Asphalt mixed material and mix proportion designing method thereof

A technology of asphalt mixture and mix ratio design, applied in construction, road, road repair and other directions, can solve problems such as adverse effects and direct discharge of slag bottom sludge to the environment, achieve higher utilization, improve high temperature rutting resistance, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation and application of the slag bottom mud of asphalt mixture of the present invention may further comprise the steps:

[0028] Step S1, drying the slag bottom sludge from the domestic waste incinerator in an oven at 105° C. to a constant weight to obtain hardened agglomerates, and crushing the hardened agglomerates to obtain powdery slag bottom sludge.

[0029] Step S2: Put the powdery slag bottom sludge in an oven at 200° C. for 48 hours to dry at high temperature, and then set it aside.

[0030] Step S3, performing a standard screening test on the powdery slag bottom sludge obtained in step S2, so as to obtain the gradation composition of the powdery slag bottom sludge.

[0031] Step S4, based on the gradation composition of the powdery slag bottom sludge and the gradation composition of the natural aggregate, design the mix ratio of the asphalt mixture according to the Marshall test method and determine the optimal asphalt dosage.

Embodiment 1

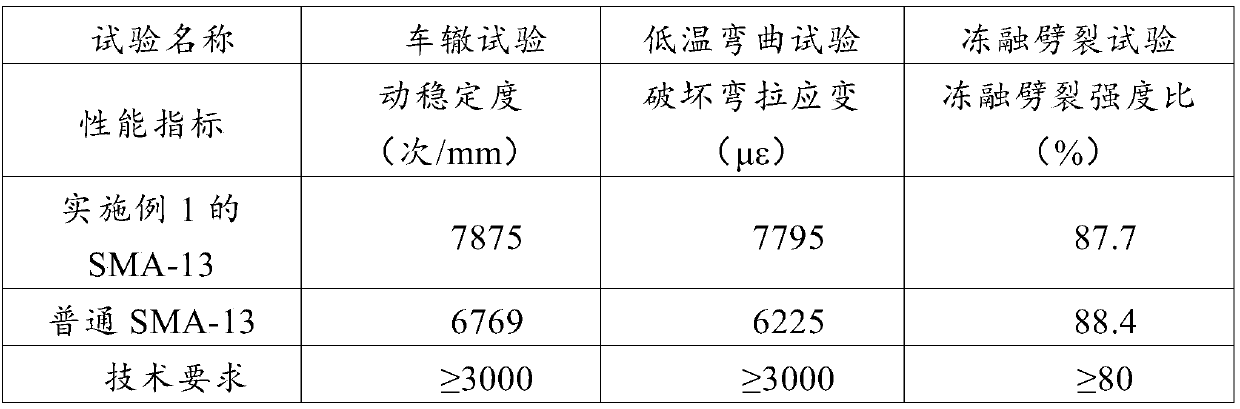

[0034] The components of the asphalt mixture and the mass fractions of each component: 11 parts of slag bottom sludge from domestic waste incinerator, 89 parts of basalt aggregate, 7.5 parts of SBS modified asphalt, and 0.3 part of fiber. The asphalt mixture is SMA-13 type asphalt mixture.

[0035] SMA-13 type asphalt mixture design method, the specific steps are as follows:

[0036] Step 1: Put the domestic waste incineration slag bottom sludge in an oven at 105°C to dry to constant weight, and crush the hardened agglomerates to make them scattered into powder;

[0037] Step 2, placing the powder of the domestic waste incineration slag bottom sludge obtained in Step 1 in an oven at 200° C. for 48 hours after high-temperature treatment for later use;

[0038] In step 3, the domestic waste incinerator slag bottom mud powder obtained in step 2 is subjected to a standard screening test to obtain the gradation composition of the domestic waste incinerator slag bottom mud powd...

Embodiment 2

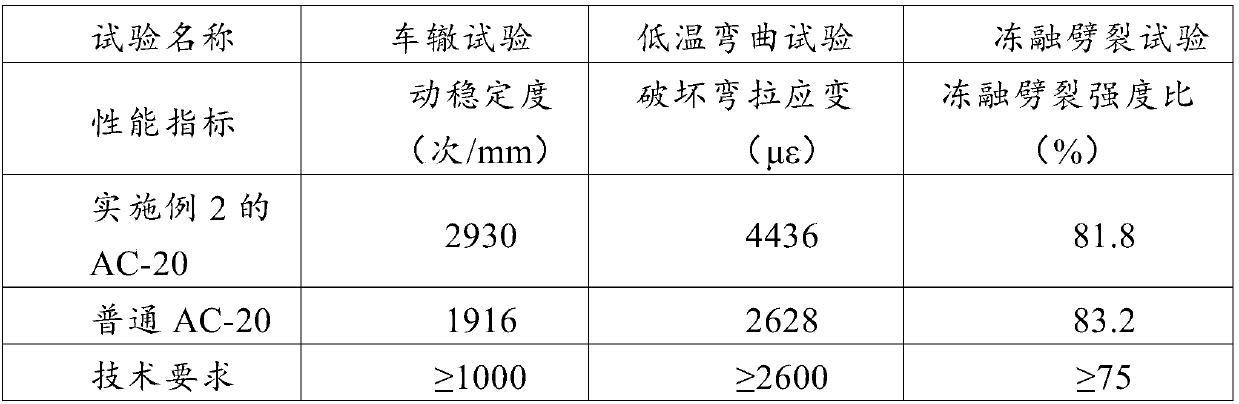

[0044]The components of the asphalt mixture and the mass fractions of each component: 2 parts of slag bottom mud from domestic waste incinerator, 98 parts of limestone aggregate, 4.1 parts of 70# matrix asphalt. The asphalt mixture is AC-20 type asphalt mixture.

[0045] The mixing ratio design method of AC-20 type asphalt mixture, the specific steps are the same as in Example 1, and the results of road performance data collection of AC-20 type asphalt mixture are shown in Table 2.

[0046] Performance test results of AC-20 asphalt mixture in Table 2 Example 2

[0047]

[0048] Note: The technical requirements are the industry standards of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0049] As can be seen from the data in Table 1 and Table 2, the high temperature anti-rutting performance, low temperature crack resistance and water damage resistance of the SMA-13 type asphalt mixture in Example 1 and the AC-20 type asphalt mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com