Production process for oil-free powdery yolk lecithin

A technology for the production of egg yolk lecithin, which is applied in the field of oil-free powdered egg yolk lecithin production technology, can solve the problems of large investment, high investment and power consumption of ultrasonic equipment, and achieve high extraction efficiency, best dispersion effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

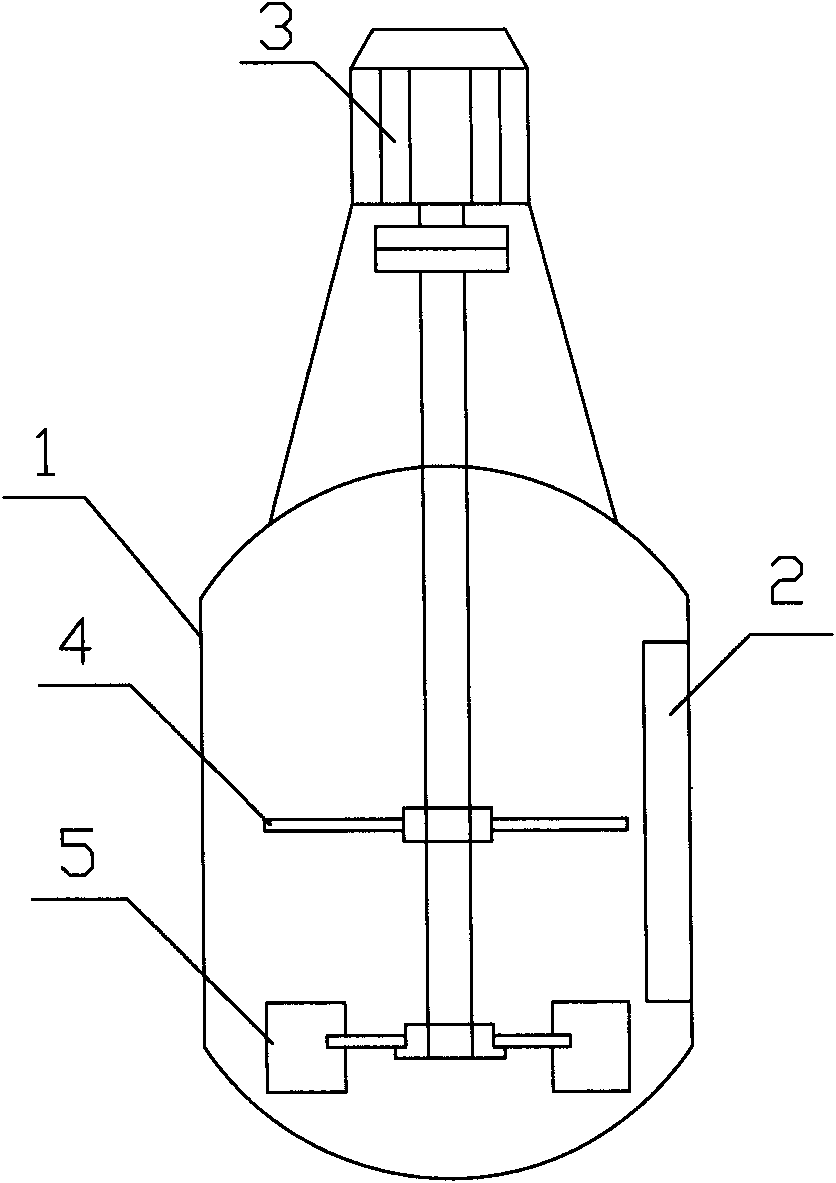

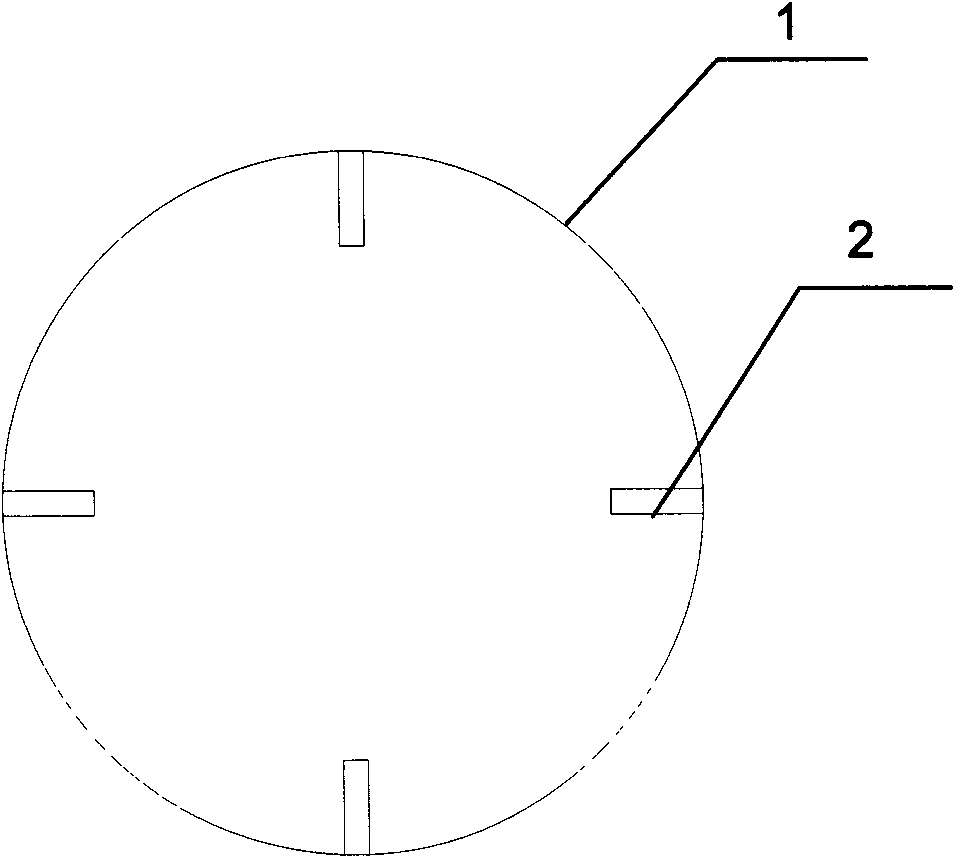

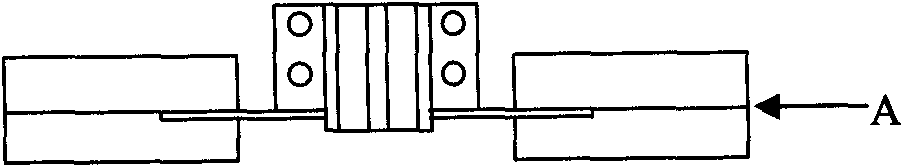

Image

Examples

Embodiment 1

[0057] (1) remove neutral fat in egg yolk powder:

[0058] (1a) In the combined stirring tank, inject 1200L acetone, start the stirrer, add 300Kg egg yolk powder simultaneously, stir and mix for 20 minutes;

[0059] (1b) Centrifuge the mixed material obtained in step (1a), recycle the liquid part (i.e. acetone), put the solid part into the combined stirring tank, inject 1200L acetone, and repeat the extraction and separation operation 2 times;

[0060] (1c) The solid part obtained in step (1b) (after 3 extraction operations) was placed in a vacuum drying equipment with a vacuum degree of -0.06 to -0.095MP, a drying temperature of 50°C, and drying for 4 hours to obtain a total of 150.7 kg oil-free egg yolk powder;

[0061] (2) Extract egg yolk lecithin:

[0062] (2a) In the combined stirring tank, inject 1000L ethanol, start the agitator, add the oil-free egg yolk powder obtained in step (1c) simultaneously, and stir and mix for 10 minutes;

[0063] (2b) Centrifuge the mixed...

Embodiment 2

[0068] (1) remove neutral fat in egg yolk powder:

[0069] (1a) In the combined stirring tank, inject 1000L acetone, start the stirrer, add 300Kg egg yolk powder simultaneously, stir and mix for 10 minutes;

[0070] (1b) Centrifuge the mixed material obtained in step (1a), recycle the liquid part (i.e. acetone), put the solid part into the combined stirring tank, inject 1000L acetone, and repeat the extraction and separation operation once;

[0071] (1c) The solid part obtained in step (1b) (after 2 extraction operations) was placed in a vacuum drying device with a vacuum degree of -0.06 to -0.095MP, and dried at 60°C for 3 hours to obtain a total of 172.3 kg of oil-free egg yolk pink;

[0072] (2) Extract egg yolk lecithin:

[0073] (2a) In the combined stirring tank, inject 1000L ethanol, start the agitator, add the oil-free egg yolk powder obtained in step (1c) simultaneously, and stir and mix for 20 minutes;

[0074] (2b) Centrifuge the mixed material obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com