Multi-functional plastic auxiliary agent

A plastic additive and multi-functional technology, applied in the field of plastic processing, can solve the problems of unstable quality and poor performance of plastic additive products, and achieve the advantages of improving fluidity, reducing particle surface energy and interfacial tension, and increasing impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Select 400g of calcium carbonate, 40g of stearic acid, 15g of calcined kaolin, 5g of lubricant, 4g of methacrylate, 5g of organic antimony, 2.5g of sodium carbonate, 5g of polyethylene wax, and 5g of silicon dioxide. Calcium is sent into the mixer and mixed and stirred for 15min. The stirring speed of the mixer is controlled to be 40r / min, and the temperature is controlled to be 40°C to obtain modified calcium carbonate, and then the modified calcium carbonate is sent to the high-speed mixer, and finally calcined kaolin is added, lubricated Additive, methacrylate, organic antimony, sodium carbonate, polyethylene wax, and silicon dioxide were mixed and stirred, the temperature was raised to 120°C, and kept stirring for 10 minutes, and then discharged to obtain a multifunctional plastic additive.

Embodiment 2

[0011] Select calcium carbonate 500g, stearic acid 53g, calcined kaolin 24g, lubricant 12g, methacrylate 6g, organic antimony 9g, sodium carbonate 5g, polyethylene wax 15g, silicon dioxide 15g, take stearic acid and calcium carbonate to send Mix and stir in the mixer for 18min, control the stirring speed of the mixer to be 40r / min, and control the temperature to be 45°C to obtain modified calcium carbonate, then send the modified calcium carbonate into the high-speed mixer, and finally add calcined kaolin, lubricant, Mix and stir methacrylate, organic antimony, sodium carbonate, polyethylene wax, and silicon dioxide, heat up to 125°C, keep stirring for 12 minutes, and then discharge to obtain a multifunctional plastic additive.

Embodiment 3

[0013] Select 600g of calcium carbonate, 67g of stearic acid, 33g of calcined kaolin, 20g of lubricant, 10g of methacrylate, 13g of organic antimony, 6g of sodium carbonate, 10g of polyethylene wax, and 10g of silicon dioxide. Put into the blender and mix and stir for 20min, control the stirring speed of the blender to be 40r / min, and control the temperature to be 50°C to obtain modified calcium carbonate, then send the modified calcium carbonate into the high-speed mixer, and finally add calcined kaolin, lubricant, Mix and stir methacrylate, organic antimony, sodium carbonate, polyethylene wax, and silicon dioxide, heat up to 130° C., keep stirring for 15 minutes, and then discharge to obtain a multifunctional plastic additive.

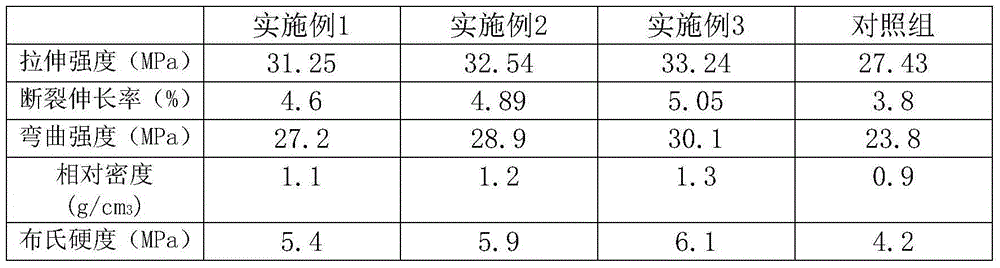

[0014] The multifunctional plastic auxiliary agent (modified calcium carbonate) obtained by the above examples and common plastic auxiliary agent (unmodified calcium carbonate) are added to PVC plastics, wood fiber, and composite stabilizer respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com