Epoxy asphalt additive for road and bridge pavement as well as preparation method and use method of epoxy asphalt additive

A technology of epoxy asphalt and additives, which is applied in the direction of building components, building insulation materials, buildings, etc., and can solve problems such as damage to low-temperature crack resistance, uncertainty in the performance stability of asphalt mixtures, and inability to meet the actual use requirements of asphalt pavement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

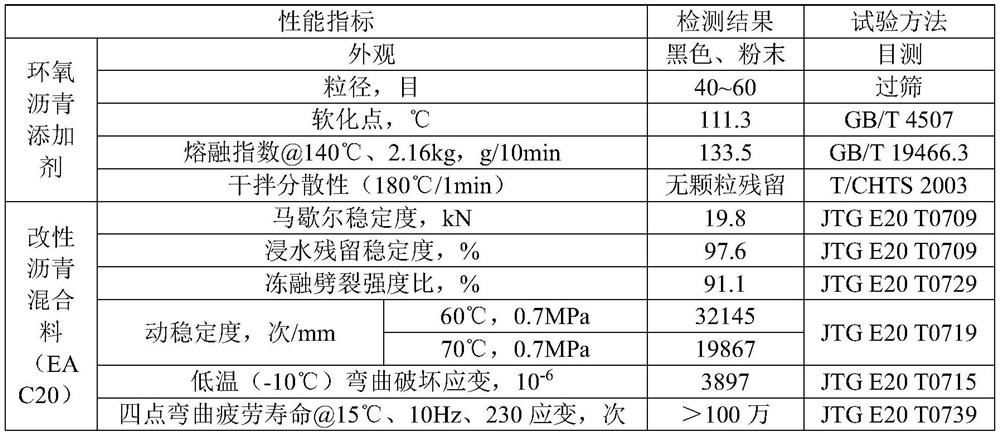

[0064] Embodiment 1: a kind of epoxy asphalt additive for road and bridge paving, preparation method and use method thereof

[0065] The epoxy asphalt additive for road and bridge paving provided in this example, calculated in parts by weight, includes 40 parts of E-12, 20 parts of HY811, 5 parts of jER1256, 35 parts of P5998, 100 parts of oxidized asphalt, 0.1 part of 2-methyl Imidazole, 1 part AW128, 2 parts Antioxidant 1010.

[0066] A preparation process of epoxy asphalt additive for road and bridge paving is as follows:

[0067] S1. Put 40 parts of E-12, 20 parts of HY811, 5 parts of jER1256, 35 parts of P5998, 0.1 part of 2-methylimidazole, 1 part of AW128, and 2 parts of Antioxidant 1010 into a high-speed mixer to mix evenly;

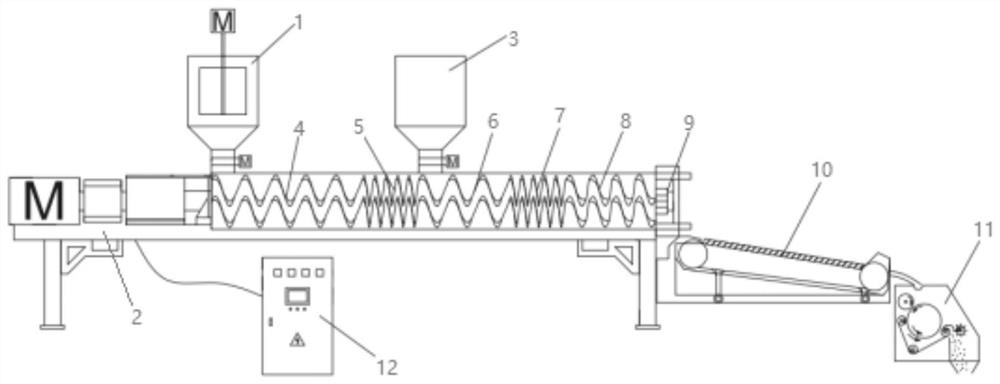

[0068] S2. Use a twin-screw extruder to plasticize, shear and mix the uniformly mixed material in S1 to form an epoxy resin melt. The temperature of the first plasticizing section is set to 125 °C, and the temperature of the first mixing section i...

Embodiment 2

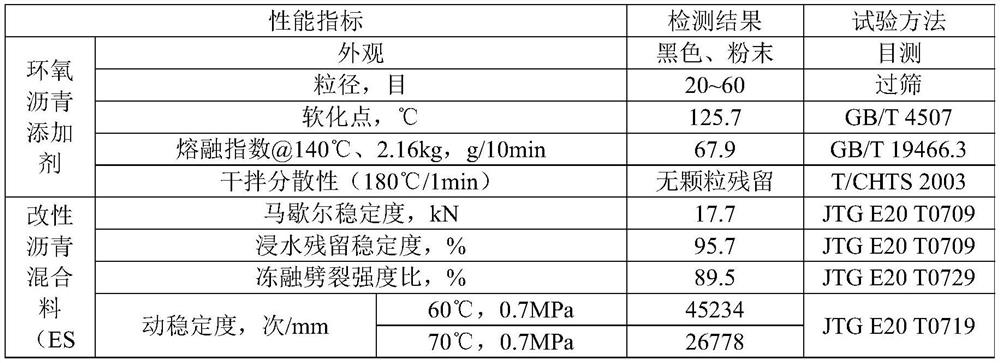

[0080] Embodiment 2: a kind of epoxy asphalt additive for road and bridge paving, preparation method and use method thereof

[0081] The epoxy asphalt additives for road and bridge paving provided in this example, calculated in parts by weight, include 60 parts of D.E.R.664UE, 5 parts of HY811, 5 parts of jER4250, 30 parts of P5061, 75 parts of coal tar pitch, and 0.2 parts of 2-methyl Imidazoline, 0.3 parts AW128, 1 part antioxidant 1010.

[0082] A preparation process of epoxy asphalt additive for road and bridge paving is as follows:

[0083] S1. Put 60 parts of D.E.R.664UE, 5 parts of HY811, 5 parts of jER4250, 30 parts of P5061, 0.2 part of 2-methylimidazoline, 0.5 part of AW128, 1 part of antioxidant 1010 into a high-speed mixer and mix uniformly;

[0084] S2. Use a twin-screw extruder to plasticize, shear and mix the uniformly mixed material in S1 to form an epoxy resin melt. The temperature of the first plasticizing section is set to 120 °C, and the temperature of the...

Embodiment 3

[0097] Embodiment 3: a kind of epoxy asphalt additive for road and bridge paving, preparation method and use method thereof

[0098] The epoxy asphalt additives for road and bridge pavement provided in this example, calculated in parts by weight, include 40 parts of YD-17, 5 parts of HY813, 10 parts of jER4250, 45 parts of P5061, 50 parts of oxidized asphalt, 0.2 parts of benzyl triacetate Ethyl ammonium chloride, 0.5 part AW163, 1 part antioxidant 245.

[0099] A preparation process of epoxy asphalt additive for road and bridge paving is as follows:

[0100] S1. Put 40 parts of YD-17, 5 parts of HY813, 10 parts of jER4250, 45 parts of P5061, 0.2 parts of benzyltriethylammonium chloride, 0.5 parts of AW163, 1 part of antioxidant 245 into the high-speed mixer and mix them evenly ;

[0101] S2. Use a twin-screw extruder to plasticize, shear, and mix the uniformly mixed material of S1 to form an epoxy resin melt. The temperature of the plasticizing section is set to 125 °C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com