Hydrophobic zirconium-metal organic framework material and preparation method thereof

A metal-organic framework and hydrophobic technology, applied in the field of preparation of zirconium-containing metal-organic framework materials, can solve the problem of poor competitive adsorption of VOC and water, and achieve the effects of good hydrophobicity, shortened reaction time, and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

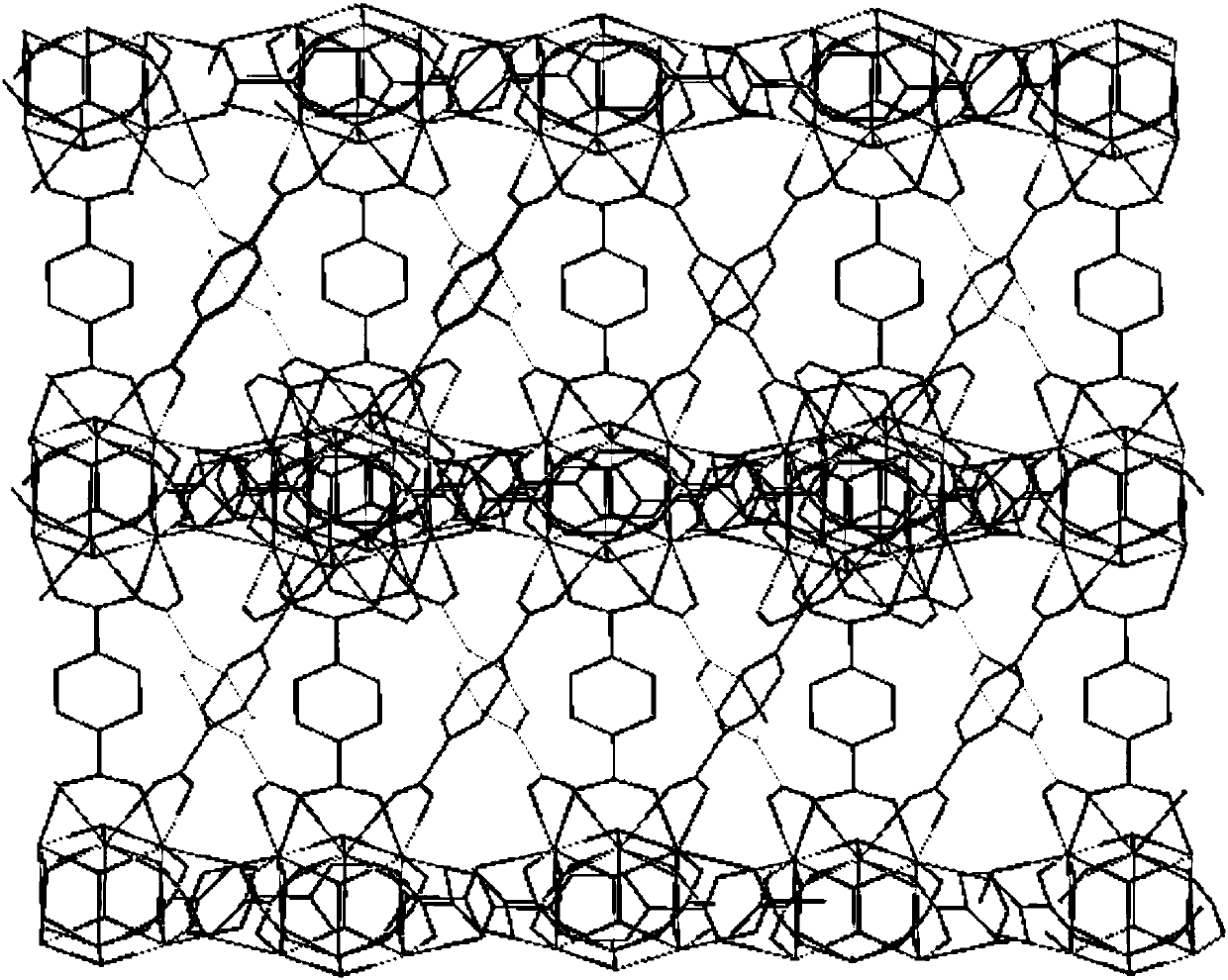

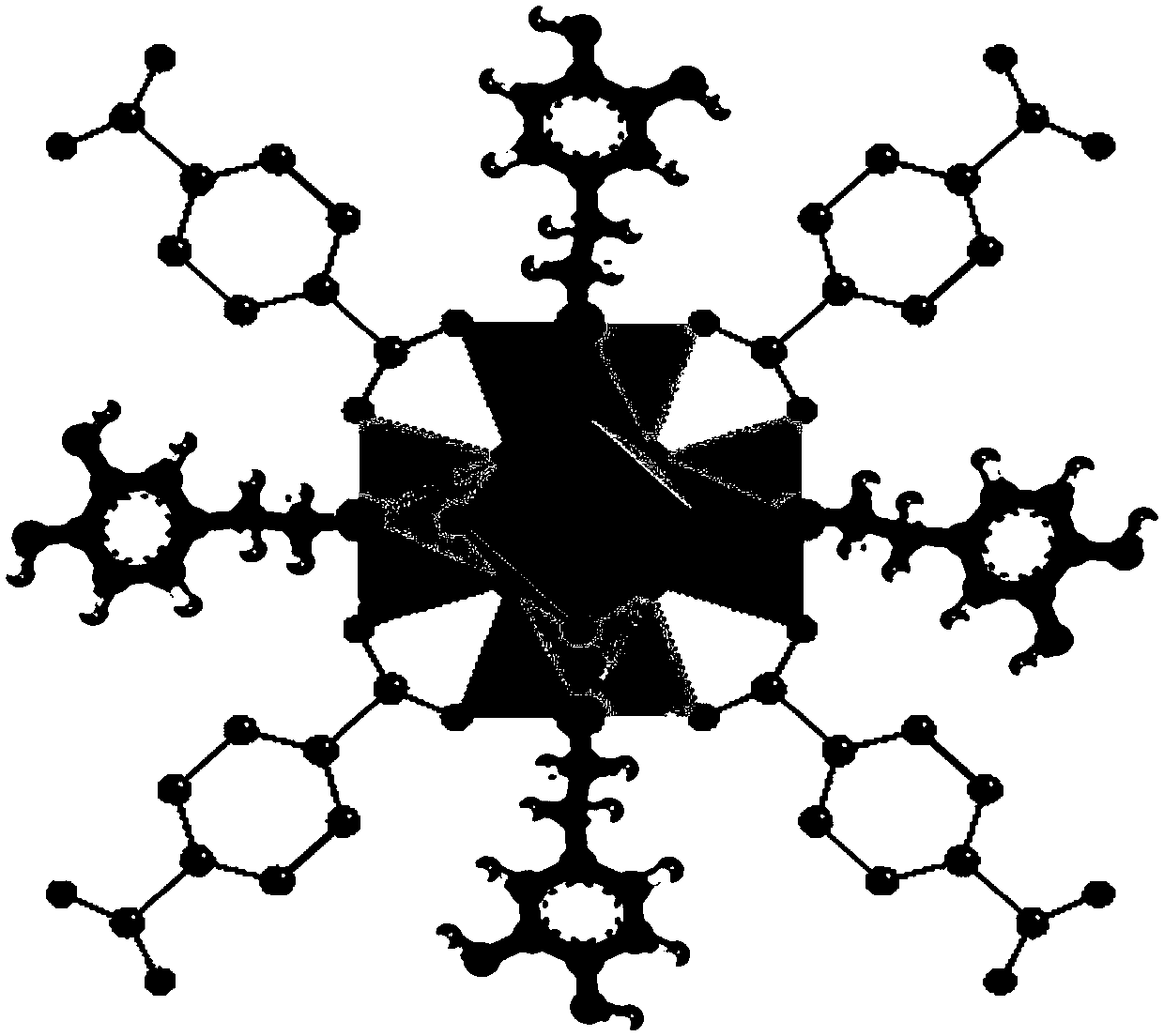

Method used

Image

Examples

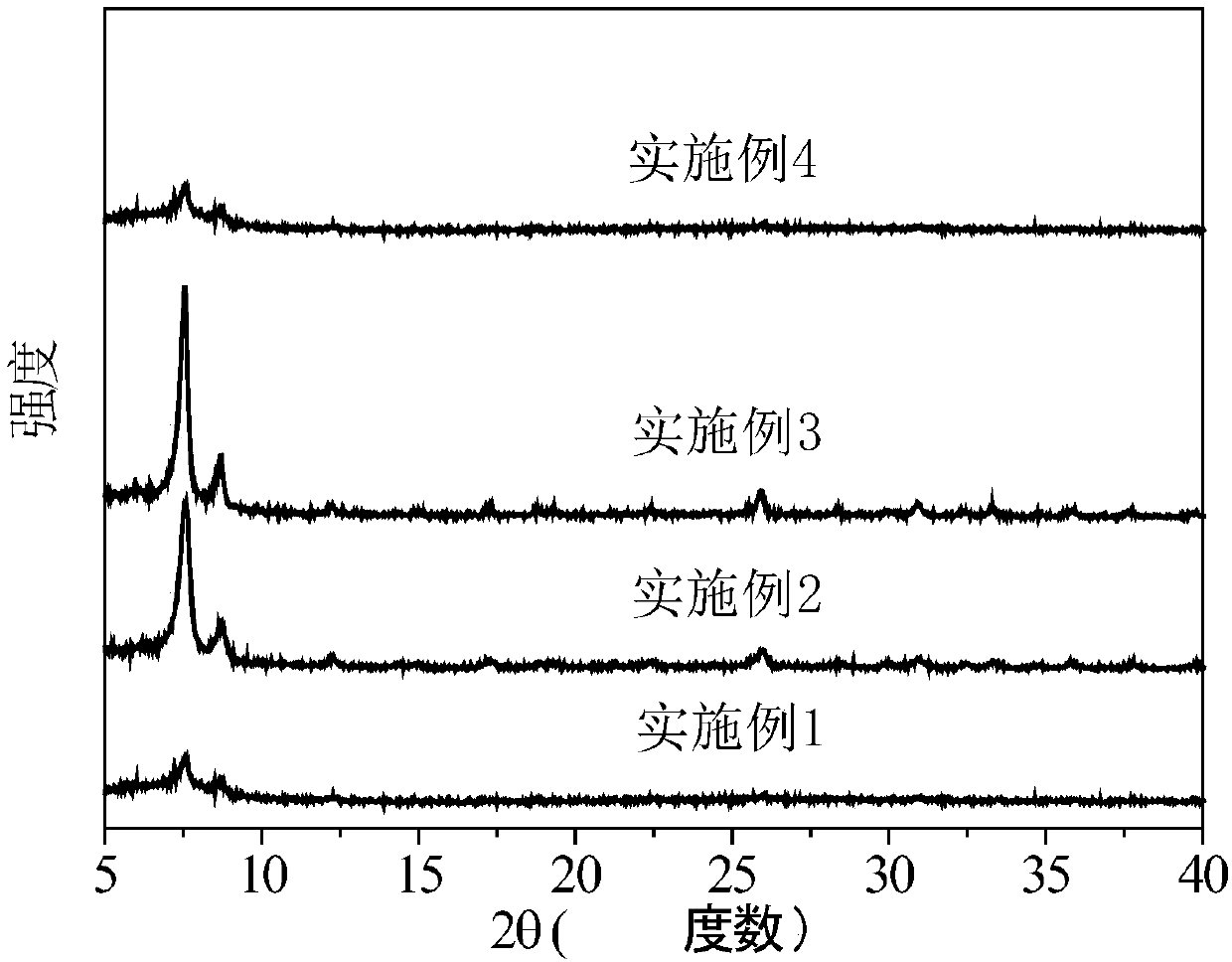

Embodiment 1

[0050] Dissolve 4mmol of zirconium chloride and 4mmol (equimolar amount) of terephthalic acid in 1.5mL of methanol, and add 0.3mL of glacial acetic acid to it, then ultrasonically (60KHz frequency) for 10min, then transfer to the set Mill in a ball mill jar (one ball milling bead with a diameter of 10.3 mm, five ball milling beads with a diameter of 5.1 mm) for 30 min. Setting procedure: frequency 50Hz; time 30min, speed 1000r / min. After the reaction, the obtained product was washed successively with methanol and DMF for 3-4 times, centrifuged at 7000r / min for 20min, filtered, and dried at 180°C for 20h to obtain the zirconium without nitrogen source of the present invention. The metal-organic framework material is denoted as M-UiO-66(Zr).

Embodiment 2

[0052] Dissolve 4mmol of zirconium chloride and 0.06mmol of dopamine (molar ratio is 1.5%) in 1.5mL of methanol, and add 0.3mL of glacial acetic acid to it, and then ultrasonically (frequency is 60KHz) for 10min, then transfer to the set Mill in a ball mill jar (one ball milling bead with a diameter of 10.3 mm, five ball milling beads with a diameter of 5.1 mm) for 30 min. Setting procedure: frequency 50Hz; time 30min, speed 1000r / min. Add an equivalent amount of terephthalic acid to it after the reaction is over, and continue ball milling for 30 min under the same conditions. Then the obtained product was washed with methanol and DMF for 3-4 times respectively, centrifuged at 7000r / min for 20min, filtered, and dried at 180°C for 20h to obtain the zirconium metal organic framework doped with nitrogen source of the present invention Material, denoted as M-UiO-66 (Zr-N 1.5 ).

Embodiment 3

[0054] Dissolve 4mmol of zirconium chloride and 0.12mmol of dopamine (molar ratio is 3.0%) in 1.5mL of methanol, and add 0.3mL of glacial acetic acid to it, and then ultrasonically (frequency is 60KHz) for 10min, then transfer to the set Mill in a ball mill jar (one ball milling bead with a diameter of 10.3 mm, five ball milling beads with a diameter of 5.1 mm) for 30 min. Setting procedure: frequency 50Hz; time 30min, speed 1000r / min. Add an equivalent amount of terephthalic acid to it after the reaction is over, and continue ball milling for 30 min under the same conditions. Then the obtained product was washed with methanol and DMF for 3-4 times respectively, centrifuged at 7000r / min for 20min, filtered, and dried at 180°C for 20h to obtain the zirconium metal organic framework doped with nitrogen source of the present invention Material, denoted as M-UiO-66 (Zr-N 3.0 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com