Modified asphalt mixture modifier and preparation method therefor

A technology of modified asphalt and mixture, which is applied in the direction of building insulation materials, building components, building structures, etc. It can solve the problems of asphalt aging, adverse effects of construction environment and operators, and even exceed 200°C, and achieve the improvement of low temperature resistance. Crack performance, broad market promotion and application prospects, and the effect of promoting compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

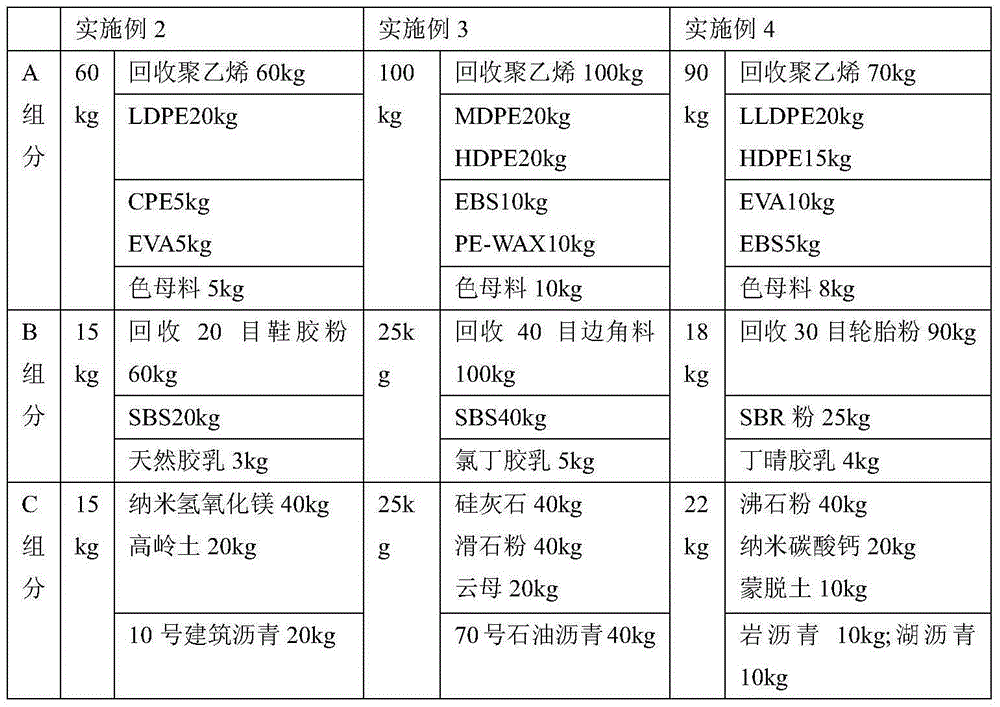

Embodiment 1

[0059] Weigh 80kg of recycled polyethylene granules, 30kg of low-density polyethylene, 5kg of polyethylene wax, 10kg of ethylene-vinyl acetate copolymer, and 7kg of polyethylene masterbatch, add the above materials into the mixer, and mix them evenly to form component A.

[0060] Weigh 80kg of 30 mesh recycled tire rubber powder and 30kg of styrene-butadiene rubber powder into the mixer. During the mixing process, 4kg of styrene-butadiene latex with a solid content of 50% is evenly sprayed on the surface of the mixed particles in a mist, and then the mixed particles Drying is the B component.

[0061] Weigh 30kg of nano-calcium carbonate, 30kg of nano-silica, and 20kg of carbon black powder, add the above materials into the mixer, mix evenly, then add the mixture into the batch machine, and heat 30kg of lake asphalt to 160°C Melt it to a fluid state, then add the fluid asphalt dropwise to the powder in the agglomerate machine, and agglomerate into small particles, which is the...

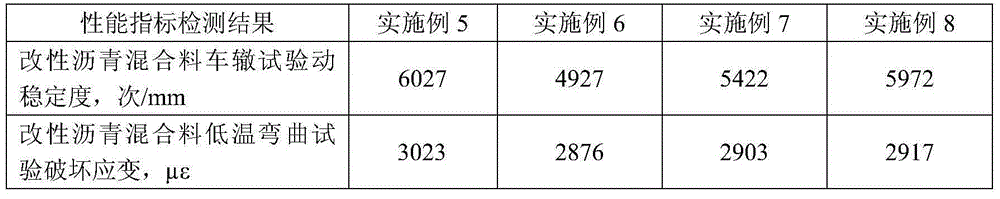

Embodiment 5

[0068] Heat the AC-20 graded aggregates to 175-185°C, add the heated aggregates into the mixing tank of the mixing building according to the designed grading ratio, and add the modified aggregate prepared in Example 1 manually or by feeding machine. Asphalt mixture modifier, the additive amount of the modifier accounts for 0.5% of the asphalt mixture mass, mix for 25 seconds, then add 90# petroleum asphalt with a temperature of 155°C, mix for 15 seconds, then add mineral powder and mix for 15 seconds The modified asphalt mixture can be prepared in seconds. The discharge temperature of the modified asphalt mixture is 170°C, the paving temperature is 160°C, and the rolling temperature is 140°C.

[0069] The performance index test results of the above-mentioned modified asphalt mixture:

[0070] The dynamic stability of modified asphalt mixture rutting test is 6027 times / mm

[0071] Failure strain of modified asphalt mixture in low temperature bending test: 3023με

[0072] The...

PUM

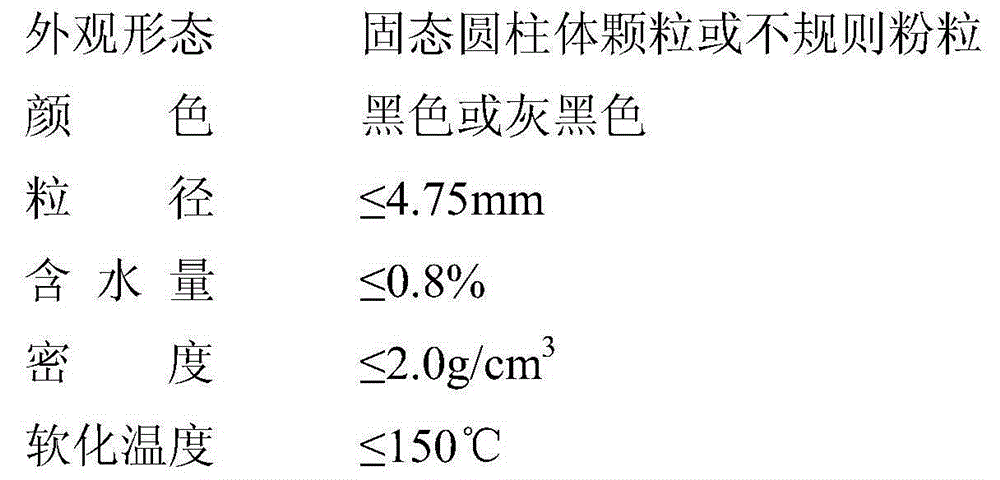

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com