Method for normal temperature high voltage continuous extracting natural product effective ingredient and equipment thereof

A natural product, high-pressure extraction technology, applied in the direction of solid solvent extraction, etc., can solve the problems of reducing production efficiency, difficult to promote industrialization, and difficult to realize large-scale equipment, so as to improve the extraction rate, improve the dissolution efficiency, and completely break the wall Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

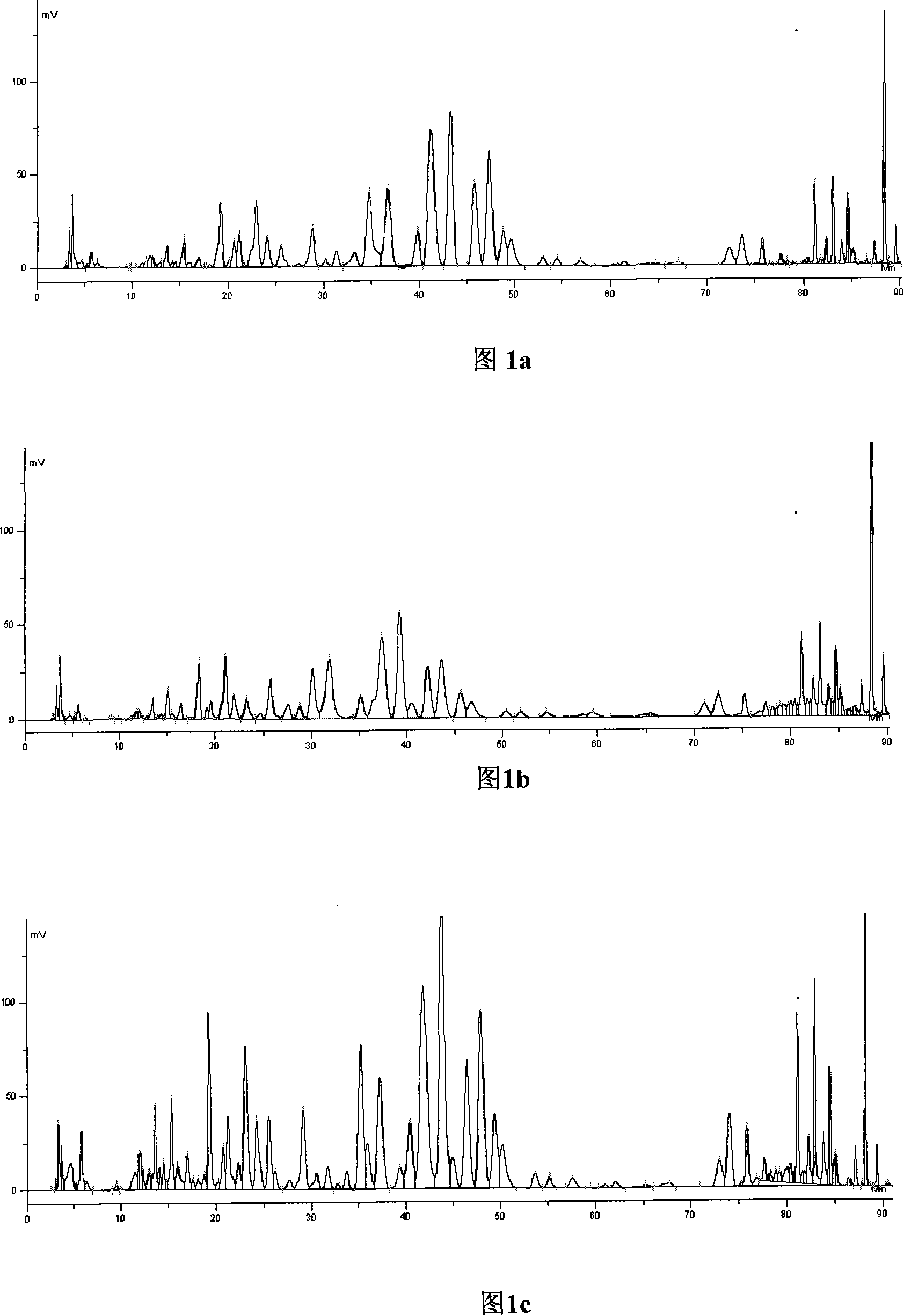

[0088] Embodiment 1: Ginkgo biloba active ingredient extraction

[0089] As shown in Figure 7, the extraction of active ingredients from Ginkgo biloba comprises the following steps:

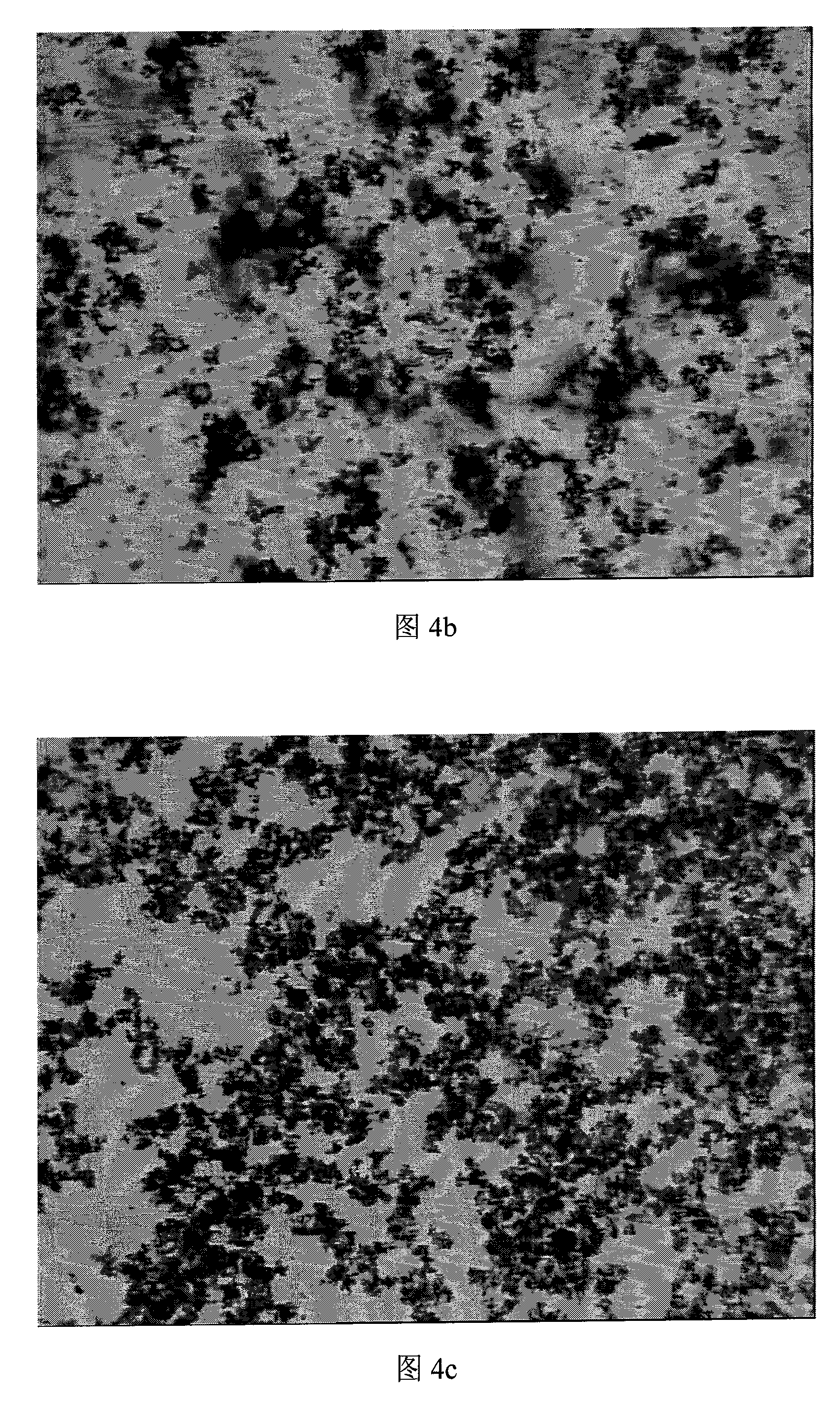

[0090] (1) Crushing: Ginkgo biloba is pulverized to 50-80 orders by fine pulverizer;

[0091] (2) Soaking: put the pulverized Ginkgo biloba into a stirring tank, add a certain concentration of ethanol and stir and soak for 1 hour, wherein the solid-to-liquid weight ratio of Ginkgo biloba and ethanol is shown in the table below;

[0092] (3) Superfine crushing: use a ball mill to carry out superfine crushing of the soaked ginkgo leaves, and continuously crush to 100-150 mesh;

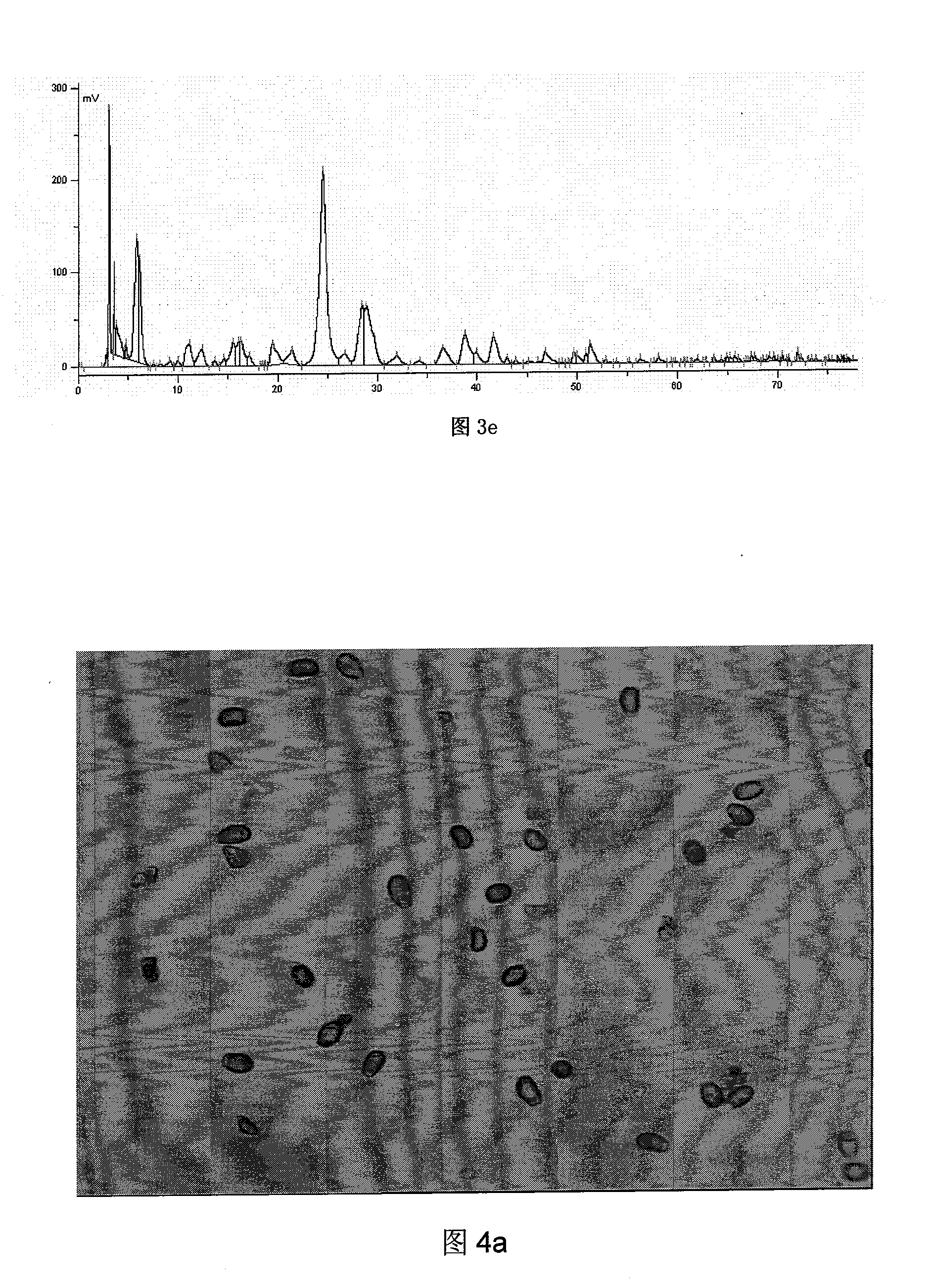

[0093] (4) High-pressure extraction: The ultrafine crushed material liquid is continuously pumped into the high-pressure extractor through the thick slurry pump, and then the material liquid reaches a certain pressure value through the high-pressure pump, and the material liquid passes through the high-pressure extractor u...

Embodiment 2

[0098] Embodiment 2: Ginseng active ingredient extraction

[0099] (1) Crushing: Ginseng is pulverized to 50-80 mesh by jet mill;

[0100] (2) Soaking: Put the pulverized ginseng into a mixing tank, add water and soak for 0.5 hour, wherein the solid-liquid weight ratio of ginseng and water is shown in the table below;

[0101] (3) Superfine crushing: use a ball mill to carry out superfine crushing of the soaked ginseng liquid, and continuously crush it to 100-150 mesh;

[0102] (4) High-pressure extraction: The ultrafine crushed material liquid is continuously pumped into the high-pressure extractor through the thick slurry pump, and then the material liquid reaches a certain pressure value through the high-pressure pump, and the material liquid passes through the high-pressure extractor under high pressure The ring-shaped working gap inside impacts the collision ring in the high-pressure extractor at high speed to break the ginseng cells in the feed liquid;

[0103] (5) Sol...

Embodiment 3

[0107] Embodiment 3: Radix Puerariae active ingredient extraction

[0108] (1) Broken: Pueraria puerariae is pulverized to 50~80 orders by fine pulverizer;

[0109] (2) Soaking: put pulverized puerariae in a stirring tank, add water and soak for 0.5 hour, wherein the solid-to-liquid weight ratio of pueraria puerariae and water is shown in the table below;

[0110] (3) Superfine pulverization: use high-pressure homogenizer pump and colloid mill to superfine pulverize the soaked natural product extract, and continuously pulverize to 100-150 mesh;

[0111] (4) High-pressure extraction: The ultrafine crushed material liquid is continuously pumped into the high-pressure extractor through the thick slurry pump, and then the material liquid reaches a certain pressure value through the high-pressure pump, and the material liquid passes through the high-pressure extractor under high pressure The ring-shaped working gap inside impacts the collision ring in the high-pressure extractor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com