High-modulus modified asphalt and preparation method thereof

A modified asphalt, high-modulus technology, used in building components, building insulation materials, buildings, etc., can solve the problems of inability to meet the requirements of low-temperature crack resistance of asphalt pavement, poor storage stability of modified asphalt, and poor low-temperature performance of asphalt. , to achieve good high temperature rutting resistance, improve softening point and improve high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

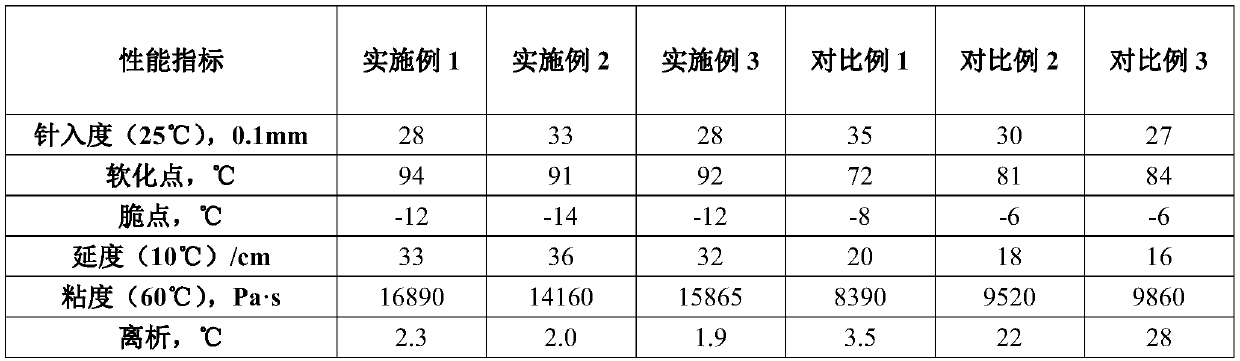

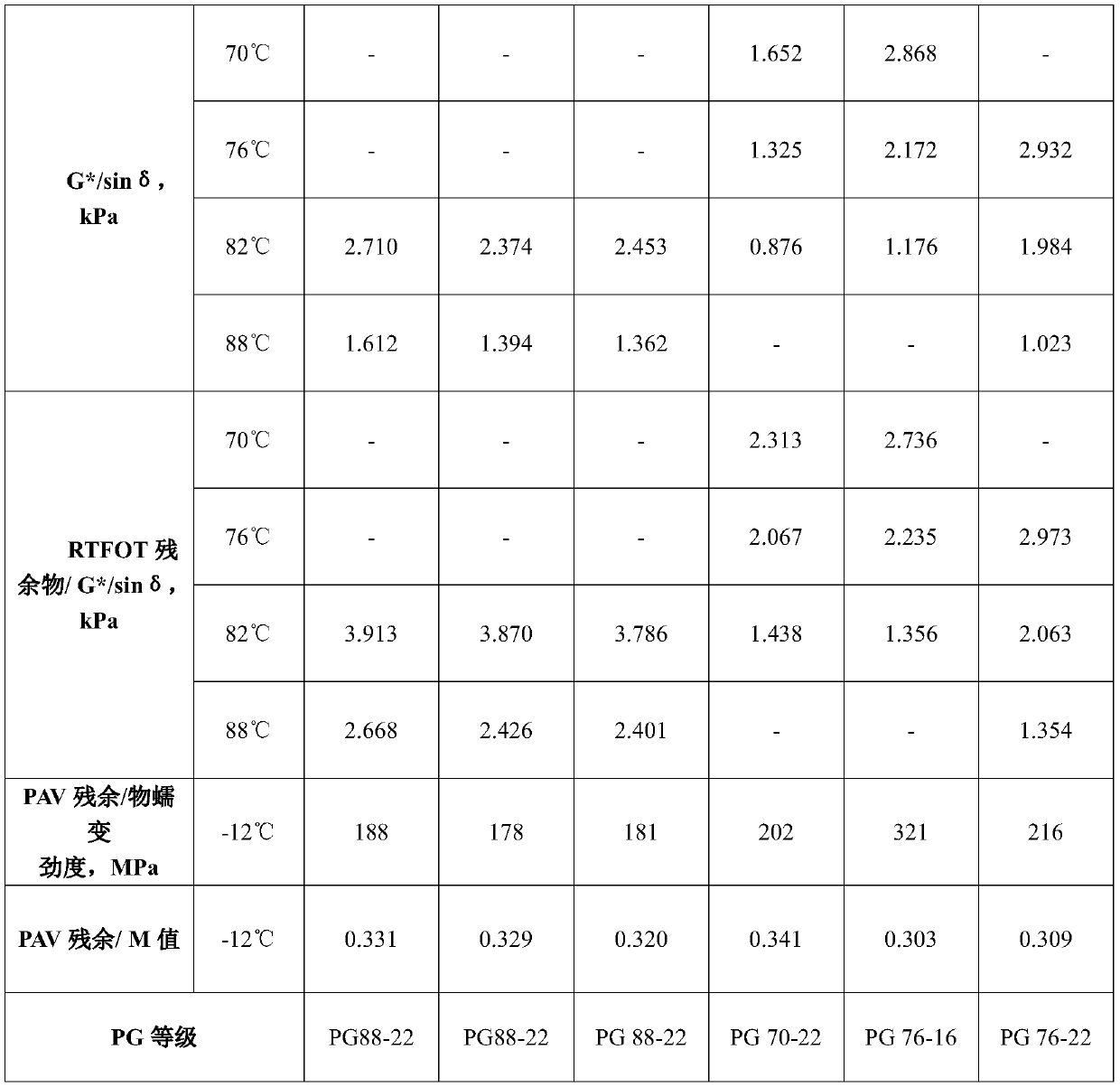

Embodiment 1

[0072] This embodiment provides a kind of high modulus modified asphalt, and described modified asphalt comprises the base asphalt that internal blending amount is 85%, the hard asphalt that internal blending amount is 9%, the internal blending amount is 5.4% SBS and 0.6% additives; the hard asphalt has a penetration of 0 (25°C, 0.1mm), a softening point of 147°C, a saturated content of 2wt%, and an aromatic content of 20wt%. , a colloid content of 33wt%, an asphaltene content of 45wt%, a solubility of 99.7%, and an ash content of 0.16%; the hard asphalt is a deoiled asphalt prepared by solvent deasphalting using Canadian oil sand asphalt as a raw material; the hard asphalt The preparation of hard bitumen makes the solvent used be 1 or at least 2 kinds of combinations in n-pentane, isopentane or cyclopentane; There are spiral finned tubes, and the heat transfer oil flows into the finned tubes through the upper and lower branch tubes to heat the top of the extraction tower; the...

Embodiment 2

[0078] This embodiment provides a kind of high modulus modified asphalt, and described modified asphalt comprises the base asphalt with internal blending amount of 85%, the hard asphalt with internal blending amount of 8.5%, the internal blending amount of 6% SBS and 0.5% additives; the hard asphalt has a penetration of 0 (25°C, 0.1mm), a softening point of 165°C, a saturated content of 1.5wt%, and an aromatic content of 16.5% wt%, colloid content 29wt%, asphaltene content 53wt%, solubility 99.5%, ash content 0.2%; the hard asphalt is deoiled asphalt prepared by solvent deasphalting process with Canadian oil sand asphalt as raw material; The preparation of above-mentioned hard asphalt makes the solvent that adopts be the combination of 1 or at least 2 kinds in normal pentane, isopentane or cyclopentane; There are spiral finned tubes inside, and the heat transfer oil flows into the finned tubes through the upper and lower branch tubes to heat the top of the extraction tower; th...

Embodiment 3

[0084] This embodiment provides a kind of high modulus modified asphalt, and described modified asphalt comprises the base asphalt that internal blending amount is 85%, the hard asphalt that internal blending amount is 9%, the internal blending amount is 5.4% SBS and 0.6% additives; the hard asphalt has a penetration of 0 (25°C, 0.1mm), a softening point of 152°C, a saturated content of 2wt%, and an aromatic content of 18wt%. , colloid content 30wt%, asphaltene content 50wt%, solubility 99.7%, ash content 0.19%; the hard bitumen is deoiled bitumen prepared by solvent deasphalting process with Canadian oil sand bitumen as raw material; the hard bitumen The preparation of hard bitumen makes the solvent used be 1 or at least 2 kinds of combinations in n-pentane, isopentane or cyclopentane; There are spiral finned tubes, and the heat transfer oil flows into the finned tubes through the upper and lower branch tubes to heat the top of the extraction tower; the condition in the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com