Purification device and separation method of oily sewage

A sewage purification and purification device technology, which is applied in the direction of separation method, liquid separation, grease/oily substance/floating matter removal device, etc., can solve the problems of separation method limitation and achieve the effect of low flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

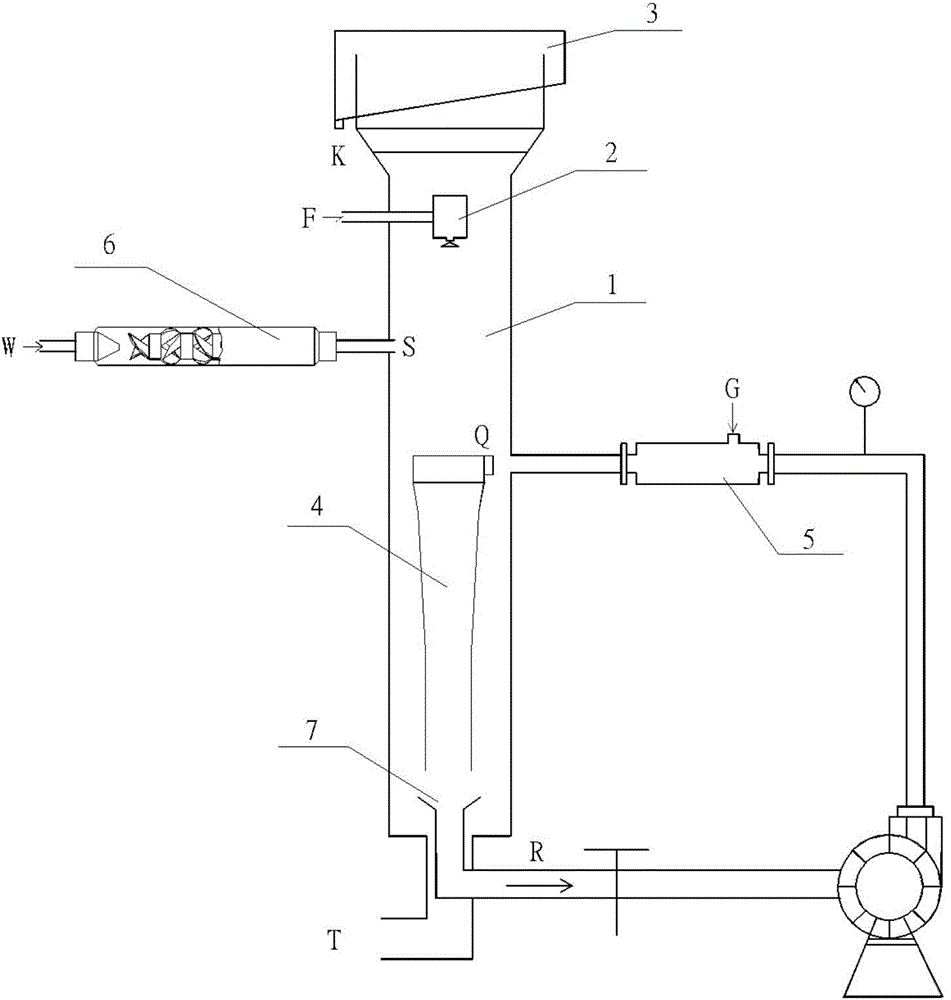

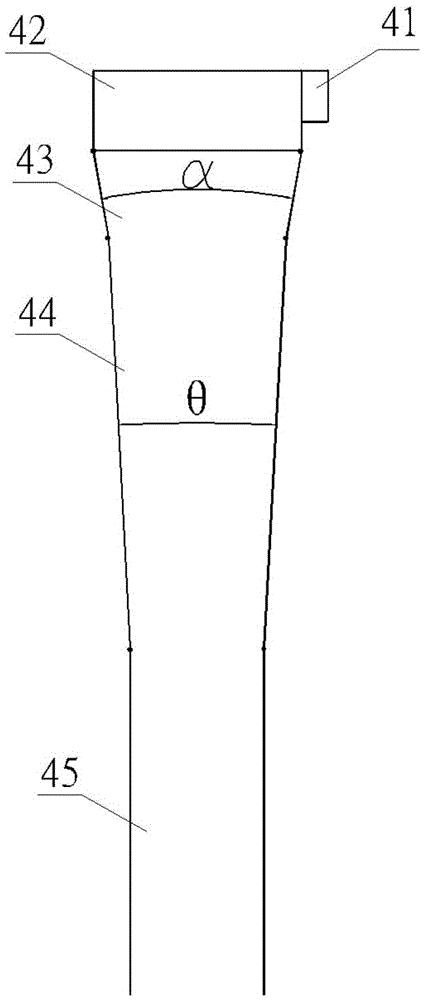

[0020] Embodiment 1: The purification device includes a column separator 1, an inflow distribution device 2, a floating oil collection device 3, at least one inflatable cyclone separator 4, at least one self-priming microbubble generator 5 and at least one dissolved air separation microbubble generator. Bubble generator 6; in the column body of described purifying device, the upper part is column separator 1, and the lower part is inflatable cyclone separator 4; The filling point Q of the formula microbubble generator 5 is at the lower part of the cylinder.

[0021] The water inlet distribution device 2 is connected to the feeding pipe at the upper center of the column separator 1 .

[0022] One section of the self-priming microbubble generator 5 is connected to a circulating pump through a pipeline, and one section enters the column separator 1 through a pipeline and is connected to the tangential inlet Q of the inflatable cyclone.

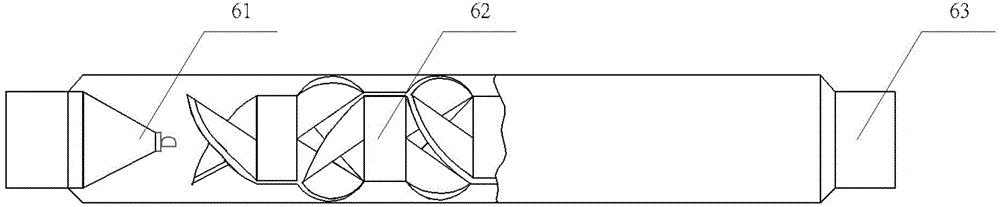

[0023] Described gas-dissolved micro-bubb...

Embodiment 2

[0028] Example 2: In figure 1 Among them, along the column separator 1 from top to bottom, there are water inlet distribution device 2, gas filling point S of dissolved air precipitation microbubble generator 6, gas filling point Q of self-priming microbubble generator and gas cyclone separator 4 . The water inlet is at the middle and upper part of the cylinder, and is connected with the water inlet distribution device. The dissolved air precipitation microbubble generator 6 is placed outside the column, and a tube is connected with the dissolved air precipitation microbubble generator 6 and inserted into the column body, and the insertion position is in the middle of the column body. Further down is the gas-filled cyclone separator 4, and the lower segment of the gas-charged cyclone is an inverted cone 7. The self-priming microbubble generator 5 is placed outside the column, one section of which is connected to the outlet of the circulation pump through a pipeline, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com