Vertical coaxial anti-explosion fire-retardant breather valve

A breathing valve, coaxial technology, applied in the direction of container, packaging, transportation and packaging, etc., can solve the problems of blocked passage, inability to operate correctly, medium condensation and blockage, etc., to reduce the number of repairs and maintenance, easy installation and disassembly , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

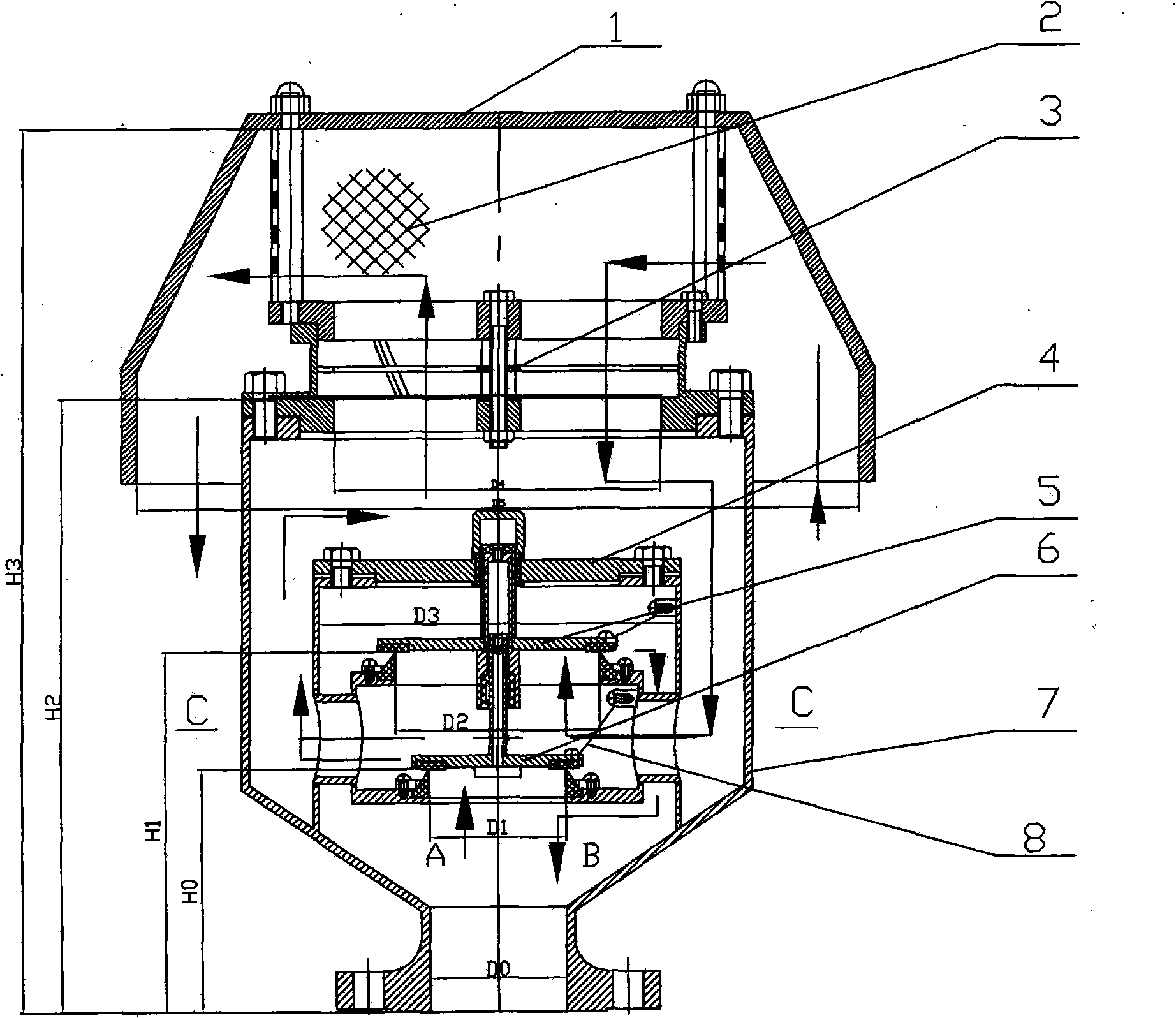

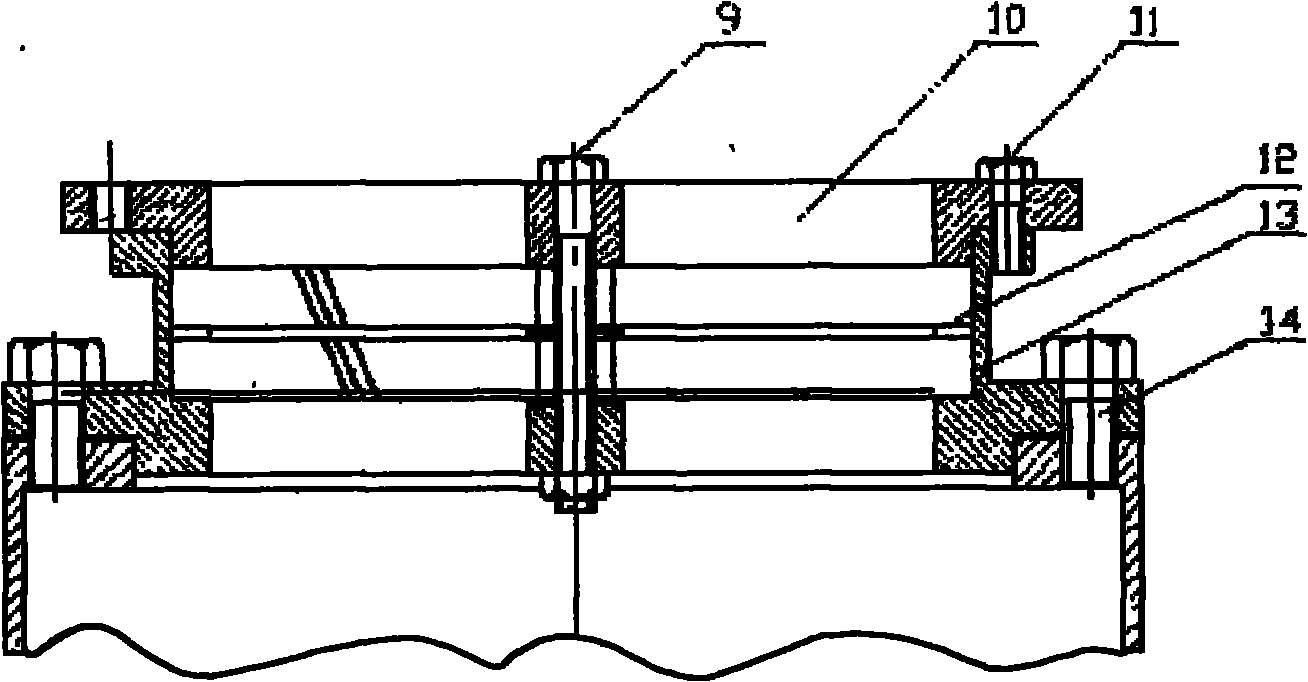

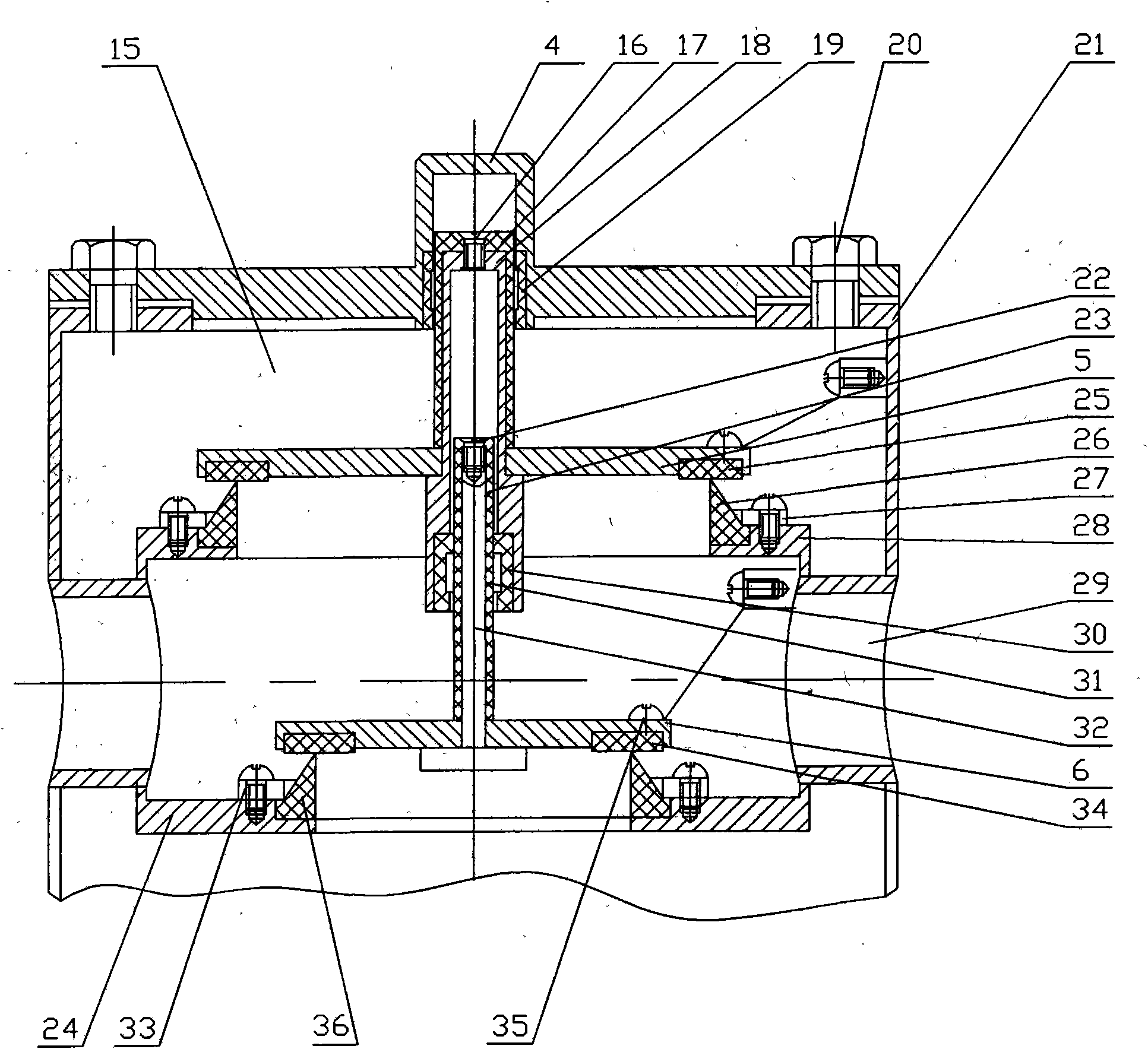

[0011] figure 1 The vertical coaxial explosion-proof flame arresting breathing valve given in is composed of an explosion-proof flame arrester 3 and a breathing valve. The lower part of the outer casing 7 of the present invention is a reducing flange connected with the storage tank. The breather valve is installed in the outer shell 7 of the present invention, and the explosion-proof flame arrester 3 is installed on the top of the outer shell 7 . figure 1 The arrow direction A in the figure is the gas flow path of the "exhale" action, and B is the gas flow path of the "inhale" action. Such as figure 2 As shown, the explosion-proof flame arrester 3 is composed of a fire-blocking layer seat 13 , a fire-blocking layer 12 and a fire-blocking laminate ring 10 connected together by a long rod bolt 9 . 11,14 are connecting bolts. The flame-retardant layer 12 of the explosion-proof flame arrester 3 adopts a stainless steel explosion-proof and fire-proof double-layer oblique wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com