Uniformly dispersed electrode material and preparation method thereof

A technology of electrode materials and composite materials, applied in the field of lithium-ion battery electrode materials and their preparation, can solve problems such as difficulty in ensuring product consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

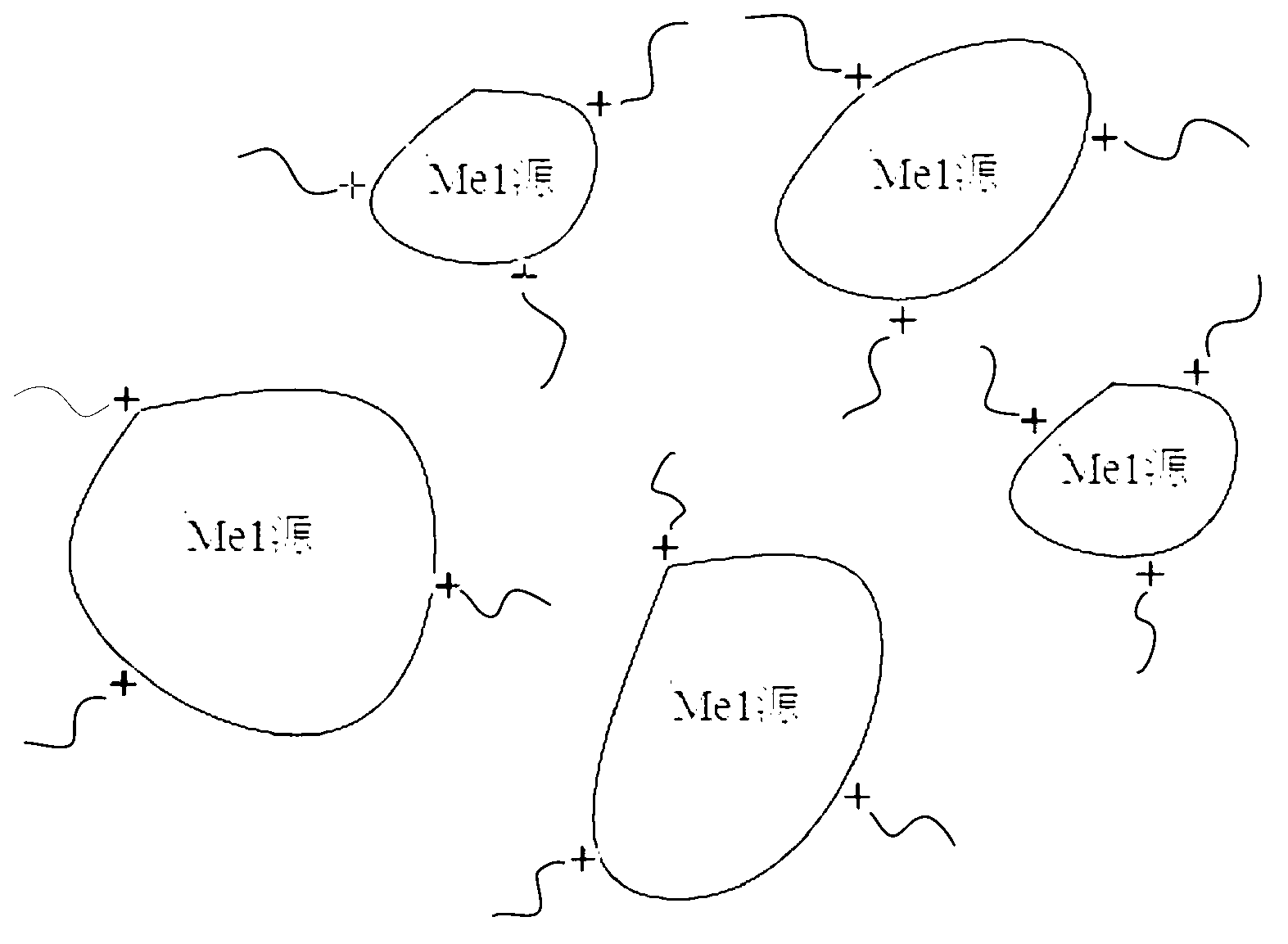

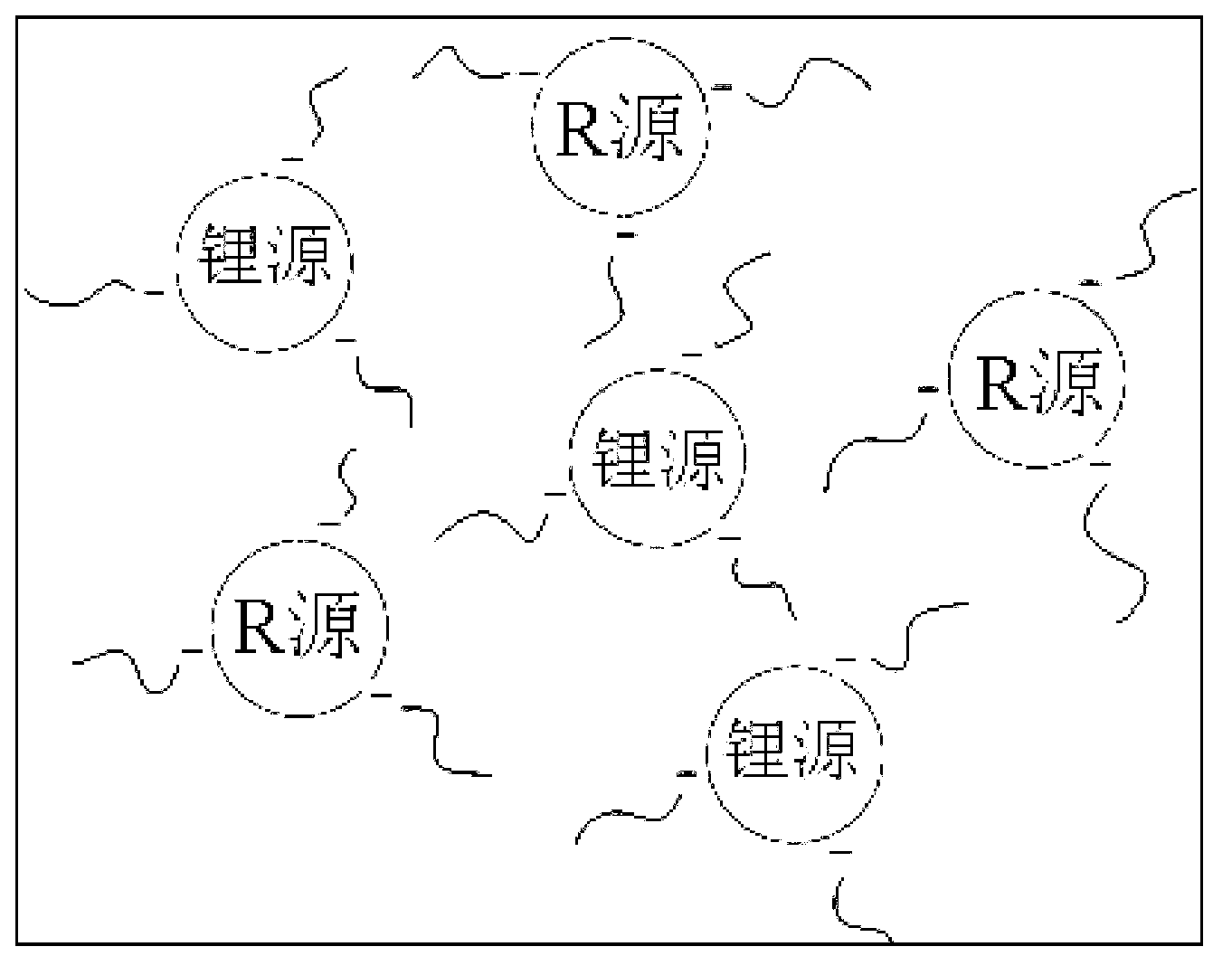

Problems solved by technology

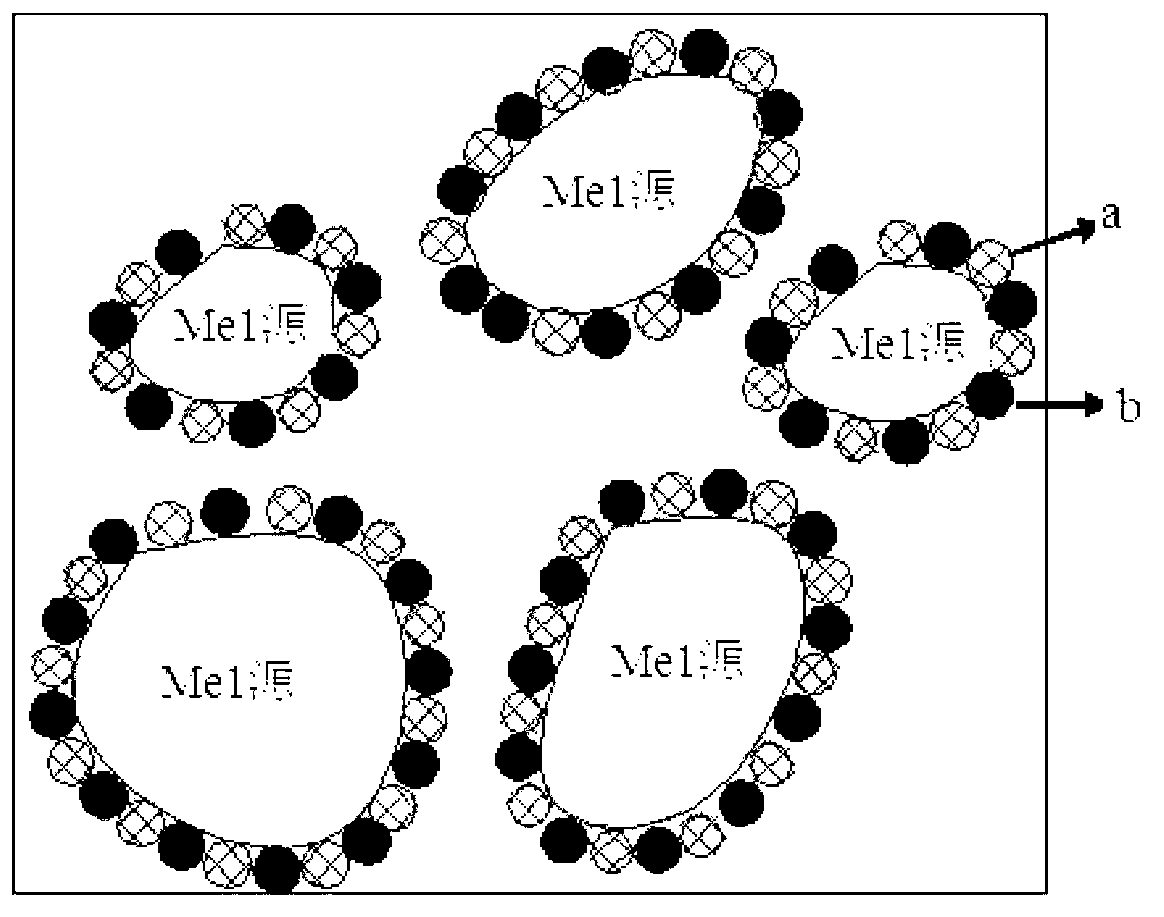

Method used

Image

Examples

Embodiment 1

[0094] Weigh 1 part of ferrous oxalate, add 3-6% carbon source of iron source mass and EFKA-5010 of 1-5% carbon source mass at the same time, and then add one of the compounds of magnesium, manganese, chromium, nickel, aluminum or more, these compounds account for 0.02%-0.05% of the total iron source, add ethanol and deionized water (3:2 volume ratio) mixed solvent, stir and ball mill for 2h; weigh 1 part of lithium dihydrogen phosphate, and at the same time Add SN-5040 with 1-5% carbon source mass, add ethanol and deionized water (3:2 volume ratio) mixed solvent, stir for 1 hour; slowly drop lithium dihydrogen phosphate solution into ferrous oxalate solution, At the same time, the precursor was continuously stirred and spray-dried to obtain the precursor. The lithium iron phosphate precursor was sintered at 700° C. for 7 hours under a high-purity nitrogen atmosphere, and then taken out after being cooled. The product is pulverized, fused, and passed through a 200-mesh sieve t...

Embodiment 2

[0096]Weigh 2 parts of iron phosphate, add 3-6% carbon source of iron source mass and dispersant CNF of 1-5% carbon source mass at the same time, then add one of the compounds of magnesium, manganese, chromium, nickel, aluminum or Various, these compounds accounted for 0.02%-0.05wt% of the total iron source, added to deionized water solvent, stirred and ball milled for 2 hours; weighed 1-3% of lithium carbonate mass sodium carboxymethylcellulose (CMC), added to In deionized water, stir until CMC is completely dissolved, then take 1 part of lithium carbonate, EFKA-5010 with 1-5% carbon source mass, add it to the mixed solvent of CMC and deionized water, stir for 1 hour; slowly drop the ferric phosphate slurry into Lithium carbonate suspension, stirring continuously at the same time, and spray drying to obtain the precursor. The lithium iron phosphate precursor was sintered at 750°C for 10 hours in a high-purity nitrogen-hydrogen mixed gas atmosphere containing 5% hydrogen, and t...

Embodiment 3

[0098] Weigh 1 part of vanadium pentoxide, and add 3-10% of the mass of the vanadium source as a carbon source and 0.5-5% of the mass of the carbon source as dispersing anti-sedimentation agent DA-50, and 3-7% of the mass of the vanadium source as polyethylene Alcohol, then add one or more of magnesium, manganese, chromium, nickel, aluminum compounds, these compounds account for 0.02%-0.05% of the total iron source, add to the solvent of deionized water, stir ball mill for 2h; weigh 3 Lithium dihydrogen phosphate, add 0.5-5% carbon source quality dispersant CS at the same time, add ethanol and deionized water (volume ratio: 8:2) mixed solvent, stir for 1h; drop the lithium dihydrogen phosphate emulsion slowly Put it into the vanadium pentoxide suspension, stir continuously, and spray dry to obtain the precursor. The lithium iron phosphate precursor was sintered at 750°C for 10h in a high-purity nitrogen-hydrogen mixed gas atmosphere containing 5% hydrogen, and then taken out af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com