Postheating dimerization method for separating C5 diene

A thermal dimerization and diene technology, applied in the field of post-thermal dimerization separation of carbon pentadiene, can solve problems affecting the purity of dicyclopentadiene, loss of isoprene and cyclopentadiene, etc., to avoid self-polymerization And copolymerization loss, increase conversion rate, reduce the effect of temperature control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

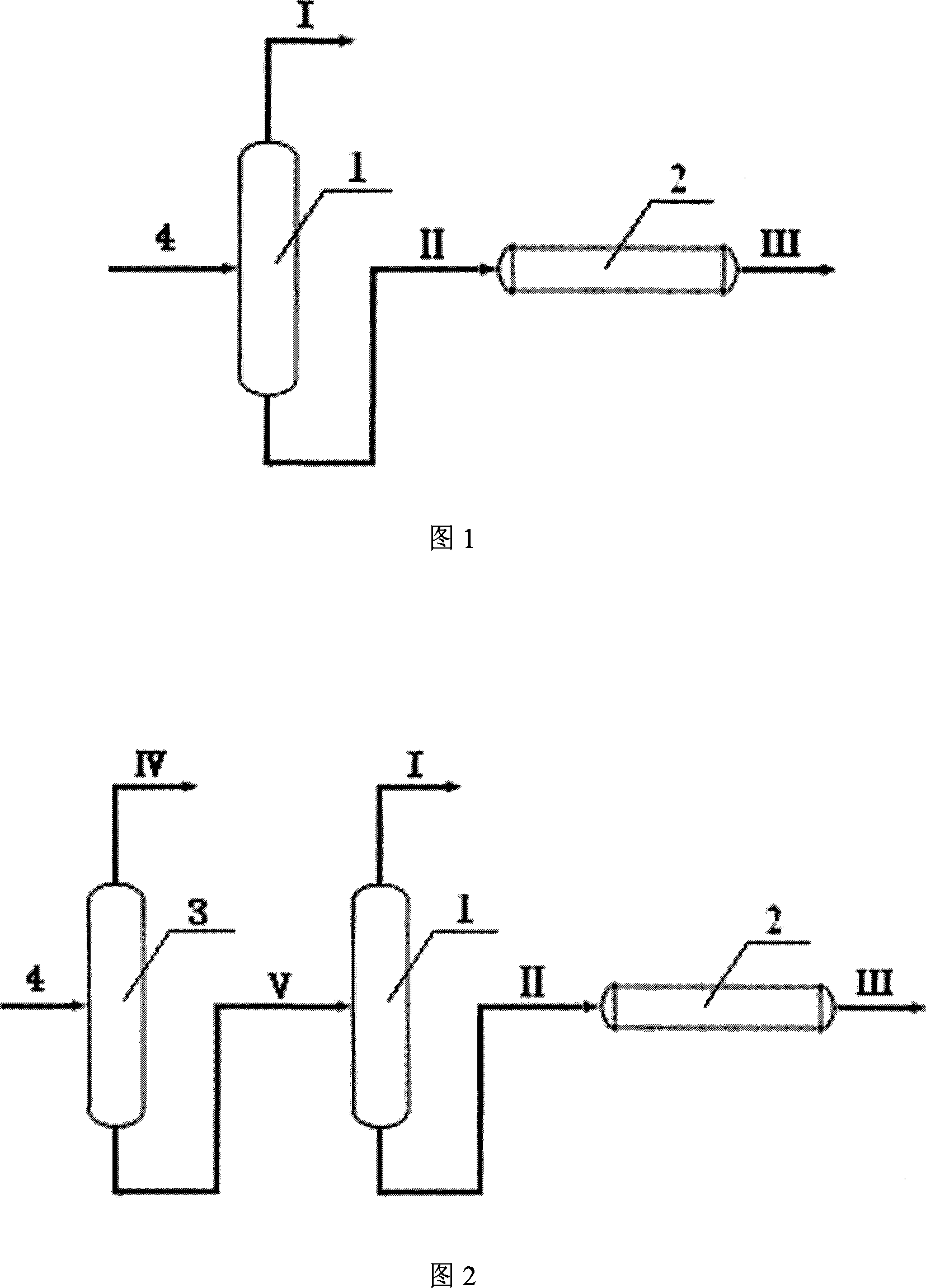

[0026]According to the technological process shown in Fig. 1, the C5 fraction of raw petroleum cracking enters the 55th plate of the isoprene separation tower 1, and the stream I rich in isoprene is obtained by separation at the top of the tower, which also contains monoolefins, alkanes, Alkynes and a small amount of cyclopentadiene; the stream II containing heavy components such as cyclopentadiene and piperylene is separated from the bottom of the tower. The feed temperature of isoprene separation tower 1 is 50°C, the number of trays is 110, the temperature of the tower bottom is 84°C, the temperature of the top of the tower is 54°C, the pressure of the top of the tower is 0.13MPa, the pressure of the bottom of the tower is 0.21MPa, and the reflux The ratio is 11.

[0027] Stream II enters thermal dimerization reactor 2 for thermal dimerization reaction, and the reactor volume is 40 meters 3 (The C5 raw material is calculated at 20 kg / hour, the same below), the reaction temp...

Embodiment 2

[0037] According to the technical process of Fig. 2, raw petroleum cracking C5 fraction and polymerization inhibitor diethylhydroxylamine enter the 44th plate of light removal tower 3, and the stream IV containing C4 and components below C4 is obtained at the top of the tower; Obtain C5 stream V. The number of trays in the light removal tower 3 is 75, the feed temperature is 68°C, the temperature of the tower bottom is 76°C, the temperature of the top of the tower is 49°C, the pressure of the top of the tower is 0.15MPa, the pressure of the bottom of the tower is 0.20MPa, and the reflux ratio is 20 .

[0038] The carbon five stream V obtained from the bottom of light removal tower 3 enters the 43rd plate of isoprene separation tower 1, and the stream I rich in isoprene is obtained by separation at the top of the tower, which also contains monoolefins, alkanes, and alkynes Hydrocarbons and a small amount of cyclopentadiene; the tower still separates stream II containing heavy ...

Embodiment 3~4

[0049] According to the technological process of Fig. 2, just the polymerization inhibitor used in [embodiment 3] is dihydroxydihydrocinnamic acid, and the polymerization inhibitor used in [embodiment 4] is o-nitrophenol. Raw materials and the weight percent composition of each unit component are shown in Table 4 (Example 3) and Table 5 (Example 4) respectively.

[0050] table 3

[0051]

operating conditions

Lightening tower 3

Isoprene separation tower 1

Thermal dimerization reactor 2

Example 3

Example 4

Example 3

Example 4

Example 3

Example 4

Feed temperature (°C)

35

60

-

-

-

-

The number of trays at the feed (blocks)

35

50

66

78

-

-

Total number of plates (blocks)

60

90

130

150

-

-

Tower kettle temperature (°C)

70

83

80

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com