Preparation method of white carbon black/graphene oxide nano-hybrid filler, nano-hybrid filler and application of nano-hybrid filler

A technology of white carbon black and graphene, applied in the field of rubber tires, can solve the problems of spray drying process not working normally, clogged pipes, etc., and achieve the effect of improving interaction and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

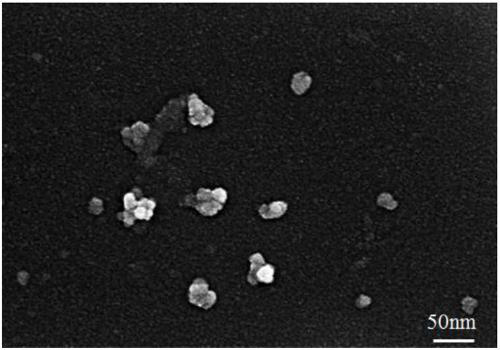

Embodiment 1

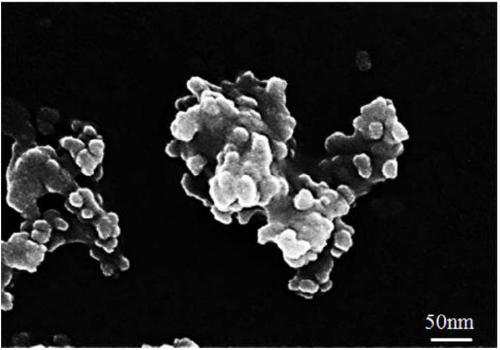

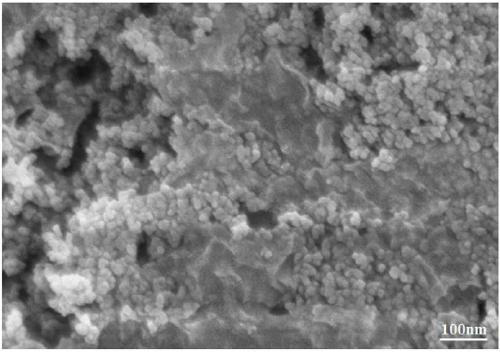

[0055] Stir and mix the silica and water evenly according to the silica mass content of 10%, and use high-speed grinding and dispersing equipment (Shanghai Yiken Machinery Equipment Co., Ltd., model CMXD2000 / 4, output speed 21000rpm, line speed 66m / s, the following implementation Example same) for dispersion, the reaction time is 1 hour, and the reaction temperature is controlled below 10°C to obtain a stable silica slurry with a silica particle size less than 50nm. Then organically modify the prepared white carbon black water slurry in a mechanically stirred 80°C water bath by adding silane coupling agent KH550 dropwise, the amount of KH550 is 10% of the dry powder mass of white carbon black, and the modification time is 3 hours , and then reacted in a high-speed grinding and dispersing equipment for 1 hour, and the temperature was controlled within 10°C to obtain a pretreated silica slurry with a silica particle size of less than 50nm. Graphene oxide and water were stirred a...

Embodiment 2

[0057]Stir and mix silica and water evenly according to the mass content of silica at 10%, and disperse with high-speed grinding and dispersing equipment. The reaction time is 1 hour, and the reaction temperature is controlled below 10°C to obtain stable silica with a particle size of less than 50nm white carbon black water slurry. Then organically modify the prepared white carbon black water slurry in a mechanically stirred 80°C water bath by adding silane coupling agent KH550 dropwise, the amount of KH550 is 10% of the dry powder mass of white carbon black, and the modification time is 3 hours , and then reacted in a high-speed grinding and dispersing equipment for 1 hour, and the temperature was controlled within 10°C to obtain a pretreated silica slurry with a silica particle size of less than 50nm. Graphene oxide and water were stirred and mixed according to the mass content of graphene oxide at 0.1%, dispersed with high-speed grinding and dispersing equipment, reacted fo...

Embodiment 3

[0059] Stir and mix silica and water evenly according to the mass content of silica at 10%, and disperse with high-speed grinding and dispersing equipment. The reaction time is 1 hour, and the reaction temperature is controlled below 10°C to obtain stable silica with a particle size of less than 50nm white carbon black water slurry. Then organically modify the prepared white carbon black water slurry in a mechanically stirred 80°C water bath by adding silane coupling agent KH550 dropwise, the amount of KH550 is 10% of the dry powder mass of white carbon black, and the modification time is 3 hours , and then reacted in a high-speed grinding and dispersing equipment for 1 hour, and the temperature was controlled within 10°C to obtain a pretreated silica slurry with a silica particle size of less than 50nm. Graphene oxide and water were stirred and mixed according to the mass content of graphene oxide at 0.1%, dispersed with high-speed grinding and dispersing equipment, reacted f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com