Patents

Literature

157results about How to "Strong shear force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite mineral-leaching bacteria colony and use of same in biological metallurgy

ActiveCN101538540AImprove efficiencyBroaden the scope of ore processingBacteriaMicroorganism based processesIonLaboratory culture

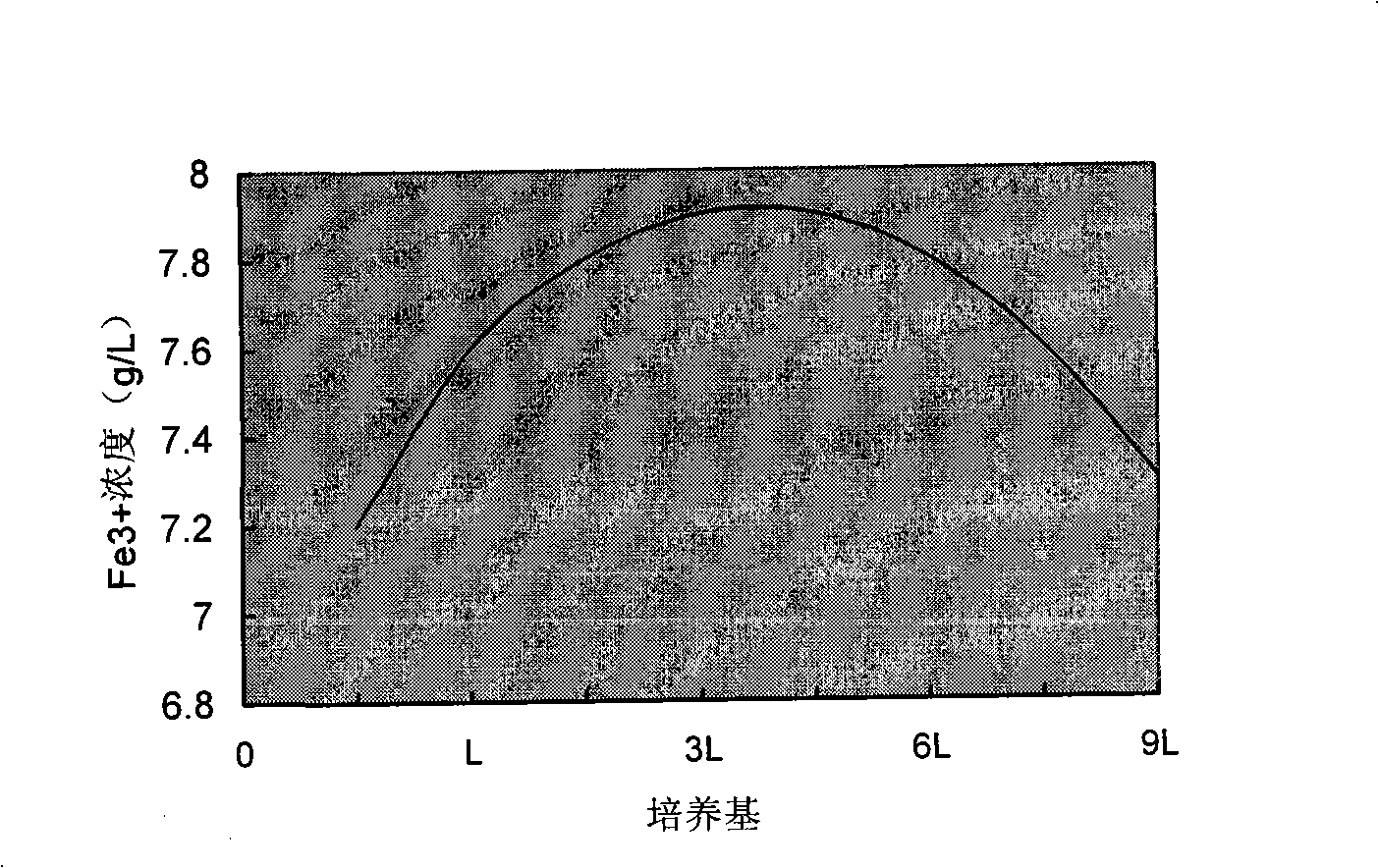

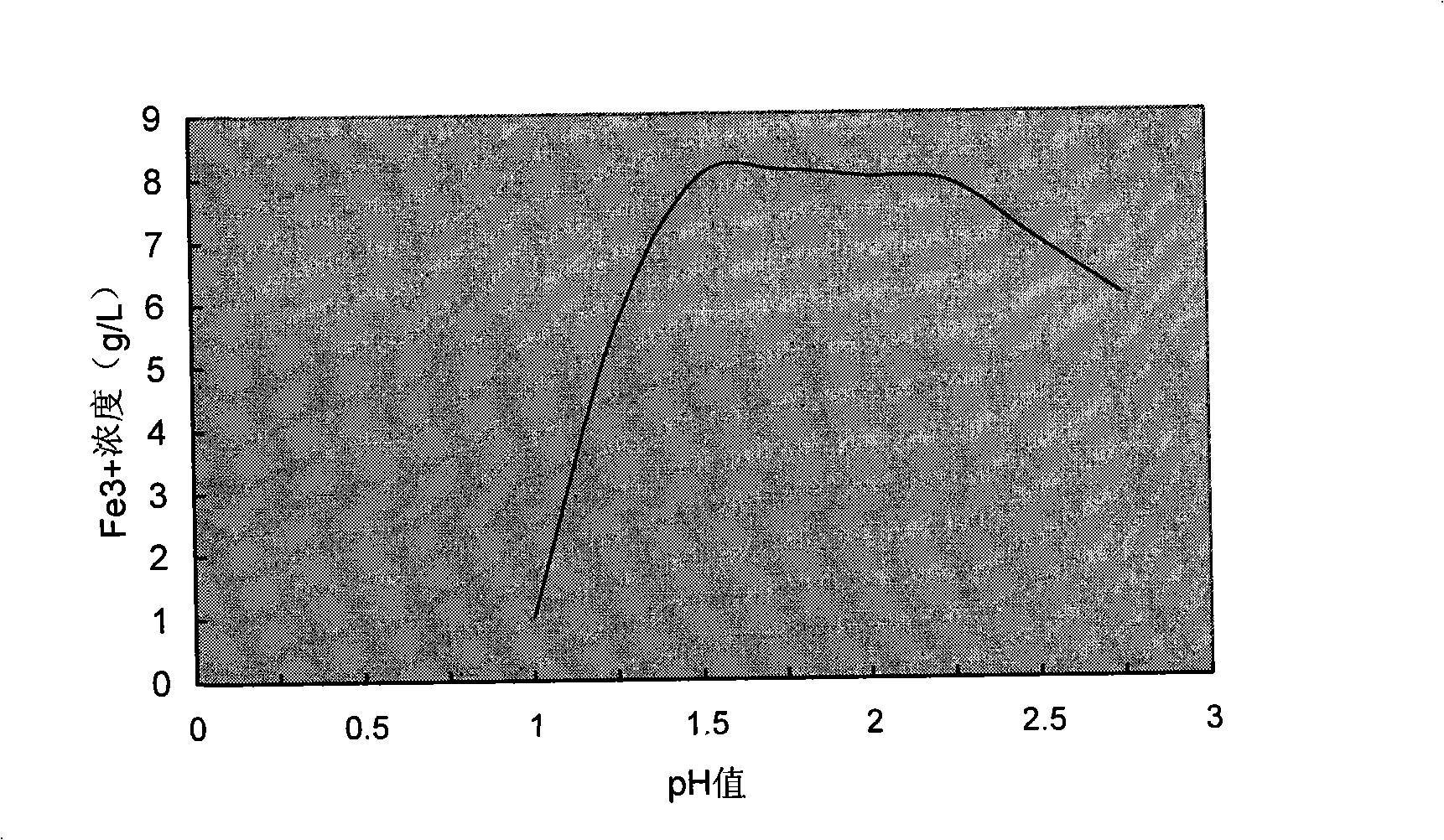

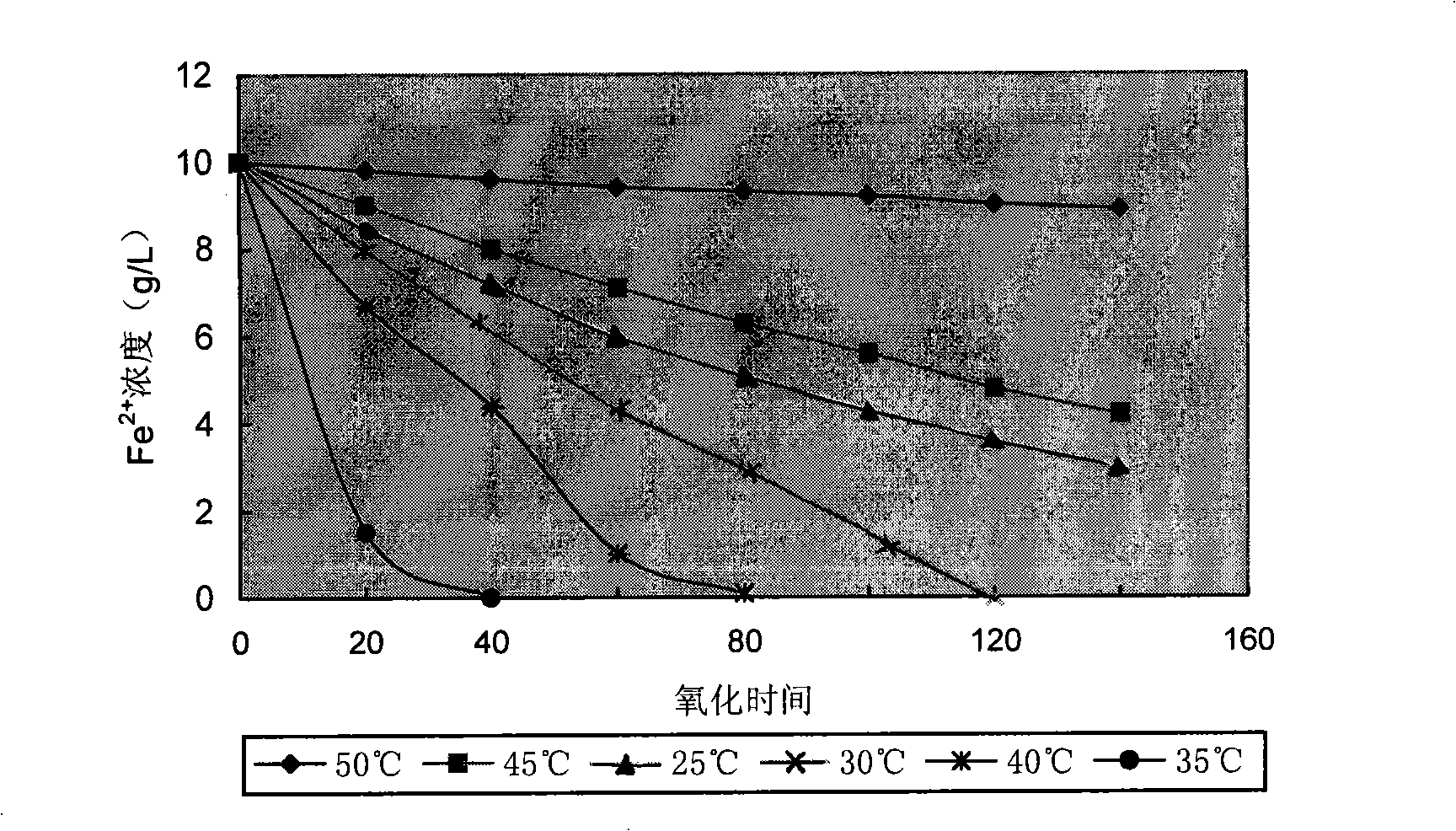

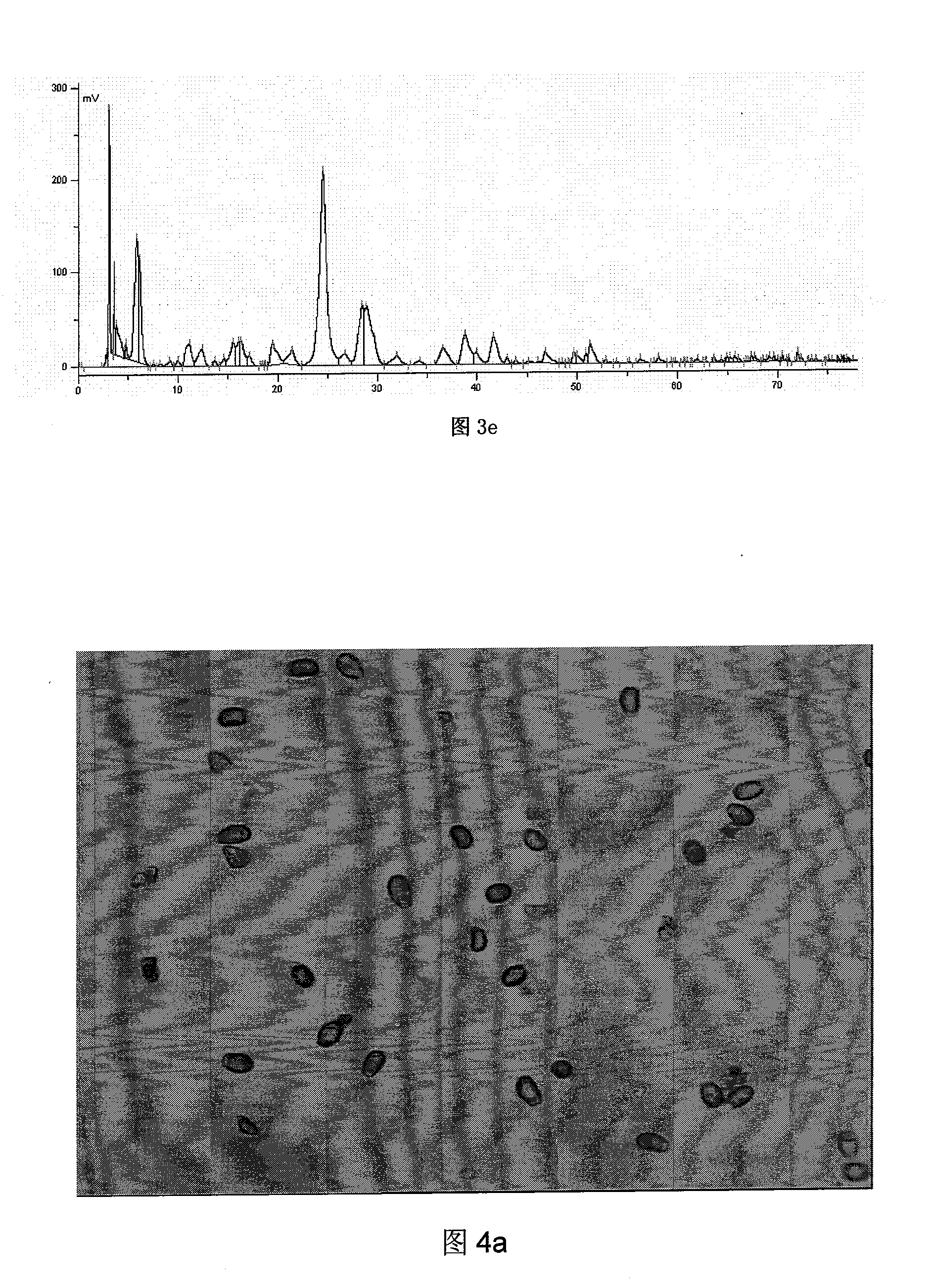

The invention relates to a composite mineral-leaching bacteria colony and use of the same in biological metallurgy. The composite mineral-leaching bacteria colony has a preserving number of CGMCC No.2395 in the Common Micro-organism Center of China General Microbiological Culture Collection Center. The composite mineral-leaching bacteria colony has strong oxidative activity within a temperature range from 30 to 52 DEG C as well as a working pH value of between 0.8 and 2.25 and an arsenic ion tolerance of 0 to 20 g / L. The composite mineral-leaching bacteria colony is used for extracting and recovering gold or copper, and greatly expands the use range of biological metallurgy in gold mines. Meanwhile, due to the wide temperature adaptation range, the composite mineral-leaching bacteria colony improves the oxidation speed and reduces production cost. Therefore, the composite mineral-leaching bacteria colony has a significant application prospect in biological metallurgy industry.

Owner:CHINA NAT GOLD GROUP CORP TECH CENT +1

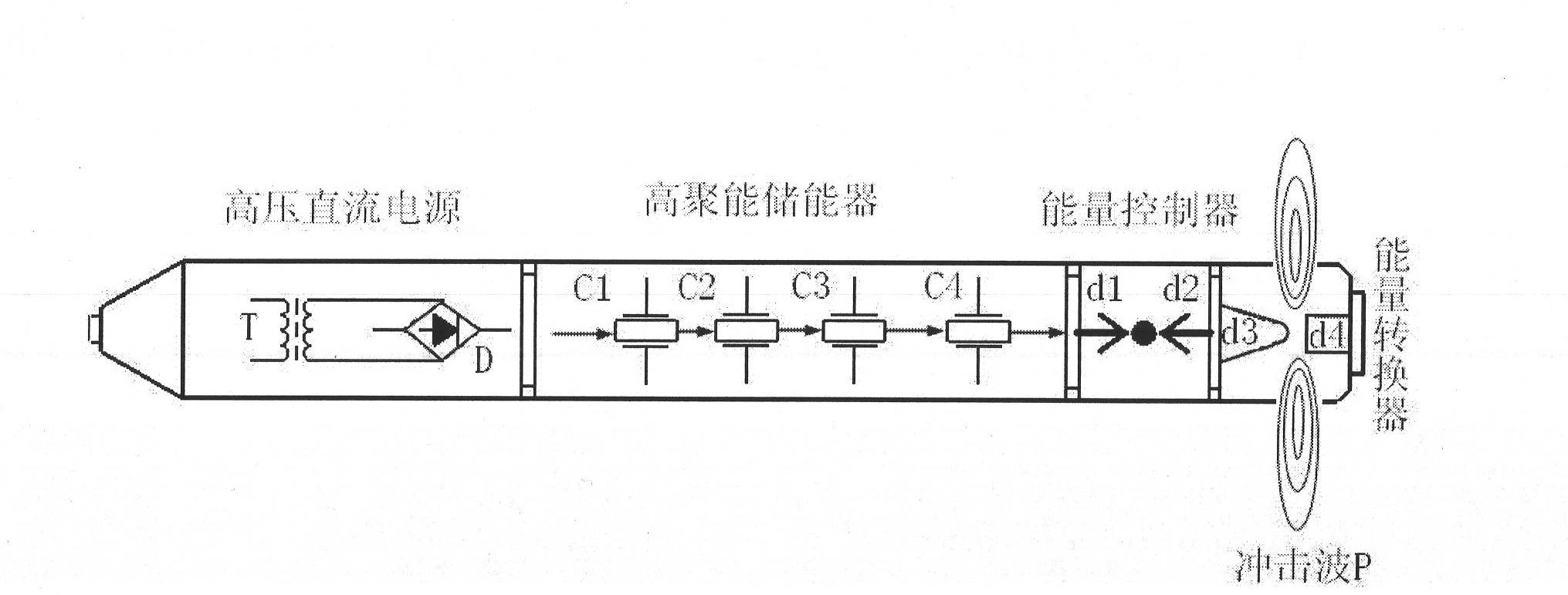

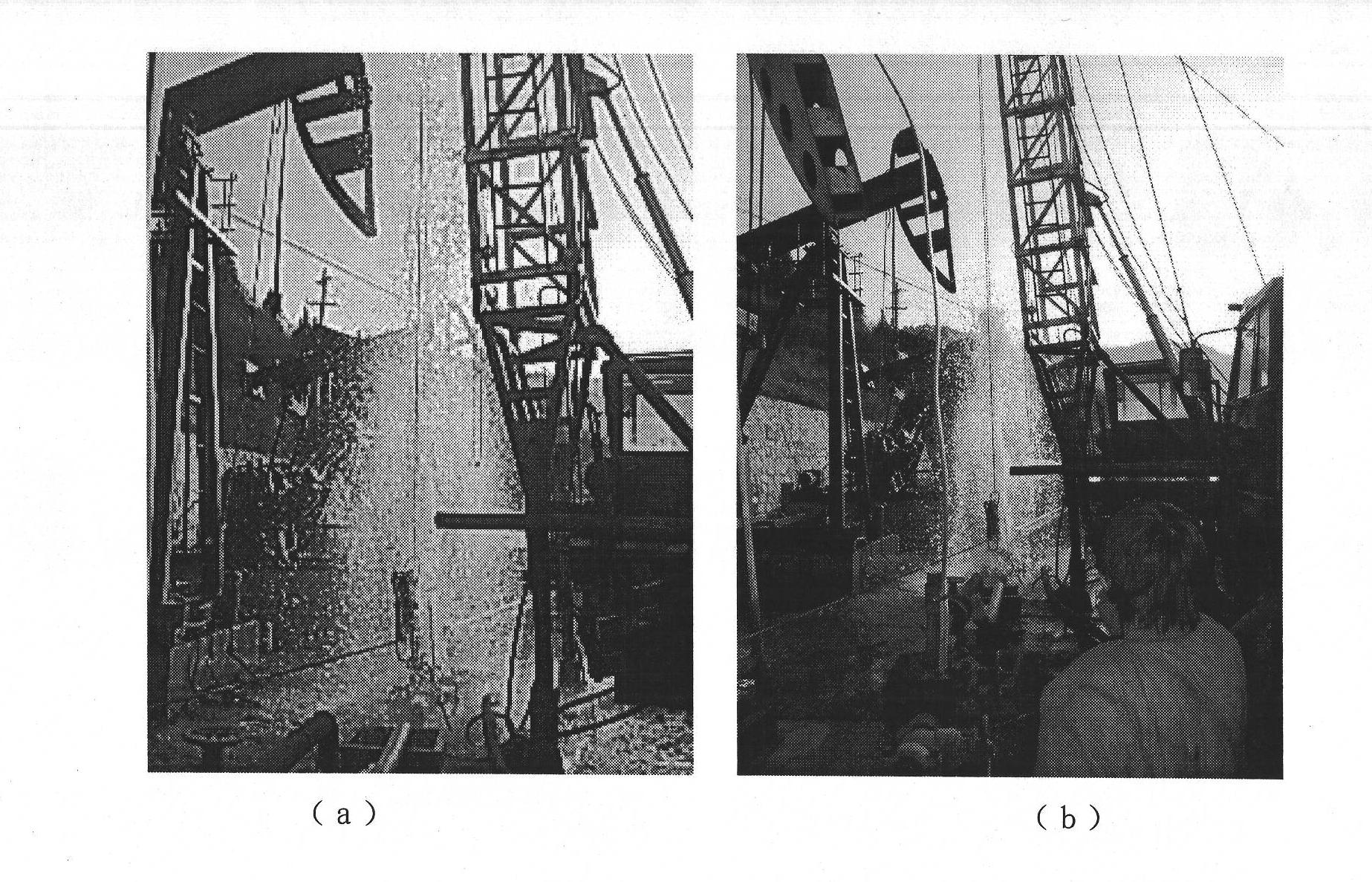

Ground pumping and mining coal seam gas well reformation method based on recurrence frequency impact waves

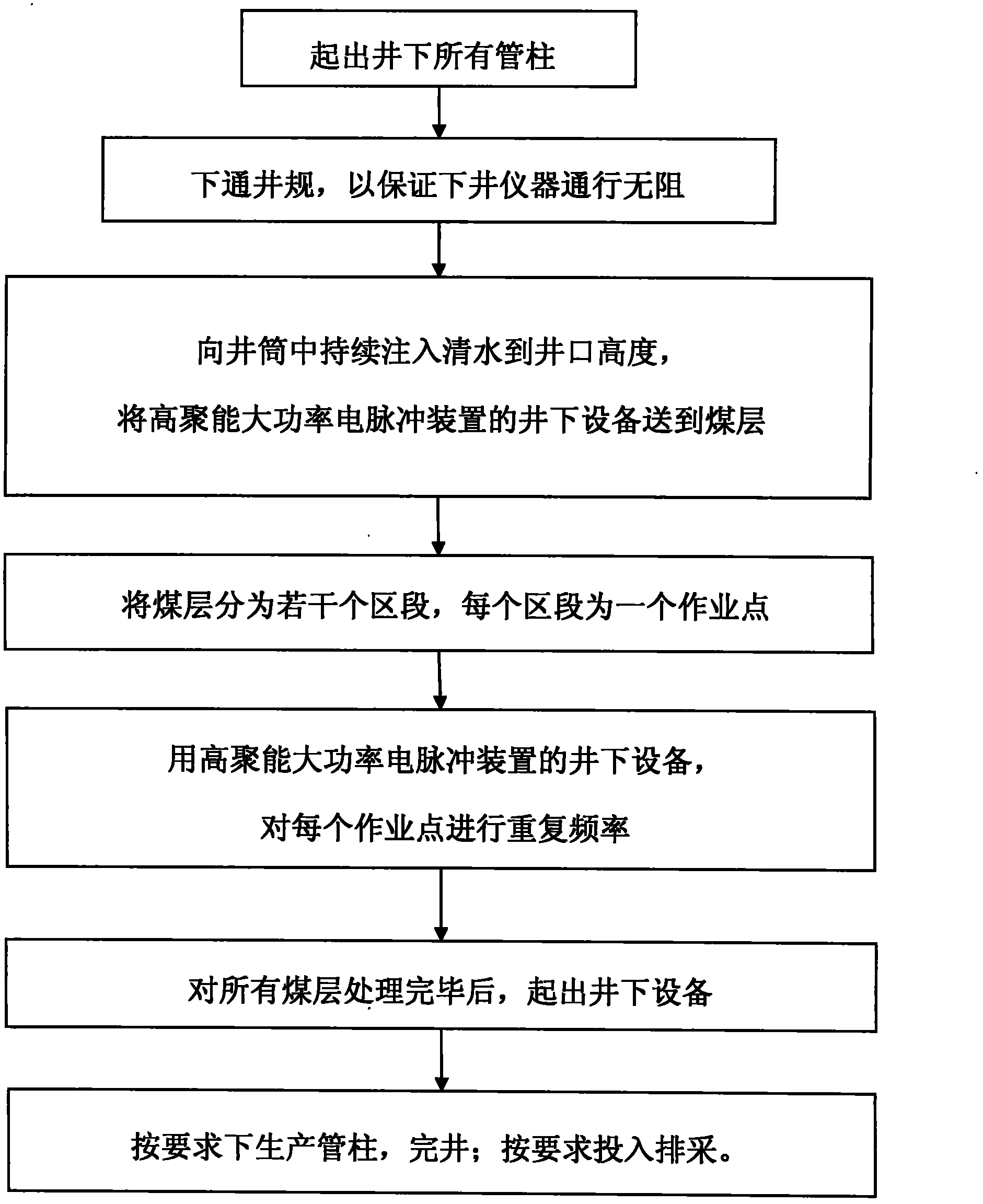

The invention discloses a ground pumping and mining coal seam gas well reformation method based on recurrence frequency impact waves; the method mainly solves the problem that in the prior art, the coal seam is damaged and compacted and the seepage and deabsorption of the coal seam cannot be improved simultaneously. The method comprises the following operation procedures of: (1) pulling out all tubular columns in a well; (2) putting a drift size gauge tool so as to ensure that downhole instruments go through the well without hindrance; (3) continuously infusing a coal bed gas well with underground water exhausted from the well or an adjacent well till water reaches the mouth of a well, and conveying underground equipment of a high energy-gathering high-power electrical pulse device to thecoal seam; (4) dividing the coal seam into a plurality of sections, wherein each section is an operation point; (5) using the underground equipment of the electrical pulse device for carrying out recurrence frequency impact wave treatment on each operation point; (6) pulling out the underground equipment after all the operation points are treated; (7) putting the production tubular column for well completion according to the requirements, and putting the production tubular column into pumping and mining. The method has the advantages that the method does not damage the coal seam and carries out the single-point recurrence frequency operation on the coal seam, and can be used for increasing the yield and production capacity of the coal bed gas well.

Owner:XIAN GUANTONG ENERGY TECH

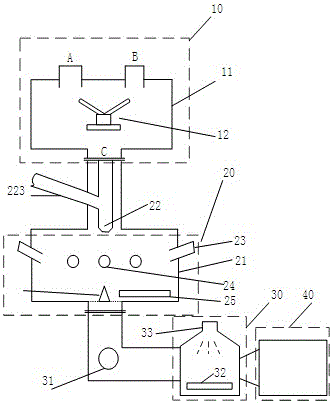

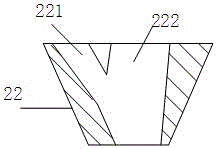

Fracturing pulse sand filling system with ultrahigh flow conductivity and method for operating fracturing pulse sand filling system

The invention relates to a fracturing pulse sand filling system with ultrahigh flow conductivity. The fracturing pulse sand filling system comprises an external control unit, an internal controlled unit, an external fracturing pump truck unit, a sand mixing truck and a fluid storage tank. Fracturing sand-mixed fluid is accommodated in the sand mixing truck, fracturing base fluid is accommodated in the fluid storage tank, the external control unit controls the internal controlled unit, so that the sand-mixed fluid in the sand mixing truck and the base fluid in the fluid storage are alternately pumped into the external fracturing pump truck unit at intervals, and the sand-mixed fluid and the base fluid are finally alternately pumped into underground exploitation cracks at intervals by the external fracturing pump truck unit. The fracturing pulse sand filling system has the advantages that propping agent slugs added with fibers can be injected in a pulse manner under the control of the system, the flow conductivity of the prop cracks is greatly improved, a lag effect due to continuous opening and closing of an existing sand mixing truck is prevented, damage to the sand mixing truck is reduced, and pressure building during propping agent injection can be effectively prevented by the system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

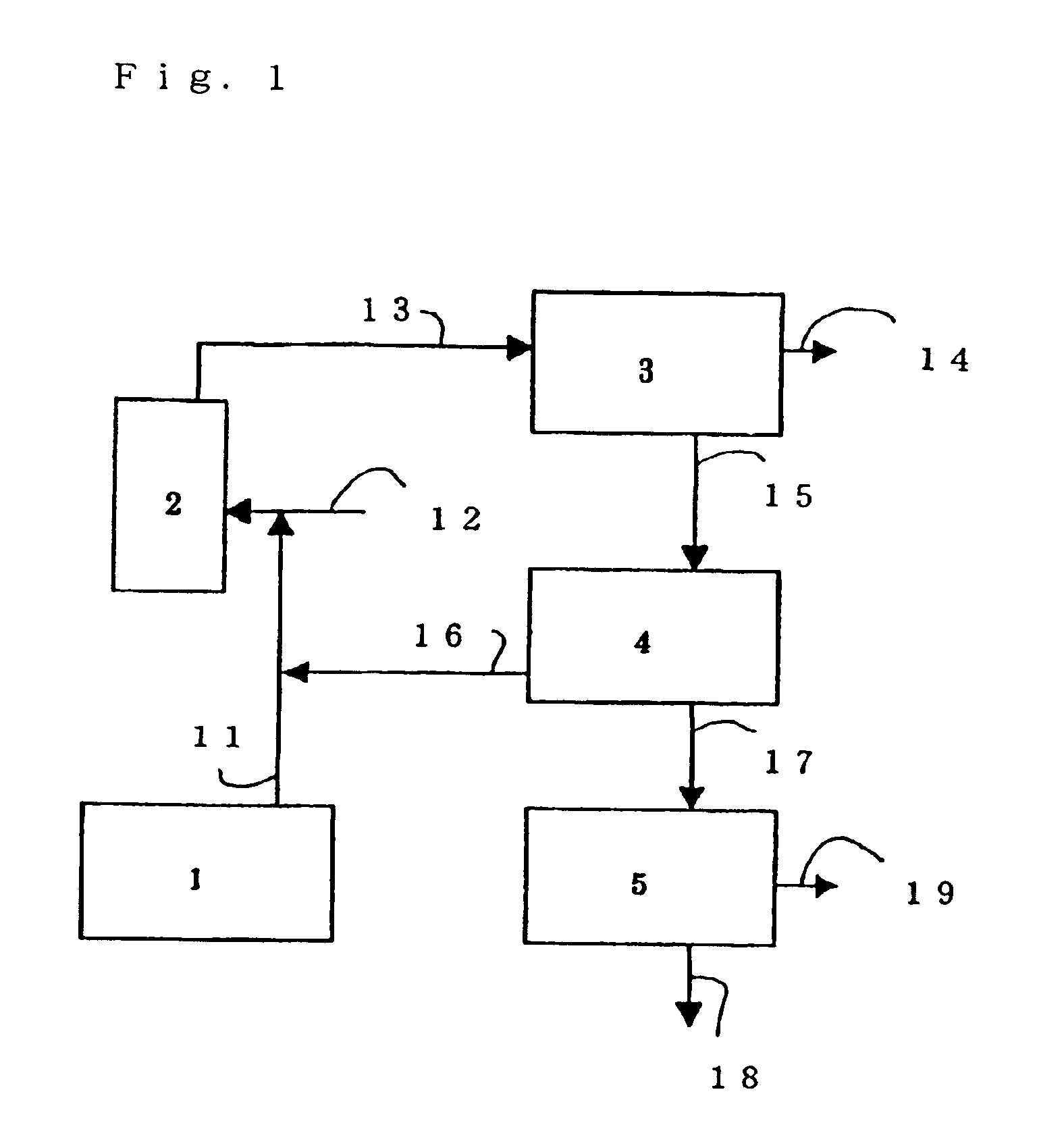

Method for normal temperature high voltage continuous extracting natural product effective ingredient and equipment thereof

InactiveCN101249315AImprove dissolution efficiencyHigh extraction rateSolid solvent extractionNatural productAdditive ingredient

The invention discloses a normal temperature high pressure continuous extraction method of active ingredients of natural products, including five steps of crushing, soaking, ultra-fine smashing, high pressure extraction and solid-liquid separation, wherein the material liquid after the ultra-fine smashing is continuously pumped into a high pressure extractor by an underflow pump in the high pressure extraction, the material liquid achieves the pressure of 1 to 90MPa via a high pressure pump, the material liquid is impacted on a collision ring in the high pressure extractor by an annular working gap in the high pressure extractor being subject to the high pressure, and the cells of the natural products in the material liquid is crushed; the five steps are carried out at normal temperature, the normal temperature refers to the temperature ranged from 10 to 45 DEG C, the better temperature ranges from 15 to 40 DEG C, and the best temperature ranges from 15 to 30 DEG C. The invention also discloses a device to realize the method.

Owner:中山装备制造工业研究院 +1

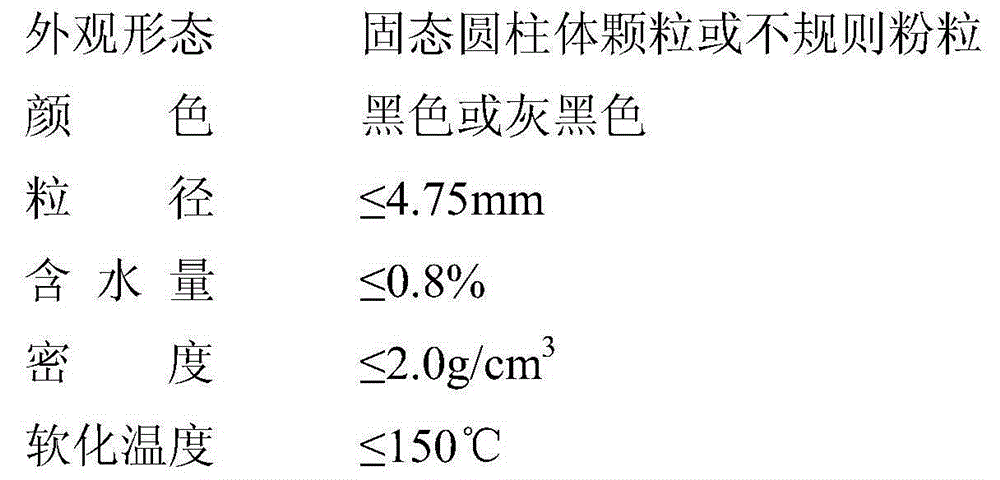

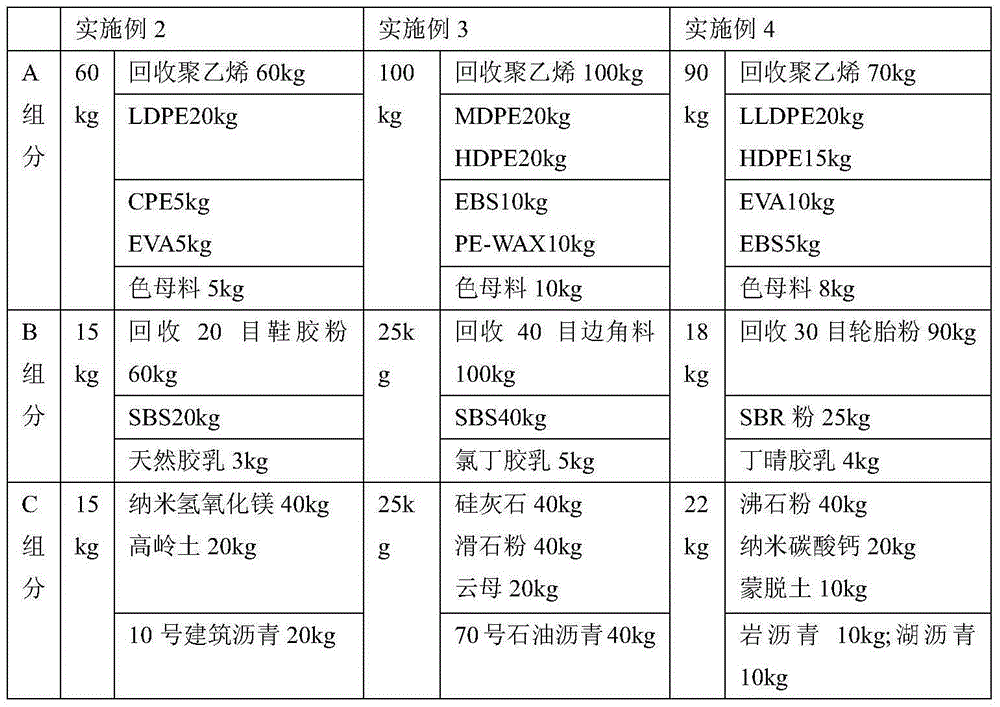

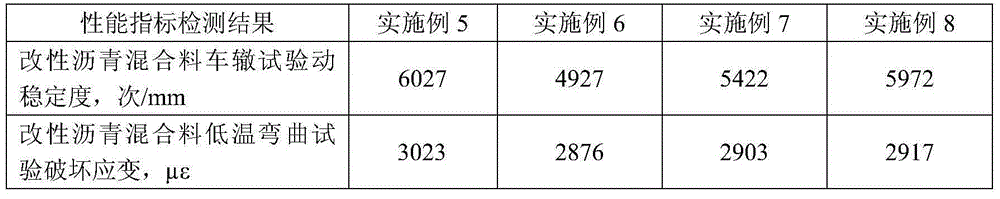

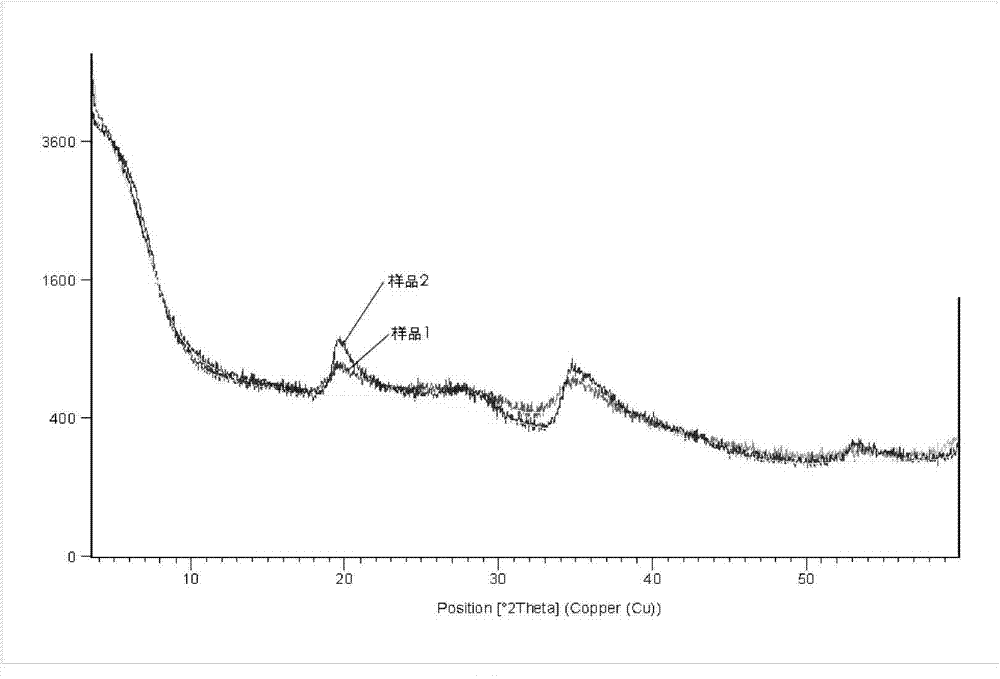

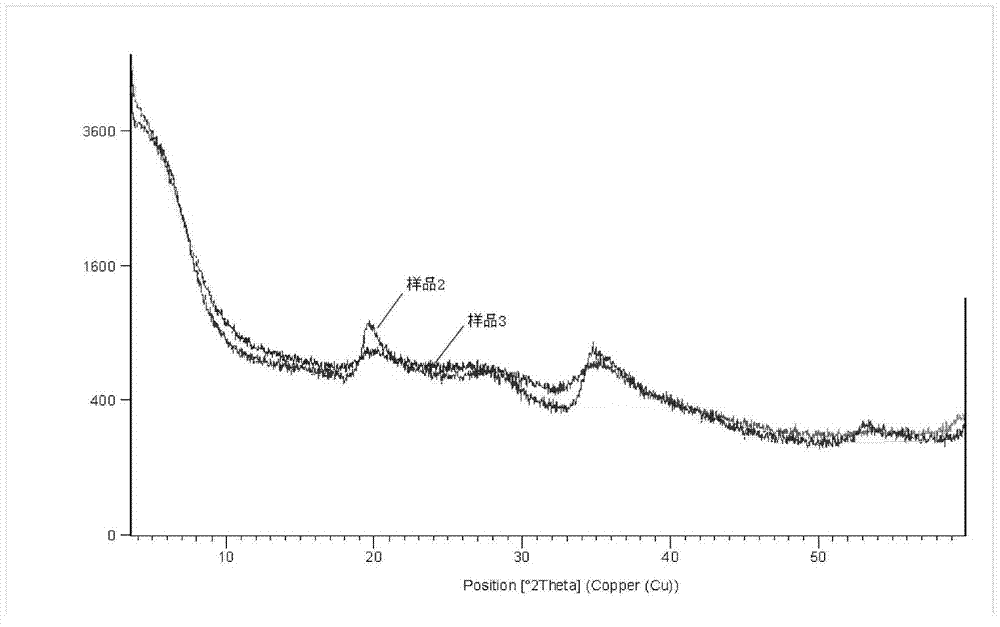

Modified asphalt mixture modifier and preparation method therefor

InactiveCN105153511AImprove high temperature anti-rutting performanceImprove low temperature crack resistanceBuilding insulationsMasterbatchAsphalt

The invention relates to a modified asphalt mixture modifier and a preparation method therefor. The modified asphalt mixture modifier is prepared from the following components in parts by weight: 60-100 parts of a component A, 15-25 parts of a component B and 15-25 parts of a component C, wherein the component A is prepared from the following components in parts by weight: 60-100 parts of recovered polyethylene, 20-40 parts of polyethylene, 10-20 parts of auxiliaries and 5-10 parts of color masterbatch; the component B is prepared from the following components in parts by weight: 60-100 parts of recovered rubber powder, 20-40 parts of rubber powder and 3-5 parts of latex; the component C is prepared from the following components in parts by weight: 60-100 parts of inorganic powder and 20-40 parts of an asphalt material. According to the modifier provided by the invention, the comprehensive performance of the modified asphalt mixture can be improved. By directly inputting the modifier into a stirring cylinder of a mixing plant, stirring and modification are synchronously implemented. The produced modified asphalt mixture is superior to a conventional modified asphalt mixture in performance.

Owner:陕西长大博源公路养护科技有限公司

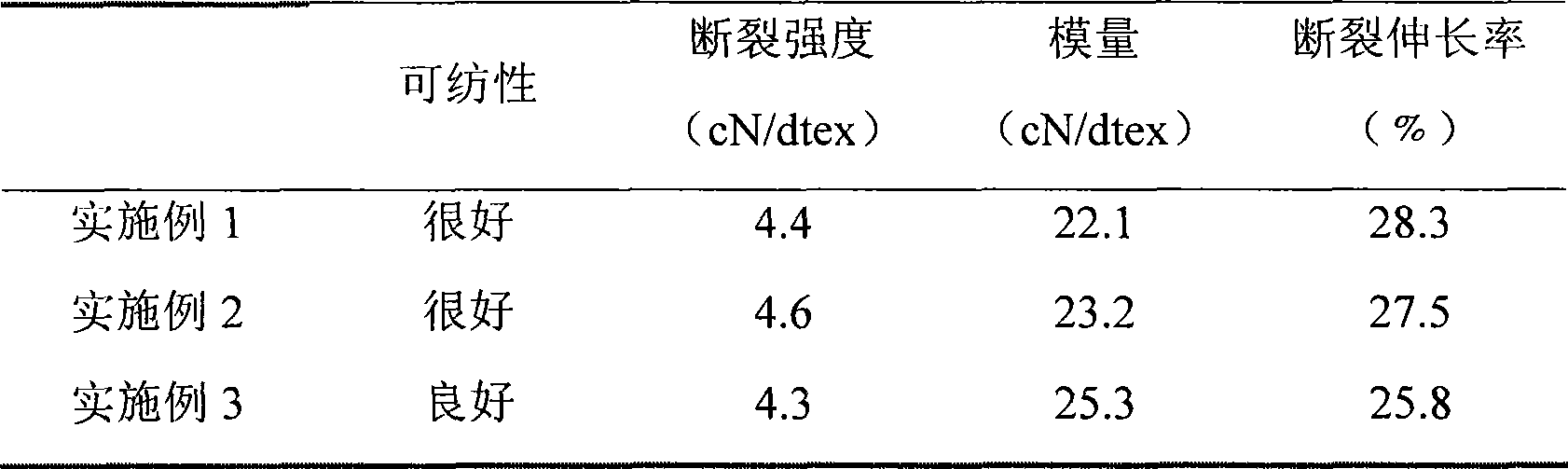

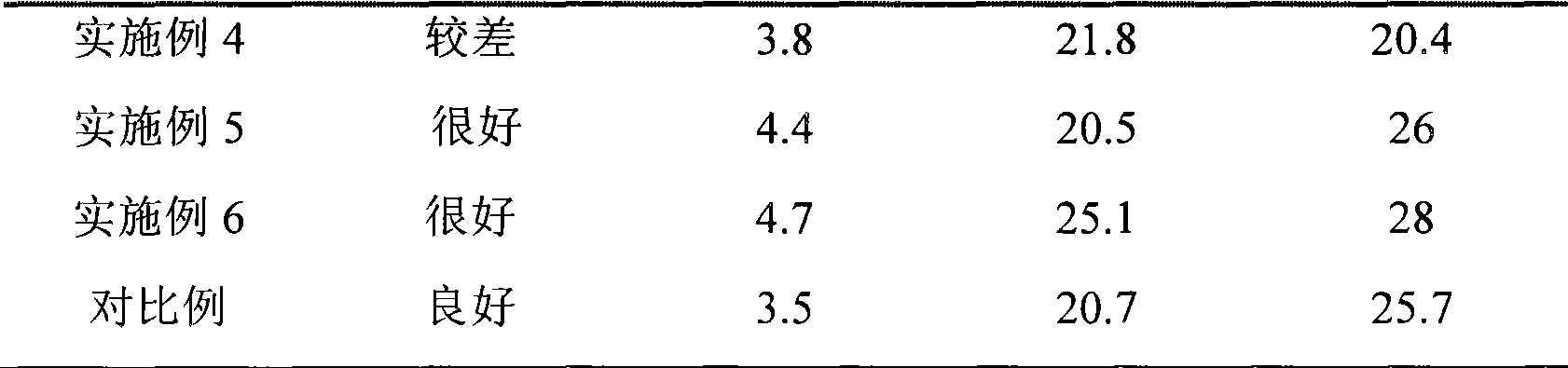

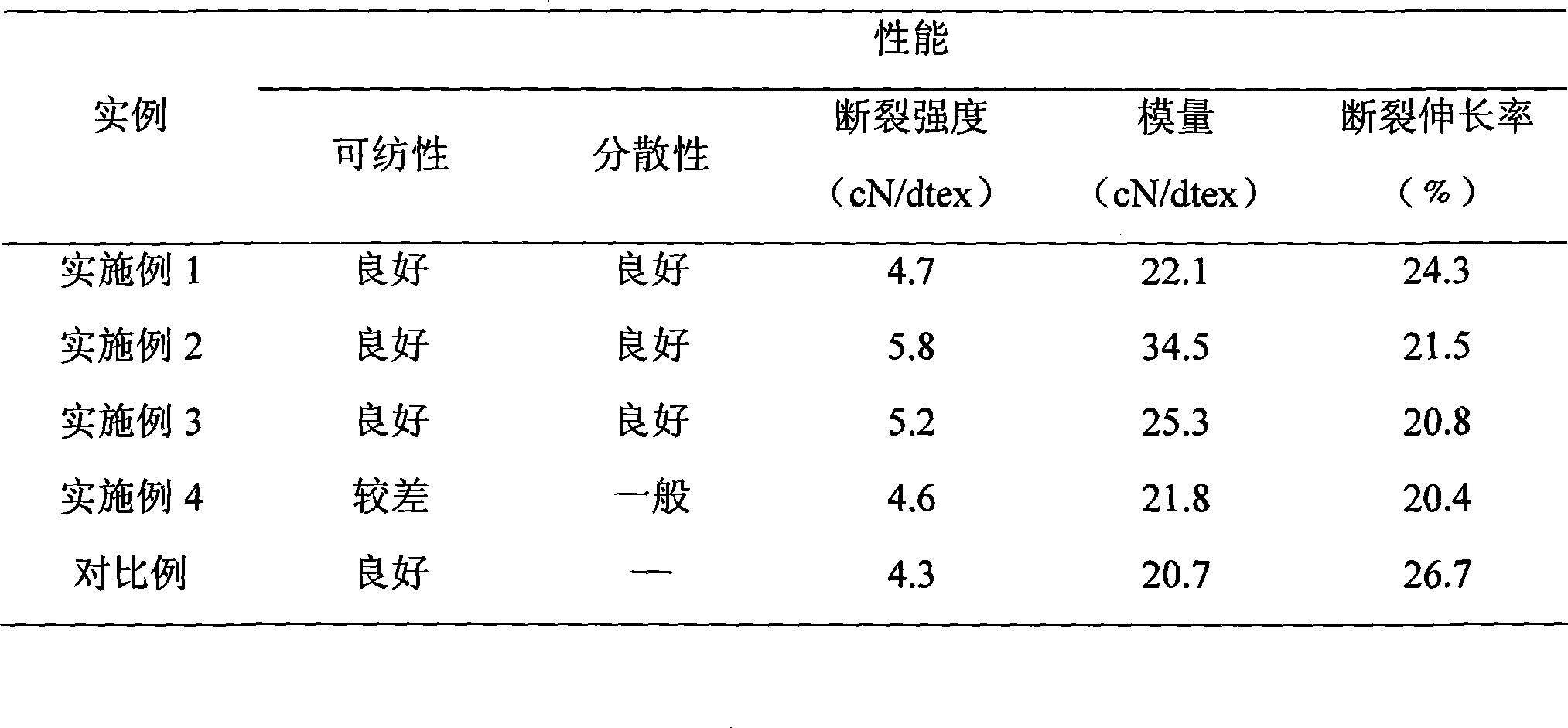

Polyphenyl thioether/ultra-fine calcium carbonate particulate composite fiber and preparation method thereof

InactiveCN101368300ANo severe adhesionsAvoid energy consumptionMonocomponent synthetic polymer artificial filamentMelt spinning methodsTextile fiberChemical industry

The invention relates to polyphenylene sulfide (PPS) / nano-calcium carbonate mixture and a preparation method for the fiber thereof. The method includes the steps of mixing polyester slices, nano-calcium carbonate particulates, reactive monomer and other additives in a high speed mixer while rising the temperature to approximately 205 DEG C so as to enable the polyphenylene sulfide slices to intenerate and the nano-calcium carbonate and other additives to be evenly adhibitted onto the polyphenylene sulfide slices, without heavy conglutination between the particles on the polyphenylene sulfide slices. The polyphenylene sulfide (PPS) / nano-calcium carbonate mixture prepared through the method has excellent processability and can be made into textile fiber, thin film or reinforcement plastics by means of melt blown or melt spinning process. The invention can greatly reduce the production cost and bring good economic benefits. The polyphenylene sulfide(PPS) / nano-calcium carbonate mixture has good thermal stability, flame retardancy, chemical corrosion resistance and good mechanical property and spinning property; therefore the polyphenylene sulfide(PPS) / nano-calcium carbonate mixture is widely applicable to the industrial sectors like chemical industry, light industry and mechanical industry, and is particularly good for accelerating the popularization and application of high-temperature house-bag dust removal. The preparation method has the advantages of simple process, easy control, low cost, short production period, environment friendly and particularly being applicable to the industrial production.

Owner:DONGHUA UNIV

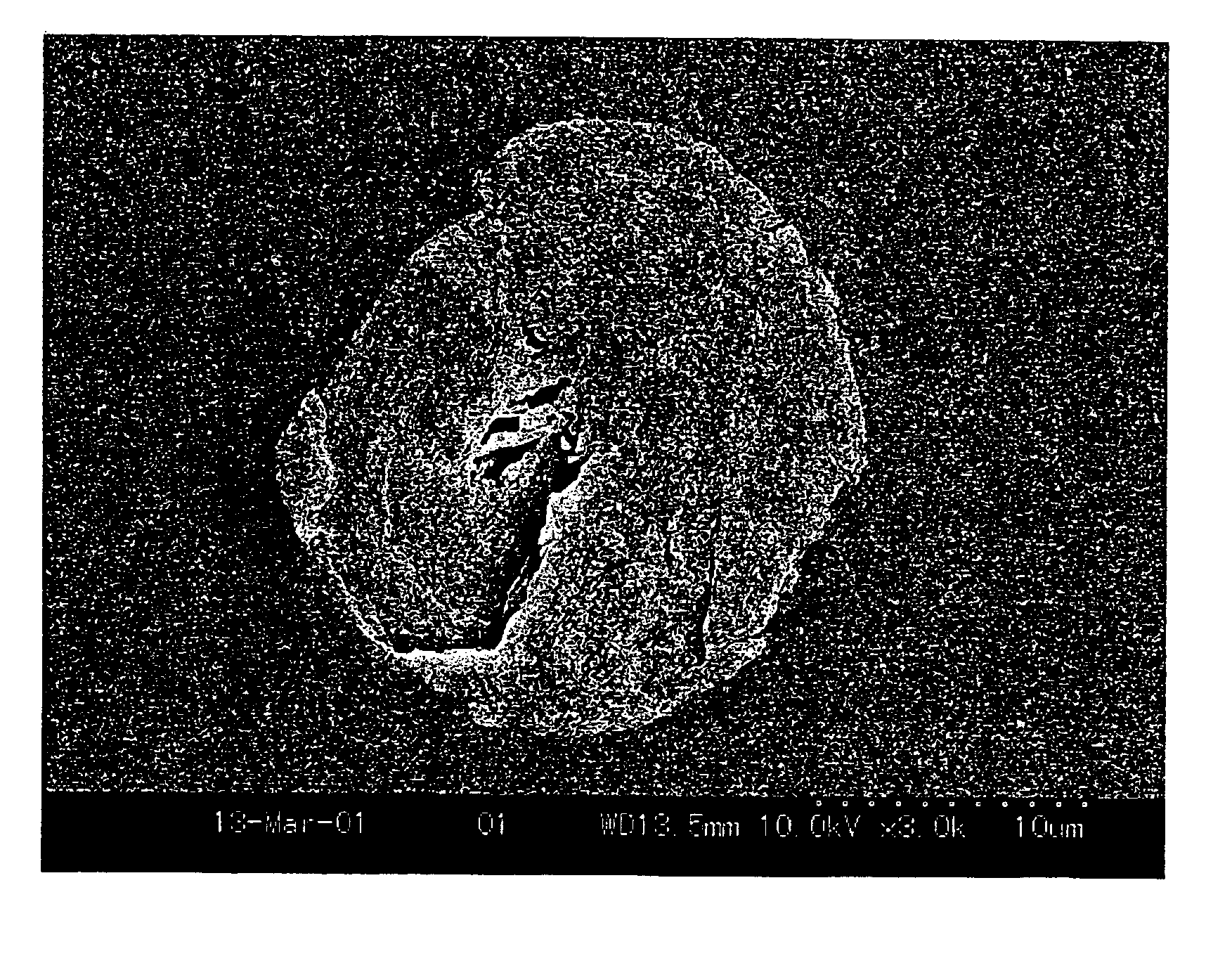

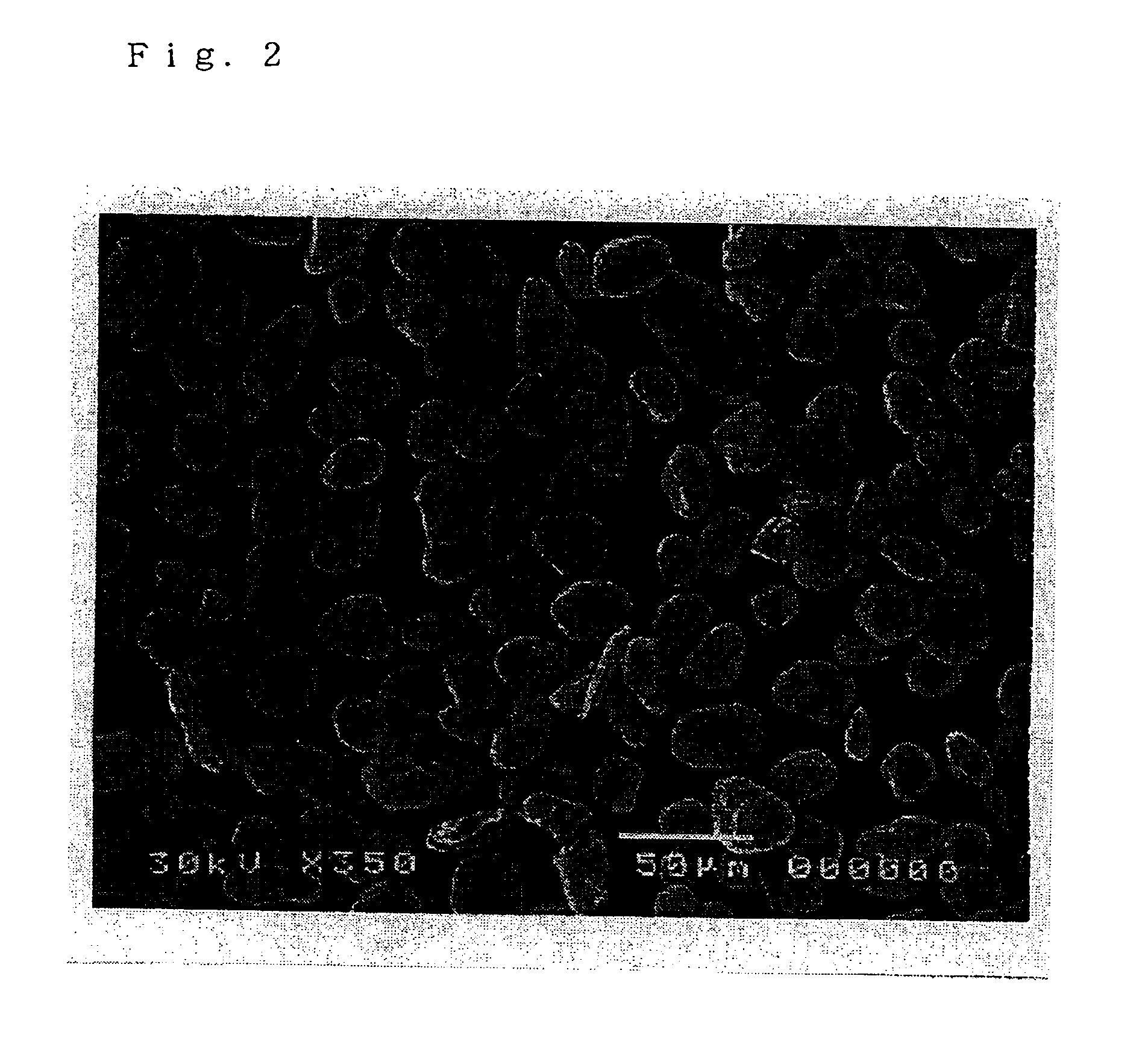

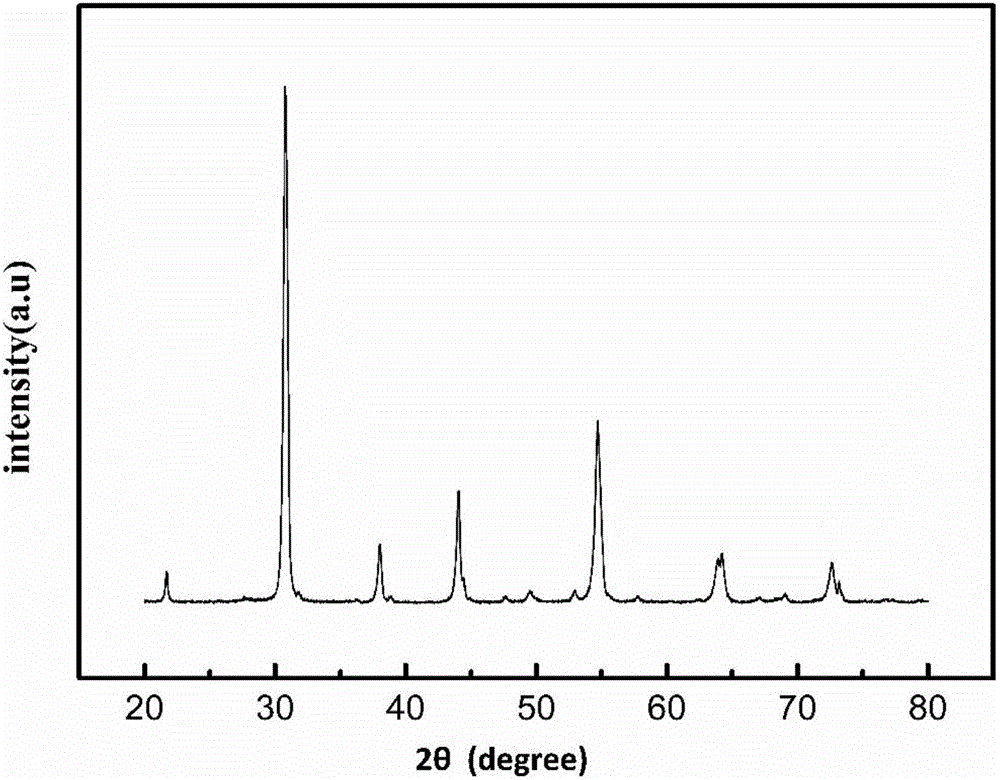

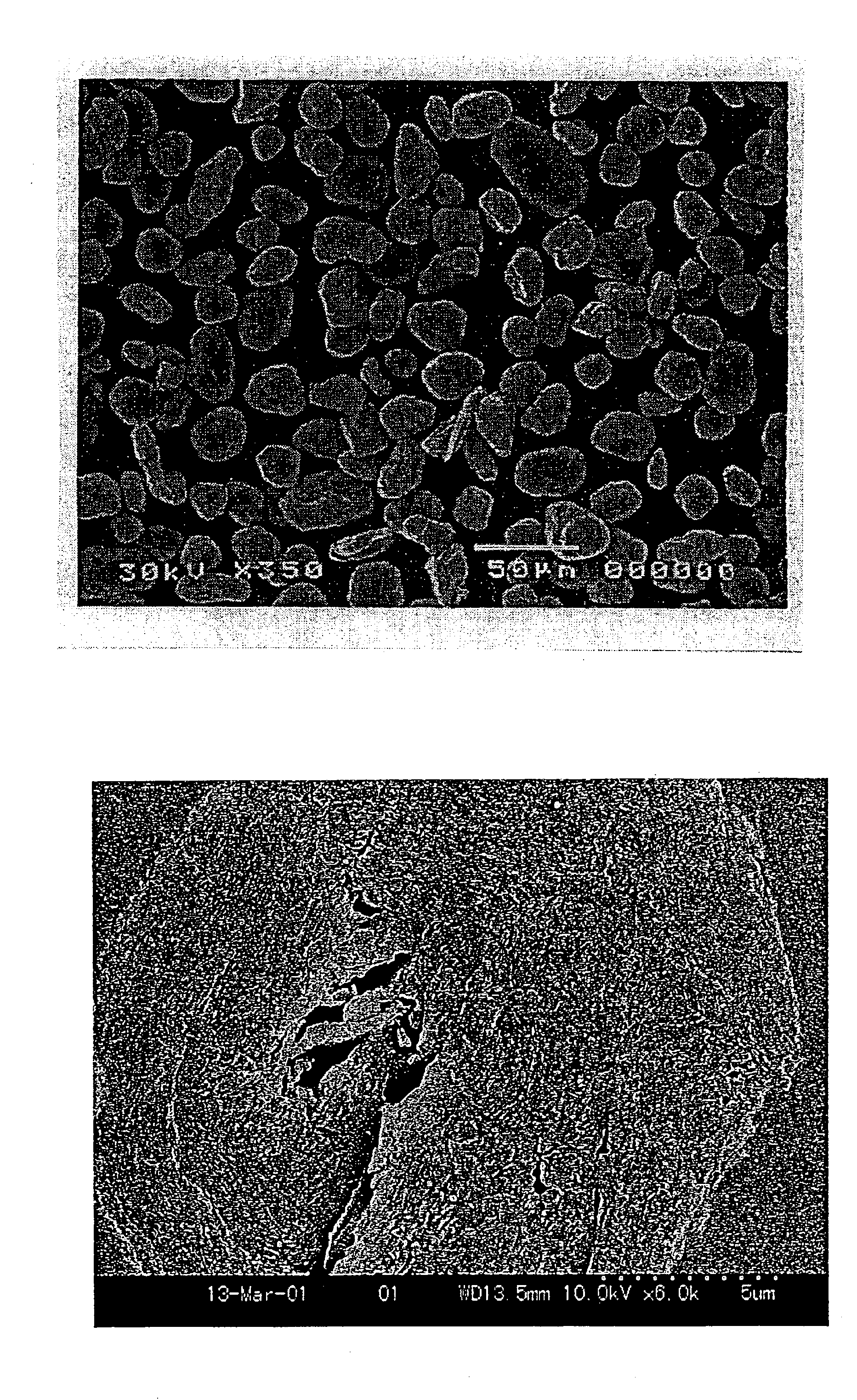

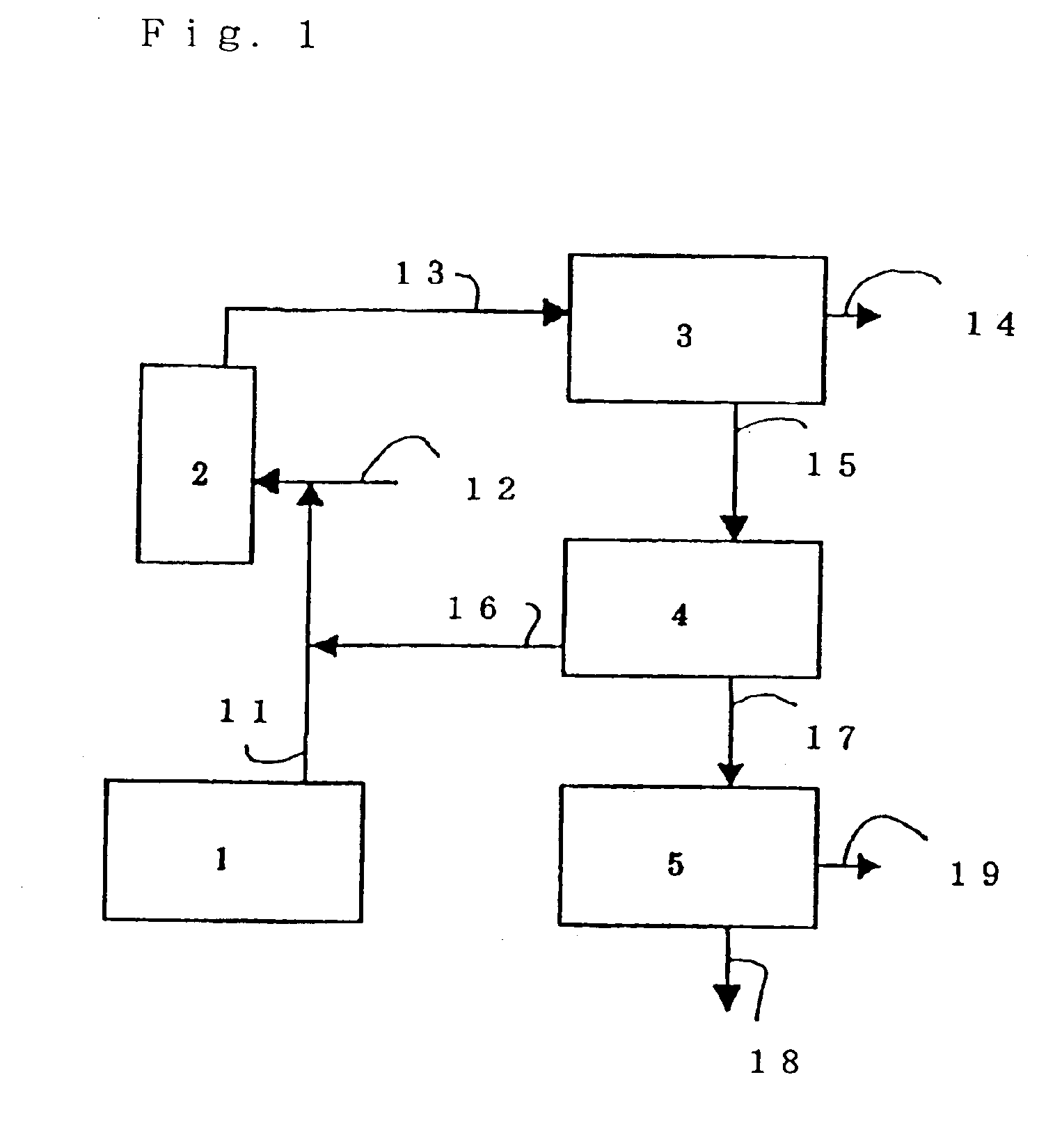

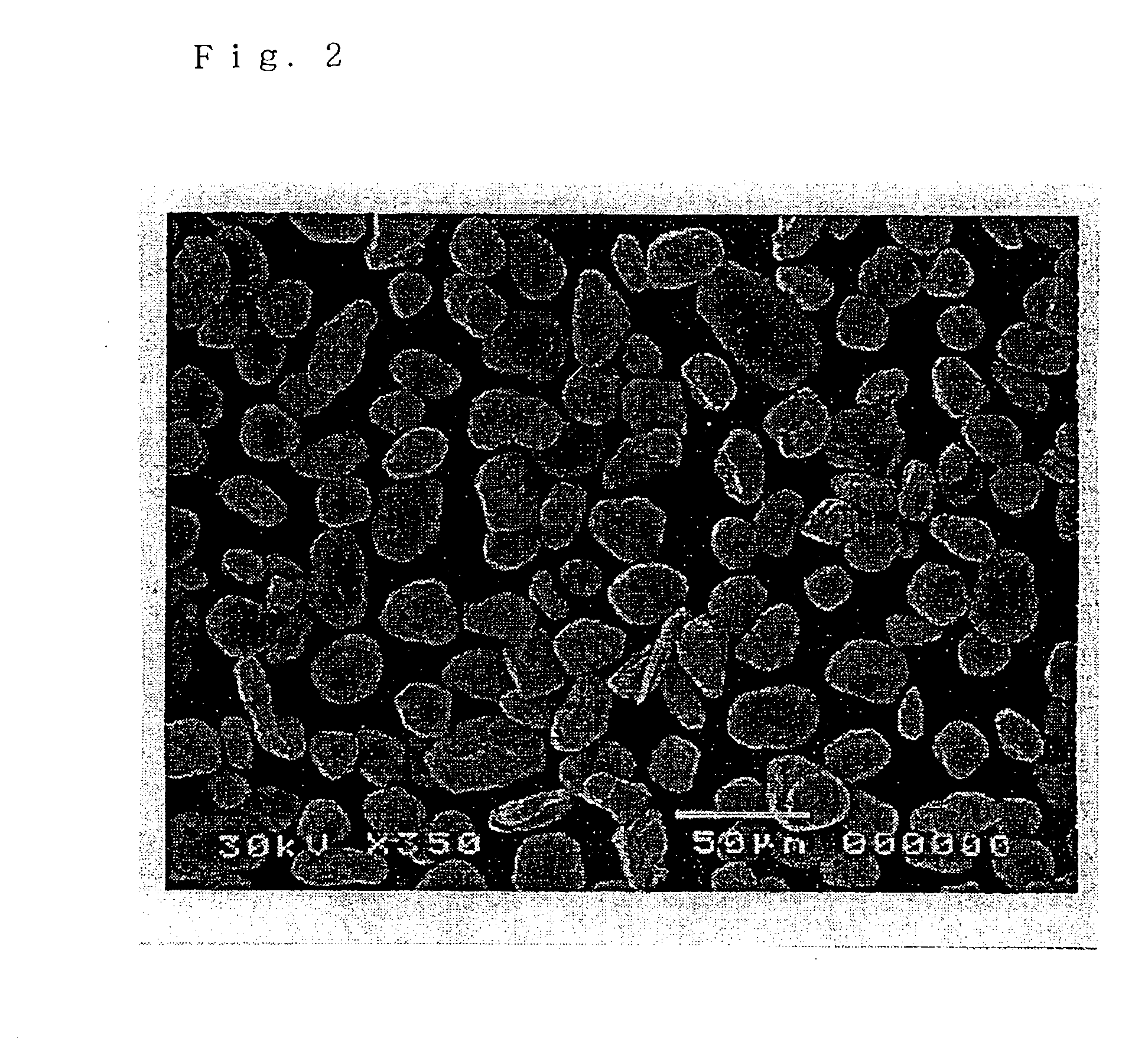

Graphite particles and process for production thereof

InactiveUS6939526B2Strong shear forceStrong compressionPigmenting treatmentNon-aqueous electrolyte accumulatorsSpherical shapedGraphite particle

Graphite particles having a bent laminate structure inside each particle are produced by feeding, into an impact grinder, graphite particles having an average particle diameter of 5 mm or less together with a gas current to apply an impact to the graphite particles to form, by a compression force, a bent laminate structure inside each graphite particle. The resulting graphite particles have an average particle diameter of 100 μm or less, are low in anisotropy, have a nearly spherical shape, and are highly crystalline.

Owner:NIPPON POWER GRAPHITE CO LTD

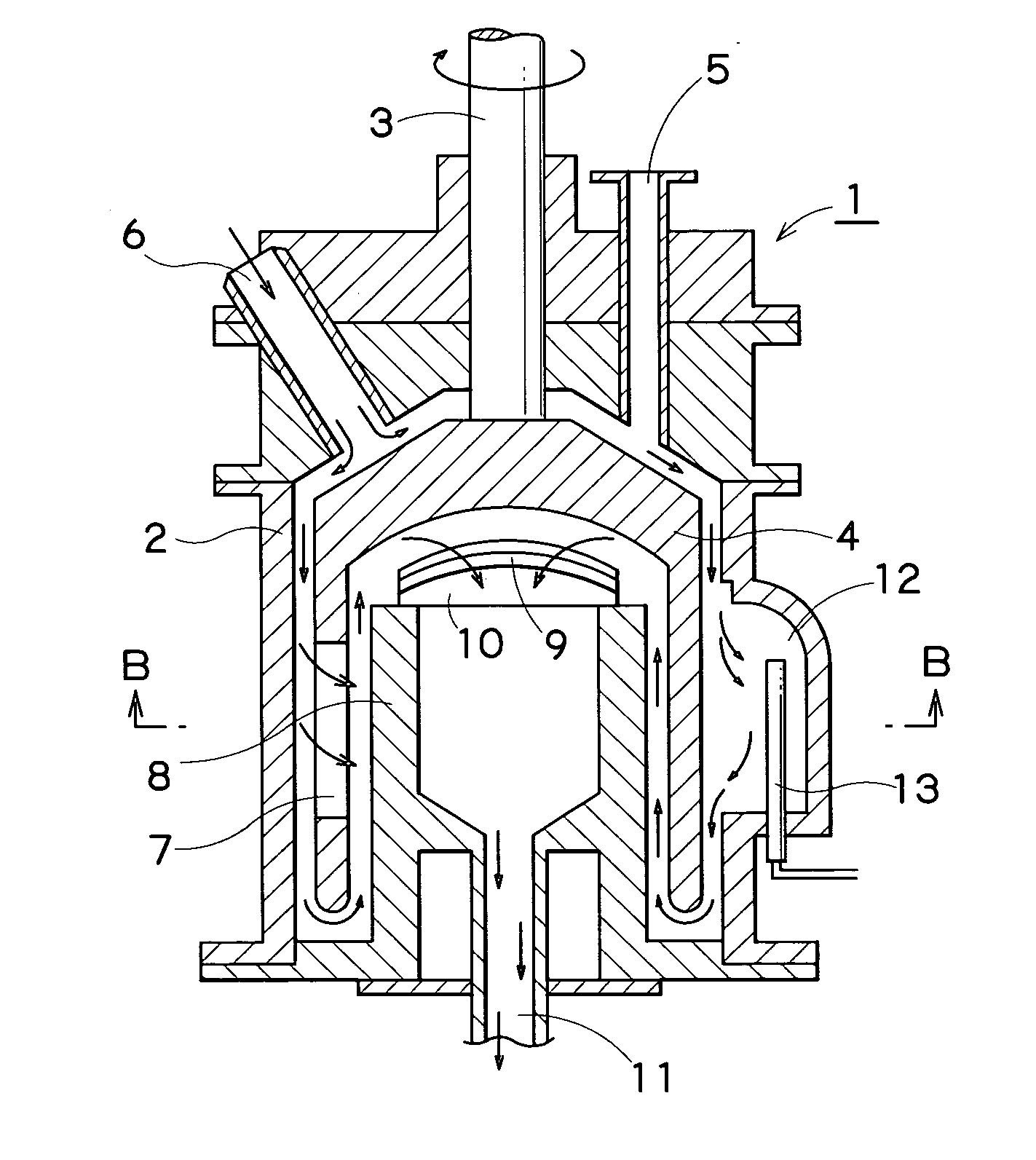

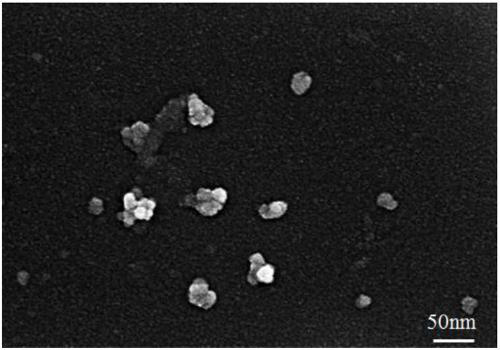

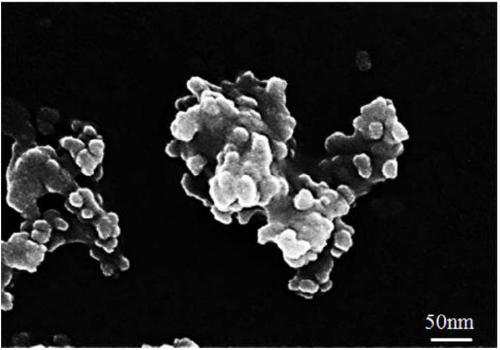

Dispersing or milling apparatus, and dispersing or milling method using same

ActiveUS20080197218A1Used economicallyOvercome problemsNanostructure manufactureShaking/oscillating/vibrating mixersShock waveCavitation

A material to be treated containing solid particles in a liquid is stirred together with milling media, and irradiated with ultrasonic waves during stirring to finely mill the solid particles to nanometer size and disperse the solid particles in the liquid. The ultrasonic waves create cavitation in the liquid and upon decay of the cavitation, shock waves are produced that cause the solid particles to vigorously collide with one another and with the milling media and these collisions, together with the shearing forces created by collision of the milling media, can produce on a commercial scale nano particles having an average particle size of at most 100 nm.

Owner:NAT INST FOR MATERIALS SCI +1

Composite polypropylene wax used for plastic and preparation method of composite polypropylene wax

The invention relates to a production method for composite polypropylene wax used for plastic. The composite polypropylene wax comprises polypropylene low polymers, Fischer-tropsch wax or microcrystalline wax and industrial hydrogenated oil, and has the properties that the softening point is 100 DEG C or above, and the average molecular weight ranges from 1500 to 3000. As an excellent dispersing agent, on the aspects of color master production and pigment dispersion, the composite polypropylene wax produced through the method has the advantages that effective molecular weights are concentrated, wherein the molecular weights are narrowly distributed and concentrated, and therefore the dispersion effect and the coloring force are easily improved, and relatively speaking, the addition amount can be decreased under the certain dispersion requirement; the excellent heat resistance and the excellent thermal stability are achieved; the melting point and the viscosity matching are moderate, and the shearing force is facilitated, wherein the softening point is 110 DEG C, the high viscosity is 150 CP / 140 DEG C, produced color master particles have high intermiscibility and mobility and moderate in viscosity, the shearing force is increased, and dispersity is improved.

Owner:扬州罗兰新材料有限公司

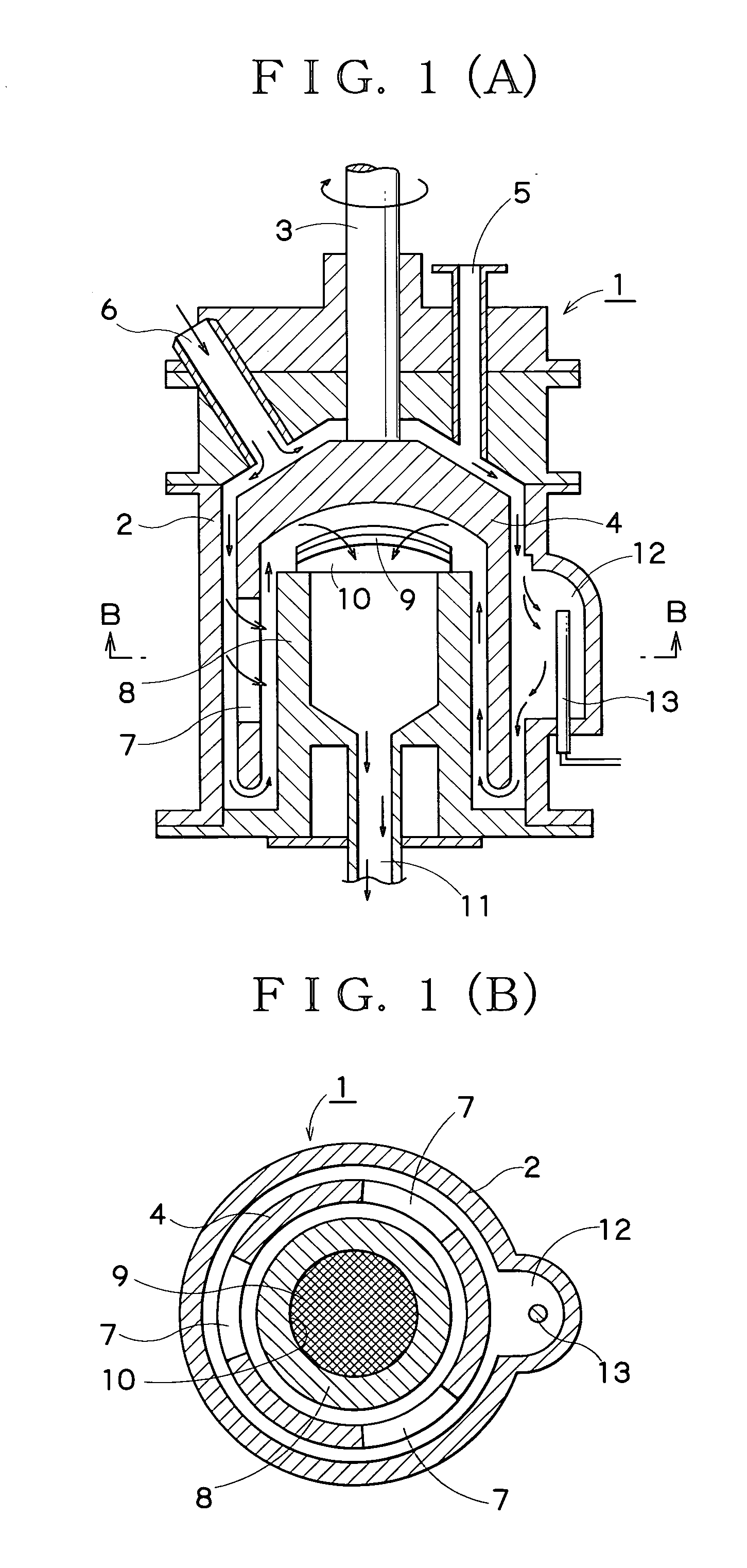

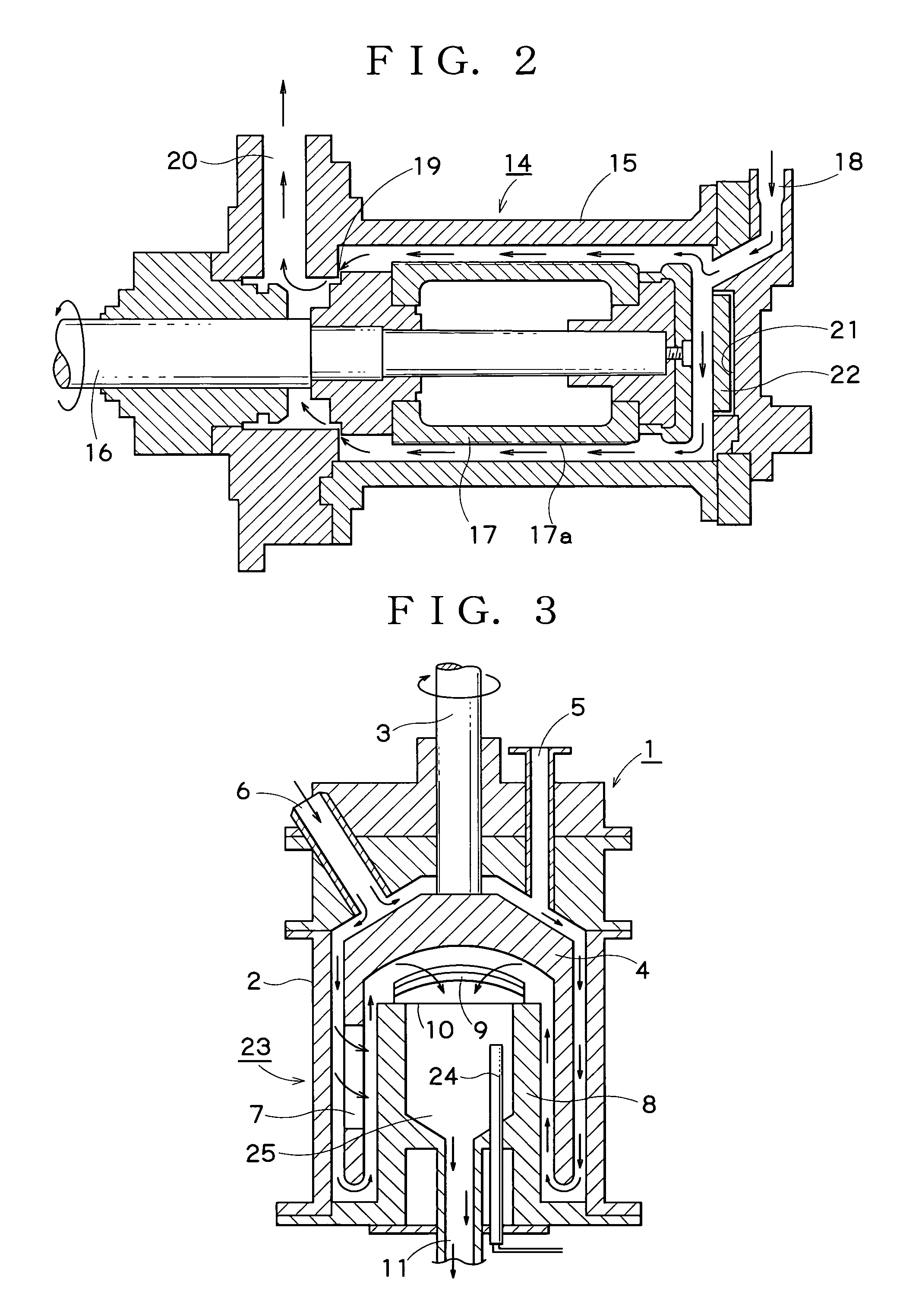

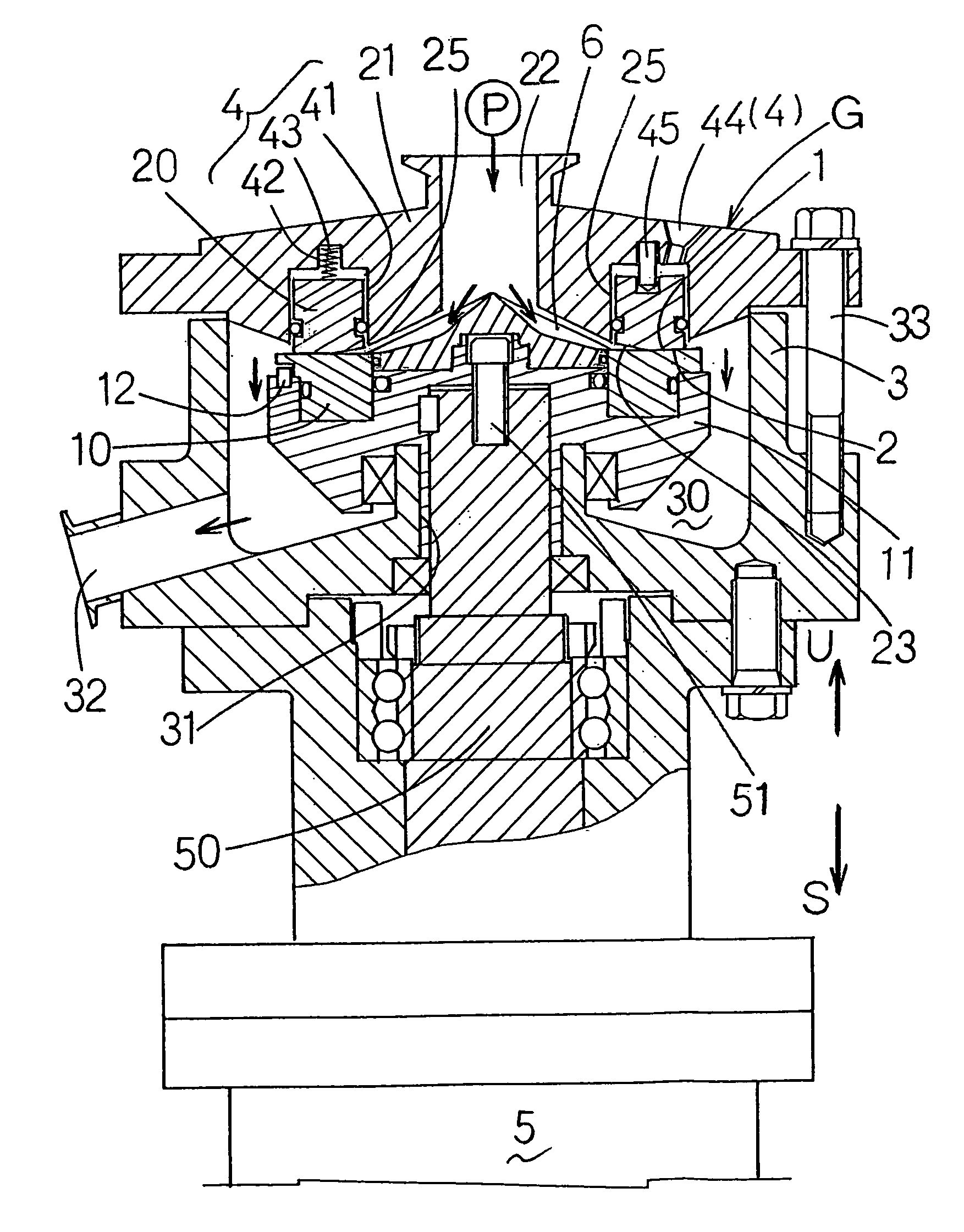

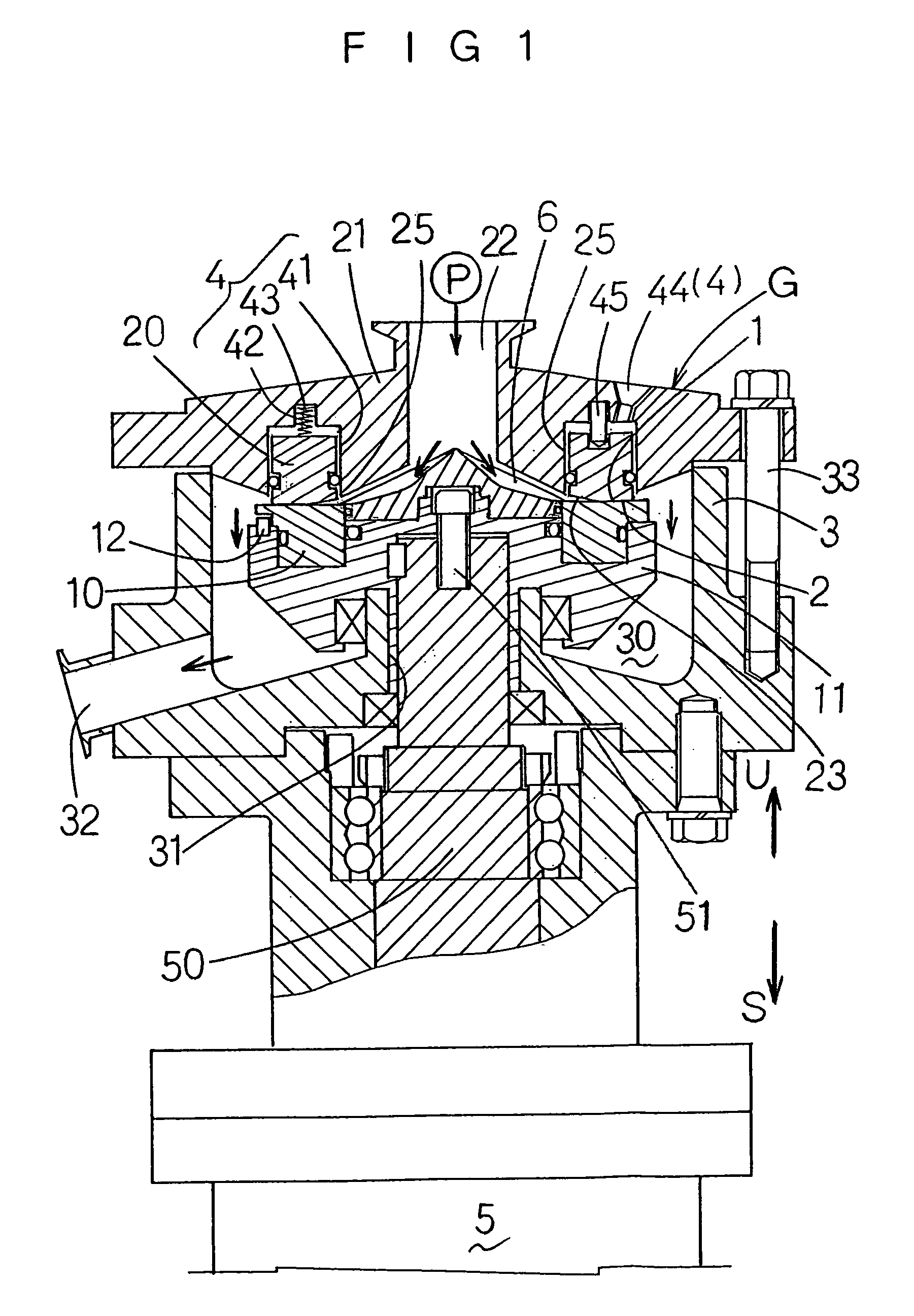

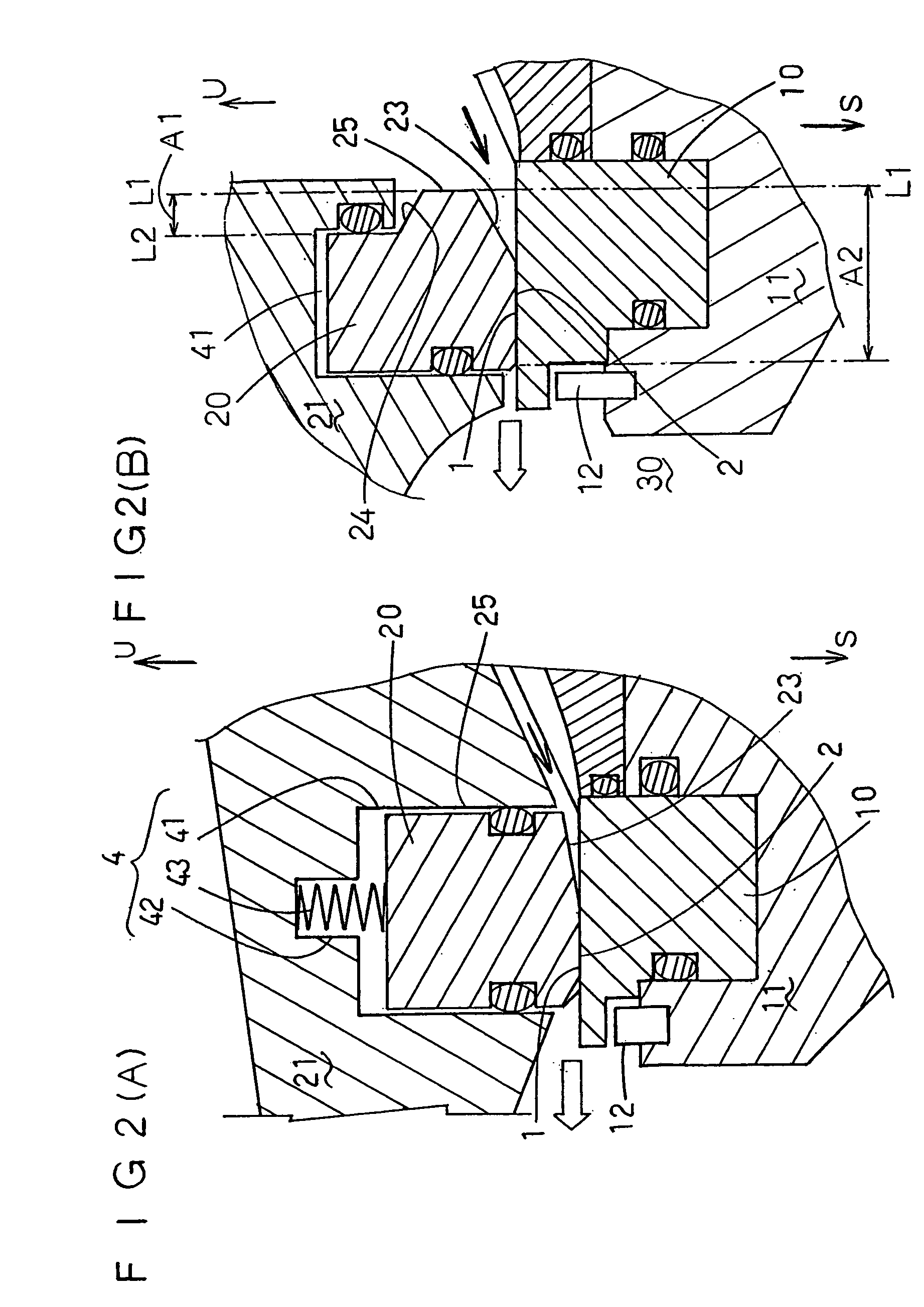

Processing apparatus and method for fluid, and deaerator therewith

InactiveUS7131604B2Simple structureImprove productivityFlow mixersTransportation and packagingProduction rateContact pressure

A processing apparatus for fluid with a simple structure, high productivity, ability of precise dispersion, emulsification and grinding, is provided.The apparatus of the present invention comprises at least two processing faces of a first face and a second face, both of which are arranged in a tight-closed passage, and positioned opposite to each other to constitute part of said passage, and a contact pressure applying mechanism for putting both faces 1, 2 into closed contact with each other, wherein the rotation of the second processing face 2 in respect of the first processing face 1 may cause dispersion or emulsification of the fluid to be processed between both processing faces 1, 2. The first and second processing faces 1, 2 are placed in closed contact with or adjacent to each other by means of said contact pressure applying mechanism, and the fluid to be processed is actuated by said rotation to pass between the first and second processing faces 1, 2, as it is forming fluid films between said processing faces 1, 2, so that said fluid will be emulsified or dispersed to a desired extent.

Owner:M TECH CO LTD

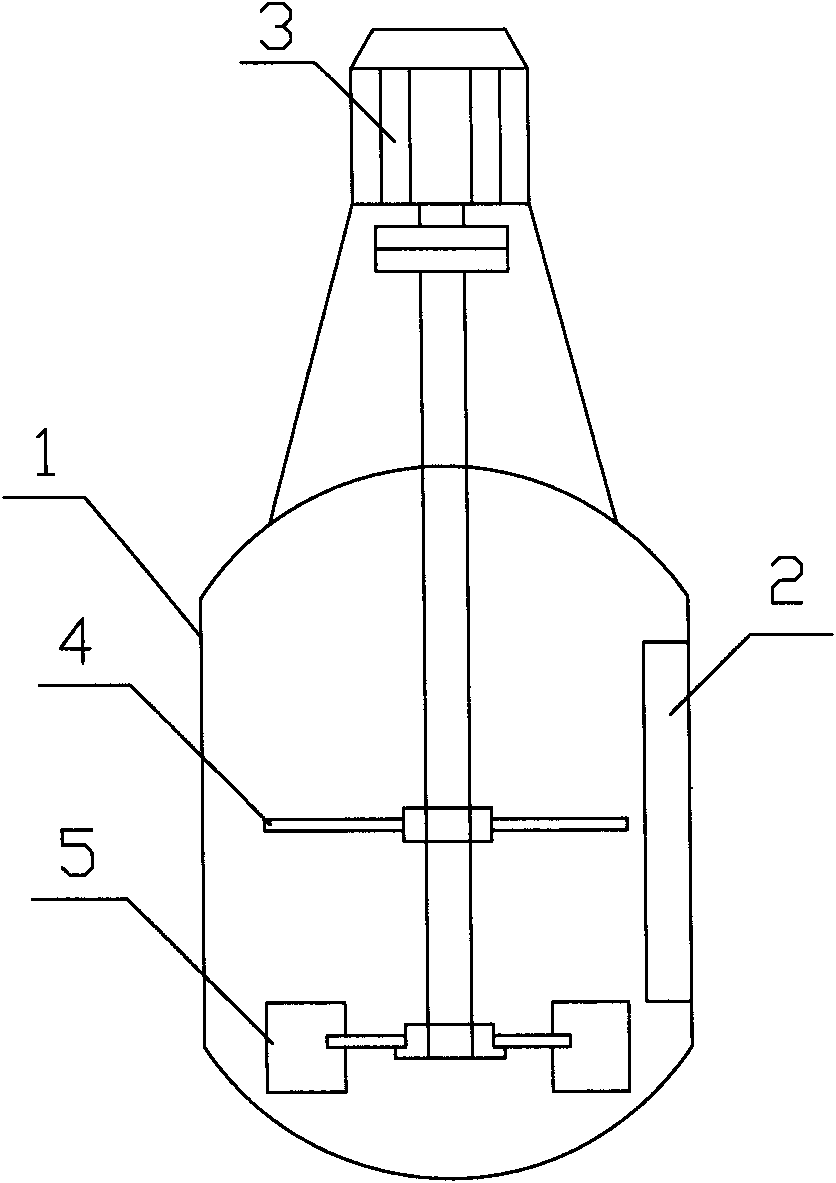

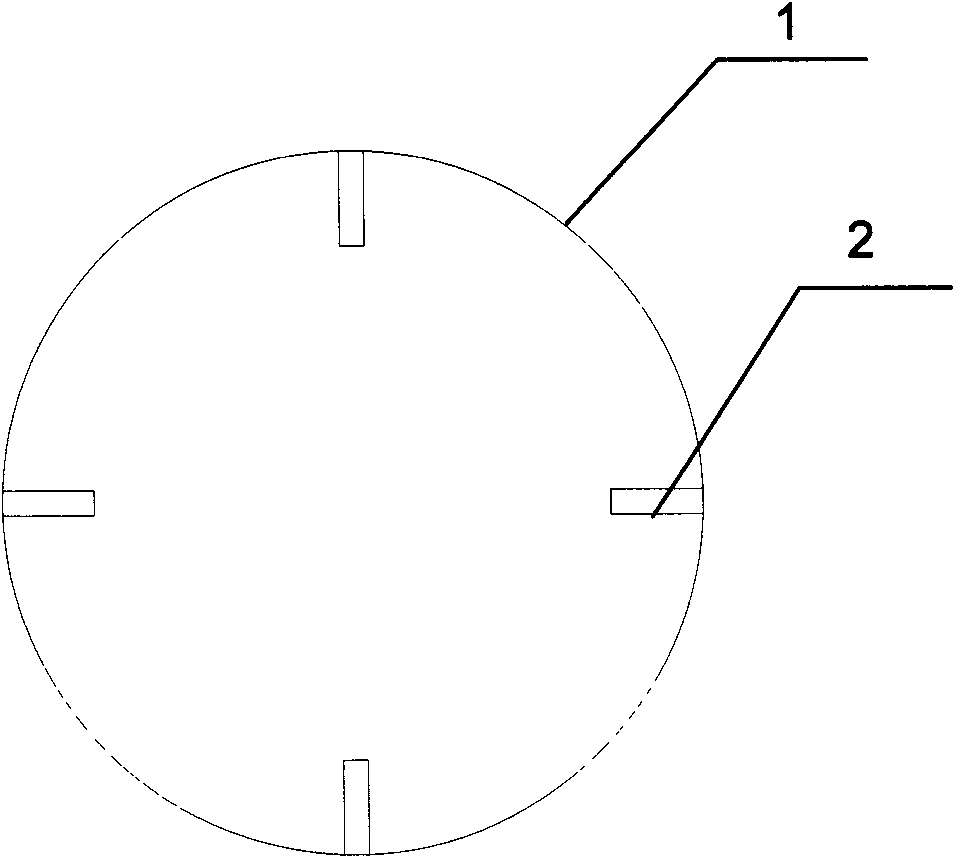

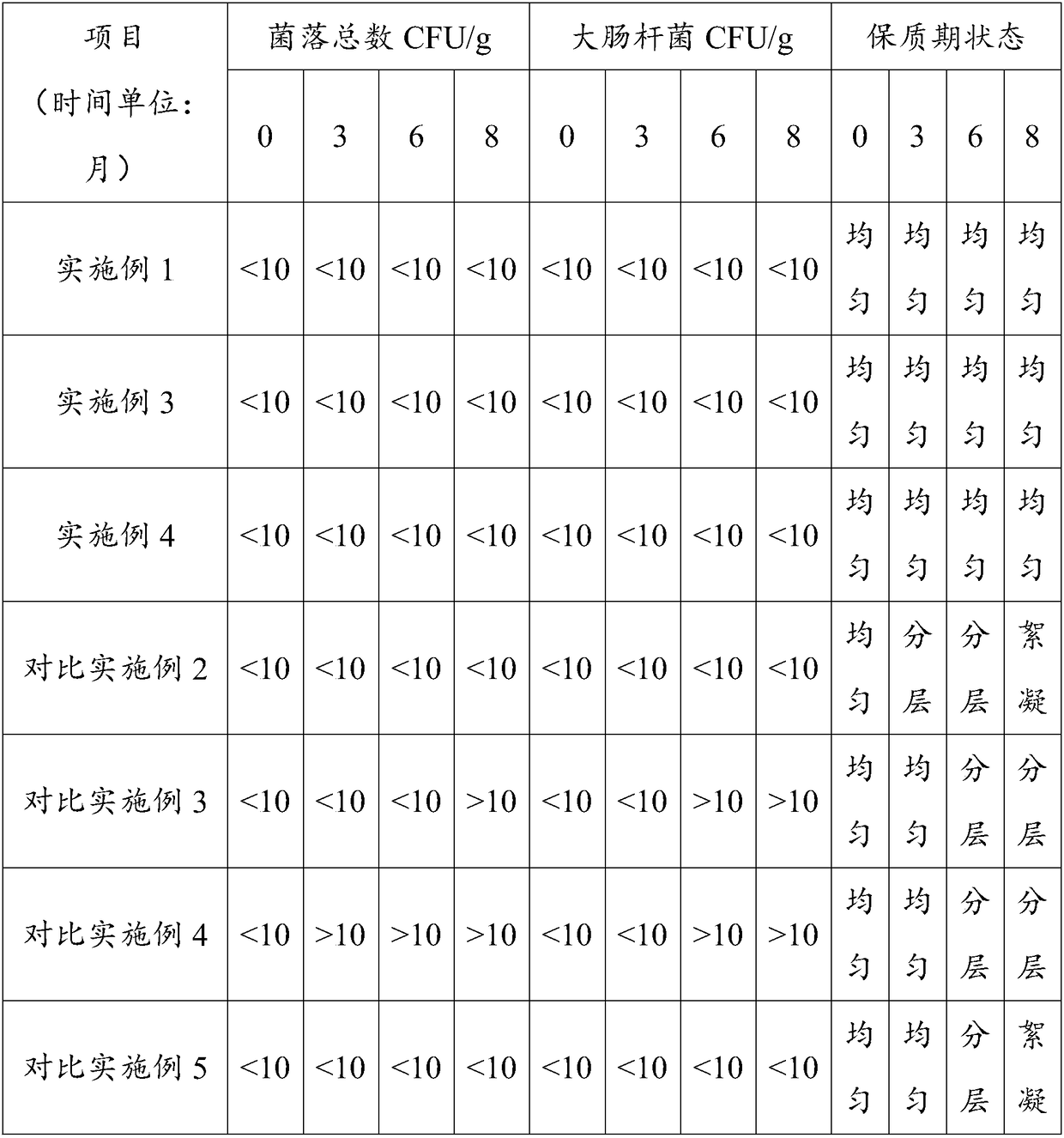

Production process for oil-free powdery yolk lecithin

ActiveCN101613369AEvenly distributedGood dispersionChemical/physical/physico-chemical stationary reactorsPhosphatide foodstuff compositionsYolkOil free

The invention discloses a production process for oil-free powdery yolk lecithin. The production process comprises the following steps: in a combined stirring tank, removing neutral fat in yolk powder with acetone and extracting yolk lecithin in the yolk powder with absolute ethanol to obtain the oil-free powdery yolk lecithin. The invention also discloses a structure of the combined stirring tank. The prepared oil-free powdery yolk lecithin has an acetone insoluble substance content more than or equal to 95 percent and a lecithin content more than or equal to 75 percent. The production process is characterized by high extraction efficiency, convenient operation, low cost and suitability for industrialized production. The combined stirring tank of the invention is used by combining a blade type stirrer and a disk turbine type stirrer to solve the problem that single stirrer cannot make fluid rapidly achieve a turbulent flow condition; the blade type stirrer can stir the upper fluid up and down to rapidly achieve a turbulent flow condition; and the disk turbine type stirrer can generate strong shearing force to fluid so as to achieve excellent material dispersion effect.

Owner:河北美业斯维生物技术有限公司

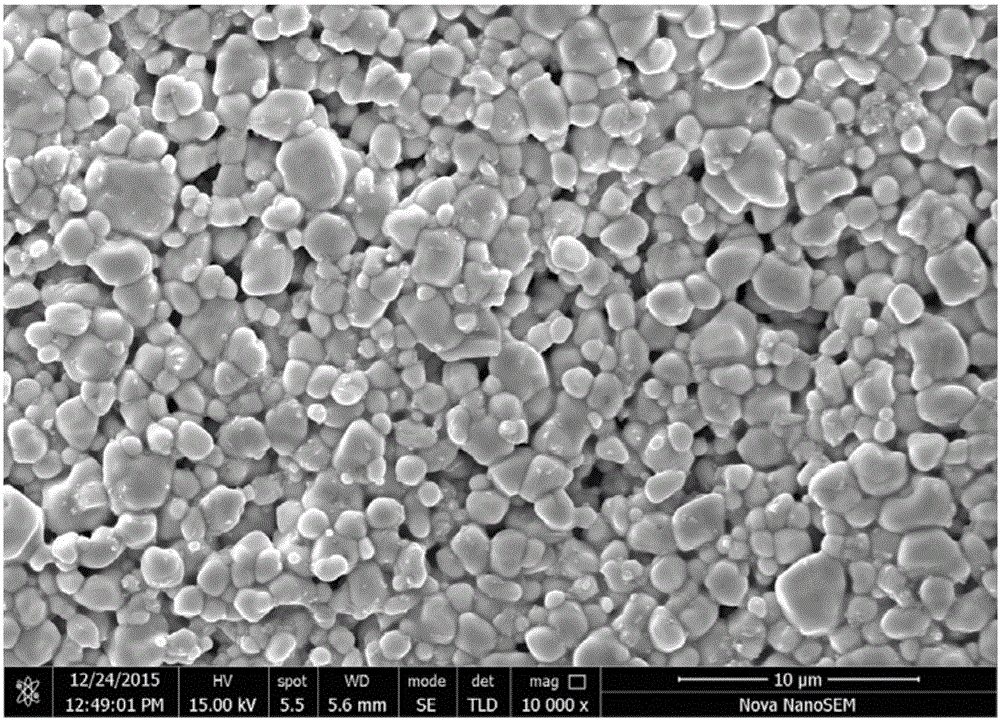

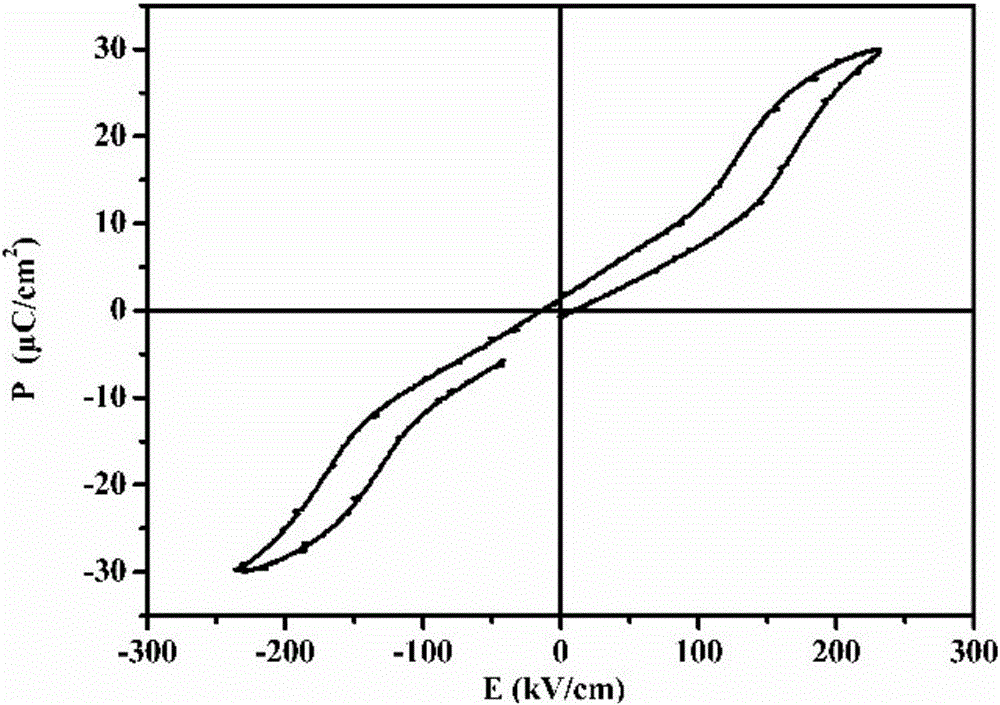

PZT-base anti-ferroelectric material based on rolling membrane process and preparation method of PZT-base anti-ferroelectric material

InactiveCN106187181AHigh energy storage densityMeet the needs of practical applicationsSputteringChemical composition

The invention relates to a PZT-base anti-ferroelectric material based on a rolling membrane process and a preparation method of the PZT-base anti-ferroelectric material. According to the material, a perovskite structured PZT system is taken as a matrix, La and Sn are utilized for partially replacing Pb and Zr to enter the matrix, and chemical components meet a chemical general formula (Pb[1-a]La2a / 3)(Zr1-x-ySnxTiy)O3, wherein a is more than 0 and less than or equal to 0.06, x is more than 0 and less than 1.0, and y is more than 0 and less than 1.0. The preparation method mainly comprises the steps of preparing powder and a binder, carrying out burdening, mixing, rough rolling, finish rolling and film cutting, finally carrying out rubber discharging and sintering, and plating or sputtering different electrodes or laminates according to the requirements. Compared with the prior art, the anti-ferroelectric material has the advantages that the breakdown field strength is very high (more than or equal to 200 kV / cm), the energy storage density is very high (2J / cm<3>-4.2J / cm<3>), the preparation process is simple, the operation is simple and convenient, and the cost is relatively low; and the anti-ferroelectric material is suitable for industrial production.

Owner:TONGJI UNIV

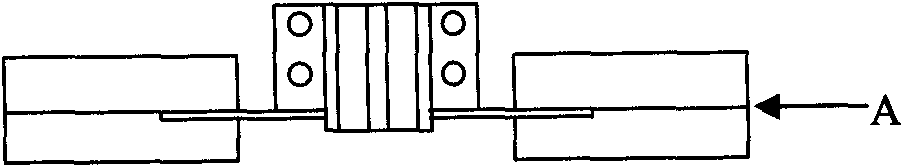

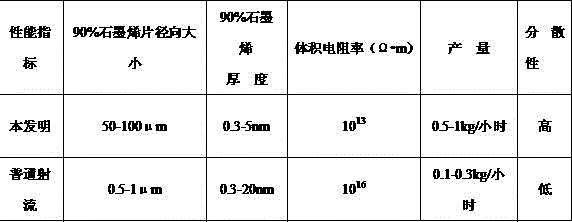

Jet device for continuous preparation of graphene and method thereof

The invention provides a jet device for continuous preparation of graphene and a method thereof. The method includes: mixing a graphite raw material with a medium solution, passing the mixture through a main nozzle for accelerated ejection, impacting and stripping the material with high speed air flow ejected by uniformly distributed convergence nozzles so as to obtain a mixed slurry, finally pumping the mixed slurry into a spray drying chamber by a super high pressure pump, conducting drying treatment to obtain a graphene material, and collecting graphene with a collecting mechanism. The method has low energy consumption, improves the graphene stripping efficiency, employs air flow and liquid flow to strip graphite, and does not introduce grinding medium pollution. The stripped material passes through a homogenizing valve with tiny gap at a high speed, and the generated strong shear force and friction force can homogenize and strip the material. Through further shearing and screening by the homogenizing valve, the graphene stripping efficiency is improved, and at the same time liquid is added in the graphite shear process to serve as the medium, the structure of graphene can be well maintained, thus obtaining high quality graphene, and promoting the mass production of graphene.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

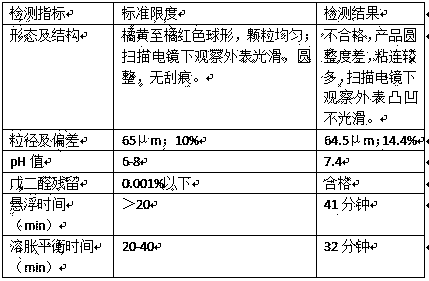

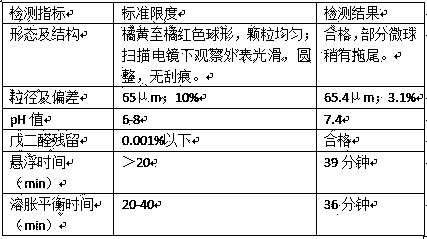

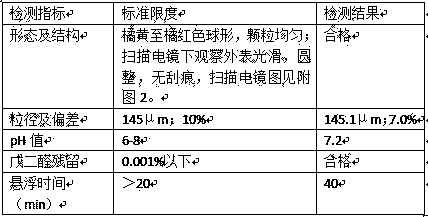

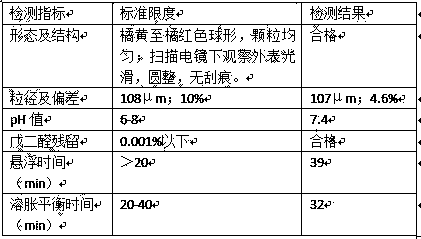

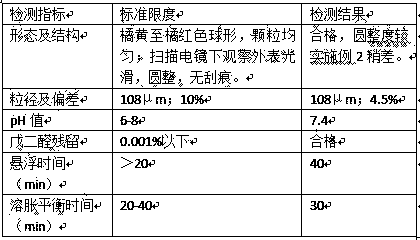

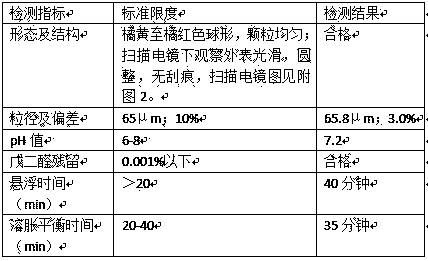

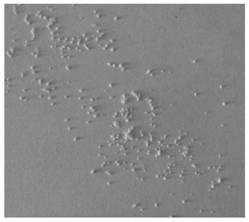

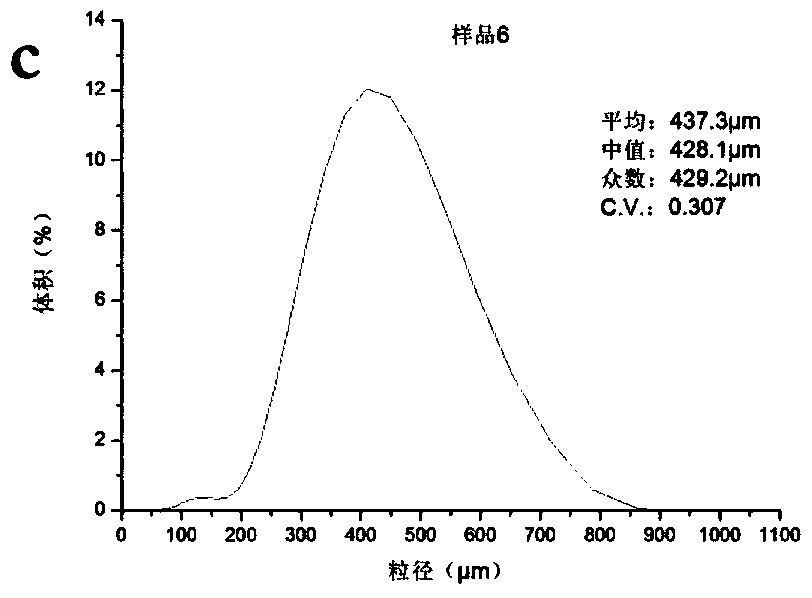

Preparation method of chitosan microsphere

The invention relates to a preparation method of a chitosan microsphere. The preparation method of the chitosan microsphere comprises the following concrete steps: causing an oil phase to flow at a certain flow rate in an oil phase pipeline; vertically injecting a chitosan aqueous phase into the oil phase pipeline from an aqueous phase pipeline at a low speed; separating the chitosan aqueous phase into liquid drops with uniform size by virtue of a shearing force of an oil phase fluid, wherein the liquid drops flow into a container filled with crosslinking agent emulsion along with an oil phase; crosslinking and solidifying to obtain microspheres while stirring; and separating and drying, so that the chitosan microsphere is obtained. The chitosan microsphere prepared by adopting the preparation method has the characteristics of small particle size and high uniformity, safety and effectiveness of embolism in an interventional therapy can be improved, clinical operability can be enhanced, the clinical safety accident rate can be reduced, excessive screening is not needed to be carried out on the chitosan microsphere product to remove microspheres which are not in target particle size, the production cost is reduced, and the production efficiency is improved.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

Nylon 6/superfine calcium carbonate microparticle complex fiber and preparation method thereof

InactiveCN101363143AReduce manufacturing costEase of industrial productionMelt spinning methodsArtifical filament manufactureYarnMicroparticle

The invention relates to a composite fiber of nylon 6 / ultra-fine calcium carbonate particles and a preparation method thereof. The temperature is raised to 140 DEG C so that nanometer calcium carbonate and other additives are evenly wrapped and stuck on the nylon resin, whereas the inter-particles of the nylon resin do not have severe conglutination. The composite fiber comprises the following component with the weight parts: 85-100 parts of nylon slices, 0.5-15 parts of ultra-fine calcium carbonate particles and 0.01-0.5 parts of surface treatment agent; the preparation method is as follows: (1) raw materials are weighed according to the weight parts; (2) calcium carbonate particles and the surface treatment agent are blended and mixed in a high-speed mixer, and added with the nylon slices to be well blended; after the mixture reaches 180 DEG C to 230 DEGC, the heating is ceased; the mixture is stirred and cooled, and then is discharged at a room temperature; (3) after being dried, the mixture is put into a screw extruder for melt spinning, and the winding wires are obtained; (4) drafting and heat setting treatments are applied to the the winding wires, and then drawn yarns are obtained; (5) the follow-up treatment of the drawn yarns is as usual. The fiber has the advantages of good mechanical properties and wear-resistance property and can be widely applied to clothing and technical textiles fields. The invention has the advantages of simple process, easy control, low cost, and short cycle; besides, the invention is environment-friendly and suitable for industrial production.

Owner:DONGHUA UNIV +1

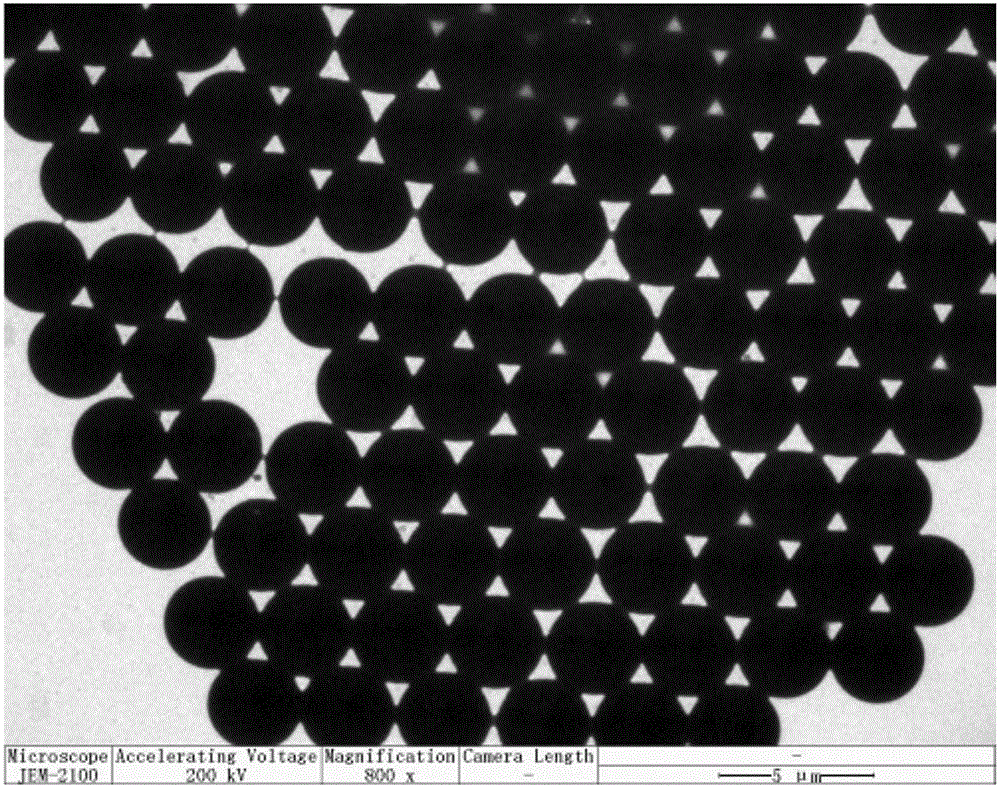

Chitosan microspheres and preparation method thereof

The invention relates to chitosan microspheres. The microspheres are solid spheres which have smooth surface and uniform granularity and are formed by crosslinking of chitosan and a crosslinking agent, wherein the grain diameter of each microsphere is 50-1200 mu m, preferably 50-600mu m, and further preferably 150-300mu m; and the grain diameter difference is not more than 20 percent, and preferably not more than 10 percent. The microspheres provided by the invention have the characteristics of small grain diameters and high uniformity, and are capable of improving the safety effectiveness of embolism in interventional therapy, reinforcing the clinical operability, reducing the clinical safety accident rate and reducing the production cost.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

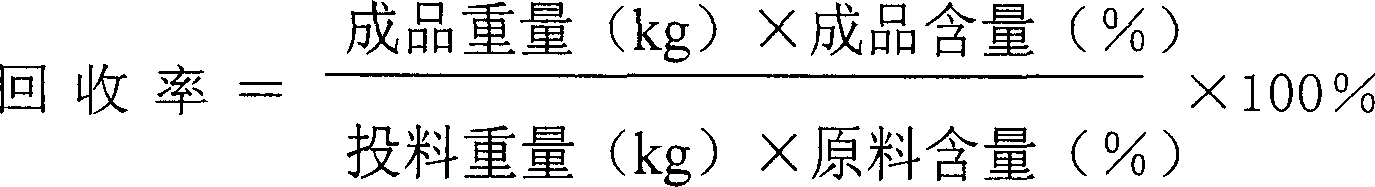

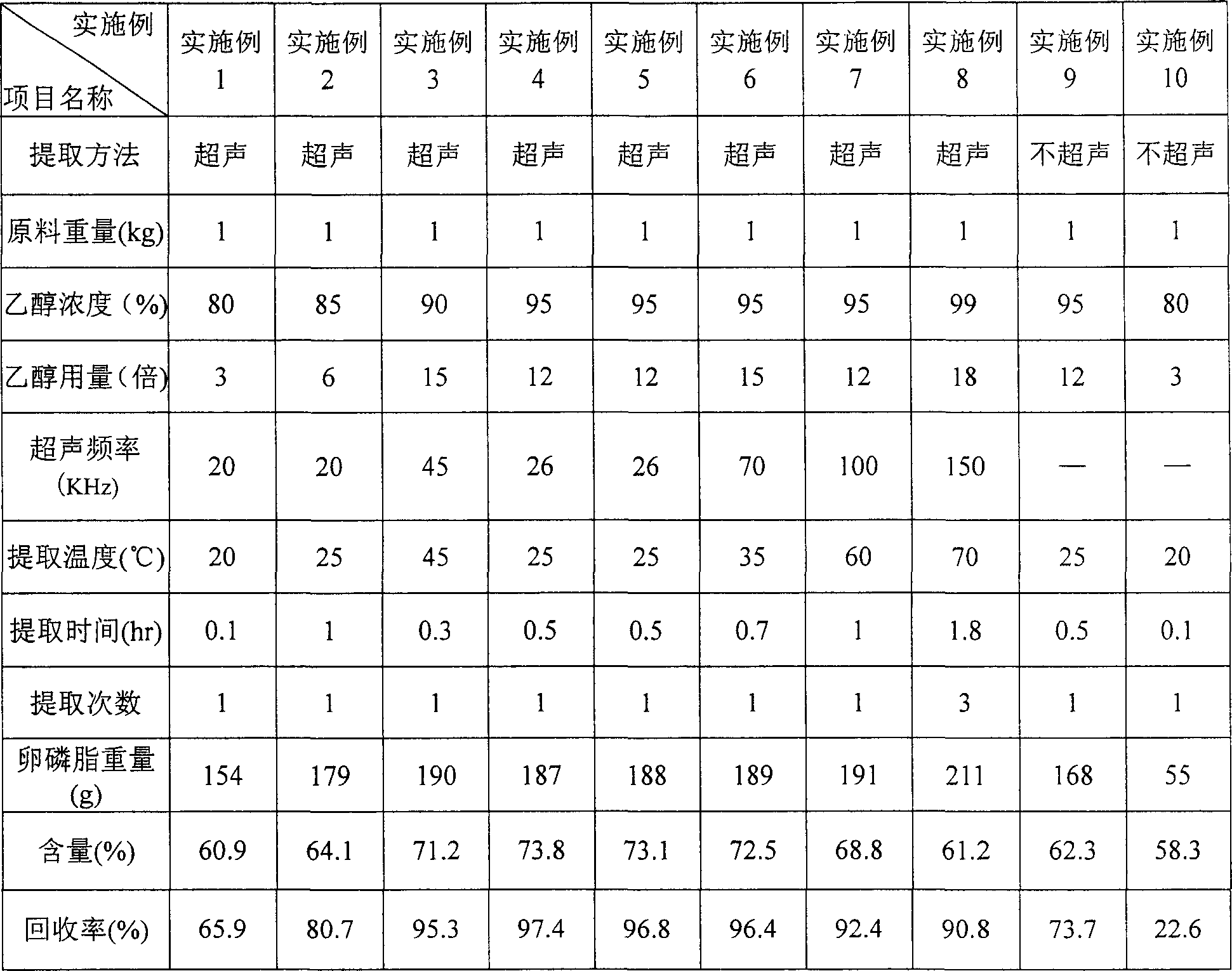

Supersonically reinforced yolk phospholipid extracting process

InactiveCN1974582AImprove transfer rateHigh temperature and high transfer ratePhosphatide foodstuff compositionsYolkAlcohol

The supersonically reinforced process of extracting yolk phospholipid with yolk powder containing protein and fat as material includes supersonically reinforced extraction of yolk powder in 80-99 % concentration alcohol solution of 3-20 times weight of yolk powder at 20-70 deg.c for 1-3 times 0.1-1 hr each, with the supersonic wave frequency being 20-150 KHz; centrifuging and filtering the extracted liquid; and decompression concentrating the supernatant and vacuum drying to obtain yolk phospholipid. Compared with available processes, the present invention has the advantages of simple operation, short extraction period, low power consumption, low extraction cost, high effective component transferring rate, etc.

Owner:GUANGZHOU HANFANG PHARMA

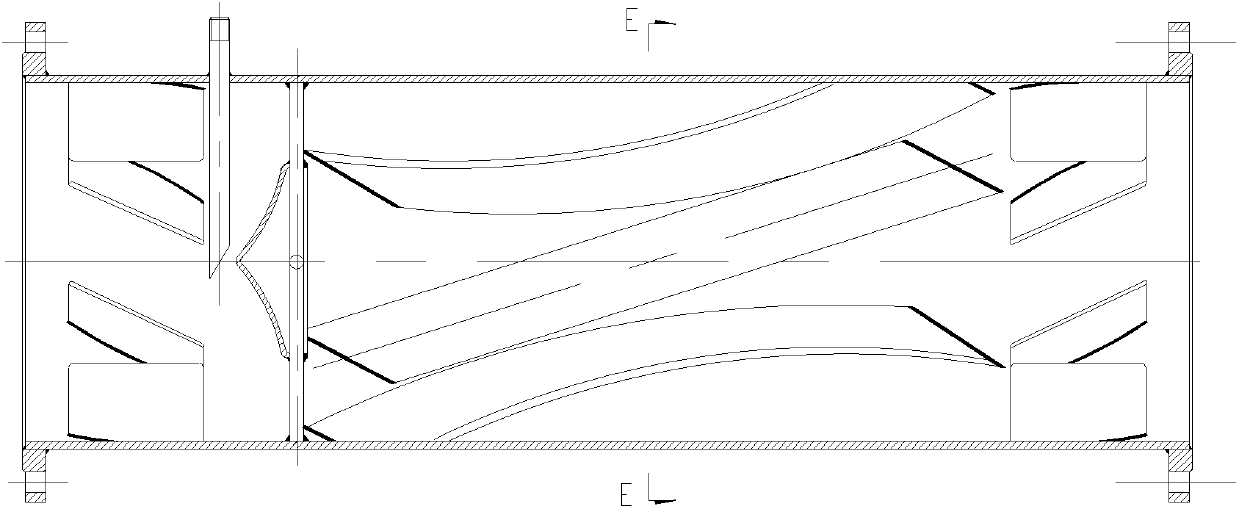

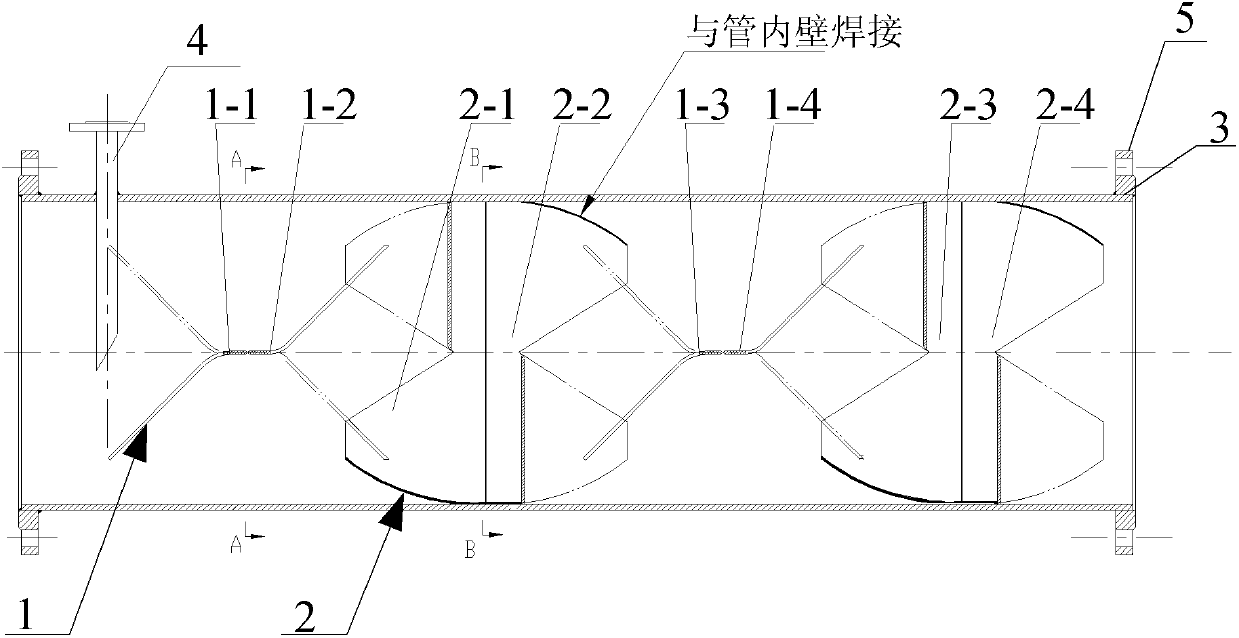

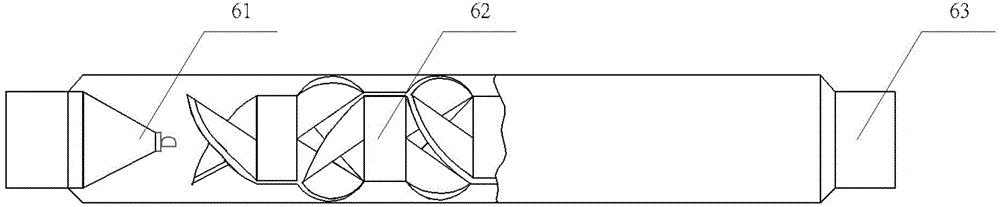

Static pipeline mixer

The invention relates to a static pipeline mixer which is a mixing device in a water treatment process. The static pipeline mixer comprises a pipeline, and a liquid adding pipe is arranged at an inlet end of the pipeline. The main characteristics of the static pipeline mixer are that: a plurality of groups of mixing blades are fixedly connected inside the pipeline; each group of mixing blades are composed of identical spiral blades; beams of two left-rotating unit blades oppositely form a left-rotating combination, or beams of two right-rotating unit blades oppositely form a right-rotating combination; the position difference between the mixing blades of the left-rotating combination and the mixing blades of the right-rotating combination in the pipeline is 90 degrees. The pipeline mixer is a novel efficient mixing device, and has the advantages of being good in mixing effect, simple in structure, convenient in production, small in pipeline loss and the like.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

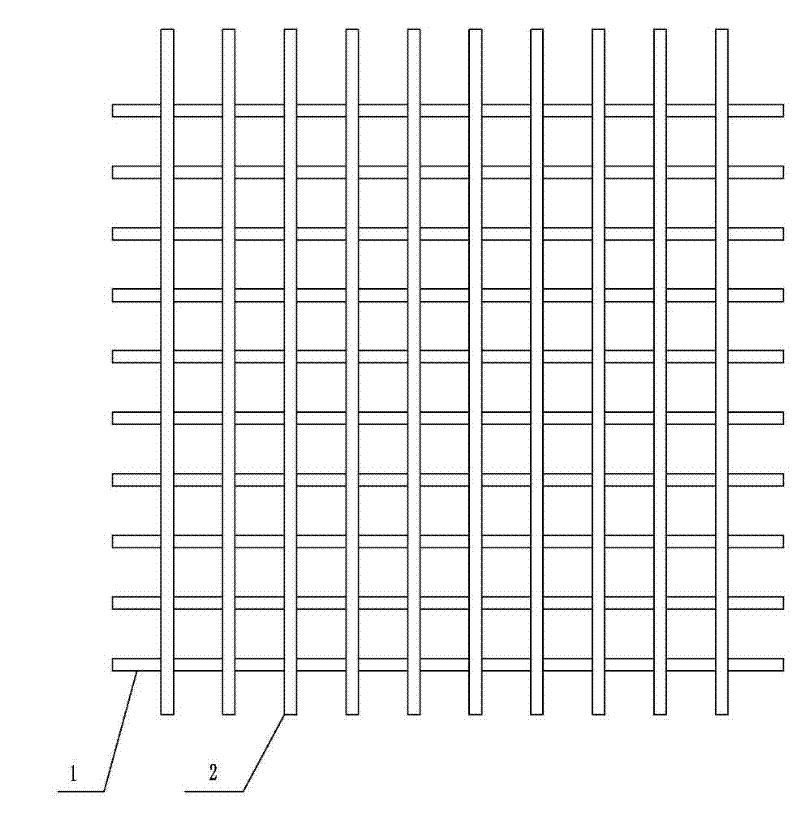

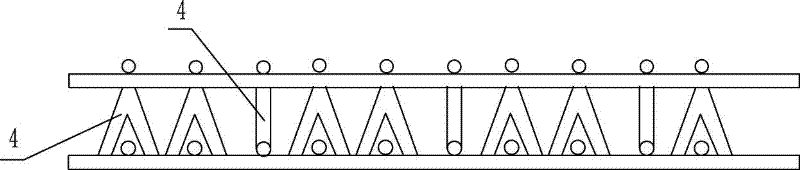

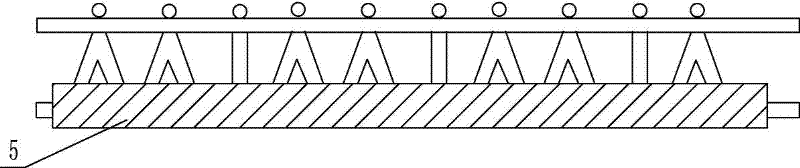

Precast slab construction member

The invention relates to a precast slab construction member, which belongs to the field of building members. The precast slab construction member comprises an upper layer reinforcing mesh and a lower layer reinforcing mesh, wherein both the upper layer reinforcing mesh and the lower layer reinforcing mesh comprise transverse bars and longitudinal bars which are arranged parallelly at intervals and are intersected and welded at intersection points; shear nails are welded between the upper layer reinforcing mesh and the lower layer reinforcing mesh; and the lower layer reinforcing mesh is buried into concrete. Due to the precast slab construction member, a bottom slab die is not needed to be supported, reinforcing bars of a floor are fully precast into a whole body by a precasting factory, the production and mounting rates are high, and the overall intensity is high, and thus the problems that the bottom slab die is needed to be supported, the reinforcing bars of the floor are bound on site, and the construction rate is low in the prior art are solved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Anode material for lithium secondary battery, process for production thereof, and lithium secondary battery

InactiveUS6884545B2Avoid decompositionIncrease energy densityPigmenting treatmentElectrode manufacturing processesCarbon coatingFluidized bed

An anode material for lithium secondary battery, which comprises graphite particles and a crystalline carbon coating layer formed thereon, wherein each graphite particle has a bent laminate structure inside, is produced by grinding a graphite of 5 mm or less in average particle diameter using an impact grinder to produce graphite particles of 100 μm or less in average particle diameter having a bent laminate structure inside each particle and then subjecting the graphite particles to chemical vapor deposition in a fluidized bed type reaction furnace to form a crystalline carbon coating layer on the graphite particles.

Owner:NIPPON POWER GRAPHITE CO LTD

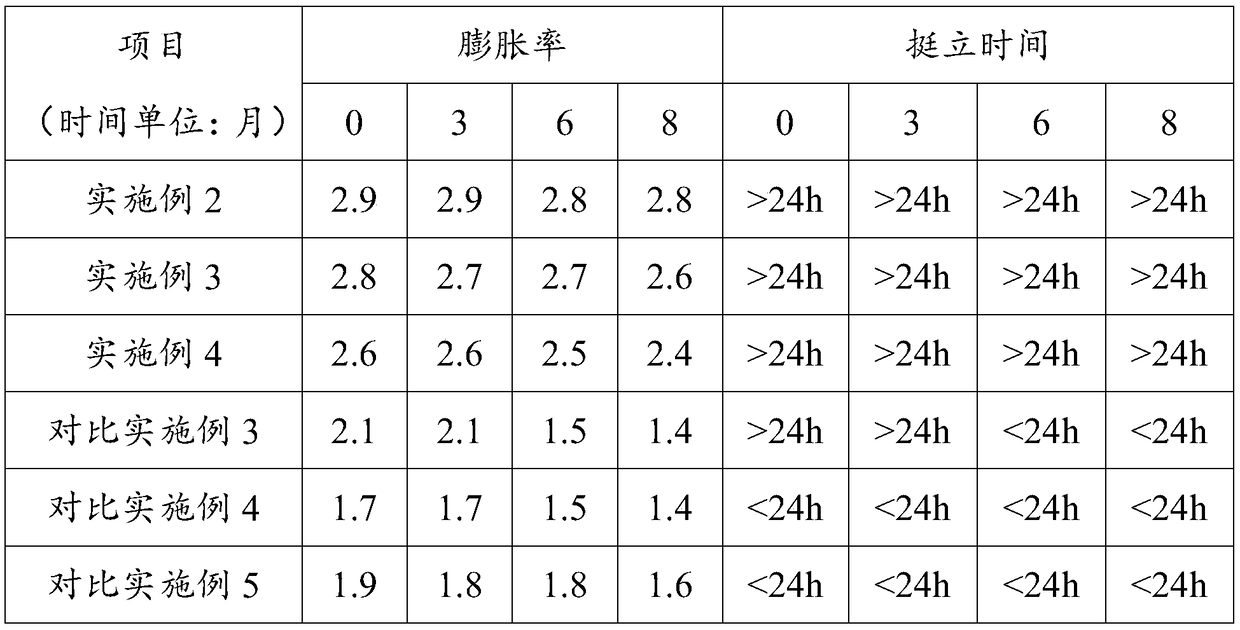

Whipped coffee cream and making method thereof

The invention discloses a making method of whipped coffee cream. The making method comprises the following steps of S1, heating raw milk to 50-55 DEG C, and performing separation with a centrifuge soas to obtain coffee cream; S2, raising the temperature of the coffee cream obtained in the step S1 to 60-65 DEG C, and adding an emulsifying agent and a stabilizing agent so as to obtain mixed liquor;and S3, stirring the mixed liquor obtained in the step S2, performing homogenizing for the first time, performing sterilization, performing homogenizing for the second time, and performing cooling soas to obtain the whipped coffee cream. According to the whipped coffee cream made by the making method disclosed by the invention, the whipping stability of the whipped coffee cream is notably improved, the whipping time is shortened, the expansion rate is increased, the quality guarantee period is prolonged, the coffee cream for baking is excellent in processing properties, and the coffee creamcan be used for baking, dining, and industrial production of candies, fat, ice creams and the like.

Owner:BRIGHT DAIRY & FOOD

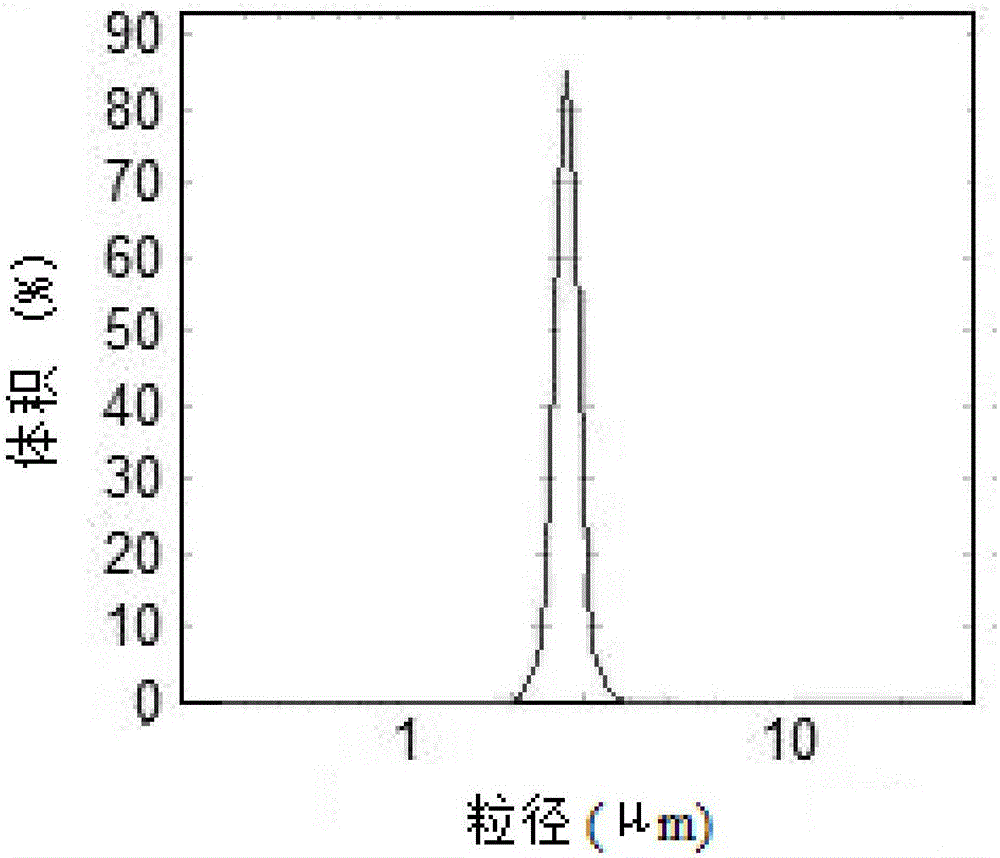

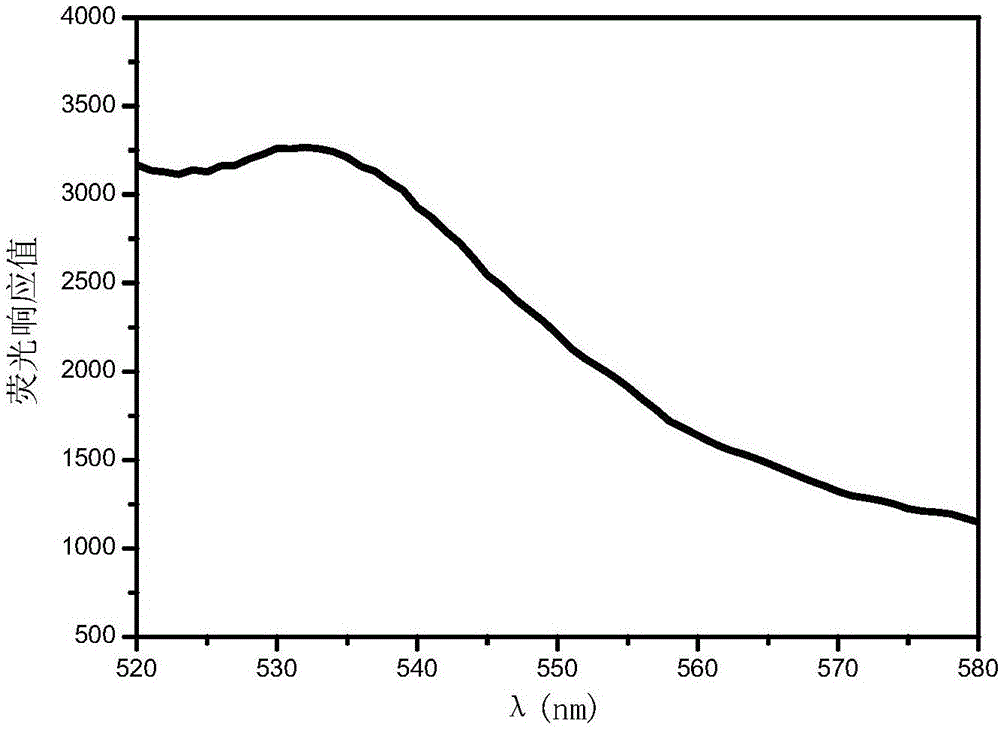

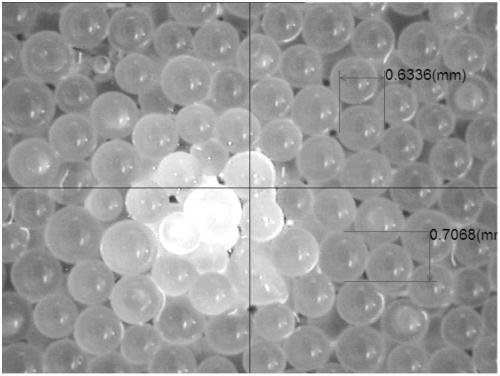

Flow fluorescent micro-sphere standard substance and method for preparing same

InactiveCN106479483AUniform fluorescence intensityImprove stabilityIndividual particle analysisLuminescent compositionsMicrometerEvaporation

The invention relates to a flow fluorescent micro-sphere standard substance and a method for preparing the same. The method includes steps of (1), preparing seed micro-spheres by the aid of dispersion polymerization processes; (2), dispersing the seed micro-spheres into sodium dodecyl sulfate aqueous solution, dissolving hydrophobic fluorescent dye in swelling agents, adding the hydrophobic fluorescent dye and the swelling agents into dispersion systems of the seed micro-spheres and carrying out emulsification, shaking and rotary evaporation to obtain the flow fluorescent micro-sphere standard substance. The flow fluorescent micro-sphere standard substance and the method have the advantages that the flow fluorescent micro-sphere standard substance is a polystyrene micro-sphere, fluorescent molecules cover the inside of the polystyrene micro-sphere, the particle size of the flow fluorescent micro-sphere standard substance is 3.0-3.5 micrometers, a variation coefficient of the flow fluorescent micro-sphere standard substance is 1%-4%, and the maximum emission wavelength of the flow fluorescent micro-sphere standard substance is 520-540 nm when the flow fluorescent micro-sphere standard substance is excited by 488 nm light; the method is simple, the particle size of the fluorescent micro-sphere standard substance prepared by the aid of the method is strictly monodisperse, and the fluorescent micro-sphere standard substance is uniform in fluorescence intensity and excellent in stability.

Owner:BEIJING HAIAN HONGMENG STANDARD SUSNCE TECH

Table rose sauce and preparation method thereof

ActiveCN104055060ASmooth tasteRetain colorFood ingredient functionsFood preparationBiotechnologyGlucose-Fructose Syrup

The invention relates to table rose sauce and a preparation method thereof. The preparation method comprises the following steps: performing superfine grinding on edible rose petals to obtain rose powder; mixing the rose powder, glucose syrup, white granulated sugar and purified water, adjusting the pH value to be 1.8-2.2 by using citric acid to obtain a mixed solution, and heating the mixed solution to obtain a rose solution with sugar content of not less than 50%; adding pectin and salt into the rose solution, and boiling to obtain rose sauce; sterilizing the rose sauce in a water bath with temperature of 80-85 DEG C to obtain a finished product of rose sauce. According to the preparation method, the technical problems of instable quality and poor sensory quality of rose sauce in the prior art are solved, and the table rose sauce is stable in quality, bright in color, fragrant in smell, comfortable in mouth feel and wide in application range.

Owner:HUNAN AGRI PRODS PROCESSING INST

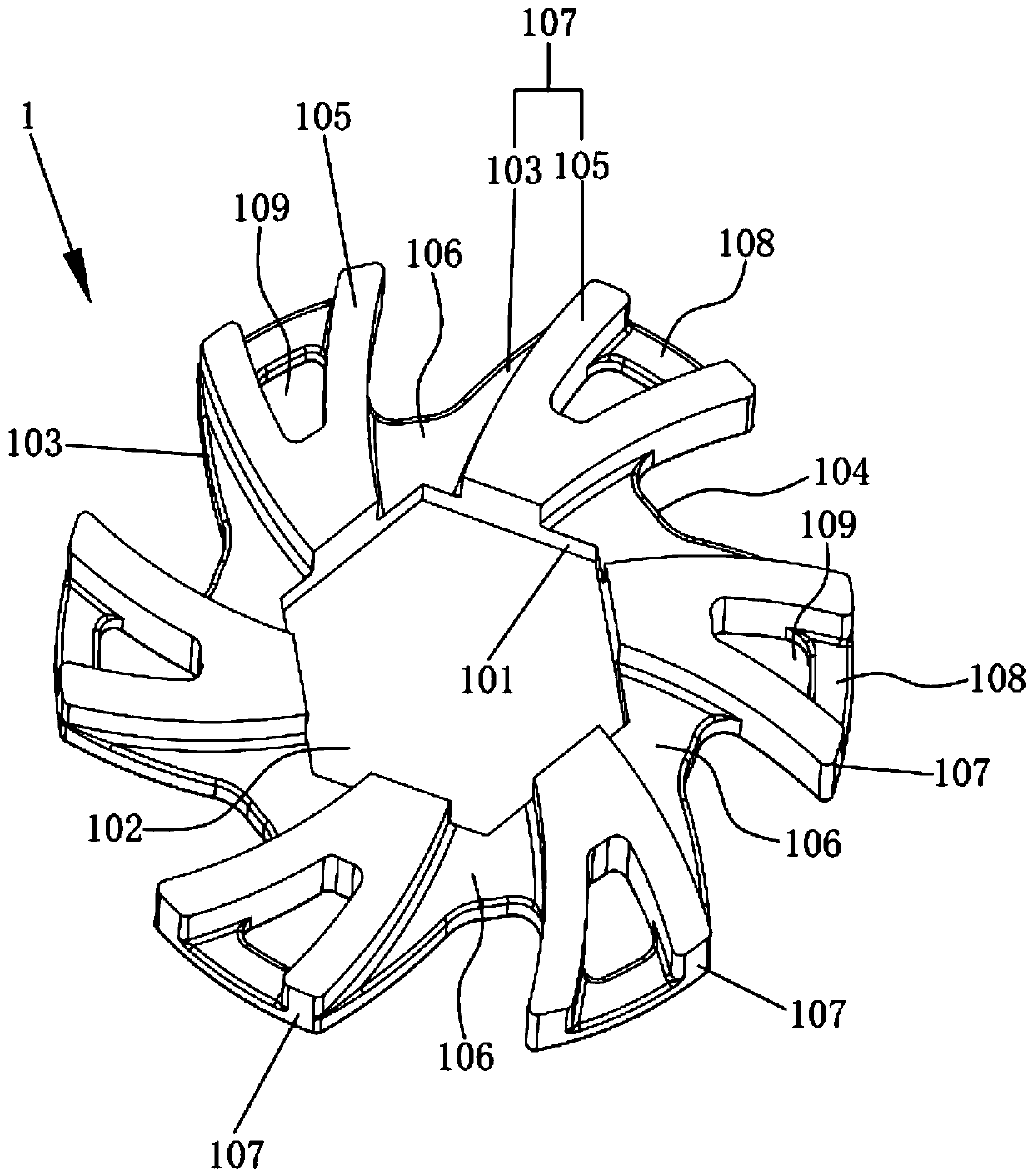

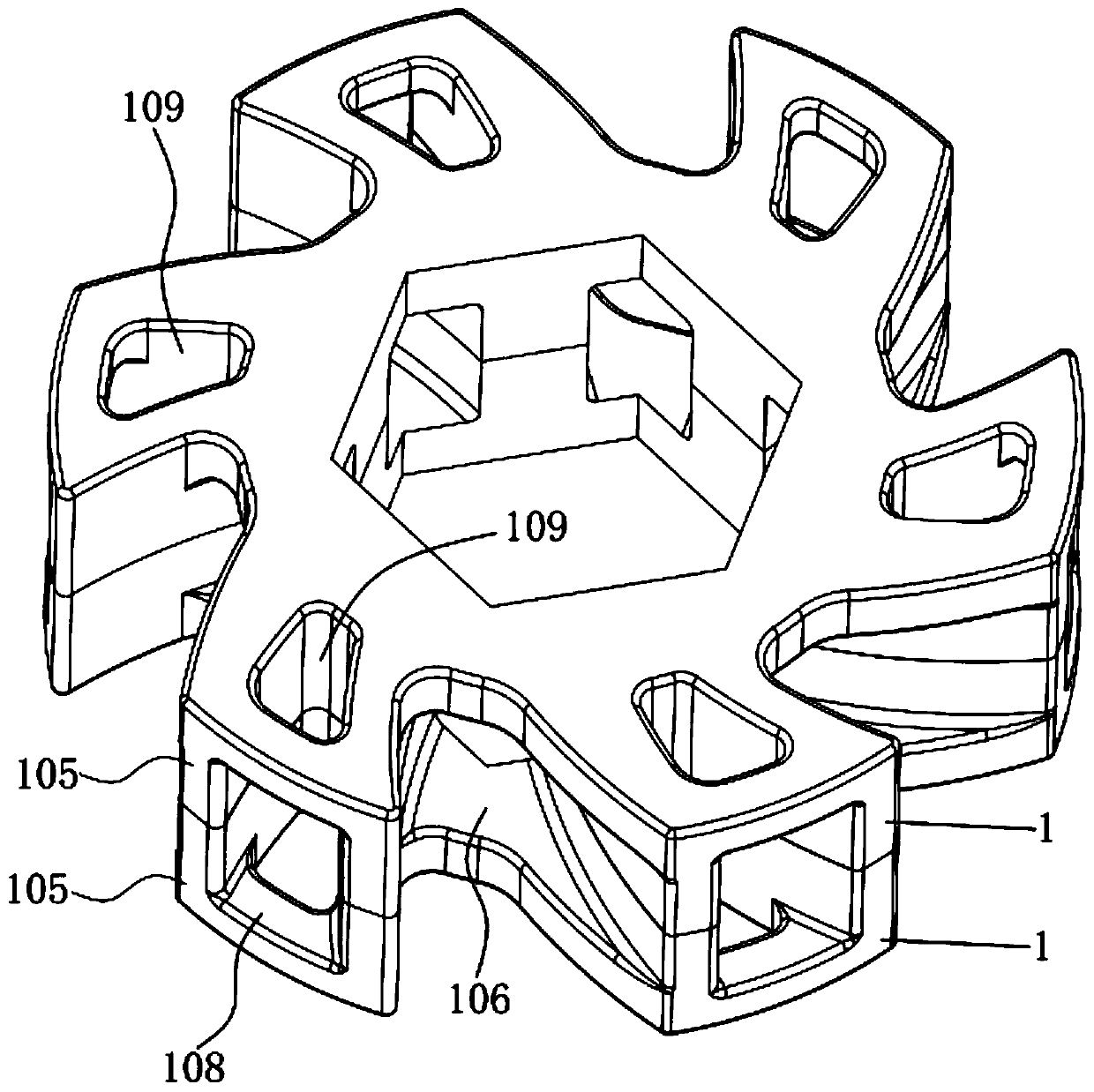

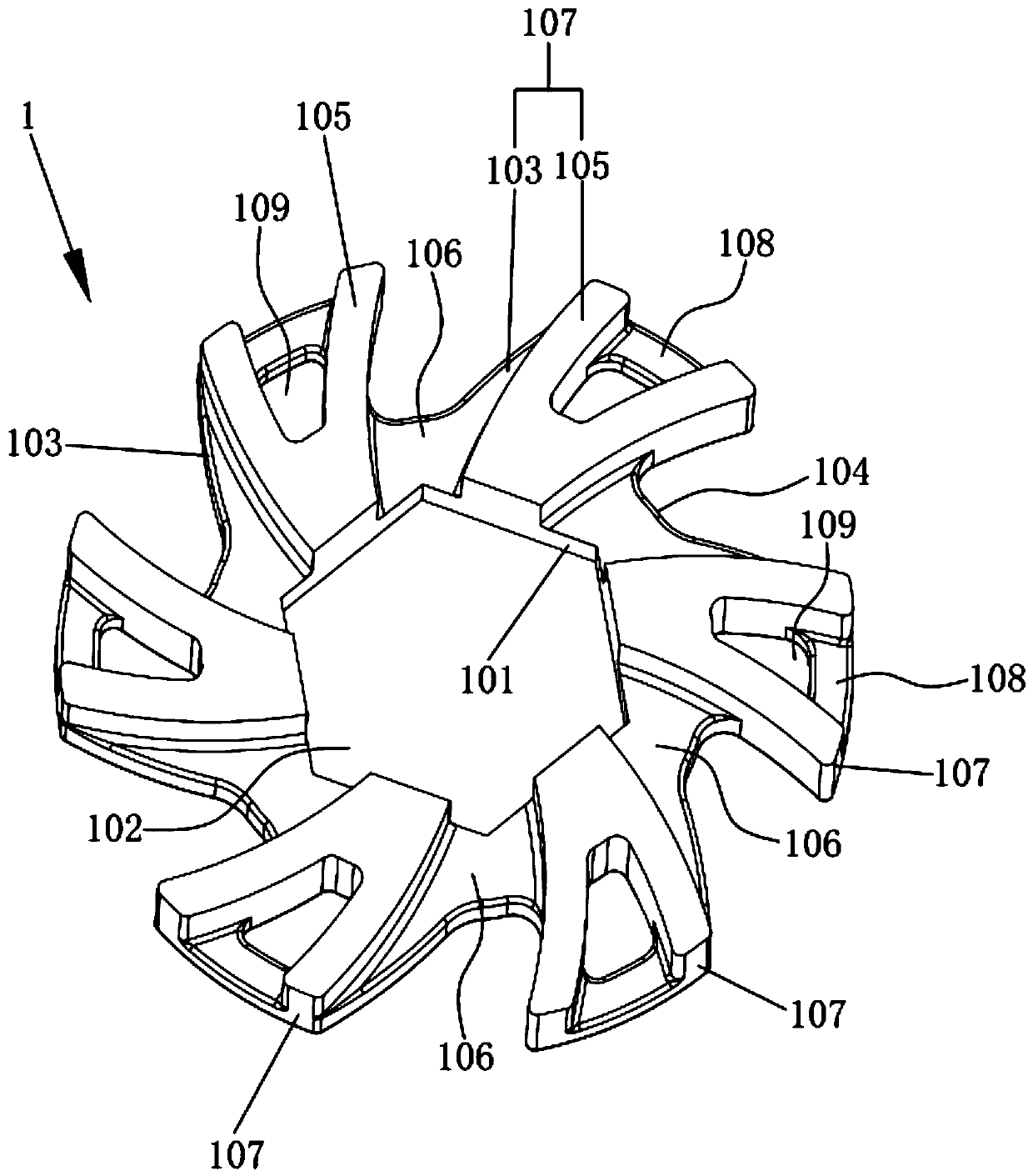

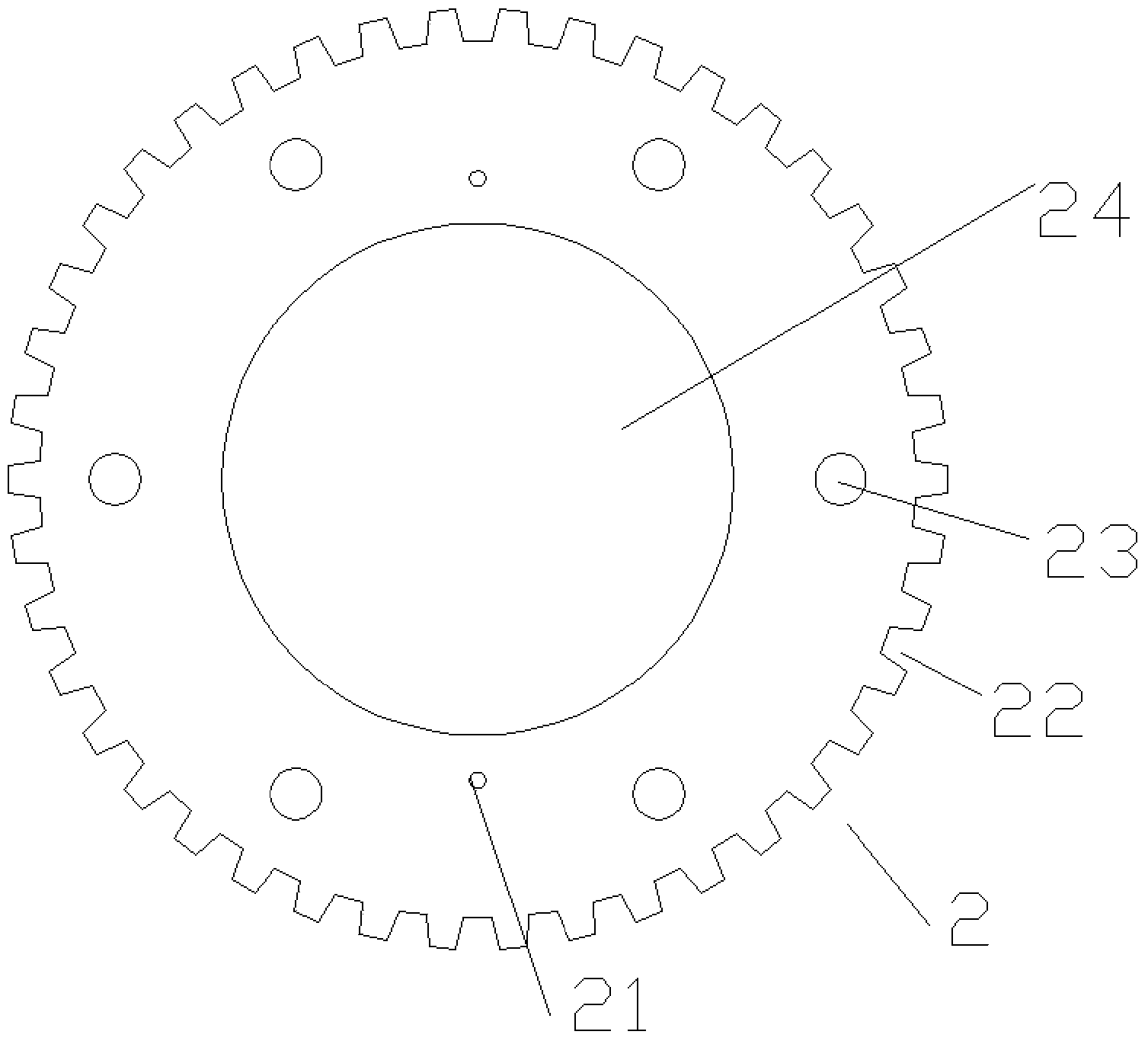

Turbine blade, grinding turbine and grinding device

The invention discloses a turbine blade, a grinding turbine and a grinding device. The turbine blade comprises a turbine body and grinding teeth. A center through hole formed in the axial direction ofthe turbine body is formed in the middle of the turbine body, multiple convex pins being convex outwards are formed in the circumferential direction of the periphery of the turbine body, and an opengroove is formed between every two adjacent convex pins. The multiple grinding teeth are arranged on at least one surface of the turbine body in the circumferential direction of the center through hole. The multiple grinding teeth are formed on the multiple convex pins in one-to-one correspondence. A radial hollowed channel allowing a grinding medium to flow in or out of the center through hole inthe radial direction of the turbine body is formed on one surface of the turbine body by every two adjacent grinding teeth. The radial hollowed channels of the turbine blade have no end faces stopping outflow motion of the grinding media, kinetic energy losses are low in the process that the grinding media flow out, grinding of the grinding media is more sufficient in the radial direction, exchange of the grinding media at different positions is more frequent, and grinding efficiency is greatly improved.

Owner:GUANGZHOU HONGKAI MACHINERY CO LTD

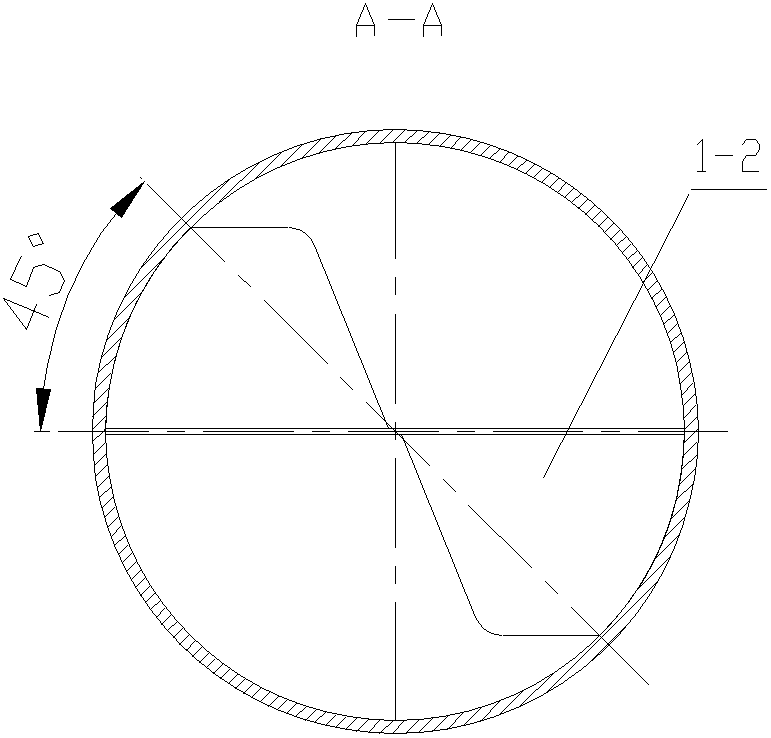

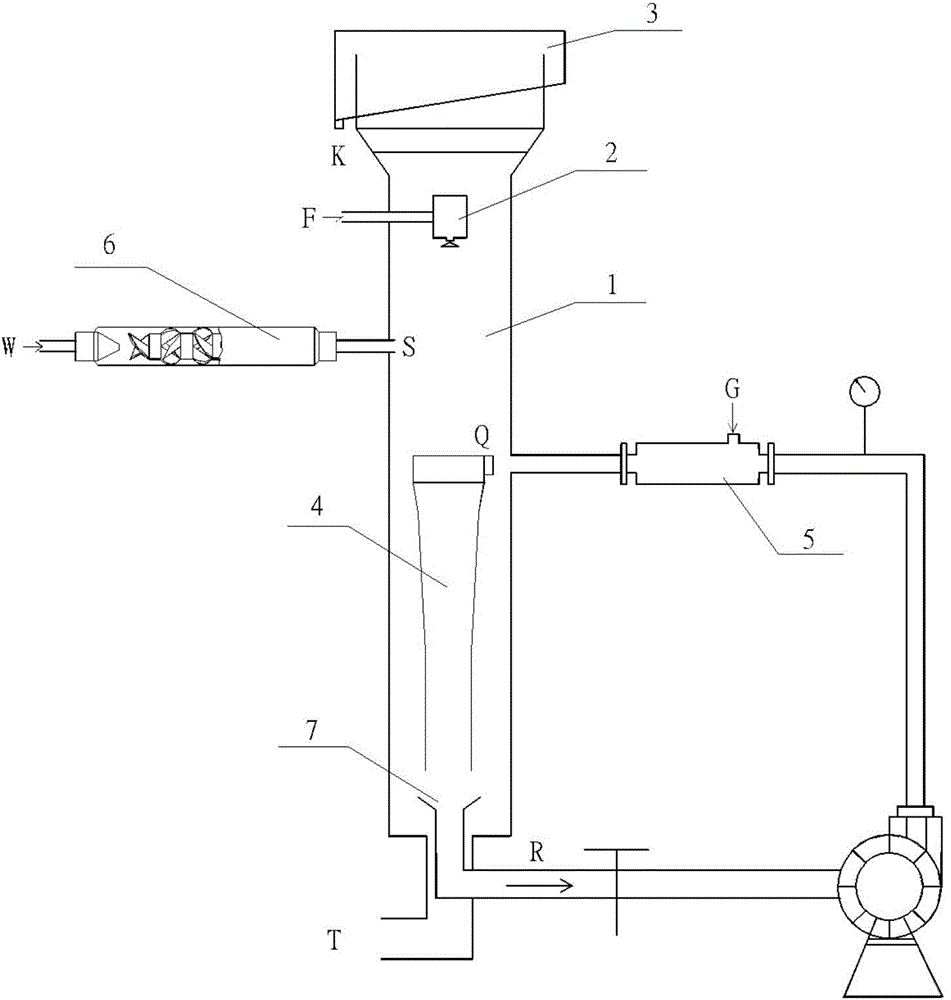

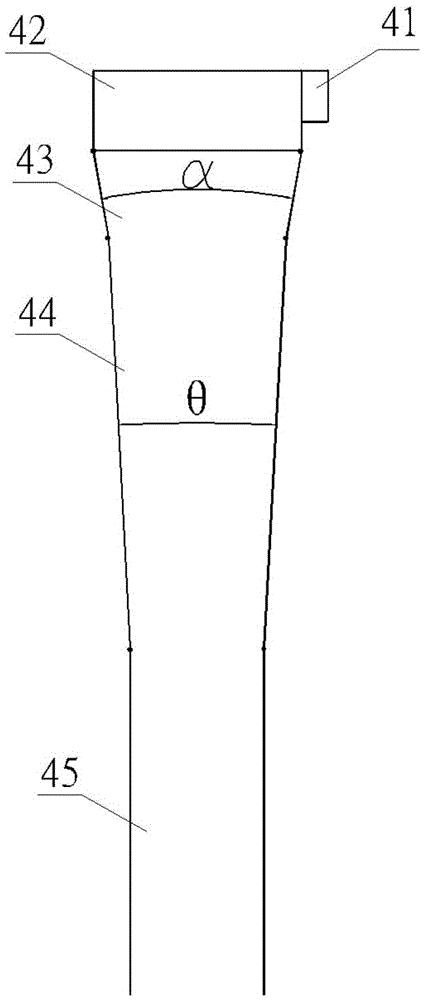

Purification device and separation method of oily sewage

ActiveCN103979637AStrong shear forceReduce kinetic energyWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesCycloneLower limit

The invention discloses a purification device and a separation method of oily sewage. The device comprises a water inlet allocation device, a column separator, a floating oil collection device, an inflatable cyclone separator, at least one self-sucked type micro-bubble generator and at least one dissolved gas separation micro-bubble generator, wherein the column separator is arranged at the upper part of the column body; the built-in inflatable cyclone separator is arranged at the lower part of the column body; the column separator and the inflatable cyclone separator are communicated vertically; an inflation point of the dissolved gas separation micro-bubble generator is arranged at the upper part of the column body; an inflation point of the self-sucked type micro-bubble generator is arranged at the lower part of the column body. By adopting the two inflation modes that the micro-bubble is generated through negative self-sucked ejection air flow and high-pressure dissolved gas depressurization separation, the hydrocyclone separation and the floating separation are coupled, refined granular oil in the oily sewage can be effectively separated, the low limit of effective flotation granularity is small, the separation time is short, the operation cost is low, and the problem that emulsified oil in the oily sewage is hard to separate is solved.

Owner:CHINA UNIV OF MINING & TECH

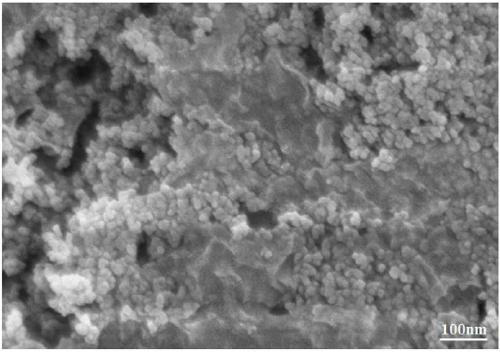

Preparation method of white carbon black/graphene oxide nano-hybrid filler, nano-hybrid filler and application of nano-hybrid filler

ActiveCN109810323AAchieve decentralizationAchieve nanodispersionEvaporation by sprayingHigh-speed grindingNano hybrid

The invention relates to a preparation method of white carbon black / graphene oxide nano-hybrid filler, the nano-hybrid filler and application of the nano-hybrid filler. The preparation method comprises the following steps: carrying out high-speed grinding and dispersion to prepare stable white carbon black slurry modified by a silane coupling agent; then uniformly stirring and grinding and dispersing the modified white carbon black slurry with a graphene oxide / water suspension solution subjected to high-speed grinding and dispersion and / or ultrasonic treatment; connecting white black carbon and graphene oxide through a bridge effect of the silane coupling agent; and then spraying and drying to prepare the white carbon black / graphene oxide nano-hybrid filler. The nano-hybrid filler is filled into any rubber variety through a traditional melting and blending technology to prepare high-performance tire tread. The preparation method and an application technology of the nano-hybrid filler are simple; and when the nano-hybrid filler is applied to rubber, nano-dispersion of graphene in a rubber matrix can be realized and the limitation of the rubber variety can be broken through, so thata composite material has excellent mechanical property, wet slipping resistance, cutting resistance, properties of delaying dynamic and static crack growth, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Polylactic acid microsphere and preparation method and application thereof

ActiveCN109265942AAccurate screening and gradingAccurately mark the particle sizeSurgical adhesivesPharmaceutical non-active ingredientsMicrosphereOil phase

The invention discloses a polylactic acid microsphere and a preparation method and application thereof. The grain size of the microsphere is between 100 mu m and 1000 mu m, preferably between 100 mu mand 300 mu m, between 300 mu m and 500 mu m, between 500 mu m and 700 mu m or between 700 mu m and 1000 mu m, the microsphere is a regular sphere, and the surface and interior of the microsphere areprovided with holes. Because the polylactic acid microsphere is a regular sphere, by adjusting the variety and molecular weight of polylactic acid, the degradation time of the microsphere can be controlled, which is favorable for the determination of the degradation time of the microsphere in the body and the recanalization time of blood vessels in clinical application. The preparation method disclosed by the invention can cut out drops with small grain size under low flow velocity, moreover, the stability of oil-phase fluid is good, the drops do not have tails after coagulant is added, the sphericity of the solidified microsphere is good, and the effect is best. Moreover, by forming the holes in the surface and interior of the microsphere, solvent can be conveniently volatilized, so thatthe amount of remaining solvent is small, meeting the standard of the pharmacopoeia.

Owner:张海军

Method for mechanochemically synthesizing magnesium lithium silicate

ActiveCN104760966AGuaranteed uniformitySmall particle sizeSilicon compoundsSlurryTemperature resistance

The invention discloses a method for mechanochemically synthesizing magnesium lithium silicate, which comprises the following steps: 1) synthesizing a magnesium lithium silicate precursor, and controlling the temperature of the precursor at 30-99 DEG C; and 2) feeding the precursor into a wet-process superfine treatment device, grinding at 90-99 DEG C for 5-90 minutes, and drying the obtained slurry to obtain the target product magnesium lithium silicate. The diameter of the grinding medium spheres used by the wet-process superfine treatment device is 0.1-5mm, and the linear speed of the grinding medium spheres is 8-20 m / s. The magnesium lithium silicate is synthesized by using high temperature and high pressure instantaneously generated by the grinding medium, so the requirements for high temperature resistance and high pressure resistance of the device are low. The superfine treatment device in peculiar structure can perform continuous production, and can solve the problem in batch production in the traditional hydrothermal reaction kettle. Compared with the traditional hydrothermal synthesis, the method disclosed by the invention has the advantages of lower cost and higher safety, and can easily implement industrialization.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

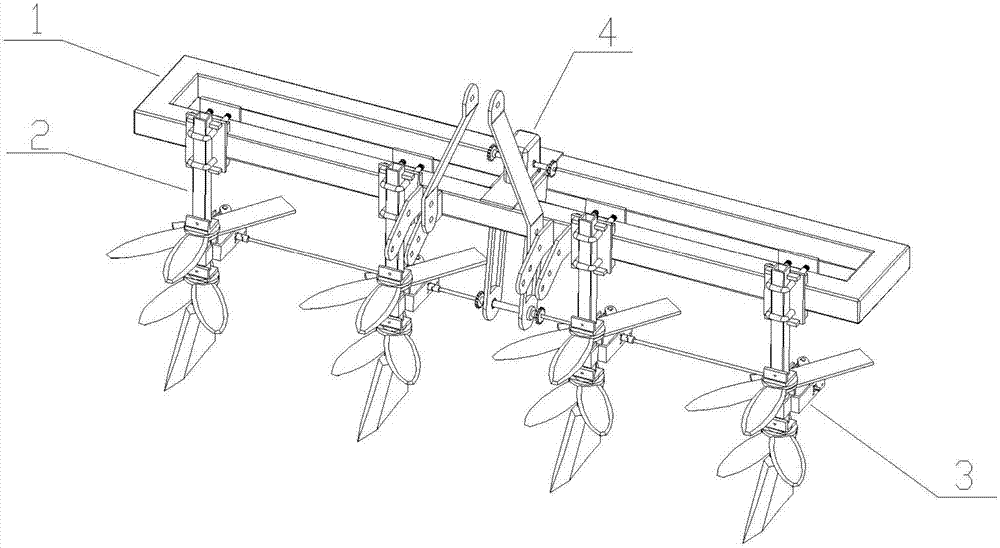

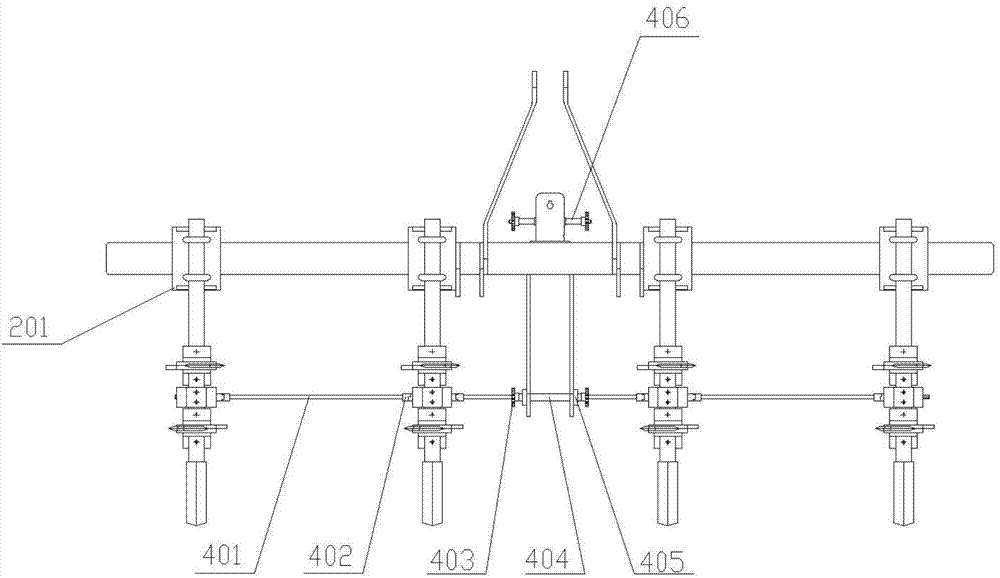

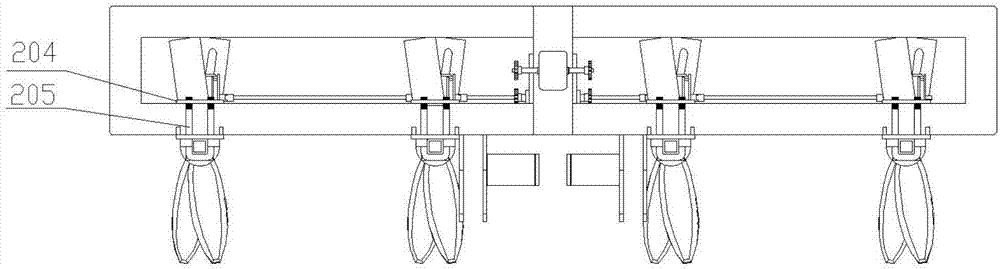

Horizontal partitioning no-tillage anti-blocking device

ActiveCN104770113AStrong shear forceStrong anti-blockingPlantingFurrow making/coveringAgricultural engineeringAgricultural machinery

The invention belongs to the technical field of agricultural machinery, and particularly relates to a horizontal partitioning no-tillage anti-blocking device. The anti-blocking device comprises a frame and a plurality of ditchers fixedly connected to the frame, wherein a horizontal partitioning anti-blocking apparatus is arranged on a handle of each ditcher; each horizontal partitioning anti-blocking apparatus comprises an upper double-edge stationary knife and a lower double-edge stationary knife which are fixed on the handle of the ditcher, and double-edge moving knives driven by a power transmission device and matched with the two double-edge stationary knives respectively; and the two double-edge moving knives can rotate to and fro within a certain range, and are matched with the double-edge stationary knives to complete cutting. The moving and stationary knife mechanism can be used for cutting straws in front of the ditchers, and when straws cannot be fed, the upper and lower moving knives can rotate outwards oppositely to push weed and straws in front of the ditcher to two sides of the ditchers, so the anti-blocking device has strong anti-blocking capability and can realize no-tillage sowing under large coverage of straws.

Owner:CHINA AGRI UNIV

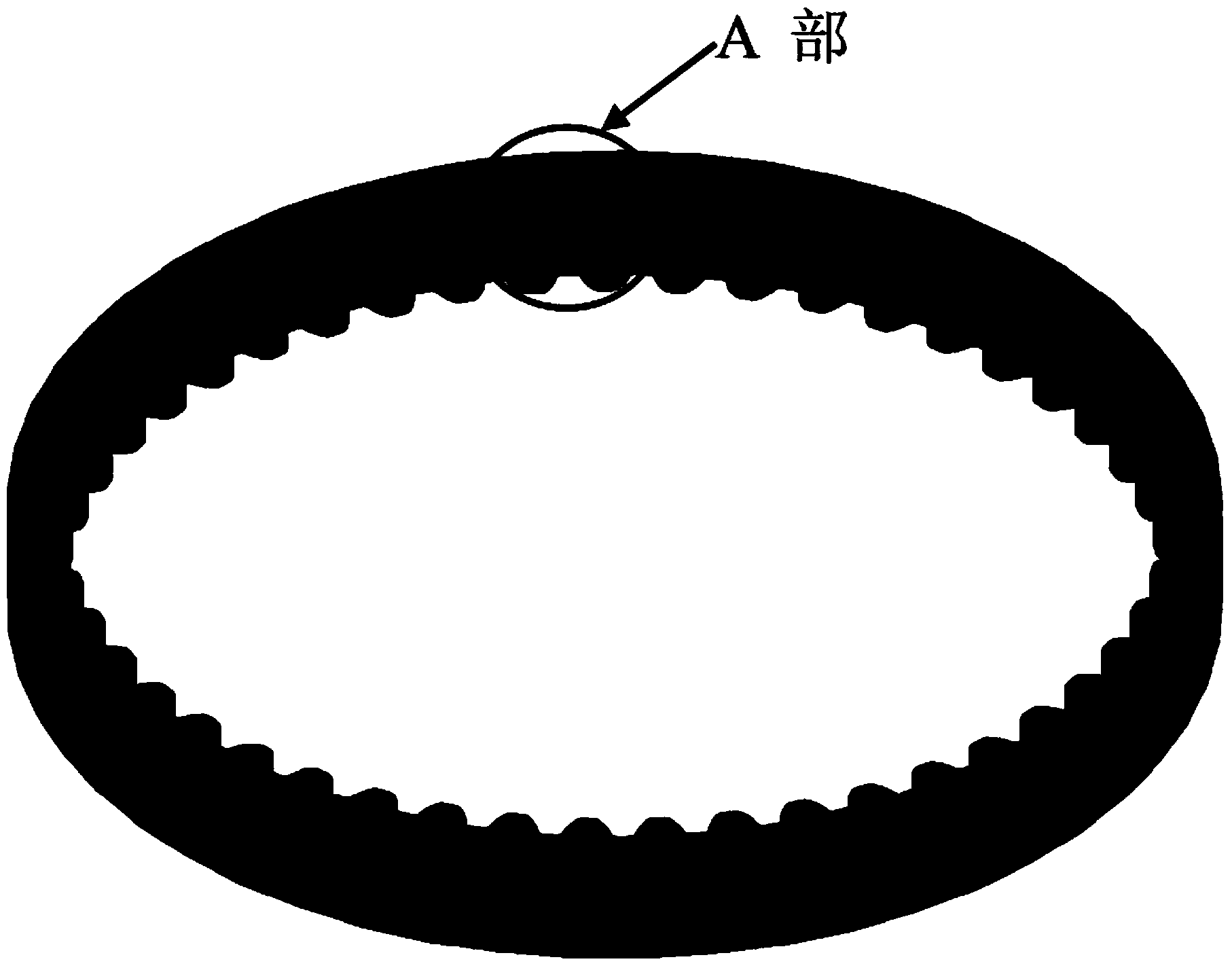

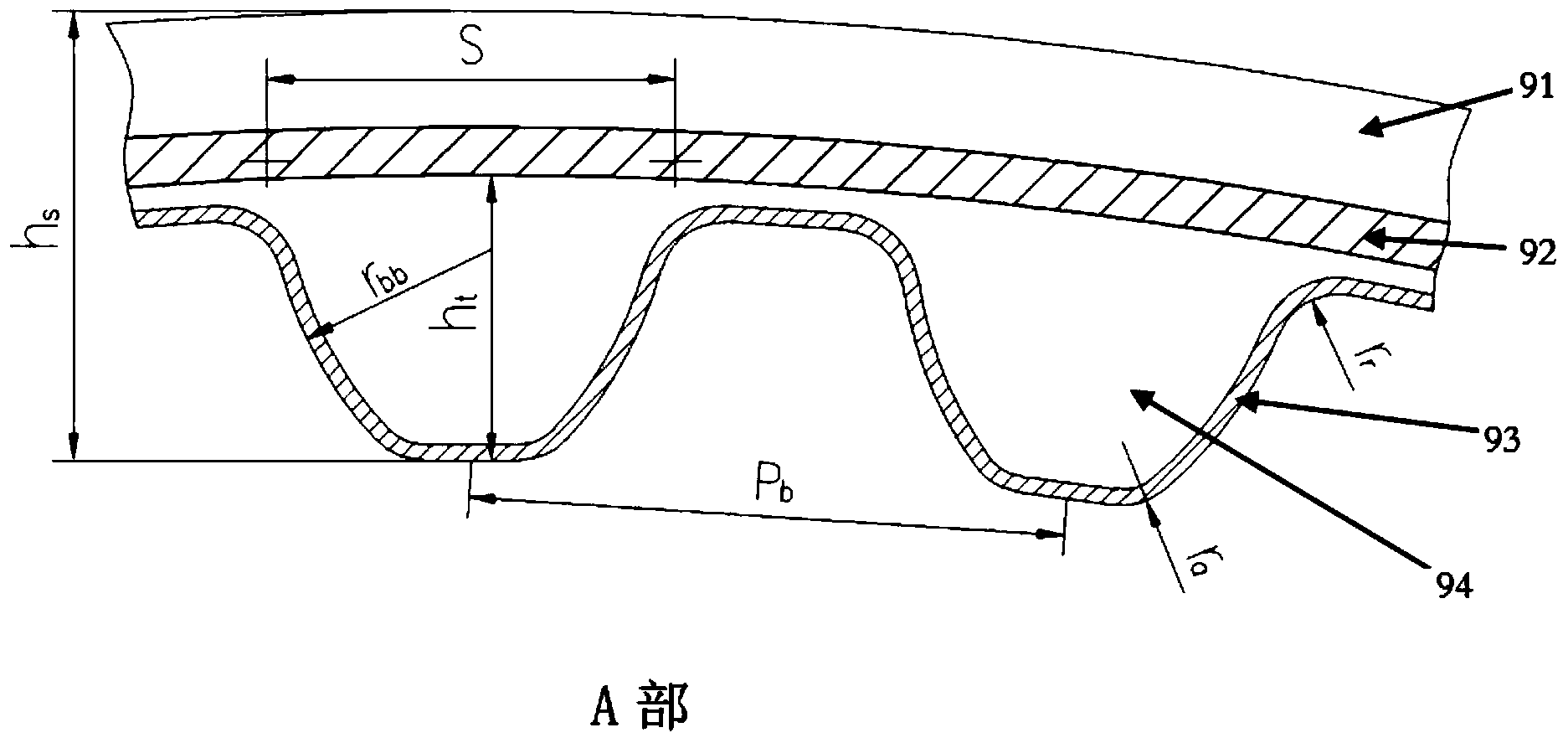

High-torque synchronous belt preparation method

The invention discloses a high-torque synchronous belt preparation method. A synchronous belt comprises an annular belt body; the annular belt body comprises a plurality of belt teeth (94), a piece of elastic nylon cloth (93), a core rope (92) and a belt back (91), wherein the belt teeth (94) are arranged at equal intervals on an inner circumferential surface of the annular belt body; the elastic nylon cloth (93) wraps the surface of the belt teeth and has the wearing resistance property; the core rope (92) is arranged in the circumferential direction of the annular belt body and inside the annular belt body; the belt back (91) is wrapped by a sizing material with the bending property on the back side of the core rope (92).

Owner:NINGBO GUL TZ RUBBER BELT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com