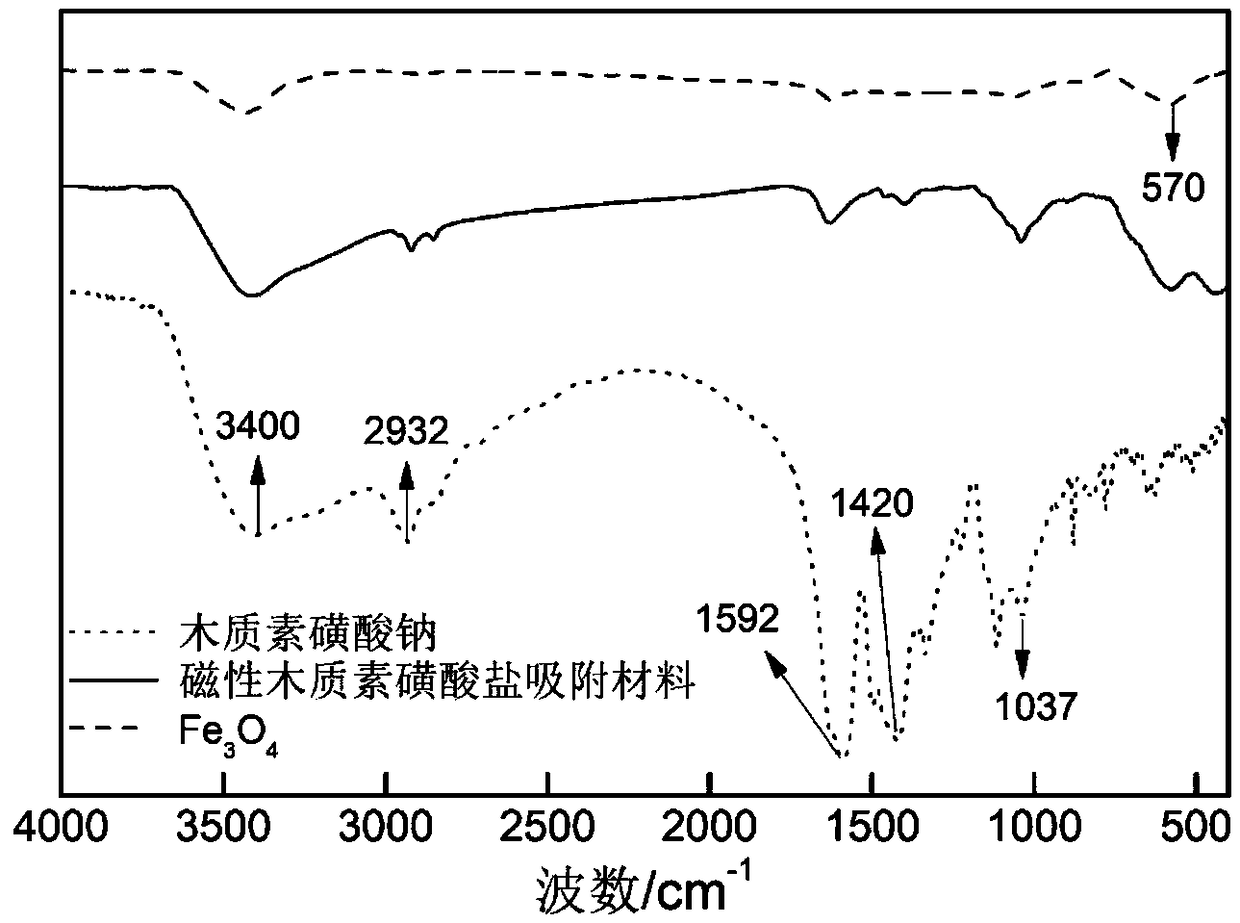

Preparation method of magnetic lignosulfonate adsorbing material

InactiveCN109126746AGood dispersionImprove stabilityOther chemical processesAlkali metal oxides/hydroxidesFerrous saltsLignosulfonates

The invention relates to a preparation method of a magnetic lignosulfonate adsorbing material, and belongs to the field of material science. The method comprises the following steps: firstly dissolving lignosulfonate into water to form a lignosulfonate water solution, sequentially adding ferrous salt and ferric salt into the solution, and stirring the solution, so as to obtain a uniformly mixed first solution, ensuring that the first solution is in reaction in an ultrasonic condition, dropwise adding an alkaline precipitator during the reaction process, ensuring that the pH value of the solution is greater than 10, so as to obtain a reactant; performing solid-liquid separation on the reactant under the action of magnetic field, and cooling and drying solid phase, so as to obtain the magnetic lignosulfonate adsorbing material. The method has the advantages that the lignosulfonate is compounded with magnetic ferroferric oxide nanometer particles to form the magnetic lignosulfonate adsorbing material, raw materials are low in price and wide in source, the preparation technology is simple, the condition is mild, the quantity of required equipment is small, and industrial production canbe realized.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of white carbon black/graphene oxide nano-hybrid filler, nano-hybrid filler and application of nano-hybrid filler

ActiveCN109810323AAchieve decentralizationAchieve nanodispersionEvaporation by sprayingHigh-speed grindingNano hybrid

The invention relates to a preparation method of white carbon black / graphene oxide nano-hybrid filler, the nano-hybrid filler and application of the nano-hybrid filler. The preparation method comprises the following steps: carrying out high-speed grinding and dispersion to prepare stable white carbon black slurry modified by a silane coupling agent; then uniformly stirring and grinding and dispersing the modified white carbon black slurry with a graphene oxide / water suspension solution subjected to high-speed grinding and dispersion and / or ultrasonic treatment; connecting white black carbon and graphene oxide through a bridge effect of the silane coupling agent; and then spraying and drying to prepare the white carbon black / graphene oxide nano-hybrid filler. The nano-hybrid filler is filled into any rubber variety through a traditional melting and blending technology to prepare high-performance tire tread. The preparation method and an application technology of the nano-hybrid filler are simple; and when the nano-hybrid filler is applied to rubber, nano-dispersion of graphene in a rubber matrix can be realized and the limitation of the rubber variety can be broken through, so thata composite material has excellent mechanical property, wet slipping resistance, cutting resistance, properties of delaying dynamic and static crack growth, and the like.

Owner:BEIJING UNIV OF CHEM TECH

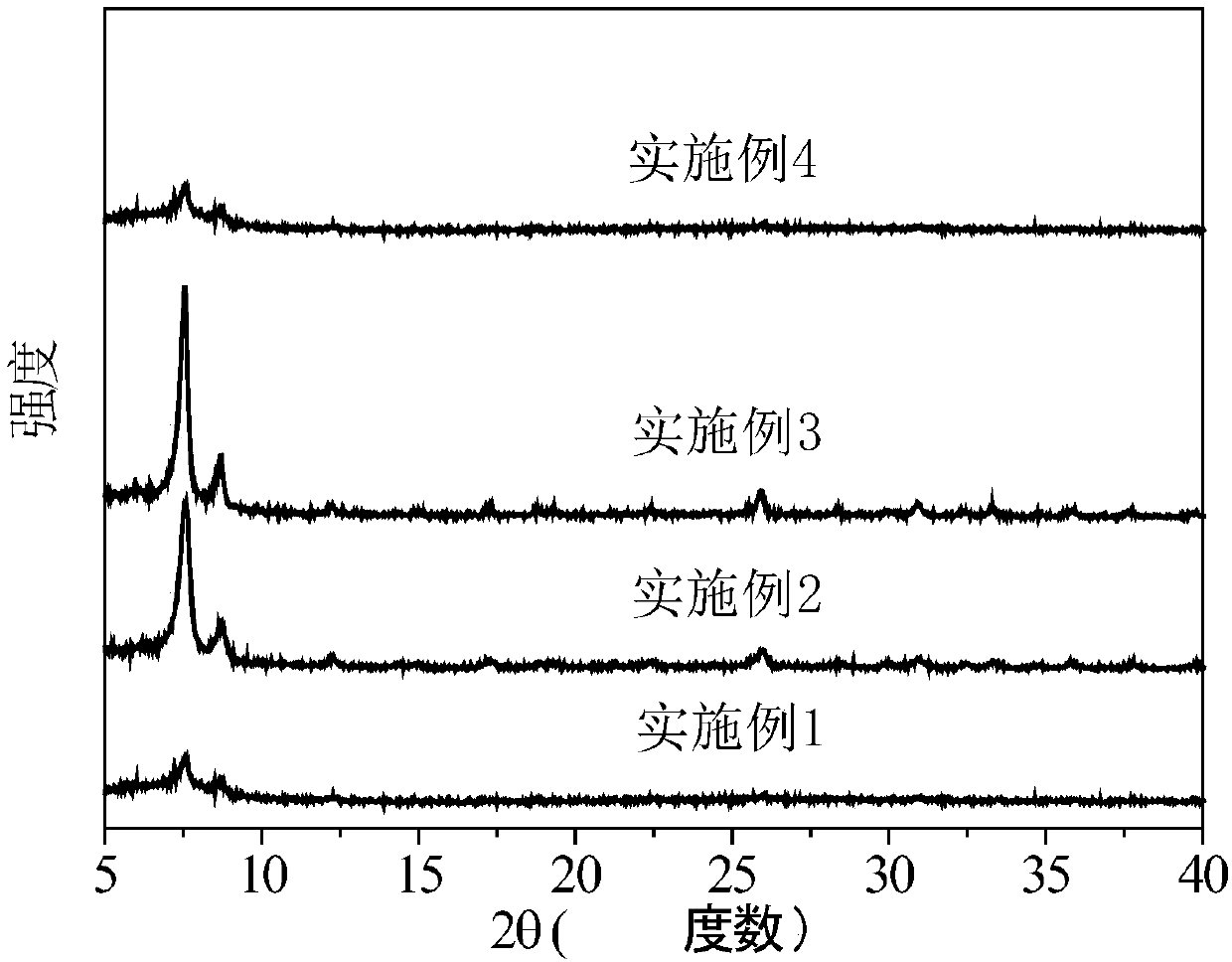

Hydrophobic zirconium-metal organic framework material and preparation method thereof

The invention discloses a hydrophobic zirconium-metal organic framework material and a preparation method thereof. The preparation method comprises the following steps: (1) feeding and dissolving zirconium chloride in methanol or DMF (Dimethyl Formamide) according to the molar ratio of 100:1.5-7.0, then adding glacial acetic acid for dissolving to obtain a mixture; (2) feeding the mixture in the step (1) into a ball milling tank to carry out ball milling for 10-30 minutes; (3) after the ball milling in the step (2) is finished, adding terephthalic acid with the amount equal to that of the zirconium chloride, continuing ball milling for 10-30 minutes; and (4) washing a product obtained after the step (3) is finished by using the methanol or the DMF in sequence, centrifuging, filtering, anddrying to prepare the nitrogen-doped zirconium-metal organic framework material. The hydrophobic zirconium-metal organic framework material prepared by adopting chemical and mechanical methods has higher specific surface area and higher hydrophobic property, so that the stronger adsorption force of the hydrophobic zirconium-metal organic framework material for chlorobenzene-aldehyde VOC (VolatileOrganic Compound) organic matters is improved.

Owner:GUANGXI UNIV

Preparation method of soybean oil-based waterborne polyurethane light-cured resin

The invention discloses a preparation method of soybean oil-based waterborne polyurethane light-cured resin. The preparation method comprises the following steps: adding epoxy soybean oil into a reaction bottle; raising the temperature and stirring; uniformly mixing one of acrylic acid and methacrylic acid, a catalyst and a polymerization inhibitor, and adding a mixture into the reaction bottle; continually raising the temperature of the reaction kettle; after reacting for a period of time, cooling to room temperature to obtain soybean oil-based polyatomic alcohol containing terminal double bonds; adding the soybean oil-based polyatomic alcohol containing the terminal double bonds into a four-opening flask provided with a condensation tube and a thermometer; stirring at low temperature and adding diisocyanate; after reacting for a period of time, adding dihydromethyl propionic acid and 1,4-butanediol; keeping the heat; adding an end blocking agent and reacting; adding a neutralizing agent for neutralizing to obtain a polyurethane pre-polymer; finally, adding de-ionized water and emulsifying to obtain needed resin. According to the preparation method provided by the invention, soybean oil, which is a renewable resource, is utilized and energy source pressure can be alleviated; the polymerization inhibitor is utilized, so that the acrylic acid or the methacrylic acid is prevented from self-polymerization under reaction temperature; the preparation method provided by the invention is simple, efficient, controllable and environment-friendly.

Owner:HUBEI UNIV

Multi-functional plastic auxiliary agent

The invention discloses a multi-functional plastic auxiliary agent comprising the components in parts by weight: 80-90 parts of calcium carbonate, 8-10 parts of stearic acid, 3-5 parts of calcined kaolin, 1-3 parts of a lubricant, 0.8-1.5 parts of methyl acrylate, 1-2 parts of organic antimony, 0.5-1 part of sodium carbonate, 1-2 parts of polyethylene wax, and 1-2 parts of silica. Modified calcium carbonate is mixed with the auxiliary agent, so that the particle surface energy and interfacial tension can be greatly reduced, auto-agglutination of micronized particles is effectively prevented, the compatibility of the auxiliary agent in plastics is increased, the macromolecule plasticization is promoted, the product impact degree, stiffness and heat resistance are increased, the melt viscosity is reduced, the liquidity is improved, and the processability of the plastics is increased; and the calcined kaolin is filled into a mixture, and the plasticity of the plastic auxiliary agent is increased.

Owner:CHIZHOU JINYI CHEM

Film dehydrating method of raw materials used for preparing polymethoxyldimethyl ether

InactiveCN106540550AEnergy savingEfficientOrganic chemistryOrganic compound preparationEtherEnergy consumption

The invention discloses a film dehydrating method of raw materials used for preparing polymethoxyldimethyl ether. The raw materials comprise a mixture of a formaldehyde solution, methylal and methanol. The mixture flows across the surface of a film in a fluid or steam state, and driven by the water partial pressure of the two sides of the film, water in the mixture selectively penetrates through the separation film. The method is high in efficiency, low in energy consumption, simple in process and convenient to operate.

Owner:东方红升江苏新能源有限公司 +1

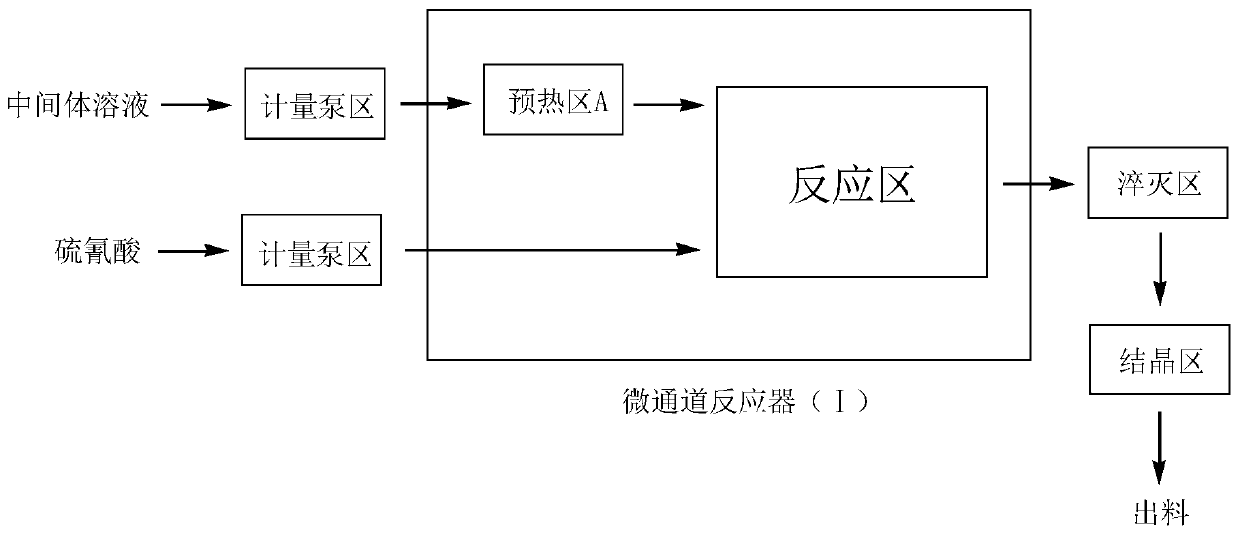

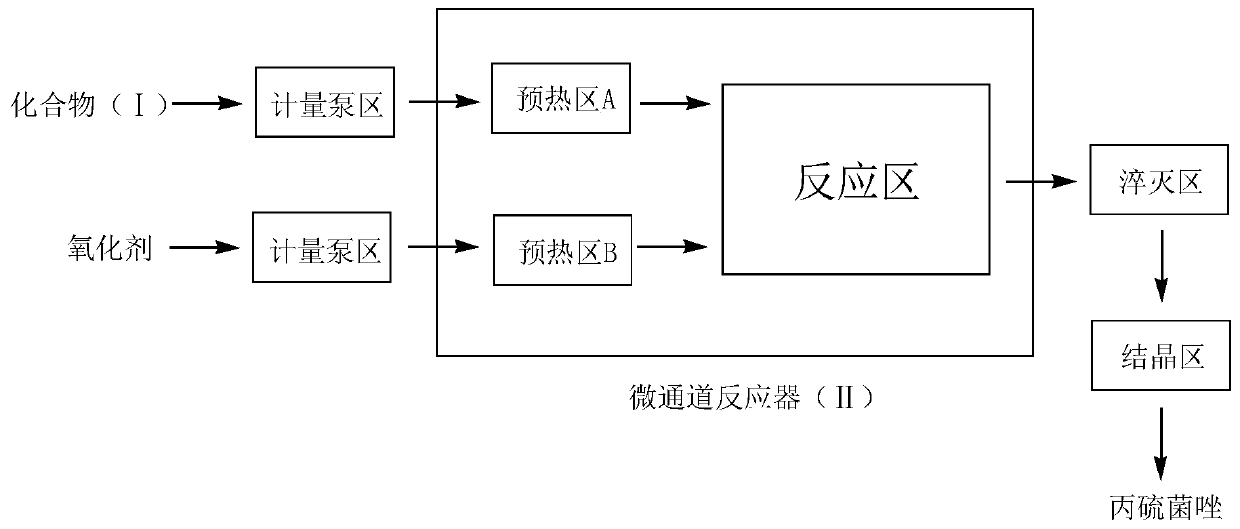

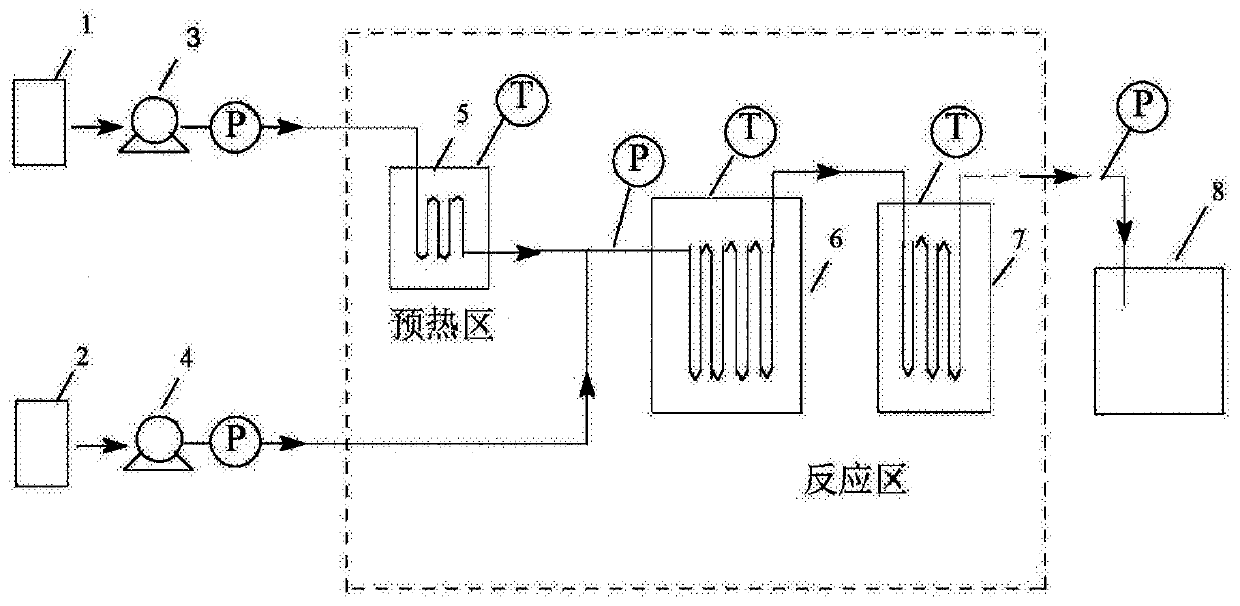

Method for continuously producing prothioconazole by utilizing micro-channel reactor and micro-channel system

ActiveCN110218197APrevent self-aggregationReduce generationOrganic chemistryChemical/physical/physico-chemical microreactorsOrganic synthesisReaction temperature

The invention relates to a method for continuously producing prothioconazole by utilizing a micro-channel reactor and a micro-channel system and belongs to the technical field of organic synthesis processes. The method comprises the following steps: taking 2-(1-chloro-cyclopropyl)-1-(2-chlorphenyl)-3-hydrazino-propyl-2-ol as a raw material, carrying out a cyclization and oxidization two-step reaction in the micro-channel reactor so as to continuously complete a preparation process of prothioconazole, introducing the material into the micro-channel reactor by a metering pump, performing preheating, mixed reaction and quenching crystallization separation so as to obtain the product prothioconazole. According to the method, mass transfer and heat transfer in the reaction process can be enhanced, the reaction temperature and reaction time are accurately controlled, side reactions and a reactant auto-polymerization phenomenon caused by material enrichment in the cyclization process are avoided, and conditions that the side reactions are increased due to 'temperature runaway' and reactive oxygen species overflow in the oxidization process and the like are also avoided. The reaction timeis finally reduced, the atom utilization ratio is improved, the reaction conversion rate is greatly improved, and production of solid wastes and side reactions is reduced.

Owner:RUICHENG COUNTY SIPULUNDI BIOLOGICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com